1. Principles and practices¶

Objectives¶

As my first assignment I have to plan and sketch a potential final project, describe what it will do and who will use it.

I also have to read the Fab Charter.

Research¶

Fashion Revolution Rewriting fashion- Copenhagen Fashion summit

Need for ubiquitous cloth waste upcycling

Fab Charter¶

I read the fab charter.

My intial idea for a final project¶

I viewed last week’s introduction session by Neil from Jaipur. Although I viewed it live, it was not very clear then. So I watched it again to understand what I’m supposed to do this week.

For my final project I would like to make a fabric segregator that segregates fabric waste from the industries by colour.

When clothes turn into pollution¶

I have been working with the textile industry particularly with cotton. The usage of water for agriculture, dyeing and printing are all environmental concerns about this industry. When fashion labels use up my textiles to make clothes a lot of cutting waste is created which is usually burned causing even more pollution.

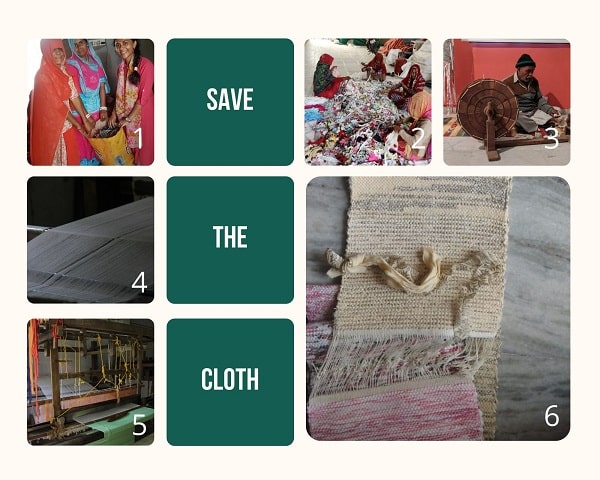

- I have been making bags under the label Soul Sanchi using waste cloth materials. 2.Other waste upcycling projects that I have done are Hand-Woven rugs on “Thorthu looms” with cotton yarn was warp while knitwear waste was Weft

- Metal boxes from fabric yarn(an oxymoron but let us call it Farn for ease). I have always wanted to create a process that can convert the waste consistently and can be replicated the world over.

What we need is a circular economy fashion all the waste get remade to other products.

Considering that India is the third-largest exporter of cotton and the second-largest producer of made-up clothes, a solution is yesterday’s requirement.

Save the Cloth Campaign

At the Jaipur Literature Festival, I met Dolly Jain who works converts leftover fabric waste to jackets. She had commissioned Neerja Jain, a weaver from Jaipur, to make textile using waste with Cotton yarn as the Warp and Farn as the Weft. Neerja had to customise her exciting loom and shuttle to effectively make it work. This prototype is very similar to my rug technically. It inspired me to join hands with Dolly Jain on “Save the Cloth” project. I tried to find out the problems she is facing and give it solutions.

Problems at present

- Cut pieces are all of different colours and comes in piles. These have to be sorted into each colour which takes a lot of human effort and makes the final price very high. Besides after a while, humans get colour negated after trying to sort colours for a long time.

- The waste pieces are cut into tiny strips with uniform length and then attaches all of them together by stitching them one by one. They then twist it to make it in the form of a yarn ball to be feeded to the shuttle. This is not only time consuming but useless as well

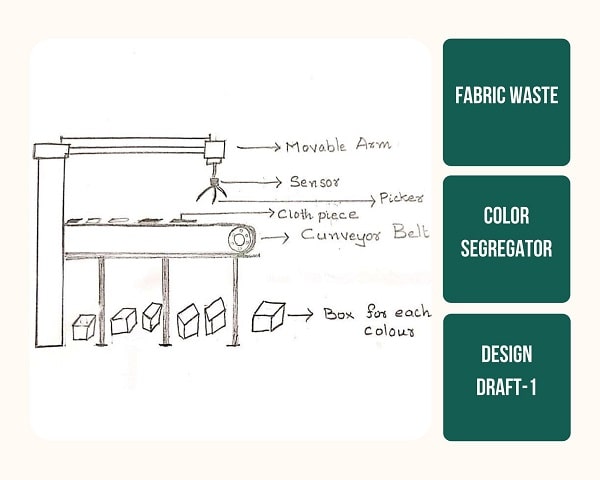

My solution is to build an automatic fabric segragator that sorts based on colour.

What it will do?¶

The segragator, with its sensor can detect the colour of each piece of clothing and the picker on the movable arm will deposit it into the respective box. The conveyor belt will ensure the proper movement of the cloth pieces.

Who will use it?¶

At the Jaipur facility where we sort I can create a separate area for keeping this machine. One or two employees can work the machine and all others who are currently involved in manual sorting can be redeployed for winding and furniture making. This machine combined with a yarn winding machine(Instead of stitching each cloth piece to another, twist and wind like how the coir is made. The general model of a coir winding machine can be used for this purpose) can totally make waste to wow.

Planning¶

The following are the parts I might require for this project:

- Colour sensor

- A motor to move the sorted colour

- A belt to on which the piece will move

-

Collecting bins

Problems I anticipate -

Segregation might pose difficulties as clothes have innumerable colour variations and patterns

- Each piece of cloth has to be separated before dumping into the conveyor belt

- The machine arm might not be fast enough to replace human hands

Addendum¶

The circumstances have changed a lot between the last week of January, when I first did this assignment and the second week of June when I finally started doing the final project. COVID-19 had its grip on everyone’s life and after the three month lockdown many industries shutdown and millions of people lost their jobs. The cloth segregator proved to be an unnecessary and time consuming at this point. Hence I changed the final project and started thinking of alternative ideas. Finally I did “Shoobot- Automatic Cat Litter Box”, the details of which is udated on the project page.