14. INVENTION, INTELLECTUAL PROPERTY AND INCOME¶

There is no group part in the tasks to be carried out this week.

The individual assignment statement is this:

Individual assignment:

-

Develop a plan for dissemination of your final project.

-

Prepare drafts of your summary slide (presentation.png, 1920x1080) and video clip (presentation.mp4, 1080p HTML5, < ~minute, < ~10 MB) and put them in your root directory.

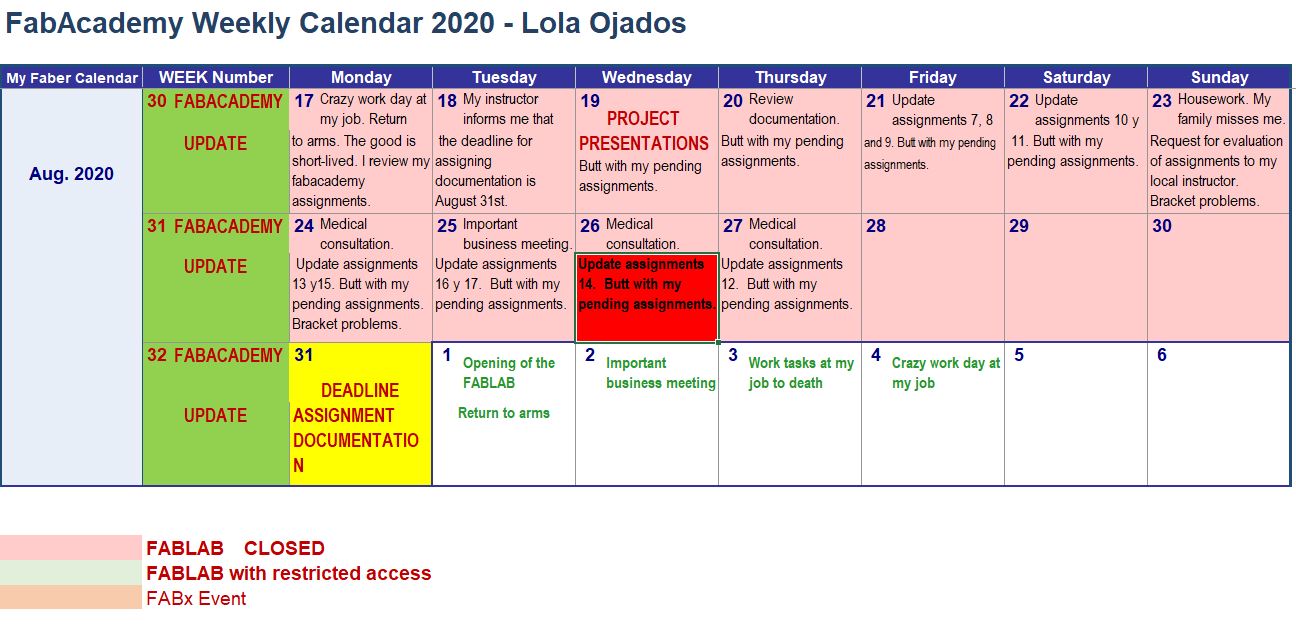

This week’s assignment was done after the deadline. For health reasons, during the week in which the Conference of this work was given, although I attended the class and thought about the content of this assignment, I was unable to develop the documentation or draft the slide and video.

For this reason, he carried out this assignment in a week in August and the chronology in the calendar for its development has been collected in my personal Schedule, which as in all previous assignments I publish it here in my documentation.

14.1. INVENTION¶

IRW Safety Device (InfraRed Window), is the name of my final project, it is a safety device for machine tools available in mechanical workshops that works by temperature control with infrared technology (IR sensors), the device itself is a product.

I have been working in Occupational Risk Prevention for many years and this development is the result of trying to cover a need detected in this type of machine that often entails a high level of risk in the event of injuries such as entrapments or cuts for example.

It is not the first safety device that I develop, in my doctoral thesis, I designed, projected, manufactured and patented an automatic safety arch actuation device in fruit tractors without a cabin in the face of imminent risk.

This took me 5 years of work and I obtained very satisfactory results in terms of technology and technology.

This accident of tractor overturn is the main cause of death of workers in the agricultural sector in Spain.

The ideal would have been that by supporting such powerful work, there would be a legal regulation that would help so that if the advances in the technique make it possible to improve the safety of workers, these advances are actually adopted by manufacturers and users, but there are always economic interests that stop the implementation of solutions, even when trying to avoid loss of human life.

In the same line of work, I have always been interested in working on things that have a utility beyond the aesthetic and whose function helps the labor, social and personal well-being of all.

