13. Molding and Casting¶

Hero Shot

Assignment Overview:¶

Group Assignment:¶

-

Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them.

-

Compare printing vs machining molds.

Individual Assignment:¶

-

design a mold around the process you’ll be using.

-

Produce it with a smooth surface finish.

-

And use it to cast parts.

Extra credit: use more than two molds parts.

Group Assignment

Here is a Group Assignment link

The group assignment link is also attached below.

Individual Assignment workflow¶

-

3D Modelling with fusion 360

-

Wax CNC Machining

-

Production of Silicn Molds

-

Casting

3D Modeling with Fusion 360:¶

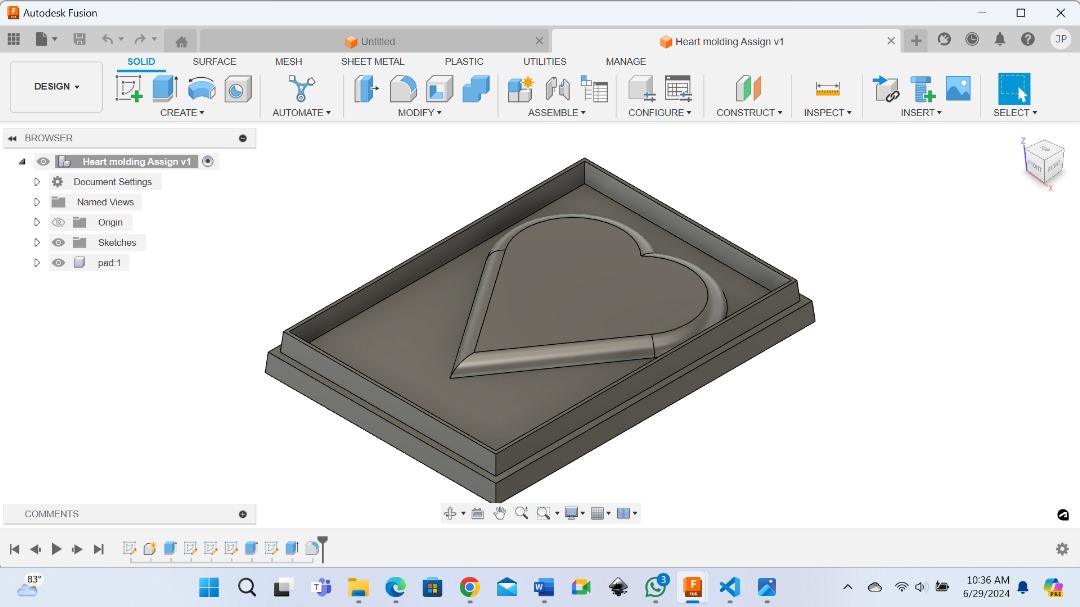

I have used Fusion 360 to design my model. I decided to create a model that looks like a Heart that often symbolizes Love to some people.

It is not connected with my project but it is just a random choice. Perhaps it can symbolise the love I have for the Fabacademy.

The material I want to use is Silicon which will be molded by an eproxy mold composed in two parts.

To do this I have to make other two molds with the Wax to make the eproxy mold.

Designing the Part¶

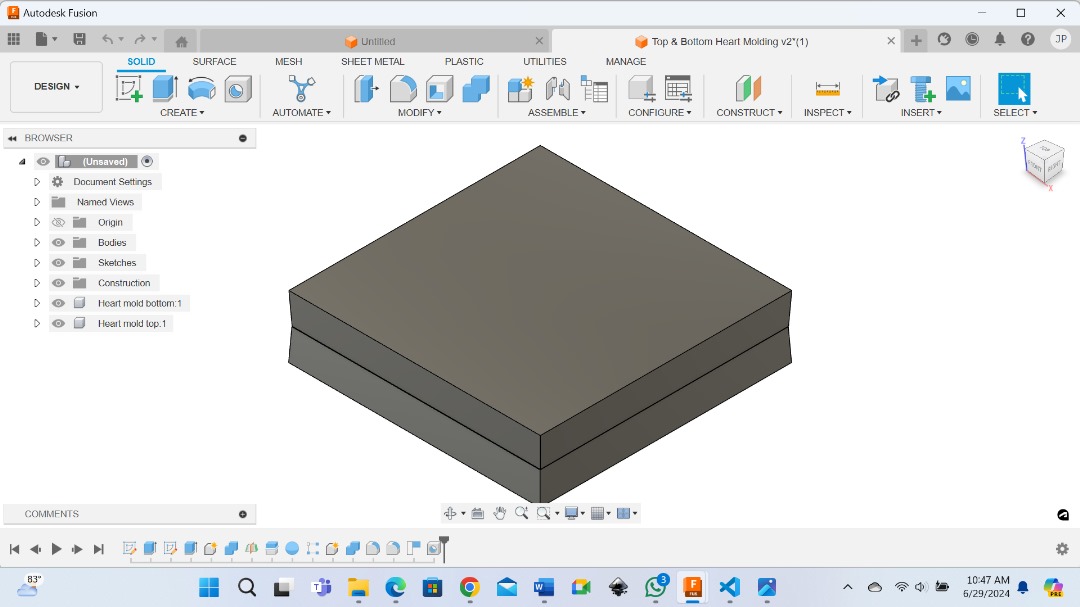

Below I used combine and split body tool to create another part.

