Menu

HomePrinciples and Practices

Project Management

Computer-aided Design

Computer-controlled Cutting

Electronics Production

3D Scanning and Printing

Electronics Design

Computer-controlled Machining

Embedded Programming

Molding and Casting

Input Devices

Output Devices

Interface and Application Programming

Networking and Communications

Mechanical Design

Machine Design

Wildcard

Applications and Implications

Invention, Intellectual Property, and Income

Project Development

Final Project

Week 15

Mechanical Design

Week Assessment :

Design a machine that includes mechanism+actuation+automation.

Build the mechanical parts and operate it manually.

Document the group project and your individual contribution.

Group page for MTM week

Mechine Design week

This week assignment was difficult for us because it based on group work which is had for us to gather at the same time. each one of us has different time in the lab this was our first challenge. whatever we whare able to sit together with Moath to discuss and to make a plan besides dividing the rules between us. We came out with good paints which are:

1- We decide which machine we will make (XY plotter).

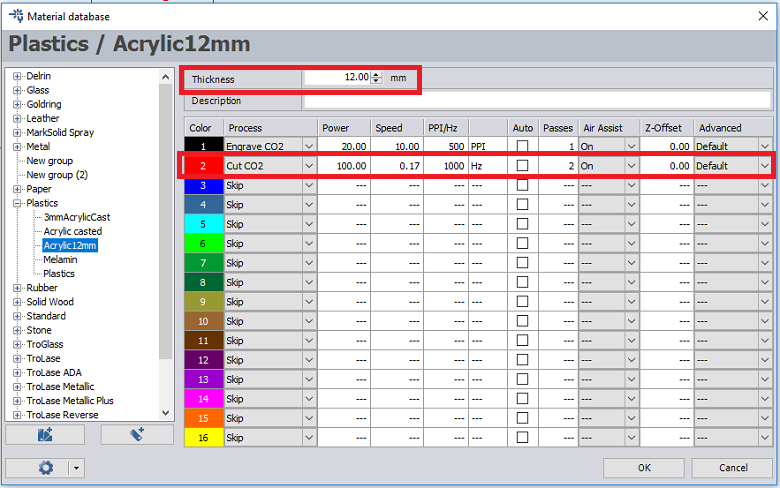

2- We chose the material which is acrylic 12mm (The previous student used acrylic. because of the joint and slot we choose 12mm).

3- Brainstorm (The mechanism of the machine).

4- Divide task between us (Abdullah was the leader).

5- We did a lot of tests in the acrylic 12mm and MDF.

Our biggest mistake was that we did not finalize a sketch. We only describe how it will look without drawing. Becuase of that we had to change the design many times. To be honest I felt lost from the first day. The first day was test day we did a lot of tests with different materials like cardboard and MDF and acrylic.

For the second day, Abdulla , Darshan , Al-Zubair . I was not in the lab that day because it was Saturday and I don't come to the lab at the weekend.

I did not do much to this day. I was walking around to help others. The first problem that we faced in this day is that the laser cutter Universal (ILS12.75) didn't cut and we didn't know why so Abdulla ask for Wendy helps.

she opened the back of the machine and she told us that there is no issue with the laser tube she was checking that no one has moved it.

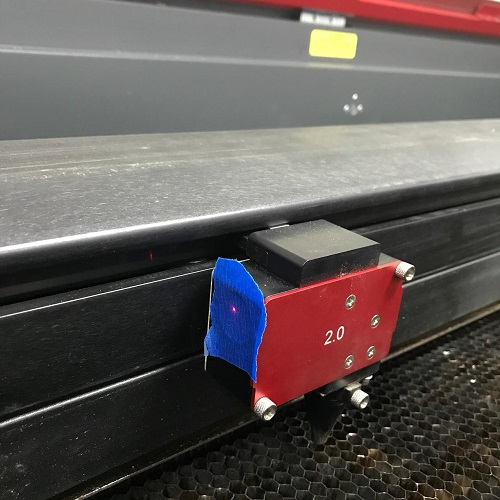

Then she put a blue tape on the laser head mirror. we found something interesting, the laser not in the center of the laser head mirror

when the laser beam moves away from the source, it begins to deviate. Wendy recommends us not to use the machine till they fix it. We moved to use Universal (PLS6MW).

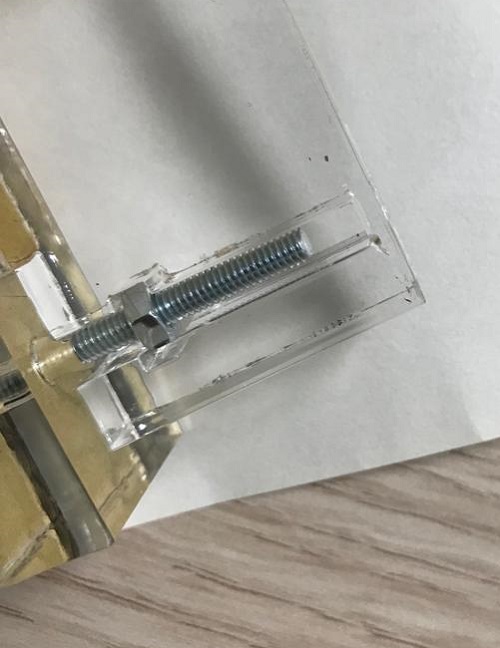

I was with Abdulla assembling the body. He preferred to drill the acrylic 12mm and I helped him.

Then Moath said this will give you the impression that you are in a hurry and want to finish quickly and you do not want this impression about your machine.

Fourth day Moath did a sketch for us our goal in this day is to have the body for the machine cut we could not reach this goal because there is something happen to the laser cutter and its stopped working. There was another laser machine but we did not know how to use it.