Therefore, for the realization of the final FabAcademy project, it seemed appropriate to develop IRW- Safety Device, as a useful, novel and functional project.

And thanks to the need to fulfill an essential requirement to pass this demanding FabAcademy training, this time and effort dedicated to the final project has given me the opportunity to develop a project that integrates design, electronics, programming and different manufacturing techniques, whose final objective is to improve working conditions and increase safety in work spaces.

For work reasons, in the maelstrom in which I find myself at the University of technical studies, especially engineering and architecture, in which I combine teaching tasks with the management of a central research support service specialized in industrial design and engineering. Scientific calculation and now with the implementation of a dependent Fablab, it would have been difficult, if not impossible, to be able to tackle this project due to lack of time or vital energy. (It does not give me life).

The combination of a new idea and the putting into play of all the necessary knowledge to materialize it, makes IRW-Safety Device an original product. IRW is not a copy or adaptation of a previous design, so I consider the final product to be its own milestone.

Therefore, I would like to be mentioned, attributed and cited as the author of this product. My product :)

There is also the creation of different elements to compose the safety device, and to be able to mount it on the machines to be protected.

For these components, I have used, for example, 3D printing or laser cutting, CNC milling, designed and manufactured by me.

In this case, these objects are exclusive and adapted to the particular case where I have assembled the infrared window, which is modular in nature and its sale or distribution would only be carried out by me.

14.2. INTELLECTUAL PROPERTY¶

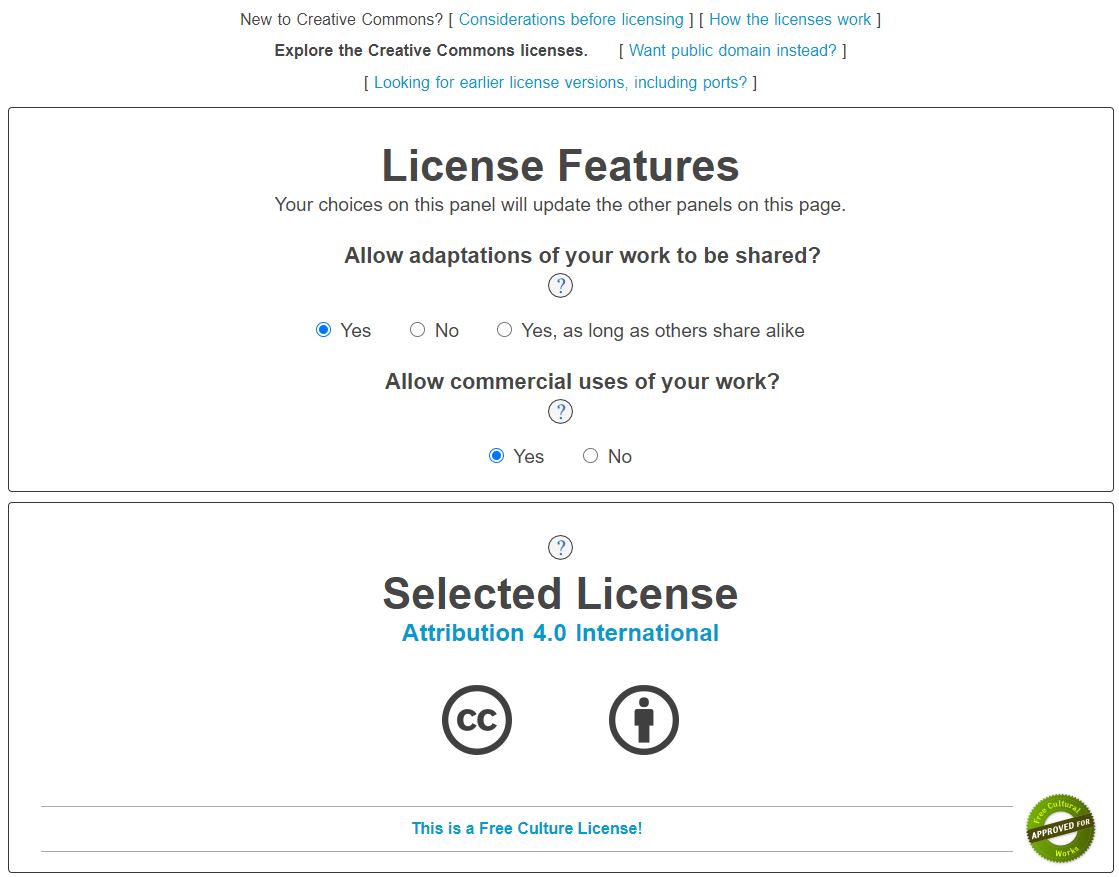

Although all the works developed during the Fab Academy are protected by the MIT License, and taking into account that many of the software that I have used to make my final project they are open source, for me, it makes sense to also have my own Creative Commons license.