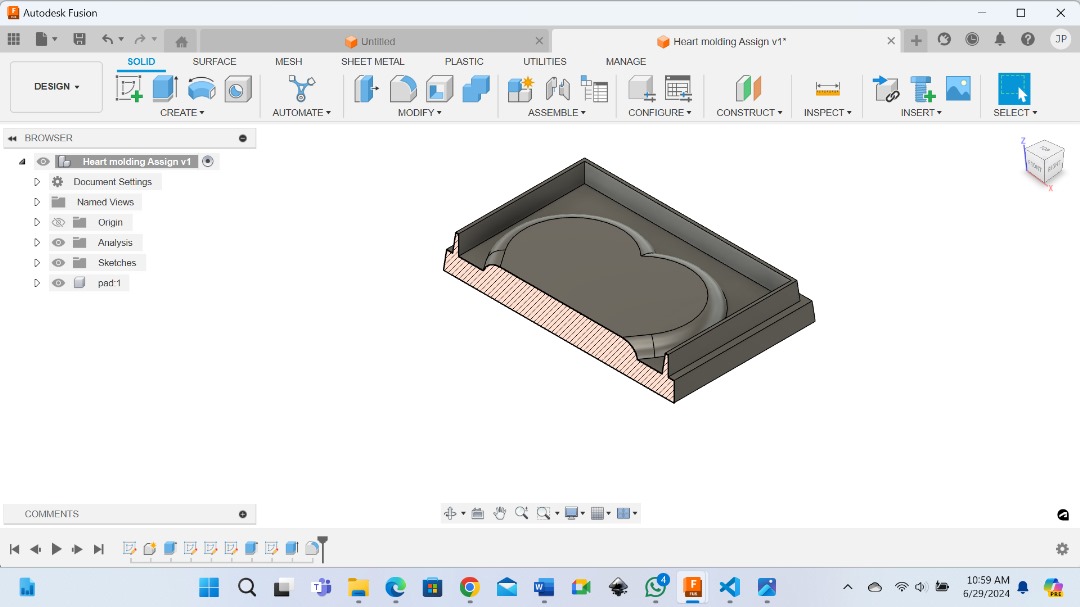

Below is a section analysis of the part

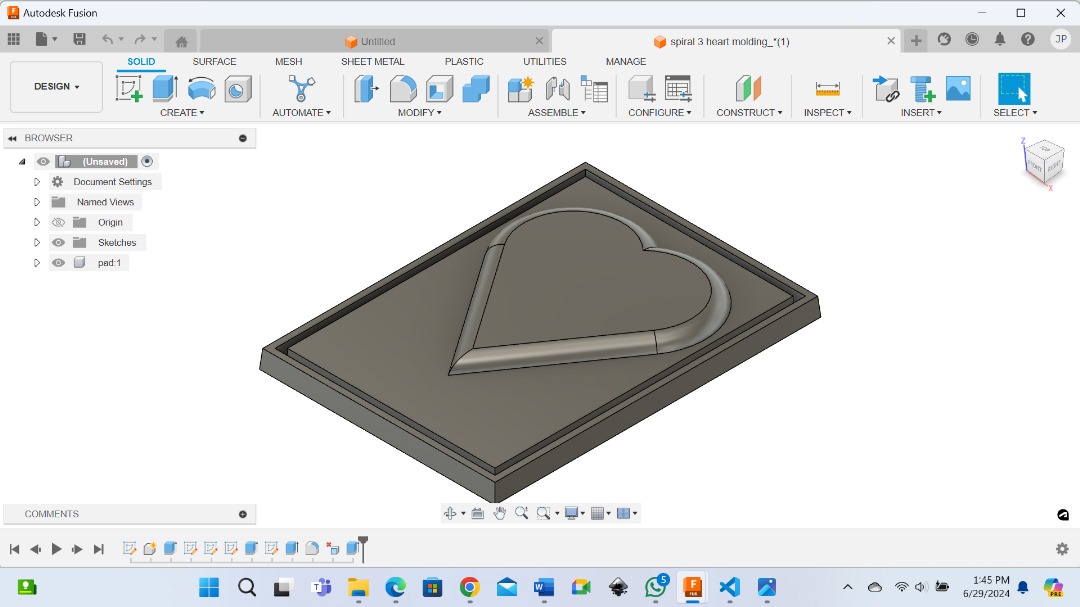

below I have the other part created.The only difference they have are the registration marks. The first one has a stub while the other one has indentation. This helps to hold them together when casting.

Wax CNC Machining with CAM¶

After finishing the modeling exercise let us switch from designing to Manufacturing to set parameters and select tools to enable us generate G-code for our CNC Machine for the milling process.

