Week 5: 3D Scanning and Printing

Group Assignment: Design rules for our 3D printer link to Group Assignment

We tested a different materials with our Ender 3 V3 SE. One the interesting findings was that the printer misbehaved under ABS settings trying to print ABS filament. We found out that ABS filament prints well under PLA settings, but with higher bend and nozzle temperature. 80-100 Celicius and 240-270 Celicius respectively (on my turn I used 250 Celcius, and it was perect).

Individual Assignment:

1. Design and print an object that could not be made substractively

I went for a custom design, with a swiped extrude cut inside. I tried to give connected holes from top to bottom, with an S shaped extruded cut between them.

.png)

.png)

I frist created a solid to extract from the main body that I would create latter.

.png)

I then created the main body around it.

.png)

For some reasons, the Combine tool didn't work in my SolidWroks, so I resorted to swept cut and with an improved cut path to enable our local printer to print without supports.

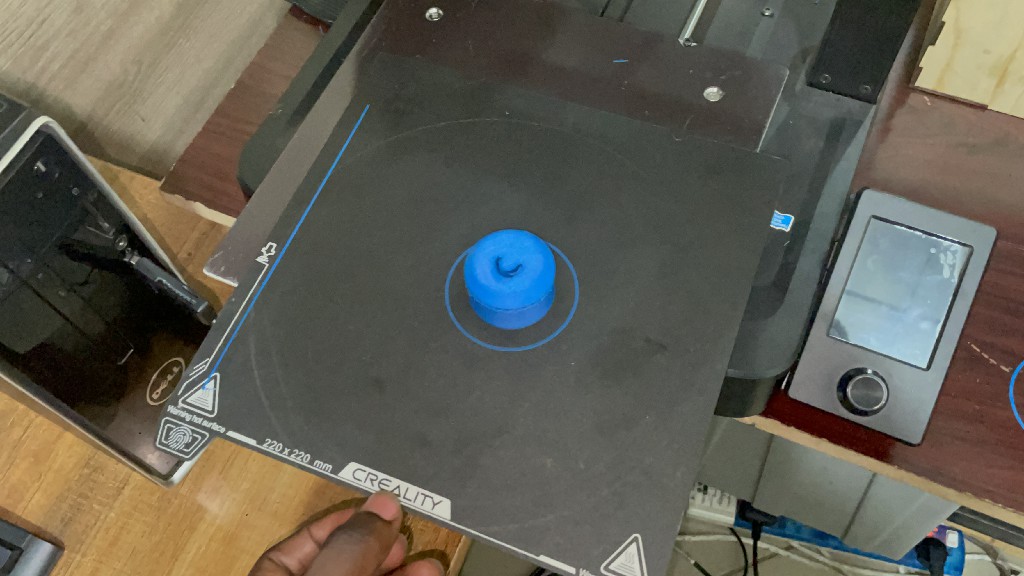

Prinitng

Then I went ahead to print the 30% model to fit our printer's dimensios and

spend less time printing.

.png)

Final product pictures: in making and complete

2. Scanning and 3D printing scans

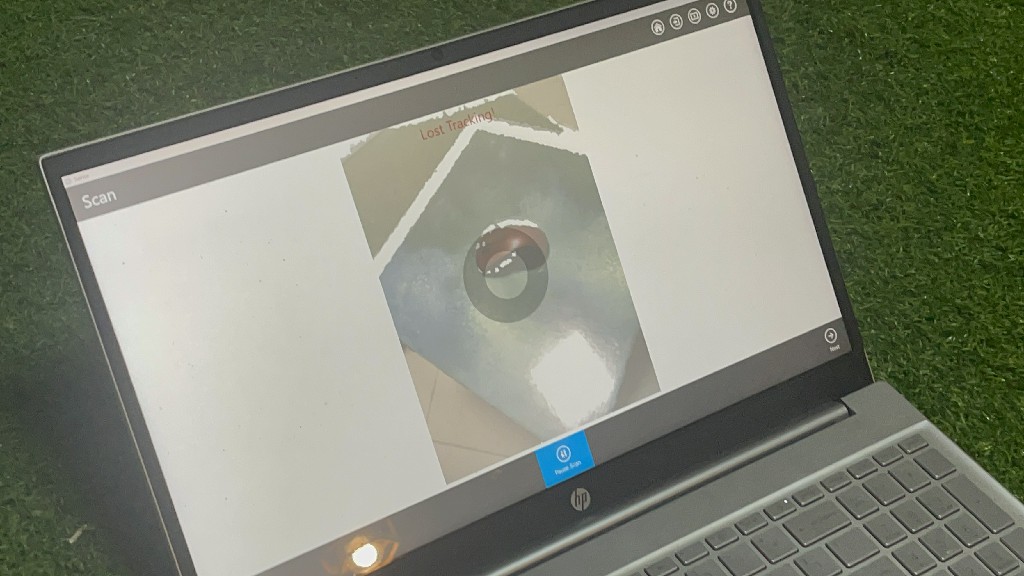

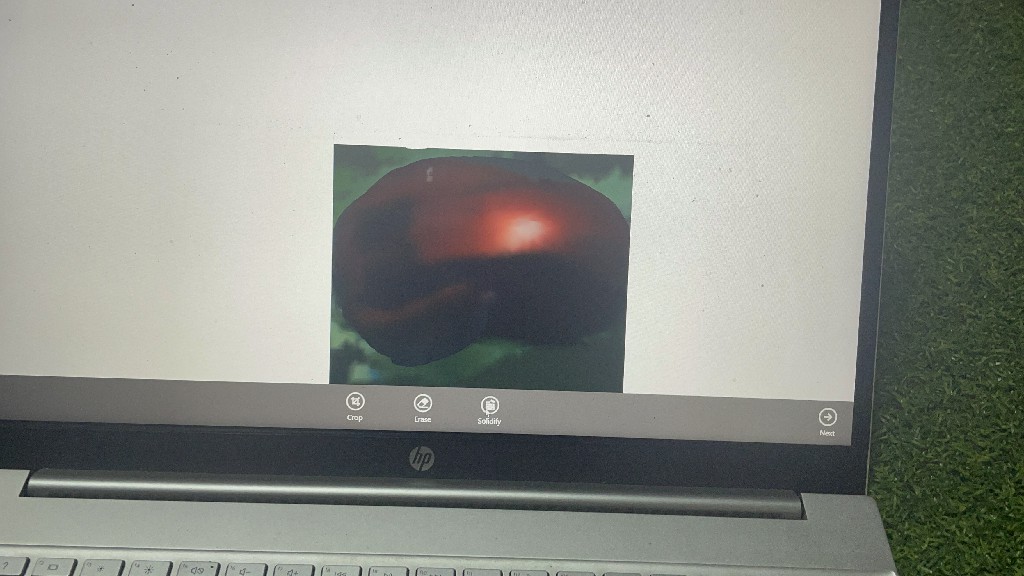

I continued to collaborate with one of collegues, Christian, and our instructor in setting up the Sense Gen 1 3D scanner.

I saved the STL files a latter printed an 30% scale with ABS filamet, using PLA settingd, except for Nozzle and Bed temperatures as we discovered in the group assignment.

.png)

.png)

.png)

.png)