10. Molding and casting

This week I worked to create a mold utilizing the CNC router and wax blocks

Group Work

Individual Work

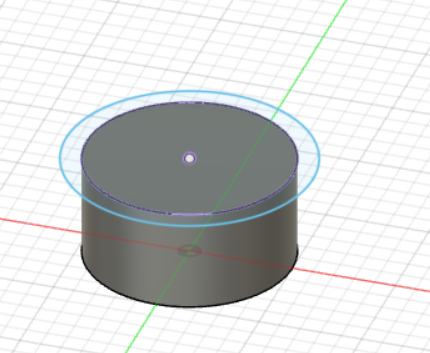

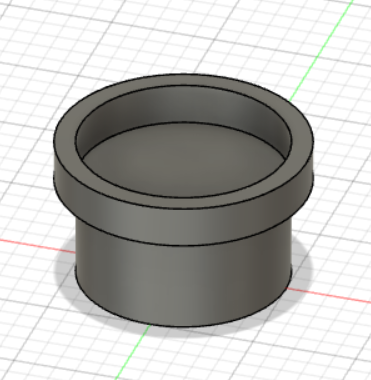

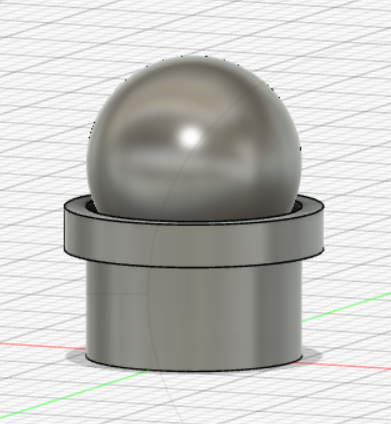