Setting Parameters

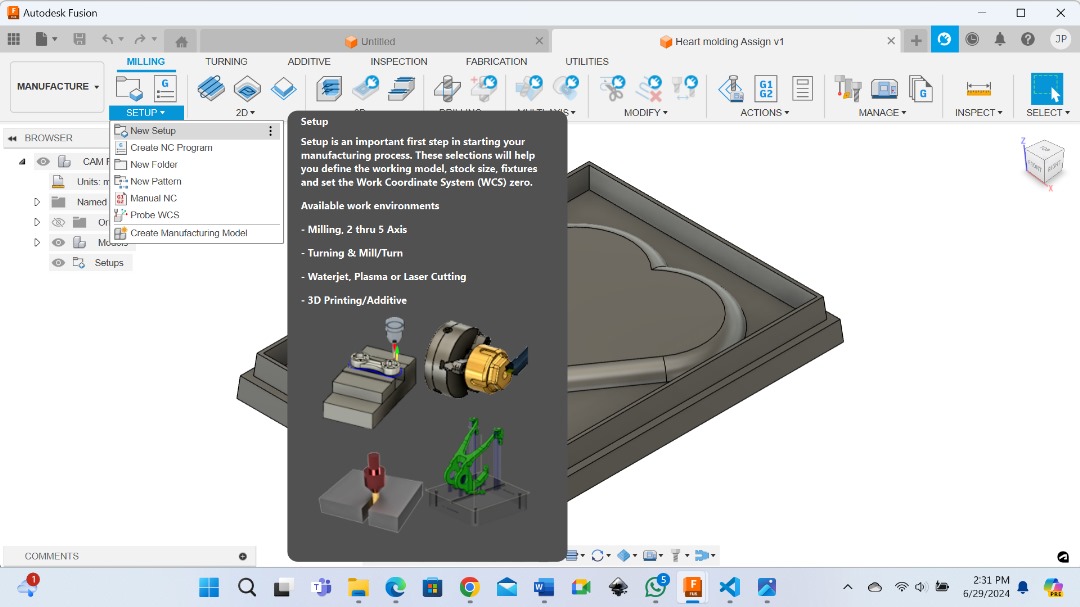

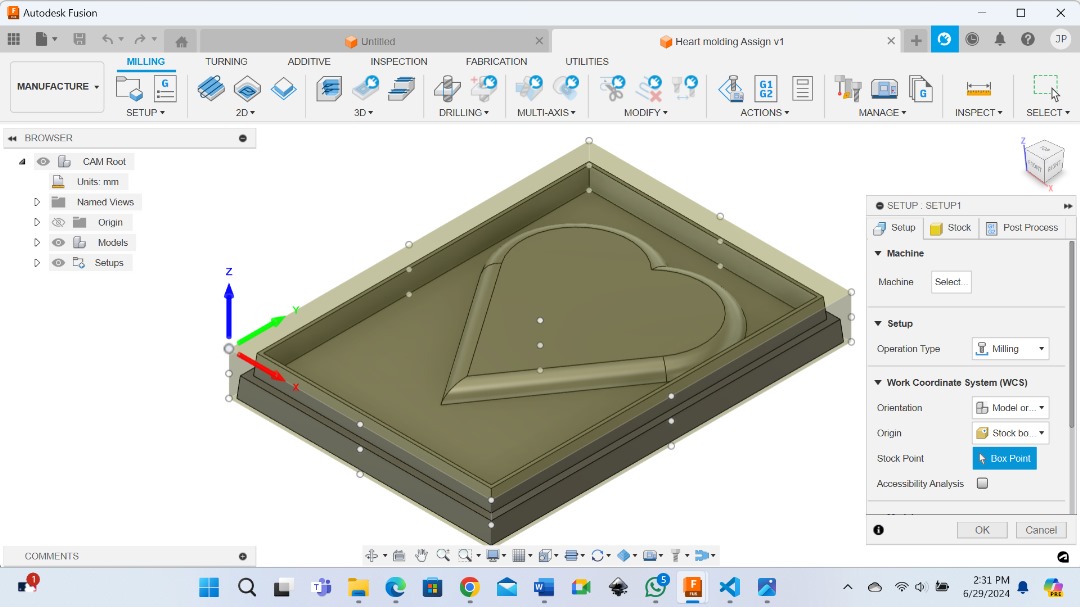

After switching to CAM, click on New setup to define the working model, stock size, fixtures, and the work coordinate system.

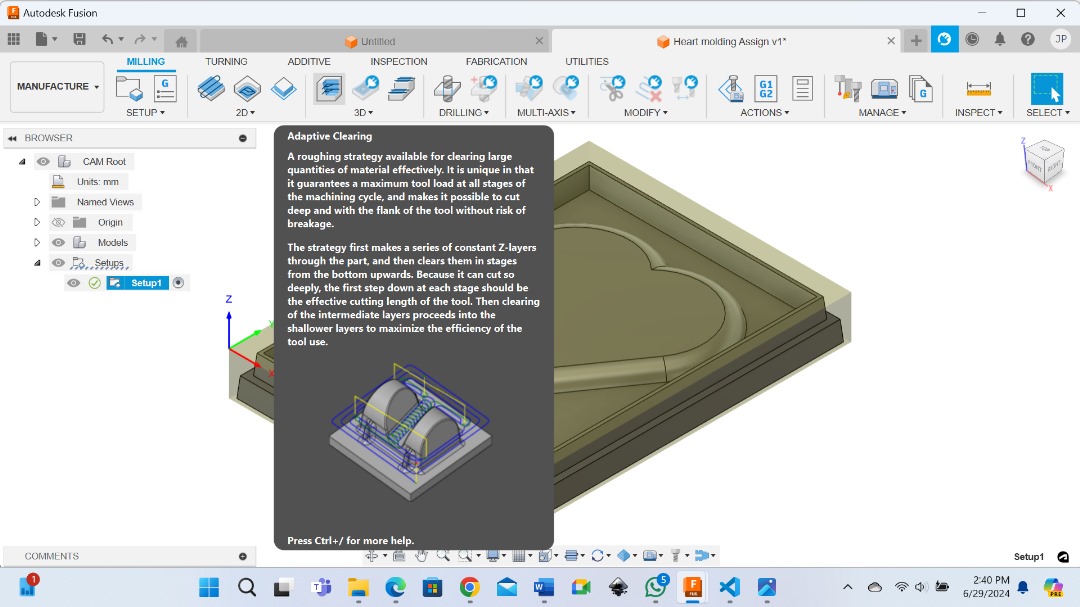

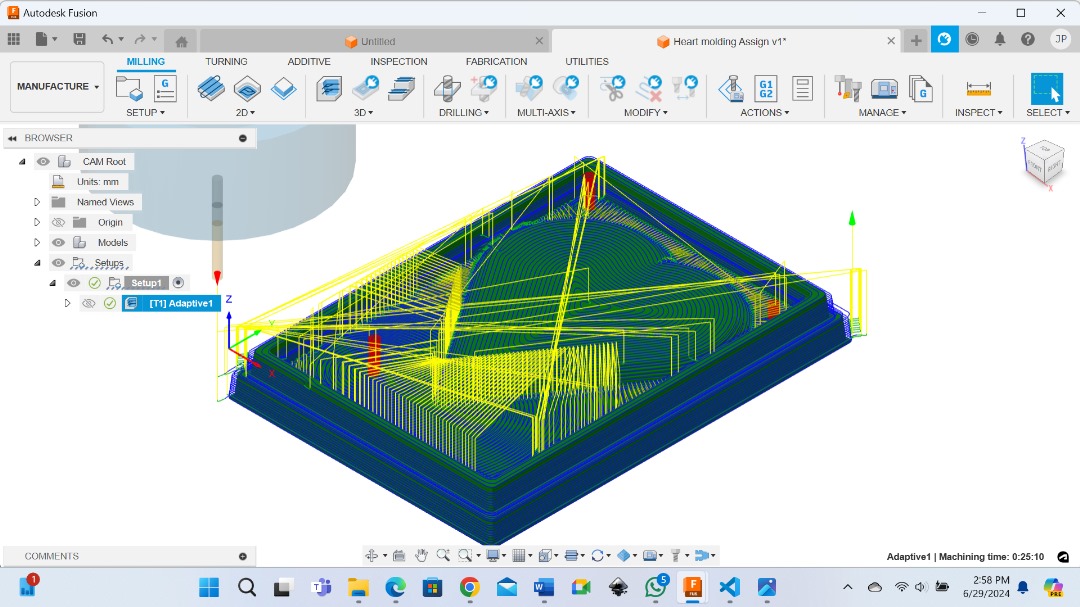

Adaptive clearing:¶

Click on adaptive clearing where we will set up all nececessary milling parameters.

