Week 14

Molding and Casting

Group assignment

- review the safety data sheets for each of your molding and casting materials,

- then make and compare test casts with each of them

- compare mold making processes

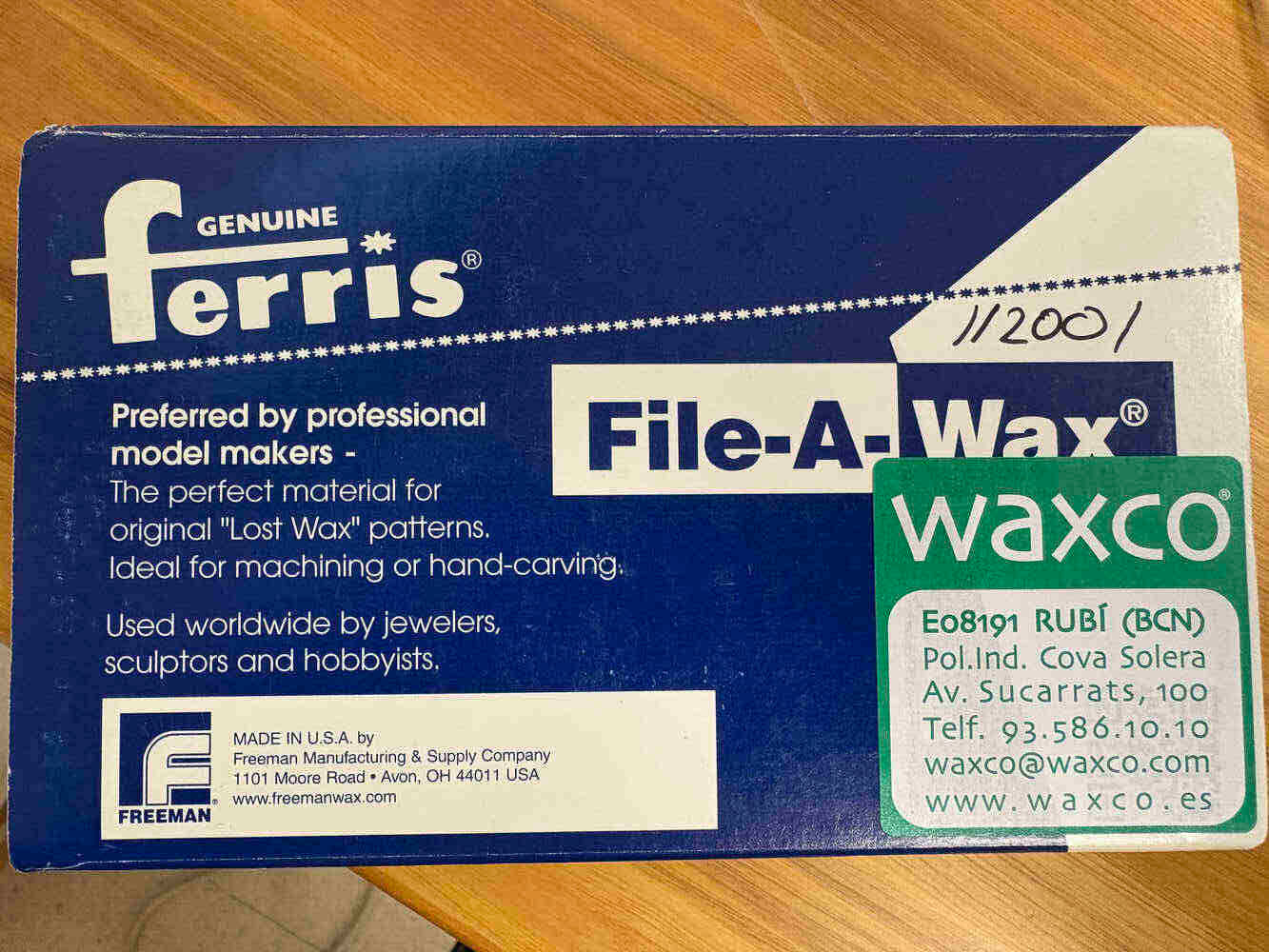

Ferris File-A-Wax

This is a professional-grade carving wax used by jewellers for creating models through the lost wax casting process. It’s specially formulated to be carved, shaped, or machined, allowing for the reproduction of highly detailed and complex designs. It’s ideal for crafting a wide variety of intricate cast forms like rings, earrings, pendants, and bracelets. The wax comes in different colors, each representing a specific hardness level.