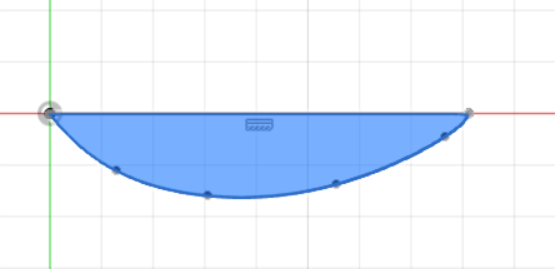

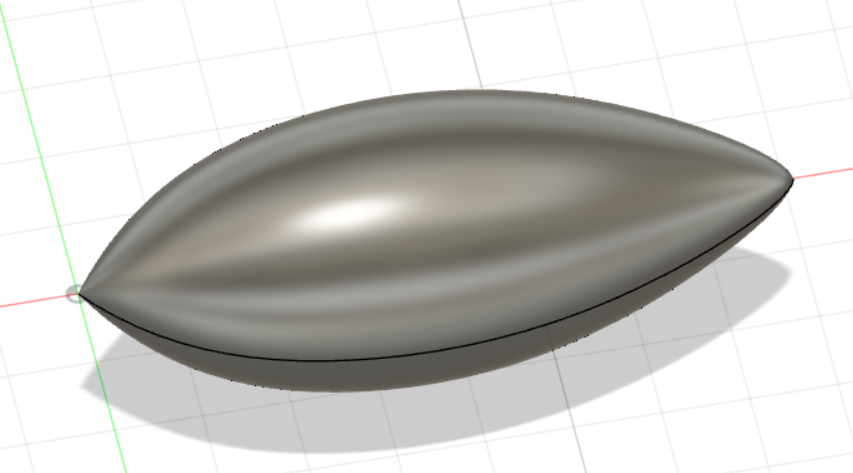

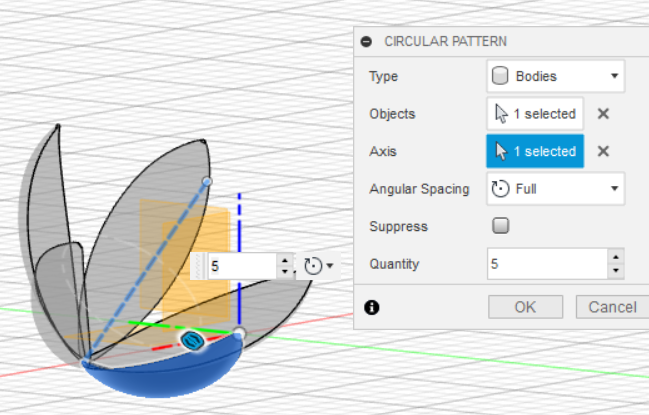

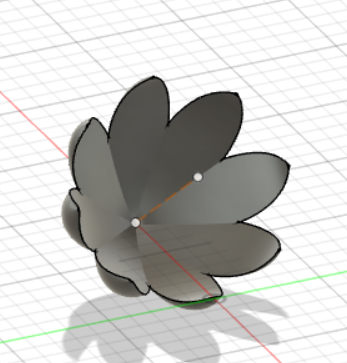

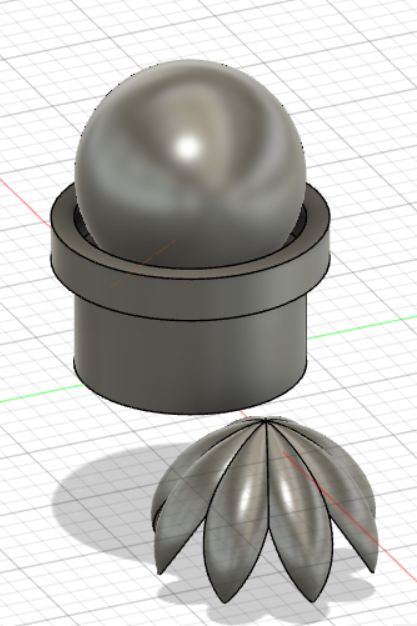

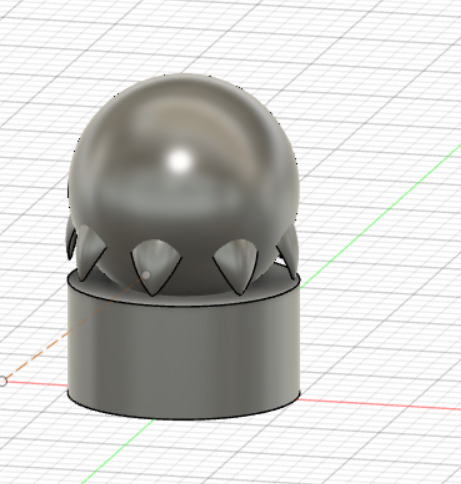

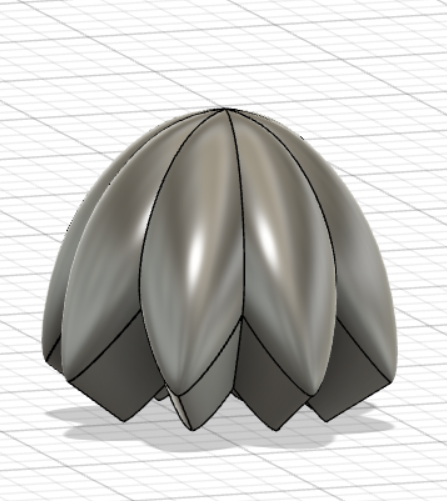