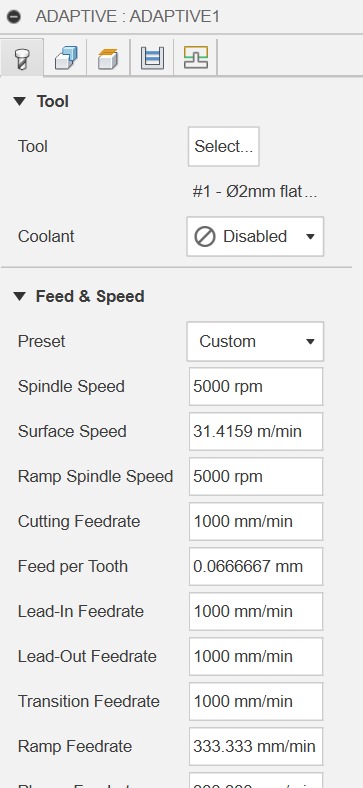

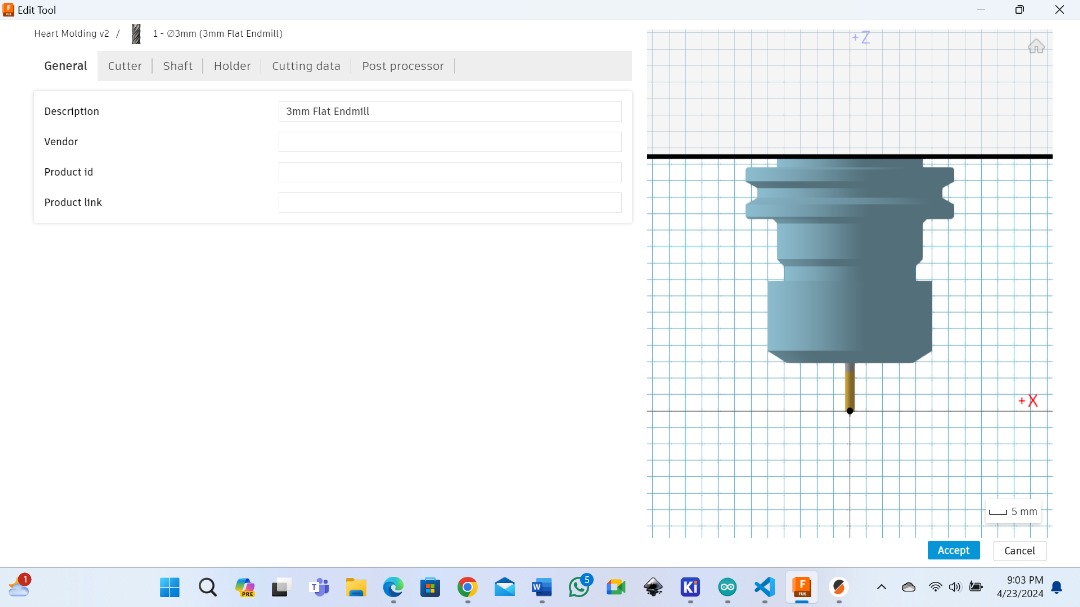

Sellecting tool:¶

Click on “select tool” in the tool tab and this takes you to the tool library where you can select the tool of your choice.

Below is a short video of the process in CAM simulation.

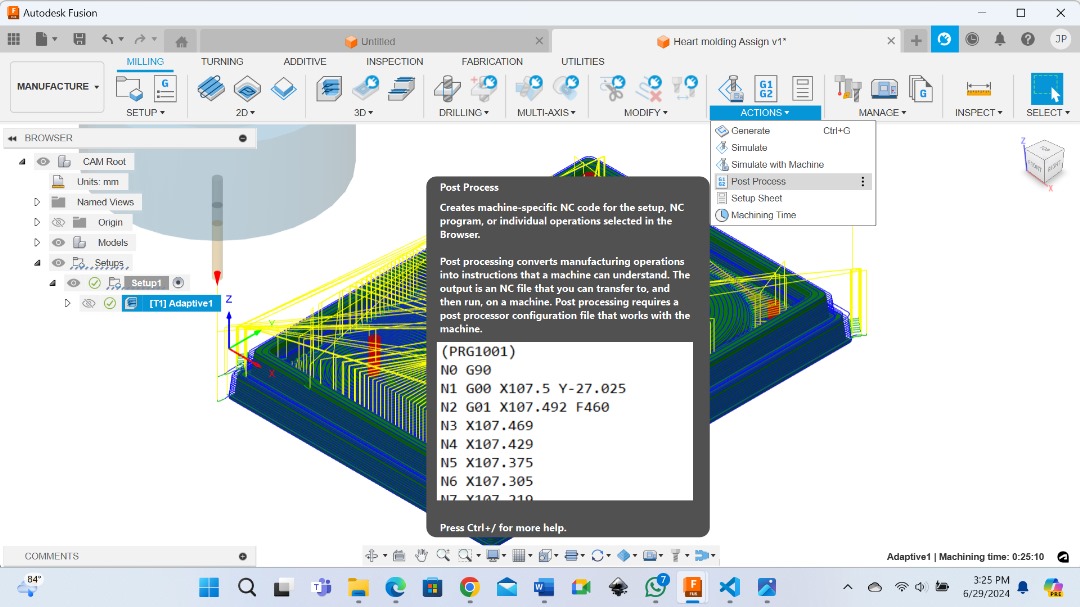

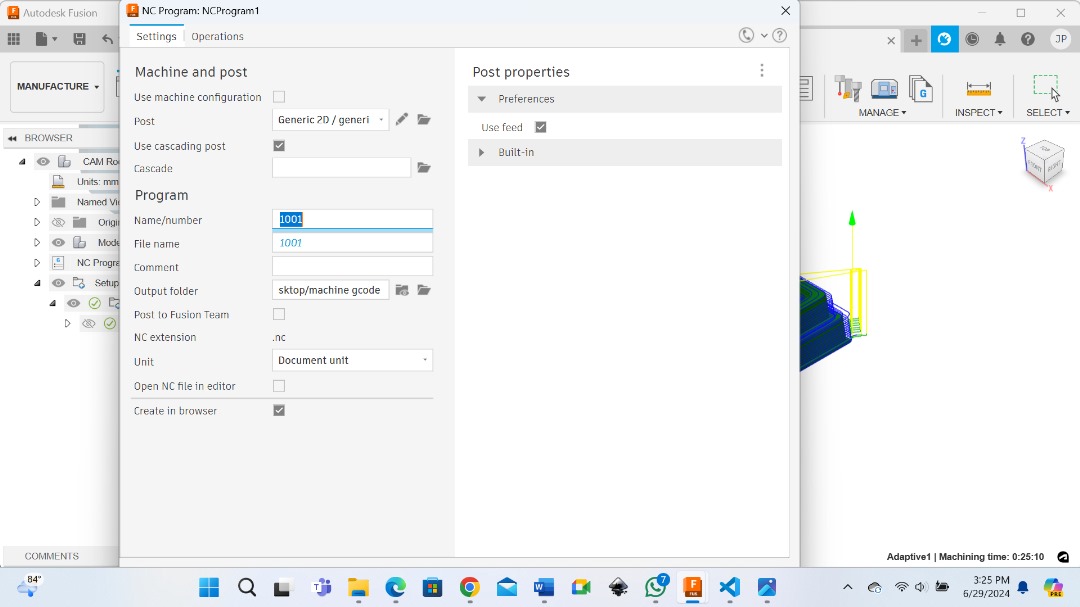

Generate G-Code:¶

After being satified with the simulation we can proceed to generate the G-code.