Ferris File-A-Wax Blue

| Characteristic | Detail |

|---|---|

| Primary Application | We use it for creating our models for lost wax casting. |

| Material | It is made from a petroleum-based wax blend. |

| Color | Blue. |

| Flexibility | Excellent, perfect for fine, detailed hand carving. |

| Manual Workability | Very good, it's easy for us to carve by hand. |

| CNC Machining Compatibility | Low, we don't recommend it for high-speed CNC machining. |

| Melting Point | 240 °F (approximately 116 °C). |

| Hardness (Shore D) | 52, moderately soft and easy for us to work with. |

| Density | 0.92 |

| Ash Content | 0.003% very low, which allows us to achieve clean castings. |

| Flash Point | 585 °F very safe under normal working conditions. |

| Available Formats | We have it in solid blocks. |

| Our Block Dimensions | Luis provided us with blocks measuring 92.1 mm × 152.4 mm × 38.1 mm. |

Extra Tip: We always think ahead about demolding, smooth curves and slight draft angles help us remove the wax model cleanly from a flexible mold without breaking it.

Types of Commercially Available Wax Blocks and Their Main Characteristics

| Wax Type | Main Characteristic | Hardness (Shore D) |

Density (g/cm³) |

Melting Point (°C) |

Flexibility | CNC Machining |

|---|---|---|---|---|---|---|

| Blue | Maximum flexibility for fine hand carving | 52 | 0.92 | 116 | Excellent | Low |

| Purple | Maximum hand-workability | 55 | 0.93 | 117 | Very good | Moderate |

| Green | Balanced flexibility and hardness | 57 | 0.94 | 118 | Good | Moderate |

| Gold | Optimized for high-speed CNC machining | 60 | 0.95 | 119 | Lower | Excellent |

| Orange | Ideal for high-speed CNC machining | 62 | 0.96 | 120 | Low | Excellent |

| Turquoise | Excellent for both hand carving and CNC machining | 59 | 0.94 | 118 | Good | Very good |

Notes:

- Higher hardness means greater resistance to hand carving but better CNC machining performance.

- Greater flexibility is better for creating detailed models and for easier mold release without breakage.

- Blue is the most recommendedour work is primarily manual (like artistic jewelry or detailed molds).

- Gold and Orange are perfect if our workflow involves fast CNC milling.

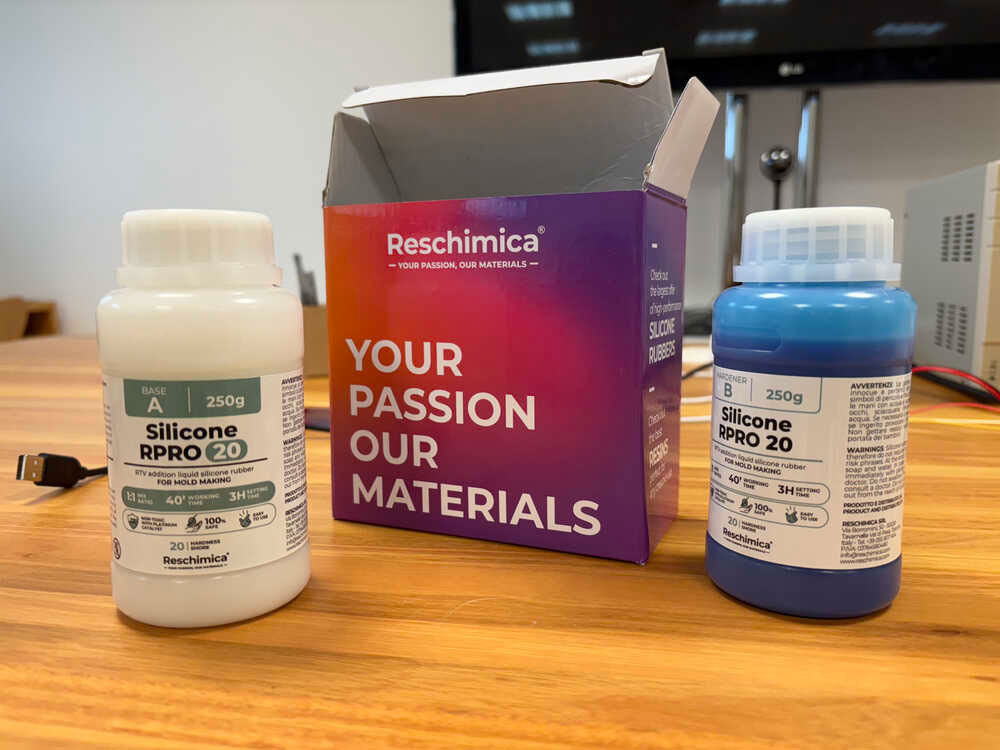

Silicone RPRO20

Produced by Reschimica, RPRO20 is a platinum-cured addition silicone rubber. It cures at room temperature within 3 hours and offers exceptional dimensional stability (0% shrinkage) along with enhanced technical and mechanical performance (up to 15% better casting results compared to other silicones). It's designed for easily creating professional-grade medium hardness molds (21 Shore A).

