Project development

The final will consist in the development of 1 or 2 elements of a system.

In order to test how a component works and that will mean it, the program could be apply to all of them.

1_RESERCH

Just to give you and idea of what was this project about I would like to drop a couple of lines explain the purpose of the research.

We started studying a component, this component was a 3d unit that was capable of growing in all the dimensions, meaning it was scalable, we establish a range in which this component will be working considering the smallest component as a tile and the biggest as a shelter.

The idea was to create a surface where the components will be place organize by size, and their own geometry will be creating the hole surface, by placing them one next to the other.

Since we were working with magnets the idea was to study how will these components react to each other, just because all the branches will contain a magnet.

We needed an starting point, one piece moving first, this component was place at the center and had a motor. The motor moved the mechanising and this made the "flower" rotate in a certain direction, we could realized the other flowers surrounding this one were moving as well as this first one. creating a field that was using just the magnetic force imput to move.

I would like to continue using everything I have learnt doing this project and implement it with some electronics that could be the force this time. meaning I would like this project to be place in an inner space, for example , one of the big rooms we have here at LABoral and I would like people to be the IMPUT of the installation.

FABRICATION COMPONENTS.

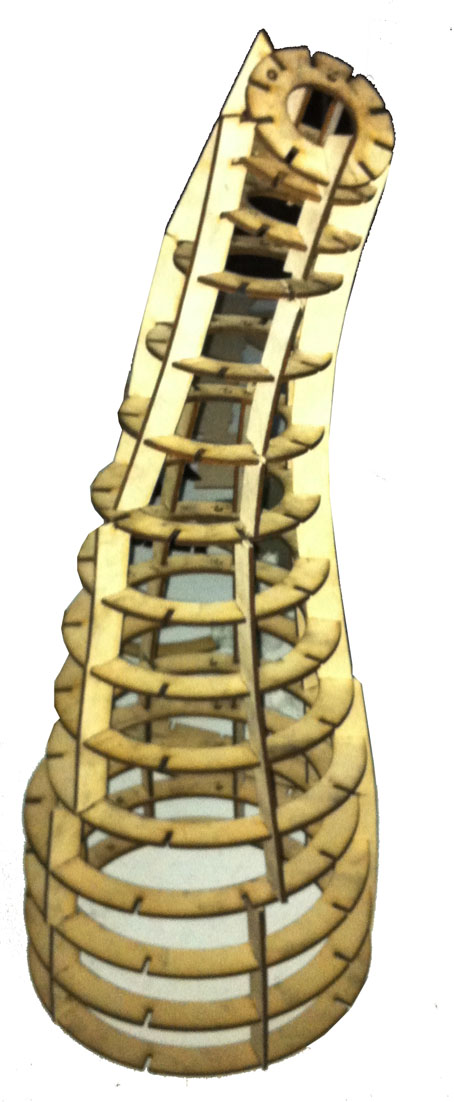

3mm black acrylic _In this first test the geometry was to extreme and I model the surface in rhino and use a command called sweep 2 rails, using this one you get a very nice shape but then it is difficult to make it work unless you 3d printed.

2_ Plywood 3mm_The second test was an attempt to redo the same shape but using plywood that it is more flexible that the acrylic, it did not work either and it was a really dirty finish.

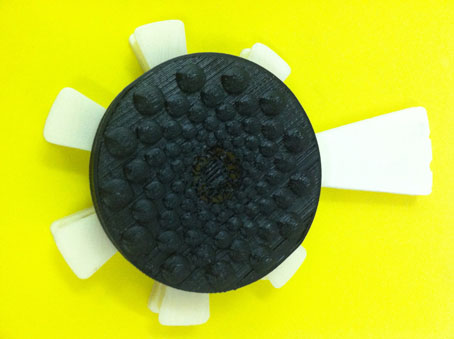

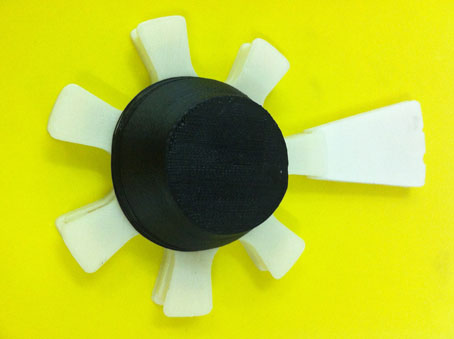

FLOWER HEART_ To build this part I have to run a couple of test to see if the petals would fit in. because the abs when you come to detail it is not very precise.

FRONT SIDE_ A first run for the phylotaxis in black acylic, the holesin the center are too small so it does not work.I have decided for the next text to be in color and do the holes afterwards.

BACK SIDE

This petal was initially meant to be 3d printed but the I have decided that since I have to do many( 7 petals) it was better to produce a mold. What happend? I have to change the geometry because it was not posible to milled a mold this way. So I had to inverted both designs the heart part and the petals.