Wildcard Week: 3D Printing on Fabric

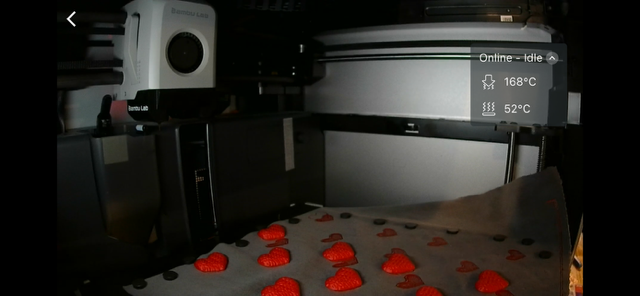

For Wildcard Week, I experimented with 3D printing directly onto fabric using a Bambu Lab 3D printer.

This technique blends rigid and soft materials, making it useful for wearable tech, artistic elements, and flexible enclosures.

Material and Tools Used

- Fabric: Velvet-like textile (soft and slightly textured)

- Filament: PLA, 1.75 mm

- Printer: Bambu Lab X1 Carbon

Experimentation Process

I ran three main experiments to test the effectiveness of printing on fabric:

-

Experiment 1 – Minecraft Sword: I printed a Minecraft sword design where the middle section was replaced with fabric.

The idea was to combine rigid edges with a soft, flexible center. The alignment worked visually, but the fabric wasn’t tightly fixed and caused uneven layers.

- Download Minecraft Sword

-

Experiment 2 – Cut Heart Shapes: I tried printing small heart shapes on the fabric, which had some pre-cut details.

However, the fabric was not properly secured and shifted during printing, causing the nozzle to miss and exposing the cuts.

-

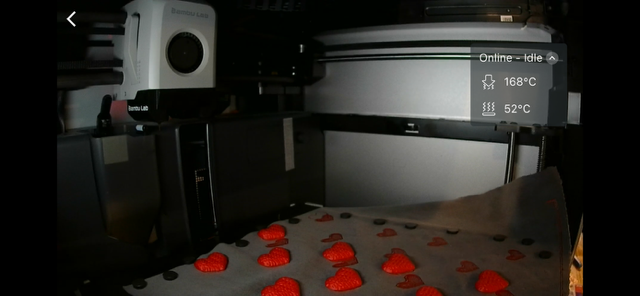

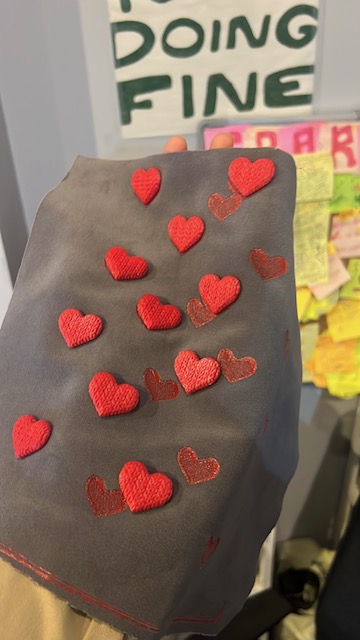

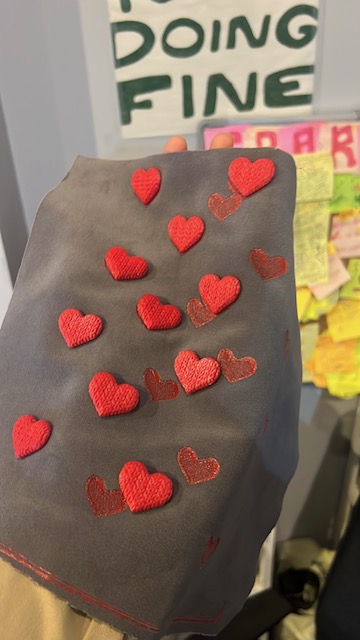

Experiment 3 – Fixed Fabric with Magnets and Tape: I repeated the heart shapes, this time fixing the fabric tightly using magnets and heat-resistant tape directly on the build plate.

This approach stabilized the fabric and allowed clean, successful prints with proper adhesion and alignment.

Download Knitted Hearts

Download Knitted Hearts

Printing Method

I used a simple but effective technique to integrate fabric mid-print:

- I sliced the design using Bambu Studio with standard PLA settings.

- During printing, I paused the print manually after the first few layers (around 1 mm height).

- I then carefully placed the fabric on the build plate, securing it flat with magnets and heat-resistant tape.

- Once the fabric was secured and flat, I resumed the print. The nozzle continued printing over the fabric, successfully bonding the PLA to the textile surface.

Results and Observations

- The PLA adhered well to the velvet-like surface due to the fabric’s texture and grip.

- Proper fixing is critical—loose fabric leads to shifted layers or nozzle collisions.

- The final result in Experiment 3 produced smooth, clean prints that merged soft and rigid elements elegantly.

Applications

- Wearable designs (e.g., logos, patches, or decorative panels)

- Textile-integrated enclosures or soft pouches

- Soft robotics or artistic textile works

Reflection

3D printing on fabric was an exciting and hands-on experience. The process of pausing the print and integrating materials mid-process required attention to detail and timing.

I learned the importance of fabric stability, nozzle clearance, and surface selection. Next, I’d like to experiment with TPU or conductive filament to explore more functional wearable applications.