Creative Commons (CC) is an American non-profit organization focused on expanding and publicizing the amount of creative works available for others, in addition to their authors, to can legally build and share.

The organization has a list of various copyright licenses, free to the public, that allow creators to communicate their work by specifying what rights they deserve and what rights they give up for the benefit of sharing with others.

These licenses come with associated visual symbols that make it easy to understand the explanation of the rights.

Creative Commons licenses do not replace copyrights, but are based on them.

I plan to use the following license for my project:

On this website you can configure your CC license.

This work is licensed under an International License Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This means that:

You are free to:

Share (copy and redistribute the material in any medium or format) and Adapt (remix, transform and build on the material).

Under the following terms :

-

Attribution: You must give the appropriate credit, provide a link to the license, and indicate if any changes were made. You may do so in any reasonable way, but in no way that suggests that the licensor endorses you or your use.

-

Non-commercial: You may not use the material for commercial purposes.

-

Share Alike: If you remix, transform, or develop the material, you must distribute your contributions under the same license as the original.

14.3. INCOME¶

After evaluating it and thinking about it, I have found several options that I can list and write, in terms of how to get IRW out to potential users and manufacturers.

Regarding the development of a plan for dissemination, from the research group to which I belong within the Technical University of Cartagena, we carry out many research projects in the field of occupational risk prevention, most of them requested by the Public institution competent in the matter at the territorial level, normally by Autonomous Communities, is how this type of competences is distributed in Spain.

-

Marketing IRW as Product:

Possibly inform the Institute of Occupational Safety and Health (competent institution referred to above) the scope of the results obtained in my final Fabacademy project and submit it to its evaluation for the study of a possible implementation of IRW Safety Device as Product in workshops where there are machines that need to limit risks derived from its use.

This entity could give technical, financial and training aid to companies that need to use IRW.

In addition, at the UPCT we have a Office for the Transfer of Research Results (OTRI) that acts as a bridge between universities and universities and companies that may be interested in exploiting any of the developments carried out by groups of research in your studies.

I can request that the IRW Safety Device product be offered to companies that have machines with similar characteristics to those of the Dremel or the sheet metal roller bending machine, in which I have tested the device, such as drills, cutters, etc …, that involve risks derived from a lack of security or the need to improve it.

This office can even manage the request for a PATENT that endorses and protects the product.

On two previous occasions from my research group we have developed and obtained a patent supported by the UPCT from the OTRI and both are in operation.

-

Scientific Disclosure:

Another means of disseminating research results is through the publication of popular science articles , if possible, (I have time, I find a good magazine to publish, I don’t lack energy, and work dynamics allow me), I can give the form of a scientific article to my work, through an appropriate wording and presenting discussed and contrasted results.

In the previous cases, it would be my work team from SEDIC and SEDI-CUp-ct FabLab who would manufacture the first IRW units and we would study if demand grows how to respond to manufacture on a larger scale.

-

Commercialization of files for IRW manufacturing:

I can also make the generated files accessible to those who are users of a Fab Lab (ours or anyone on the network) or a Maker Space and were willing to pay for the * Complete set of files * and technical support if necessary.

-

Commercialization in kit form:

Another option would be to prepare a kit with a number of pieces, (upon request), made up of the link, plate and sensor assembly, together with the electronic control system designed and mounted in a box, the programming and documentation assembly, use and operation in the form of instructions that will facilitate the implementation of IRW in any machine.

This kit is intended for those who do not have access to a Fab Lab or Maker Space, so they do not have the resources to manufacture their own IRW, but would like or would like to build their own security device adapted to a specific machine.

These types of consumers would pay for a kit with all the parts and components.

The kit could be marketed through the aforementioned routes or by looking for a trusted distribution channel dedicated to working with technical material with characteristics similar to IRW.

-

Distribute results in open spaces:

On the other hand, it would also be interesting to openly distribute what has been studied and developed.

It could be on platforms like Opendesk. It would be amazing to have the opportunity to collaborate with them.

And if I finally decide not to monetize my final project, I will probably upload my work to Instructables.

Another thing that I would love: What would also be a great satisfaction for me, is that our UPCT students, and others around the world, reproduce and improve IRW to learn about digital manufacturing, programming and electronics.

Some time ago, I was able to listen to a conference given by Tomás Díez (director of Fablab Barcelona), about the FabCity project, this time I met Tomás personally and after the conference, we were chatting about the FabFundation organization, its operation, its essence and its philosophy.