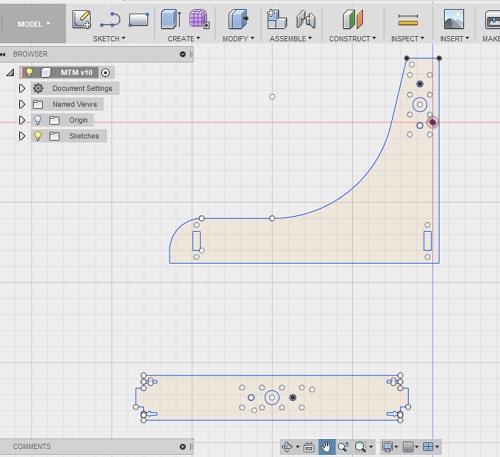

Fifth day No time left for us we had to do something. I get shocked when I enter the lab and no one from the Fab student was there so I called Zahrah to come to the lab and I told her that I can do the work alone. she came after 35 munites. After 4 hours Eidha came with his friend. Moath draws a sketch for me and based on his sketch I designed the frame in Fusion 360.

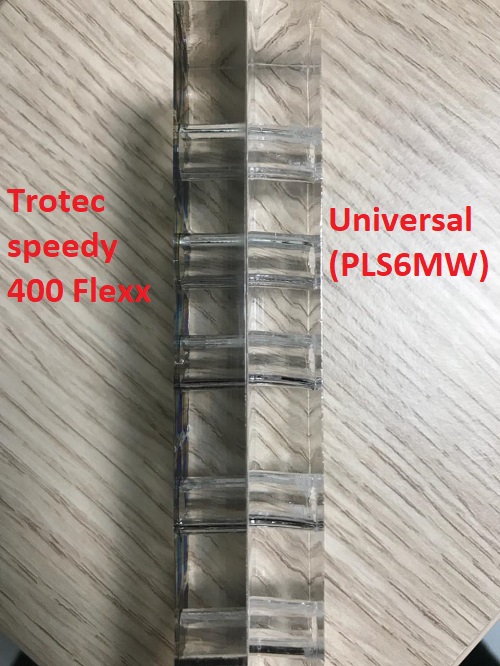

Before I cut the frame I had to test the slots and I cut it by Universal (PLS6MW). I found that the laser cutter does not cut it straight.

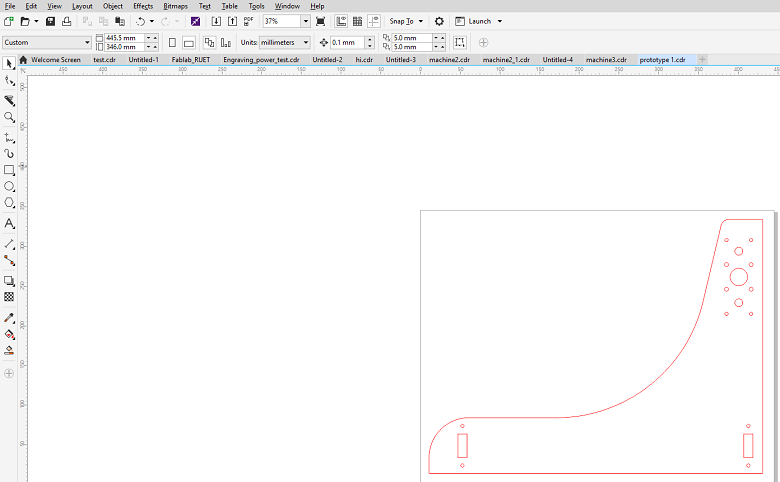

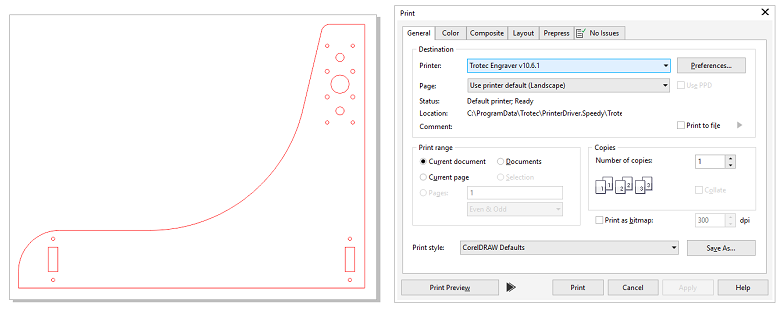

We could not rely on this machine. Fortunately, there is another machine Trotec speedy 400 Flexx but we don't know how to use it. I and Zahrah asked for Hashim to show us how to use the machine and he showed us and he creates a settings file for acrylic 12mm. Here are the steps.

Go to File > Print

Set up the cutting settings

Click on the play icon to give the order for the laser cutter machine to start

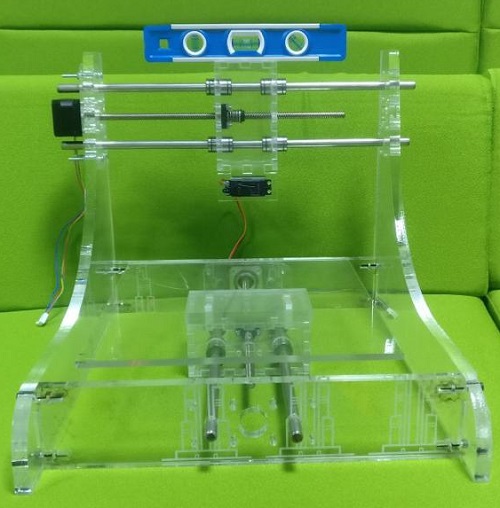

After we cut all the parts this is how our machine looks like