Click on “Action” and select post processing. From the pop-pup menu select the output folder and that’s it you have created the G-code.

Cutting the model¶

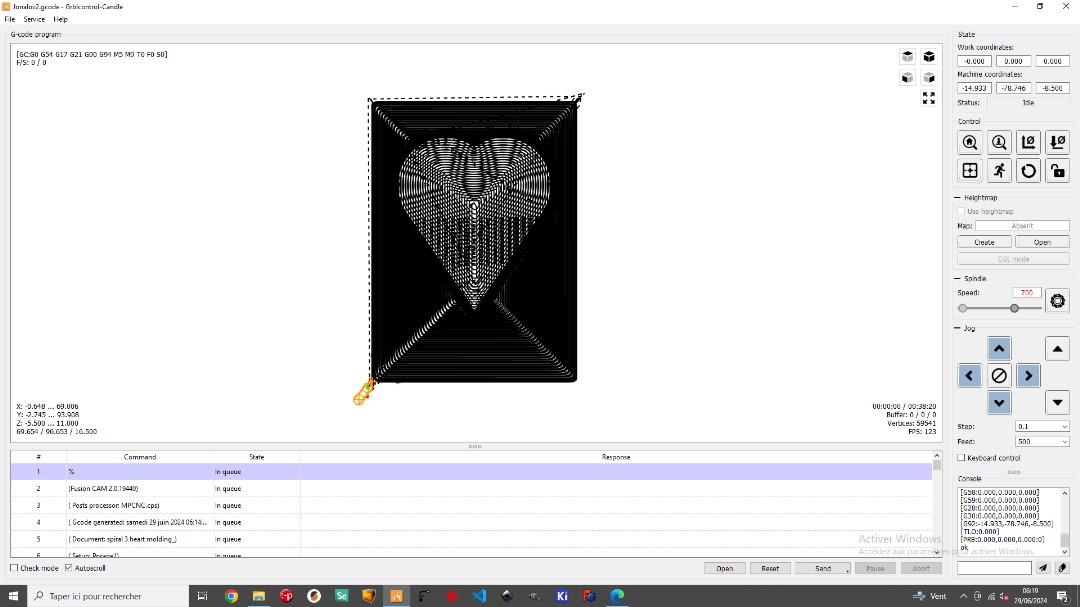

After generating the G-code we open Grbl-control candle software ready to mill the Wax.

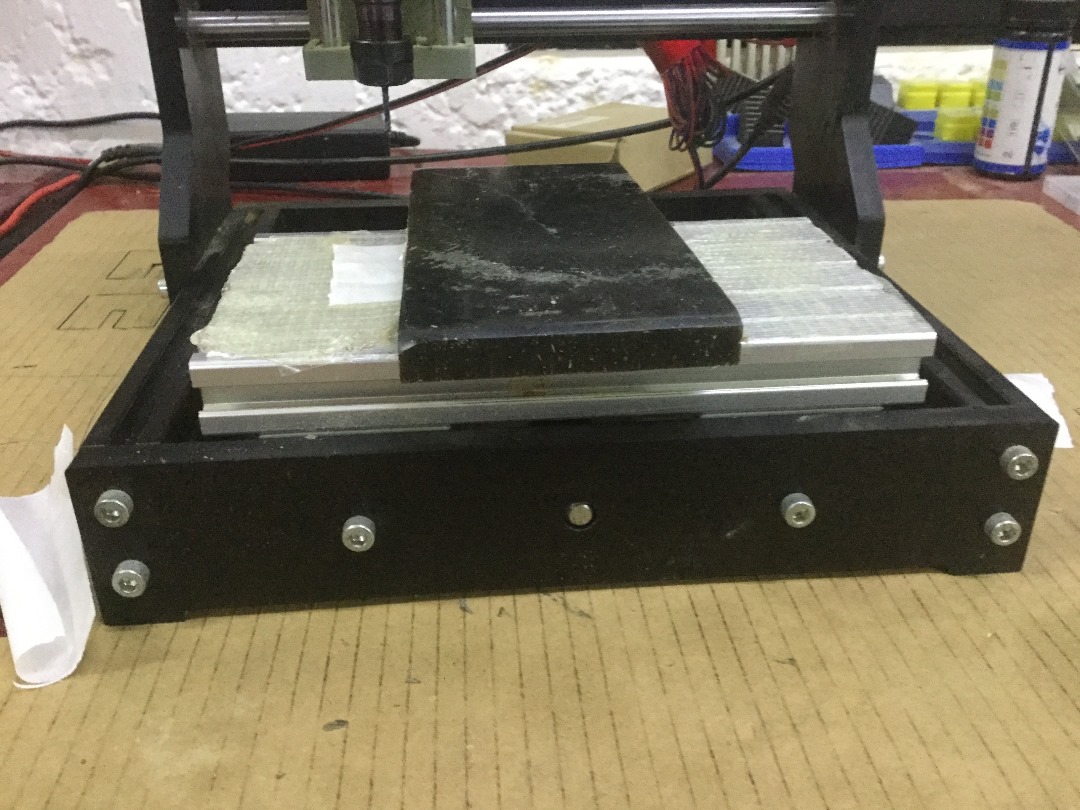

Now the Wax is ready to be cut. Make sure the Wax is hold firmly. Avoid any movement of the wax after setting the cutting parameters in the software.

Rough cut and Fine milling:¶

In CNC milling the term “rough cut and fine “milling” refer to the stages of milling processes that are used to achieve the desired final milling shape and surface finish of a workpiece.

The Rough cut 1.2mm stepdown:

The rough cutting process is the initial stage of milling where the primary goal is to remove excess material quickly. The rough cut is characterized by high material removal rates and is usually performed using a larger cutting tool with fewer flutes. The purpose is to remove as much material as possible in a shorter time, reducing the overall machining time. during the rough cutting, the machining parameters such as speed, feed rate and depth of cut, are often set to higher values compared to the fine miling stage. This aggressive cutting srategy helps to remove large quantity of material efficiently, but it may result in a rough surface finish. For this exercise I have used 1.2mm.

