11. Input devices¶

assignment

Individual assignment:¶

measure something: add a sensor to a microcontroller board that you have designed and read it

Group assignment:¶

probe an input device’s analog levels and digital signals

Introduction¶

For this assignment I got the idea of making a device that can measure the distance of a person to help people be aware of social distancing. For this project I used an Arduino Uno board because of the lockdown I could not get another board.

The components I used for this project are:¶

1-Arduino Uno

2-Buzzer

3-Ultrasonic Sensor

4-LED Red

5-LED Green

Ultrasonic Sensor¶

The Ultrasonic Sensor has four pins which are as follows:

VCC: The VCC pin powers the sensor, typically with +5V.

Trigger: Trigger pin is an Input pin. This pin has to be kept high for 10us to initialize measurement by sending US wave.

Echo: Echo pin is an Output pin. This pin goes high for a period of time which will be equal to the time taken for the US wave to return back to the sensor.

Ground: This pin is connected to the Ground of the system.

Sensor¶

The Ultrasonic transmitter sends a signal that continues to move until it hits an object and then bounces back to the Ultrasonic receiver as shown in the picture below. I got all the information and pictures I needed to explain the sensor here.

Assembling the Board¶

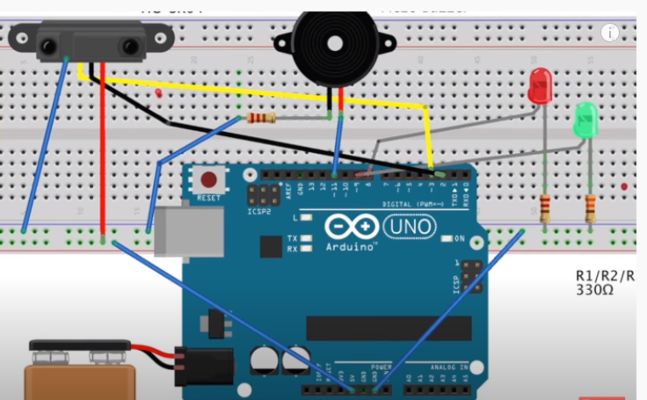

For the digital part of the board I connected the Vcc and Ground with a 5V from the Arduino port. For the Trigger I assigned it to digital 12 and Echo to diigital 13

The buzzer I assigned it to digital 8. LED Red digital 6 and LED Green to digital 9.

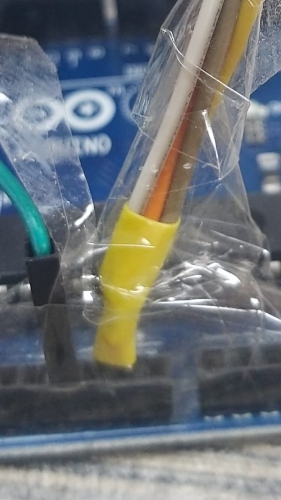

And I used the solder to join 4 wires into one connector and then I assigned those into the ground port. This way I do not have to use a breadboard to connect my components on it.

The design shown above is a demonstration of how I connected my wires to the board but without the breadboard because in the final designs photo the board is not showing properly.

I got this design and information shown above from the internet.

I connected the LED together using two wires and this is the wood LED holder that I will use to connect the LED light bulbs to the wires on the board.

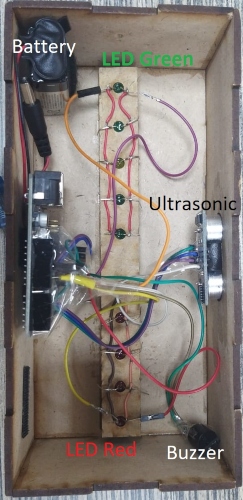

This is the final product I made the wooden box and cover that I will use to place my board inside and I also made the acrylic piece the is used to show the message “Go Back”.

This final assembled component in the box and each part is labelled inside.

Coding¶

#define trigPin 12

#define echoPin 13

int Buzzer = 8; // Connect buzzer pin to 8

int ledPin= 6; //Connect LEd pin to 6

int duration, distance; //to measure the distance and time taken

int ledPinred= 9;

void setup() {

Serial.begin (9600);

//Define the output and input objects(devices)

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

pinMode(Buzzer, OUTPUT);

pinMode(ledPin, OUTPUT);

pinMode(ledPinred, OUTPUT);

}

void loop() {

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

duration = pulseIn(echoPin, HIGH);

distance = (duration/2) / 29.1;

//when distance is greater than or equal to 200 OR less than or equal to 0,the buzzer and LED are off

if (distance >= 70 || distance <= 0)