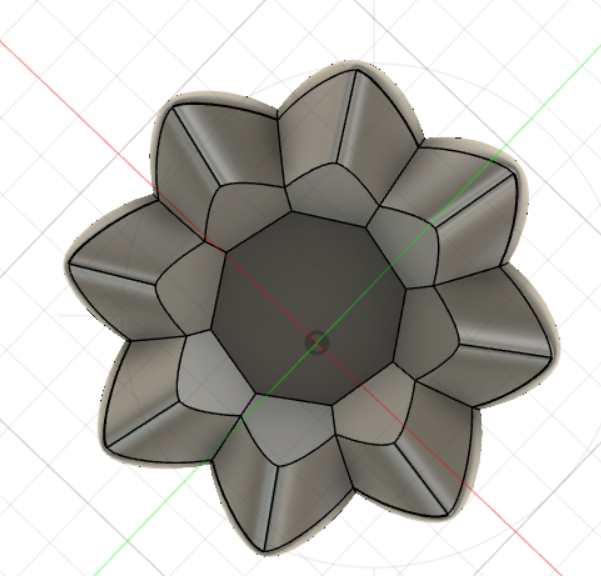

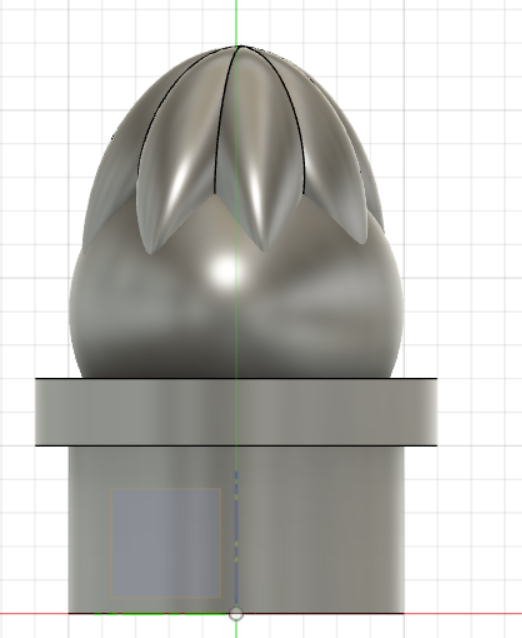

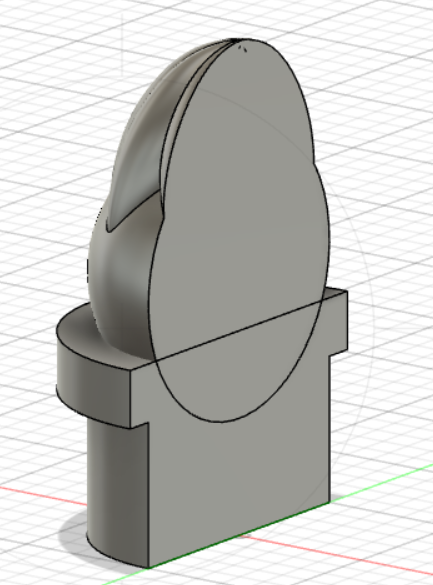

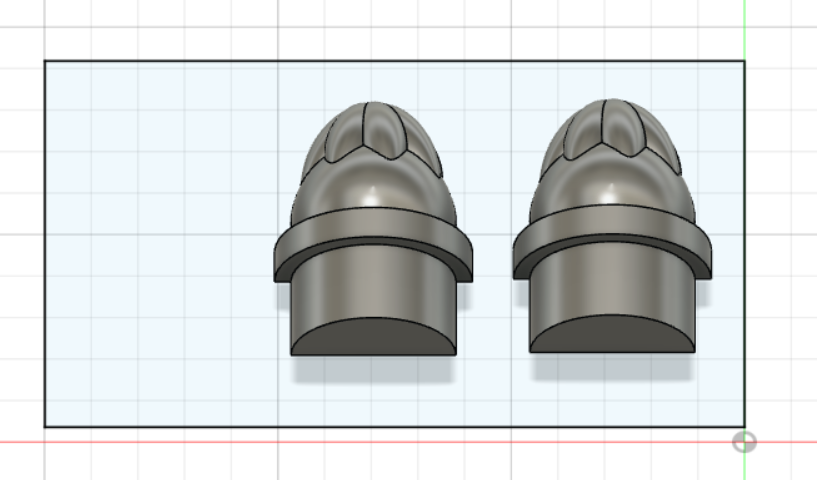

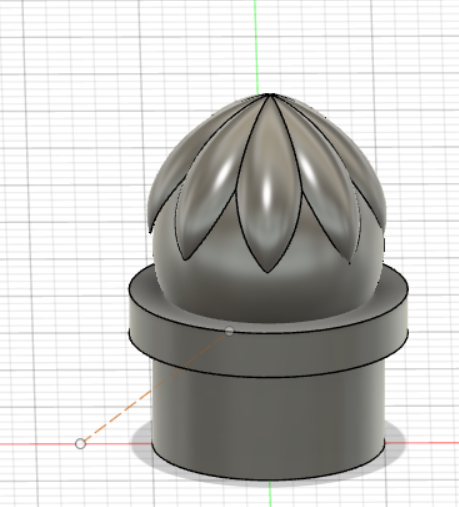

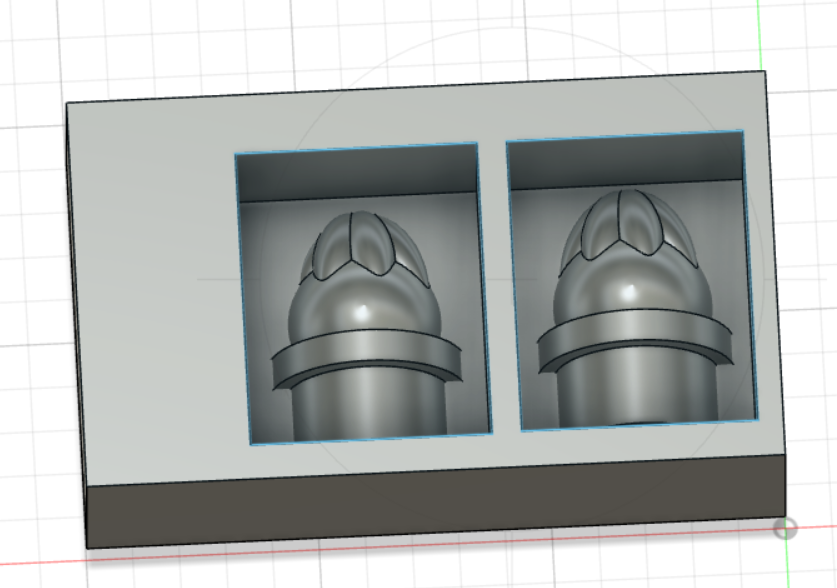

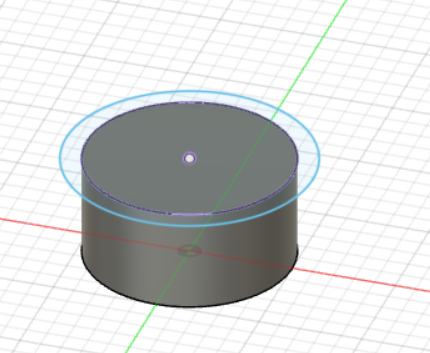