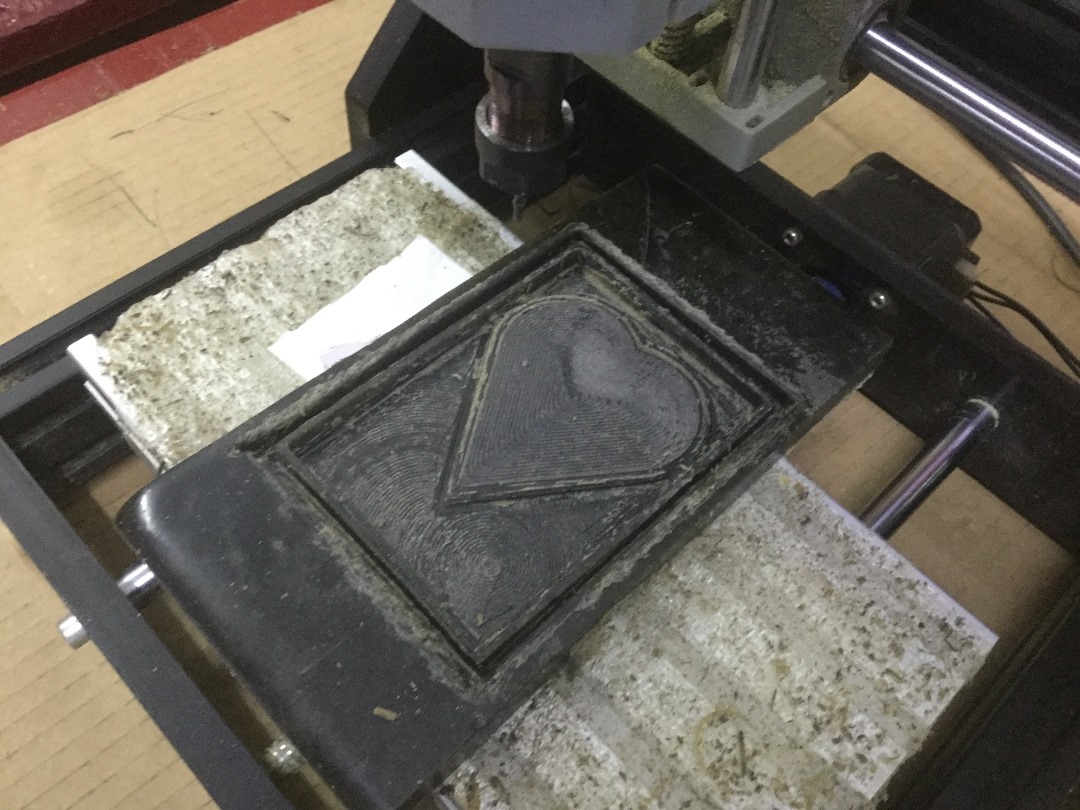

Fine milling:¶

Ater the rough cut, the fine milling process follows. This is performed to achieve a smoother surface finish and improve dimensional accuracy. Fine milling involves using smaller cutting tool with more flutes to achieve higher precission and finer detail workpiece. The fine milling process focusses on reducing the surface roughness and achieving the desired tolerances and surface quality. It involves lower cutting parameters, such as lower cutting speed, reduced feed rate, and shallower depth of cut. These adjustments allow for more controlled material removal, resulting in better surface finish. In my case I chose to use 0.12mm.

Production of Plastic molds:¶

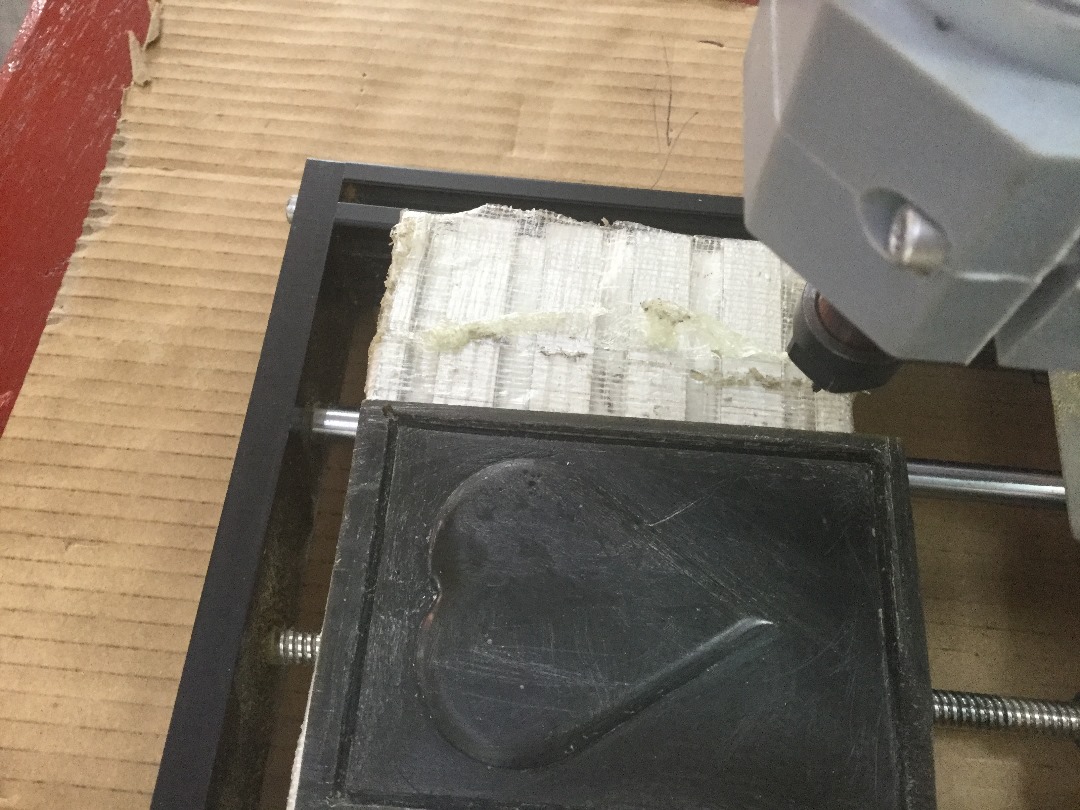

After milling the two parts A and B, I proceeded to produce the silicon molds.