This blue, two-part silicone (base + platinum catalyst) has low viscosity and high elasticity, enabling it to capture even the finest details. It provides excellent tear resistance, withstands high temperatures, and resists aging. Its non-stick surface further simplifies demolding.

Main applications include:

- Moldmaking and model production: due to its precision in detail replication, dimensional stability, and strength.

- Artistic ceramics: for its fluidity, durability, and stability during casting.

GÉDÉO Epoxy Resin

This is a transparent, two-part epoxy resin system composed of a resin and a hardener. It creates a clear, glass-like finish and is suited for experienced users. It can be used to create molds, decorative inclusions (up to 2 cm thick for small volumes), coatings, or laminates.

Thanks to its simple mixing ratio and strong final cure, it offers excellent clarity and a hard, durable surface. The resin is also suitable as a varnish or glaze, producing striking glass-paste effects.

Typical uses include: casting objects, embedded designs, trays, jewelry, coatings, surface finishes, and protective laminates.

Working time: ~1 hour 45 minutes

Full curing time: ~18 hours

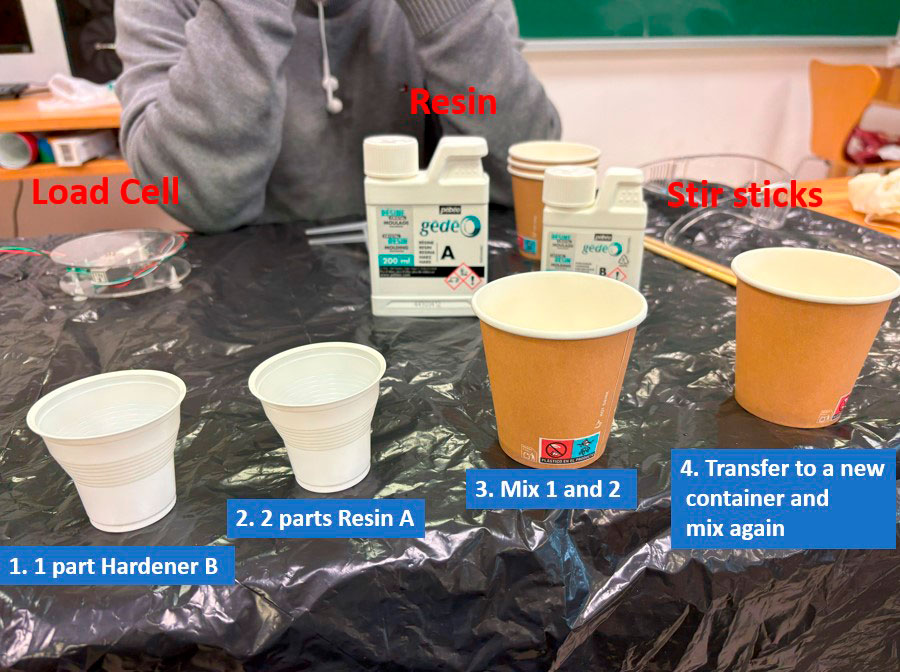

Instructions:

1) In a clean, dry container, first add 1 part Hardener B, then 2 parts Resin A.

2) Mix thoroughly, ensuring you scrape the sides and bottom. Transfer to a new container and mix again to ensure uniformity and proper curing.

3) Pour the resin mixture onto the chosen surface or mold.

4) Let it cure in a dust-free area for 24 hours. Note that curing time varies depending on temperature and humidity.

Safety Precautions

When handling silicone or resin materials, personal protective equipment is essential:

Hands: Use nitrile gloves to avoid skin contact.

Eyes: Wear safety goggles to prevent irritation from fumes or splashes.

Respiratory system: Use a mask equipped with an ABEK1 filter to protect against organic, inorganic, and acidic vapors, as well as ammonia and its derivatives.