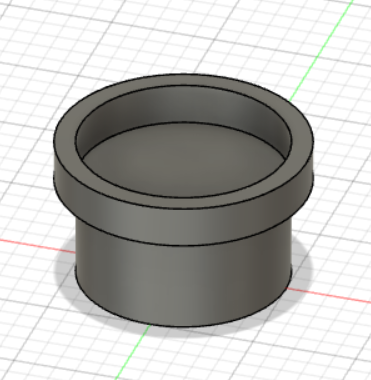

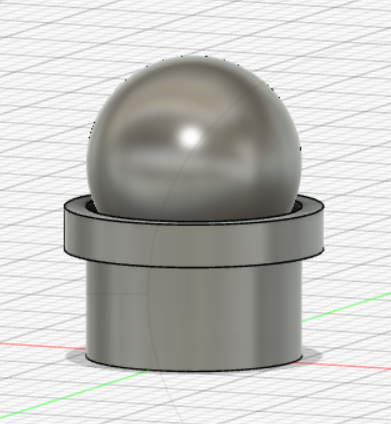

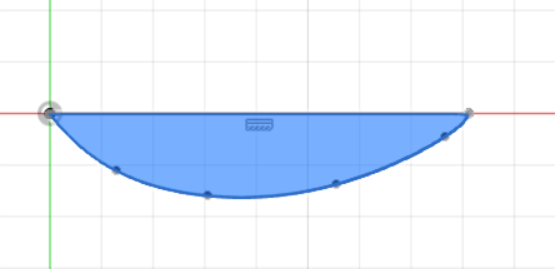

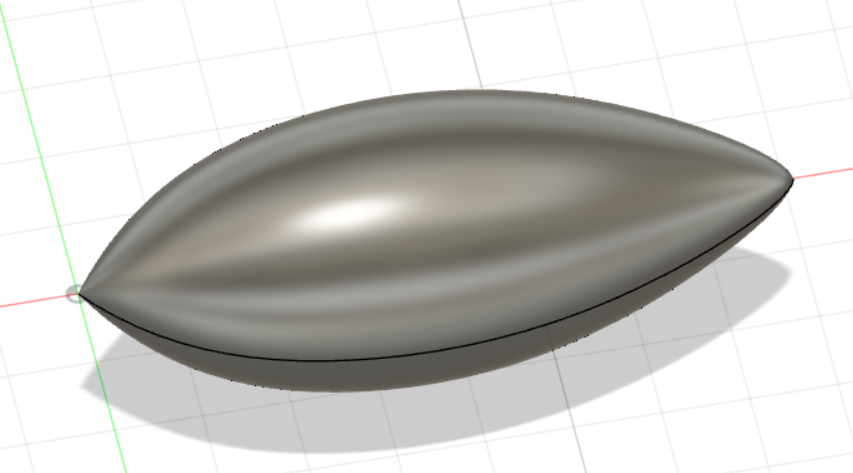

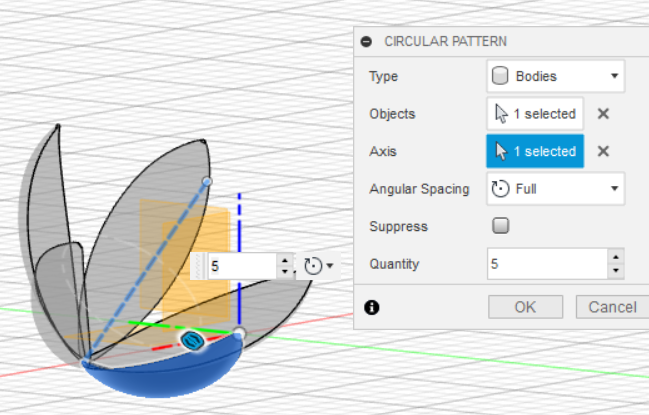

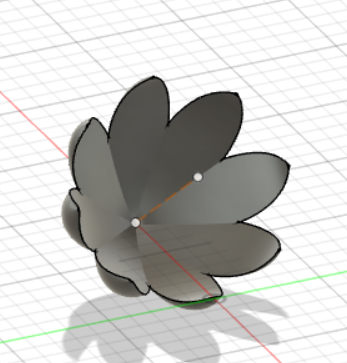

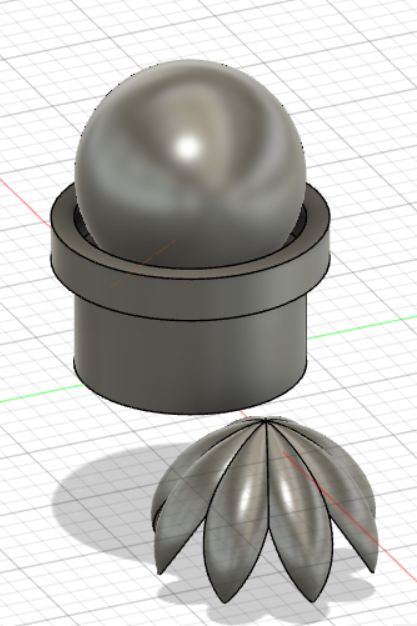

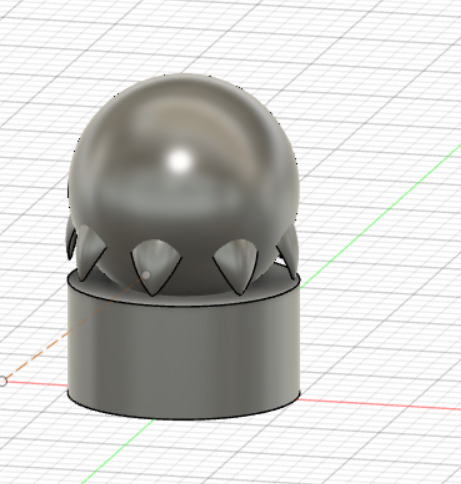

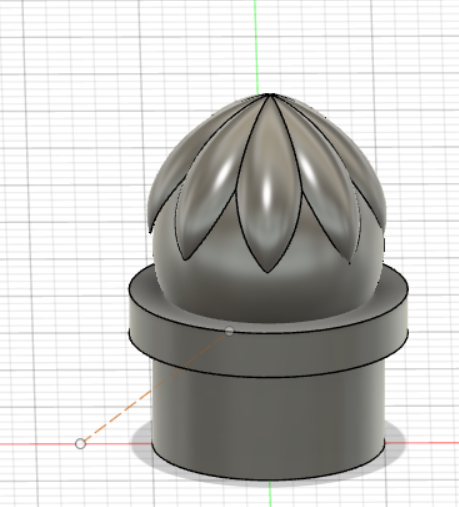

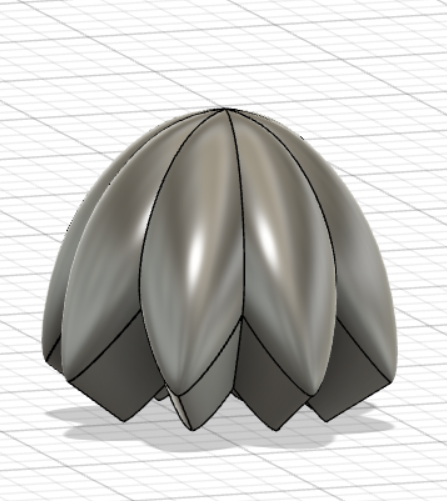

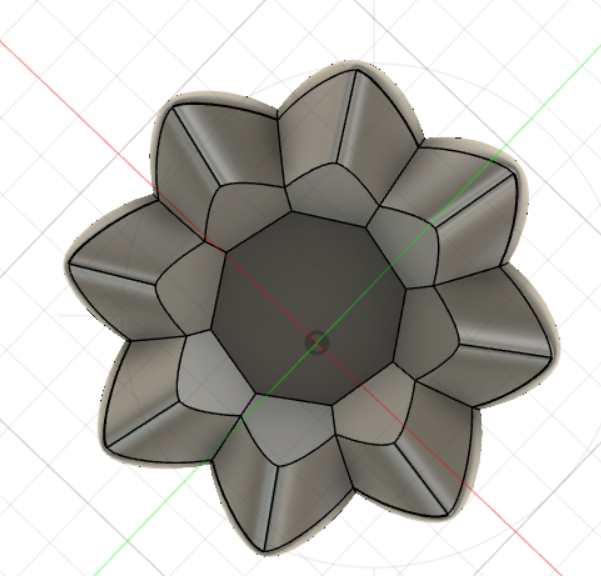

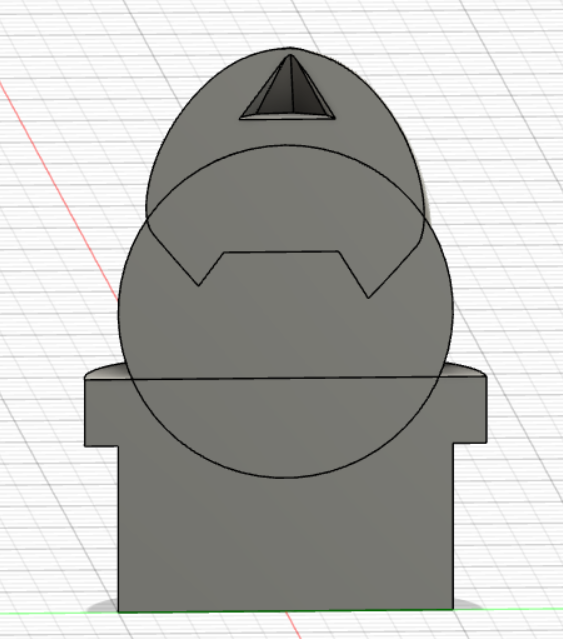

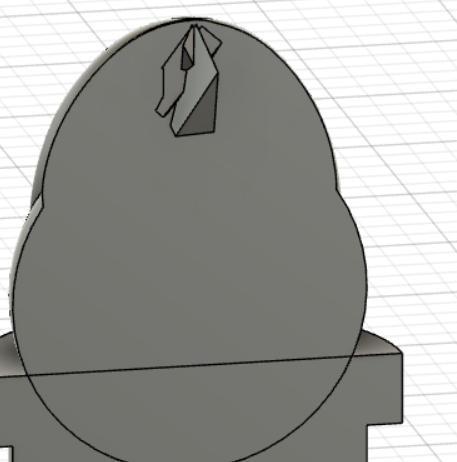