I started with making the mold box around my models.

Since I’m about to touch chemicals, Safety first. So, I had to put on my safety attire.

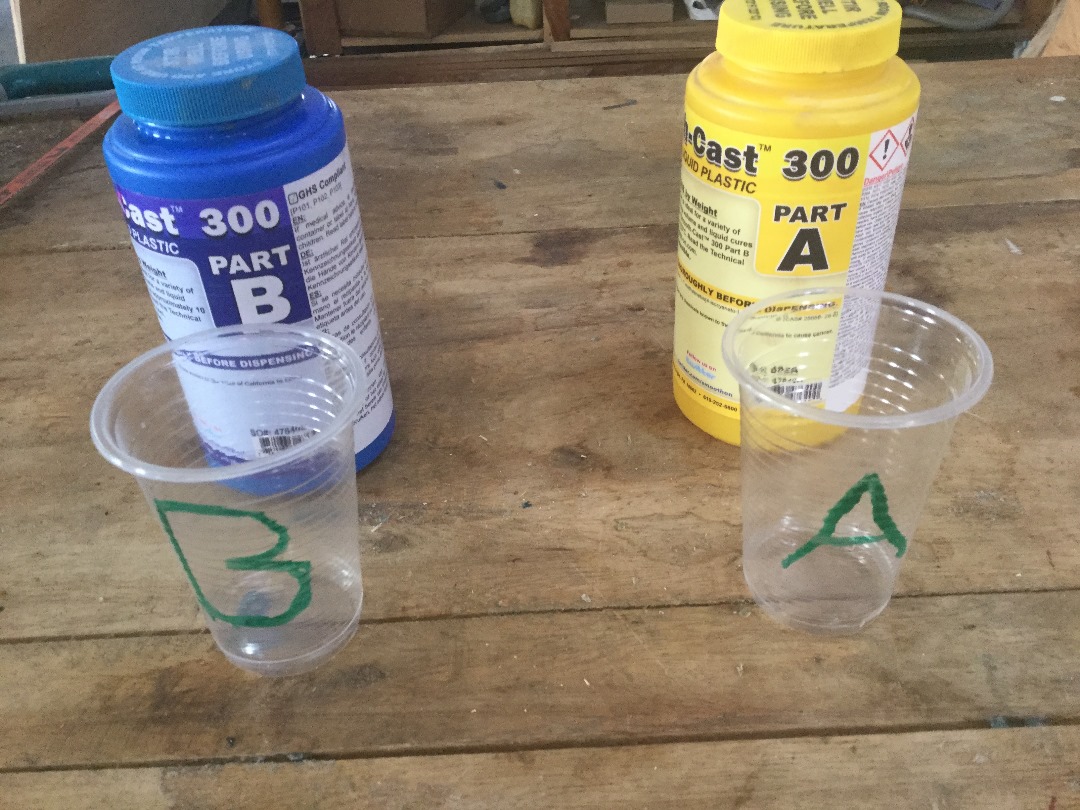

Then after, I arrange my tools and materials ready to do the mixture.

I’m using Smooth-Cast. It is a white bright liquid plastic that is Ideal for a variety of casting applications.

We are going to mix part A and B in a 1:1 ratio and it will solidify to a plastic.

Pot life for the mixture is 3 minutes and cure time is approximately 10 minutes depending on mass.