{

Serial.println("no object detected");

digitalWrite(Buzzer,LOW);

digitalWrite(ledPin,HIGH);

digitalWrite(ledPinred,LOW);

}

else {

Serial.println("object detected \n");

Serial.print("distance= ");

Serial.print(distance); //prints the distance if it is between the range 0 to 200

digitalWrite(Buzzer,HIGH);

digitalWrite(ledPin,LOW);

digitalWrite(ledPinred,HIGH);

}

}

This video shows how the device is working by maintaining a safe distance.

limit switch¶

In my final project, I have used a limit switch as an input device. I added the switch for safety reasons, so when the camera goes down into the case, the laser cut piece hits the limit switch and it triggers a signal to switch the system off. thus preventing the camera from hitting the bottom of the case reducing the chance of any damages.

The following is the code I used for the limit switch connected to my final project board.

// NeoPixel test program showing use of the WHITE channel for RGBW

// pixels only (won’t look correct on regular RGB NeoPixel strips).

#include <Adafruit_NeoPixel.h>

#ifdef __AVR__

#include <avr/power.h> // Required for 16 MHz Adafruit Trinket

#endif

#define LED_PIN 6 // Which pin on the Arduino is connected to the NeoPixels?

#define LED_COUNT 10 // How many NeoPixels are attached to the Arduino?

#define BRIGHTNESS 50 // NeoPixel brightness, 0 (min) to 255 (max)

Adafruit_NeoPixel strip(LED_COUNT, LED_PIN, NEO_GRBW + NEO_KHZ800);

/*Example sketch to control a stepper motor with A4988 stepper motor driver and Arduino without a library. More info: https://www.makerguides.com */

// Define stepper motor connections and steps per revolution:

#define dirPin 3

#define stepPin 4

#define stepsPerRevolution 200

int limit_switch= 1;

void setup() {

clock_prescale_set(clock_div_1);

strip.begin(); // INITIALIZE NeoPixel strip object (REQUIRED)

strip.show(); // Turn OFF all pixels ASAP

strip.setBrightness(50); // Set BRIGHTNESS to about 1/5 (max = 255)

// Declare pins as output:

pinMode(stepPin, OUTPUT);

pinMode(dirPin, OUTPUT);

pinMode(limit_switch, INPUT);

}

void loop() {

// if limit switch is not pressed turn the system on

if (limit_switch == LOW){

// Fill along the length of the strip in various colors...

colorWipe(strip.Color(255, 0, 0) , 50); // Red

delay(2000);

colorWipe(strip.Color( 0, 255, 0) , 50); // Green

delay(2000);

// Set the spinning direction clockwise:

digitalWrite(dirPin, HIGH);

// Spin the stepper motor 1 revolution slowly:

for (int i = 0; i < stepsPerRevolution; i++) {

// These four lines result in 1 step:

digitalWrite(stepPin, HIGH);

delayMicroseconds(2000);

digitalWrite(stepPin, LOW);

delayMicroseconds(2000);

}

delay(1000);

// Set the spinning direction counterclockwise:

digitalWrite(dirPin, LOW);

// Spin the stepper motor 1 revolution quickly:

for (int i = 0; i < stepsPerRevolution; i++) {

// These four lines result in 1 step:

digitalWrite(stepPin, HIGH);

delayMicroseconds(1000);

digitalWrite(stepPin, LOW);

delayMicroseconds(1000);

}

delay(1000);

}

// if limit switch is pressed turn off the system for emergency

if (limit_switch == HIGH){

colorWipe(strip.Color(0, 0, 0) , 50); // Red

for (int i = 0; i < stepsPerRevolution; i++) {

// These four lines result in 1 step:

digitalWrite(stepPin, LOW);

delayMicroseconds(2000);

digitalWrite(stepPin, LOW);

delayMicroseconds(2000);

}

}}

void colorWipe(uint32_t color, int wait) {

for(int i=0; i<strip.numPixels(); i++) { // For each pixel in strip...

strip.setPixelColor(i, color); // Set pixel’s color (in RAM)

strip.show(); // Update strip to match

delay(wait); // Pause for a moment

}

}

strip.show(); // Update strip with new contents

// There’s no delay here, it just runs full-tilt until the timer and

// counter combination below runs out.

firstPixelHue += 40; // Advance just a little along the color wheel

if((millis() - lastTime) > whiteSpeed) { // Time to update head/tail?

if(++head >= strip.numPixels()) { // Advance head, wrap around

head = 0;

if(++loopNum >= loops) return;

}

if(++tail >= strip.numPixels()) { // Advance tail, wrap around

tail = 0;

}

lastTime = millis(); // Save time of last movement

}

This work is licensed under a Creative Commons Attribution 4.0 International License.