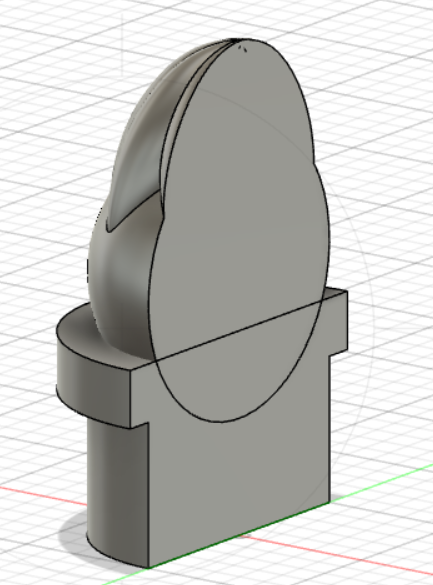

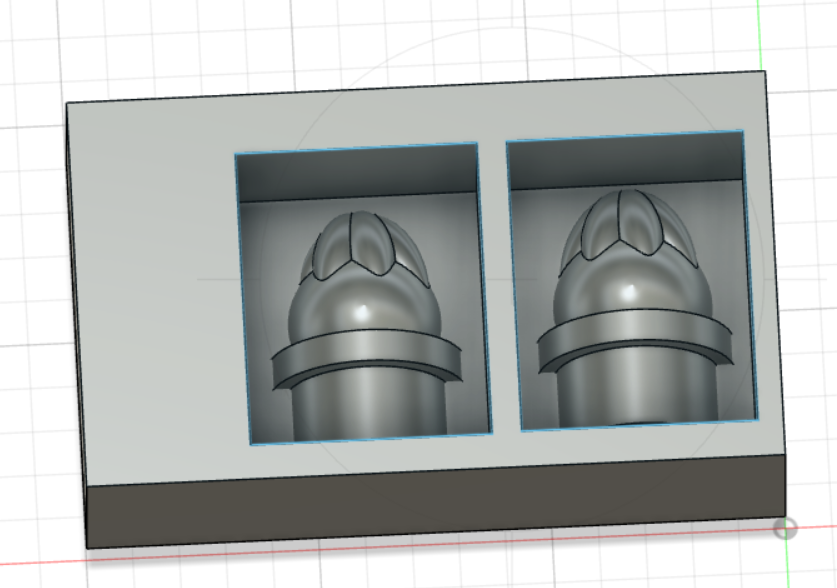

I started in Fusion360 where I initially wanted to create a cactus flower. I went through the process of creating a pot with a ball to represent a cactus. After that I went through the process of making the flower for the top of the cactus. The process was simple. I made a petal-like shape and hallowed it out before using the circular pattern tool but after noticing it would be impossible to CNC I ended up using the flower design in a reversed way.