And … I was left with a phrase that seemed very illustrative of what the network weaves.

What Tomás came to say is that, with what each of the participants, or members or whatever we may call them, of this global network, can contribute, it is with what it is reaching its true value and growing in knowledge and capacity of each of the Fablabs that form it, and correspondingly, the FABLAB network.

It is therefore important that each of us: “Feed the ecosystem” **

I also hear this phrase from the person in charge of the Fablab that is geographically closest to the one I direct, and with whom I also came into contact some time ago, Francisco J. Gómez from LAD Fablab. From here I encourage you to do this training soon and to continue feeding the ecosystem. 😊

It would make me very happy to have the opportunity to see how IRW grows thanks to the ideas and knowledge of others and that the project serves to make this “Fab Lab / Maker family” bigger and bigger, feeding all the ecosystem.

I would be very proud. 😍

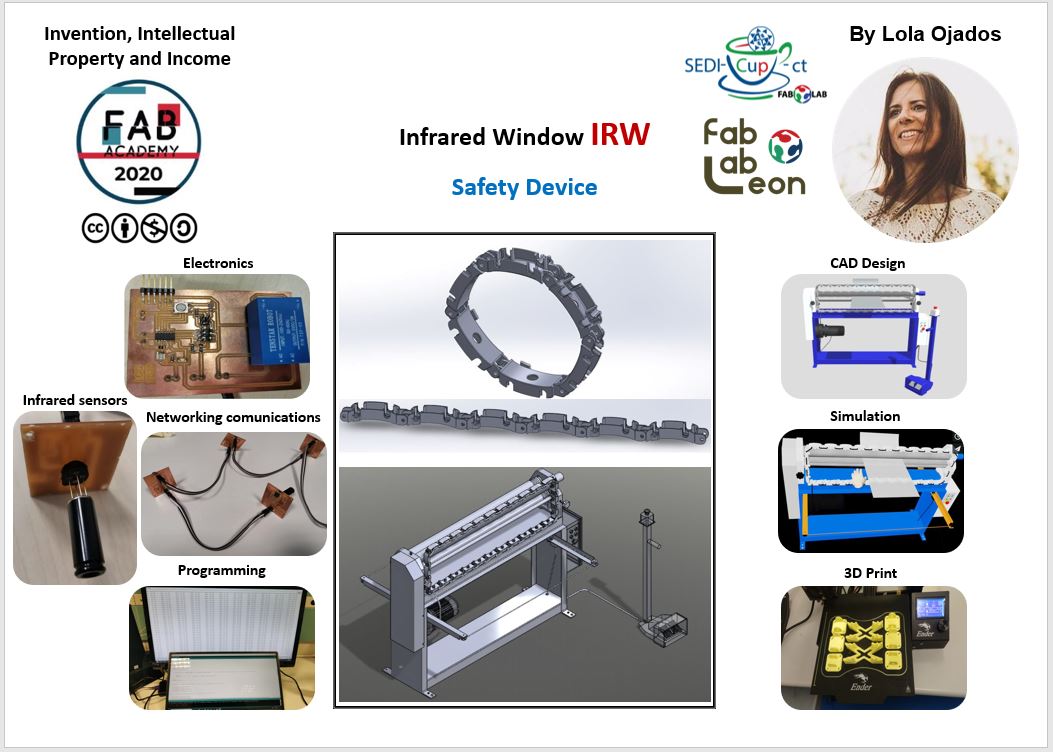

14.4. DRAFT SUMMARY SLIDE AND VIDEO CLIP¶

This week we were also asked to make an illustrative video sketch of the final project and a slide showing it as a product.

I took a look at the slides from previous years and it seemed to me that it would be best to have a single photo / image where I can explain all the components of my project in a complete and joint way, from which images will be displayed that illustrate the parts developed and that form part of the work done.

For the video, in this assignment, since I have documented it at the end of my work for FabAcademy, I will use the final version created for the presentation of my Final project.

REFLECTION:¶

Although this week seems easy, I think it really is not.

It is necessary to have a clear idea of what the objective is and how to disseminate the result of the final project.

It is important to define and limit what can or cannot be done with my project once the Fab Academy is over, if it is going to be made public and in what way.

About the slide and the video, as I have already advanced in the introduction of this assignment, for different reasons (COVID-19 among others), I have developed them outside the established time, so I have made the design and assembly of the slide And of the video at the time I have developed my project, the slide presented here is a sketch prior to the final slide, but the video is already the final one that I developed for the presentation of my project since I did not have time to do a preliminary sketch. 😅

I have compiled the focus of my final project on this SLIDE:

The summary video of my final project is this: