18. Wildcard week¶

May 22

Assignment

- ????

Summary

This lessons from the practice were very very strong for the later on project hulls. I’m going to change almost completely the process. The main lesson is that slicing the 3D design hull doesn’t make it possible to resin the hulls because they have enormous gaps and the tissue didn’t glue to the skeleton, make it impossible to produce an hard structure. The good part is that we have a new direction to explore in the final individual project.

The other issue still be the eco fabrication process: real far from accomplishing it.

Todo

- Test small pieces of different tissues with diferent dye colors

Work Done¶

The idea for this week is to use the practice done to resining the boat hulls. I start with a small hull. After slicing it using Fusion 360 slicer (described on week 3 and 8) I get the plans in DXF file and open it on QCAD, where I export it in SVG. This procedure is not necessary, since COREL work well with the DXF files from FUSION 360. Cutted this vector files on the laser cutter and assembly them. Filipe help me out on the firts steps of the RESIN. We use paper for the RESIN support becaus the tissues that I have (names ?????) did glue very well to the hull skeleton. We also use try a strong orange painting (used by children to paint with the hands) but the outcame was strange when mixed with the resin: a kid of rubber that broke very easy but flexible to a low degree of longitudinal stress. We did three layers and wait to a day to see the outcame:

Info

The outcame of this process was not satisfactory so, I didn’t complete the resination process. Meaning that I didn’t test the vacuo process for the structure to be more strong.

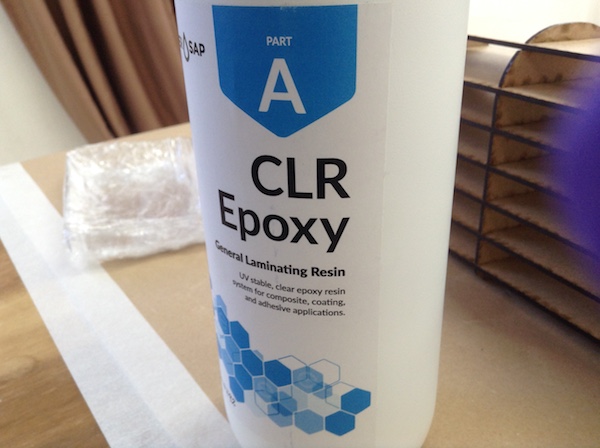

Of course, we did started with the security issues; looking to the document for each parts, epoxy and hardener:

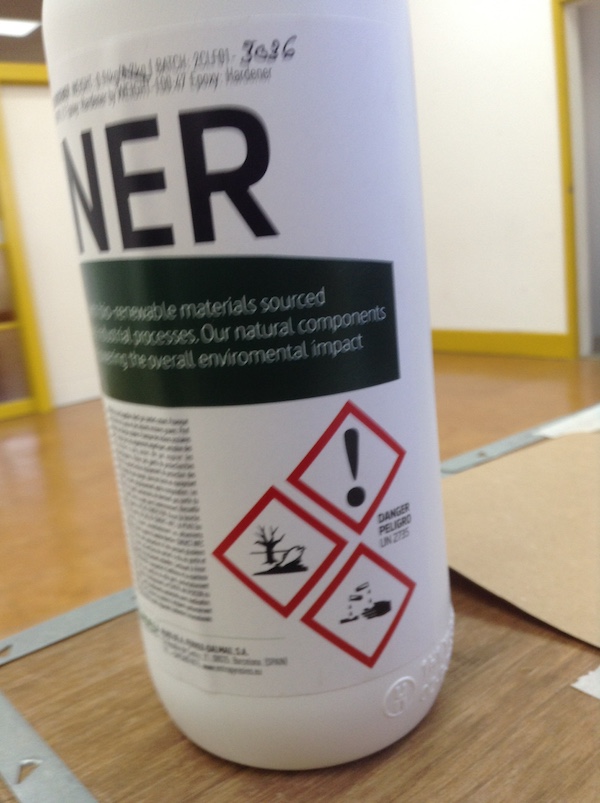

And environmental hazardous:

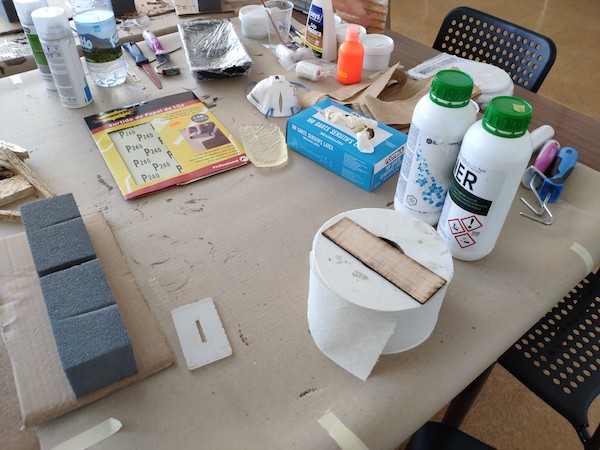

In spite of the negative outcame for the small hull I decided to continue with the same procedure but now trying to glue the tissues (name ????) but with no sucess. Paper again, five layers, a little bit less hardener them the 2:1 because the room temperature was a little bit above the normal and the solution was drying very fast.

Info

This lessons fro the practice were very very strong for the later on project hulls. I’m going to change almost completely the process. The other problem that this former process will overcame is the superior part of the hull that, as you can see were impossible to be done with this rude process.

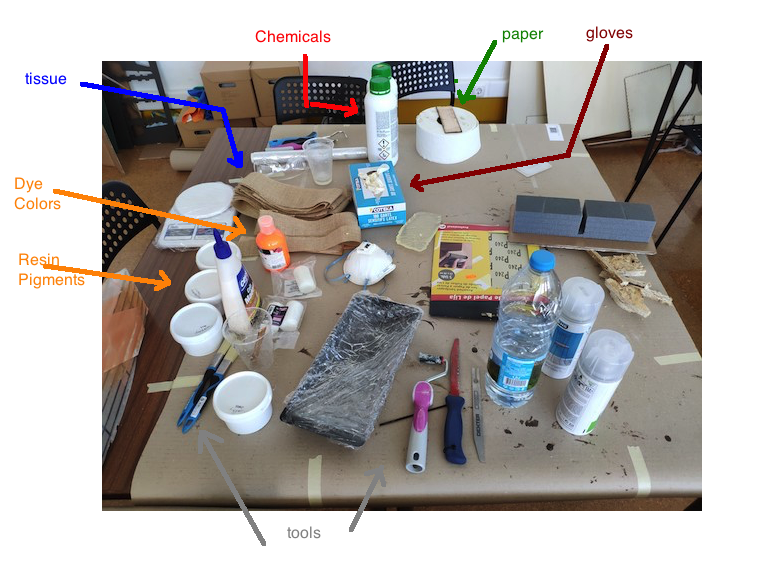

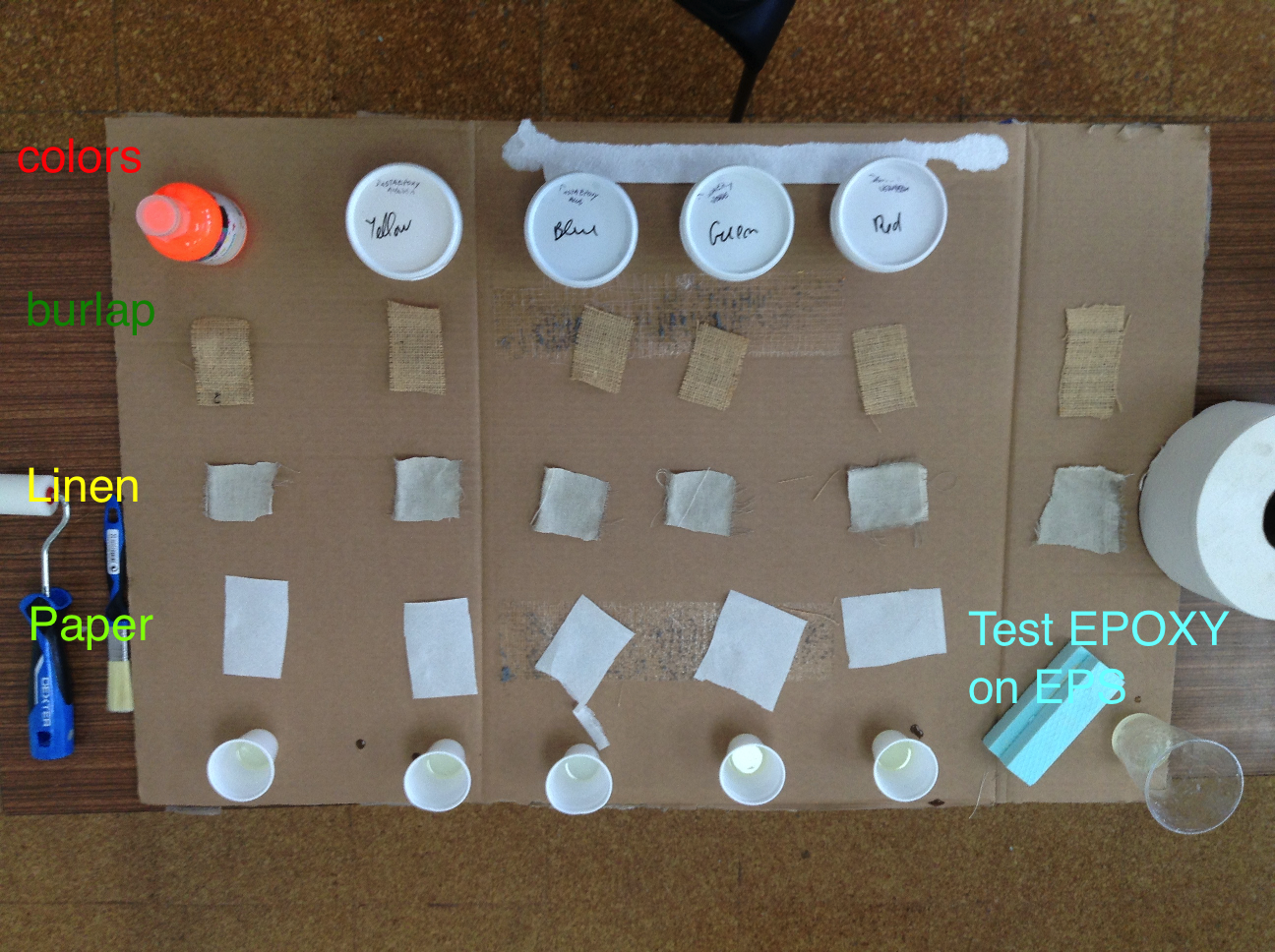

In the work table it is possible to see all the components used in this process.

Tissues test¶

I made a short test with all the tissues and same color gel that can be mixture with the epoxy resin. I found that the most favorable was the linen with all the colors included over the paper and the Burlap: it seems stronger.

The EPS became stong and impermeable with the use of epoxy. Good result.

Before

After