git

Git is a distributed version control system that tracks changes in any set of computer files.

Check our group page to see the full project

Group PageScanLab X1 is a 3D scanning platform that I co-developed with Fab Academy students Ahmed AlKooheji and Haitham Al Naser. It’s designed to simplify the process of scanning small objects (up to 10×10×10 cm³) using a smartphone.

I focused primarily on the mechanical design of the system — especially the structure, motor integration, and user-friendly layout. I also worked on ensuring the design could be easily fabricated using digital fabrication tools available in our lab.

ScanLab X1 consists of two coordinated subsystems:

It was also tested for product photography and videography, making it useful for designers and makers beyond just scanning.

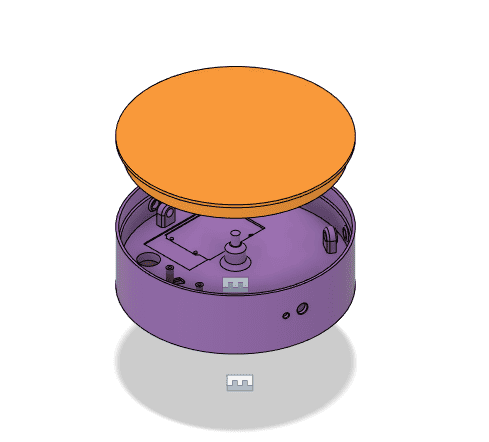

I designed the base to include three side bearings and a central 608 bearing for stability. A stepper motor drives an internal gear ring embedded in the rotating disk. All parts were 3D printed.

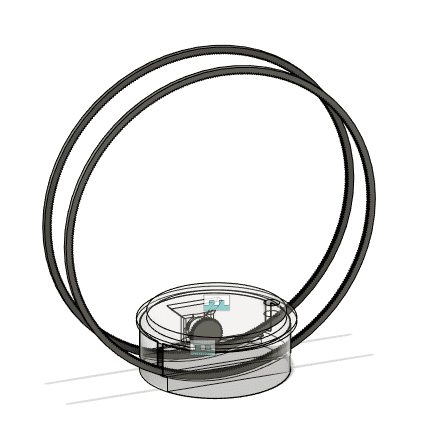

This part holds the smartphone and rotates it vertically. I laser-cut the main structure from 6mm acrylic to handle large diameter and stress, and I designed a gear + track system driven by a stepper motor.

I tested multiple tolerances for bearing fit and gear spacing, aiming for smooth and precise movement while maintaining ease of assembly.

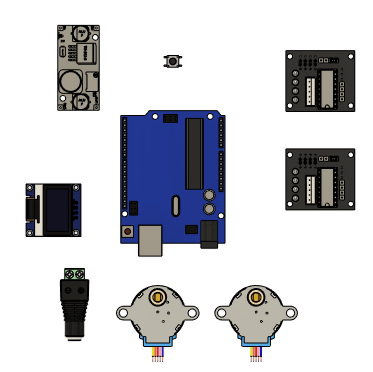

While I focused on the design side, we collaborated on the full integration. ScanLab X1 uses:

We also added an LED status indicator and used a 9V supply with a buck converter for consistent voltage.

After fabricating all parts and wiring the electronics, we assembled the platform and tested both axes.

This project helped me deepen my mechanical design skills, particularly in integrating stepper-driven motion and designing functional parts for both 3D printing and laser cutting.

I enjoyed thinking through both the functionality and the aesthetics of the platform — and finding creative ways to make it look neat, compact, and professional while remaining open-source and reproducible.