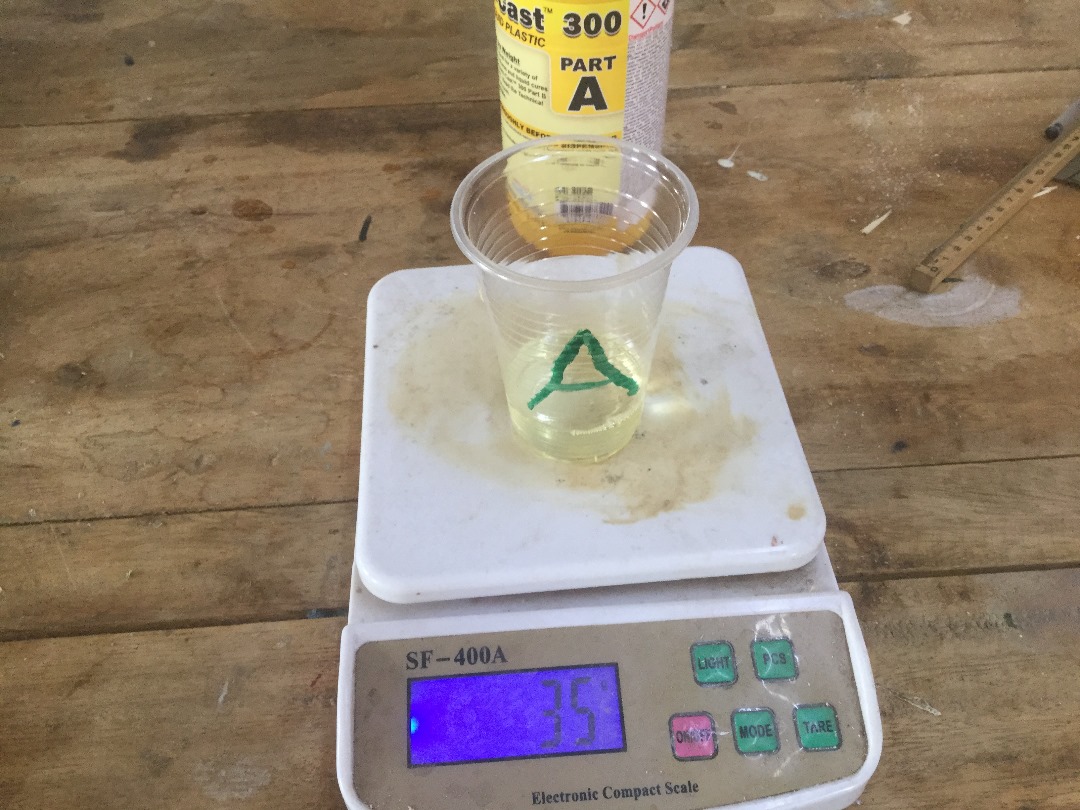

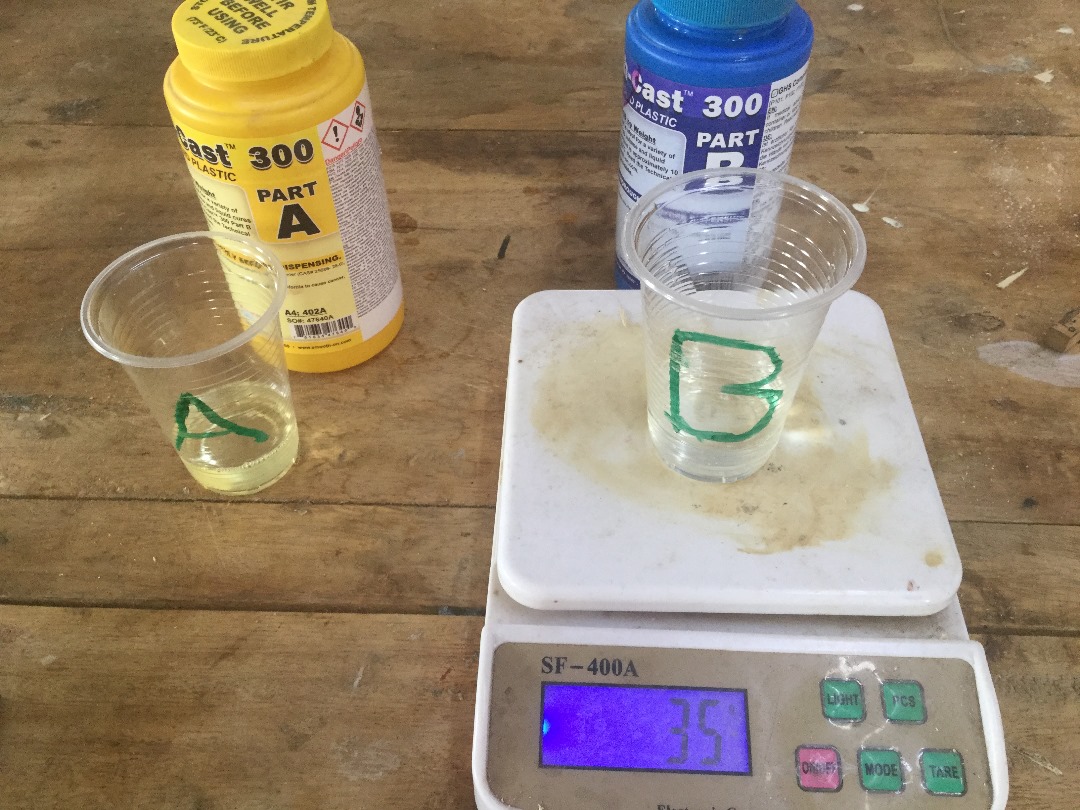

I measured 35g each part and mix.

Remember to stir thoroughly both parts before dispensing.

Then after I pored into the mold box to let it solidify.

Below are the outcome of our mold.

Casting:¶

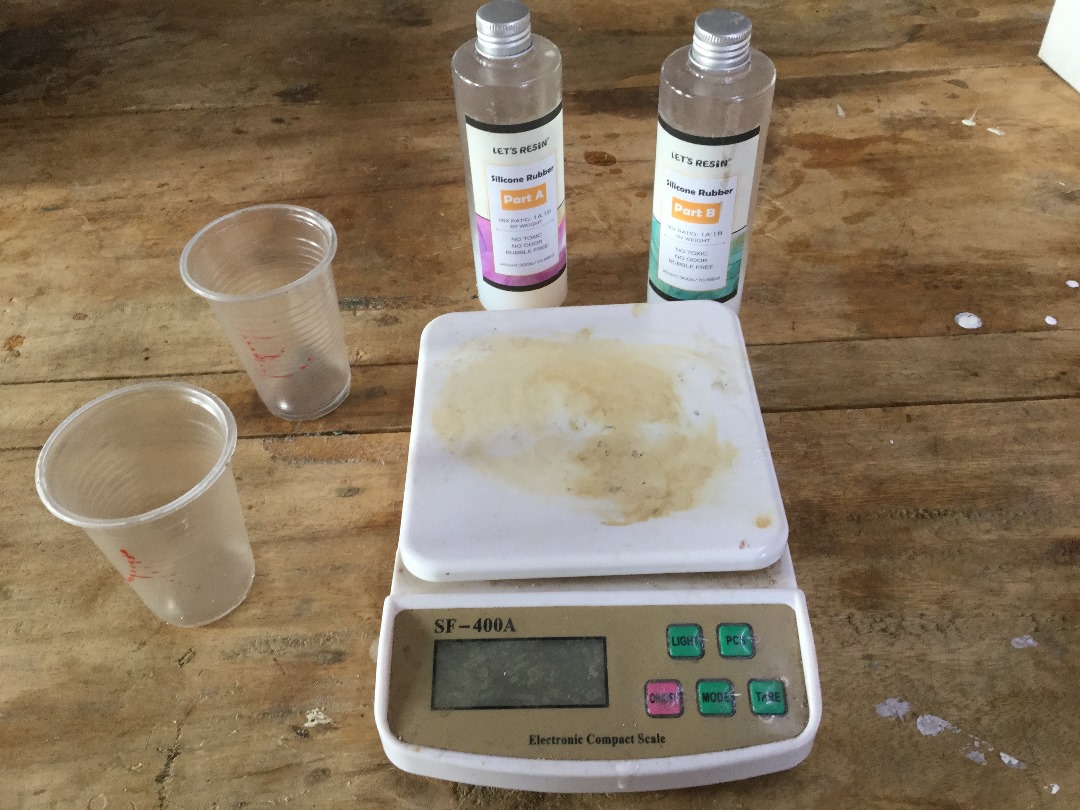

After making the epoxy mold, now it’s time to pour silicon into the mold.

Remember to create two holes which will allow us to pour silicon in, and the one which will evacuate air out. The hole for pouring silicon must be bigger and the other one is smaller.

Now we need to make the mixture for the two bottles part A and part B. The is mixing ratio is 1A:1B

After mixing, you need to pour into the epoxy mold. Make sure they are hold tight together.

After waiting for many hours let’s open to see the magic.

And finally, here we are!

Awesome! I’m sure people will like it.

Files:¶

Reflection:¶

During this week , I have learnt alot. I have never done molding and casting before all was new. It took me some time to really understand the concept. But then after, I have discovered that there is more fan in molding and casting and that I can really make something useful after mastering it.

The problem that I encountered was to do with the difference that happened to my parts after casting the epoxy mold. To resolve it I went back to my CAD design and make correction on the size to make sure I have exact parts.