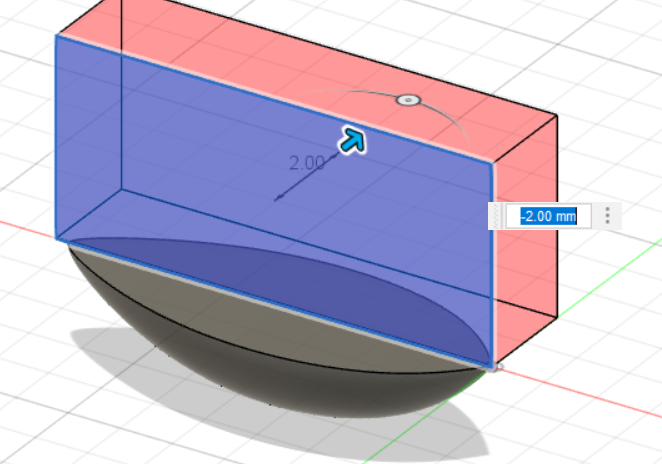

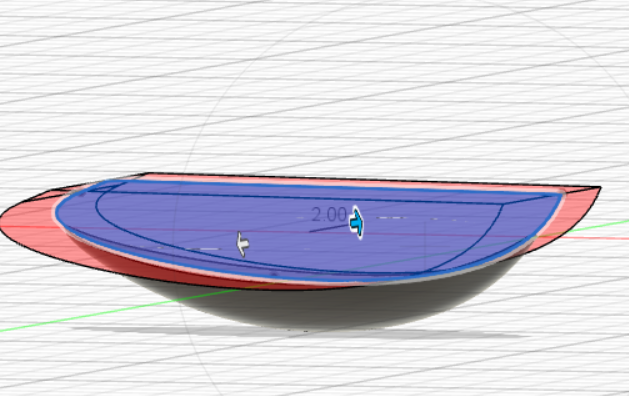

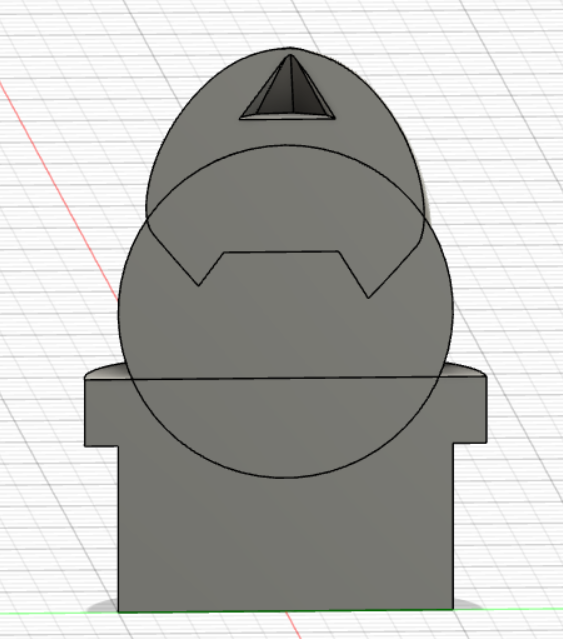

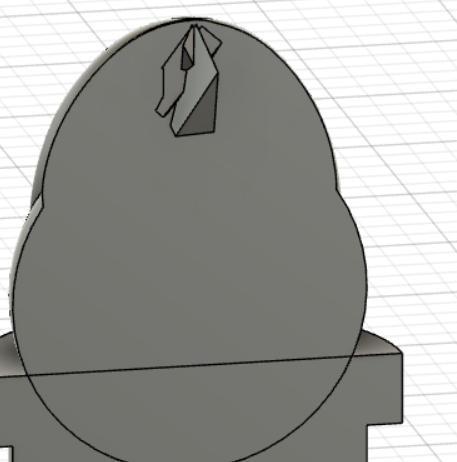

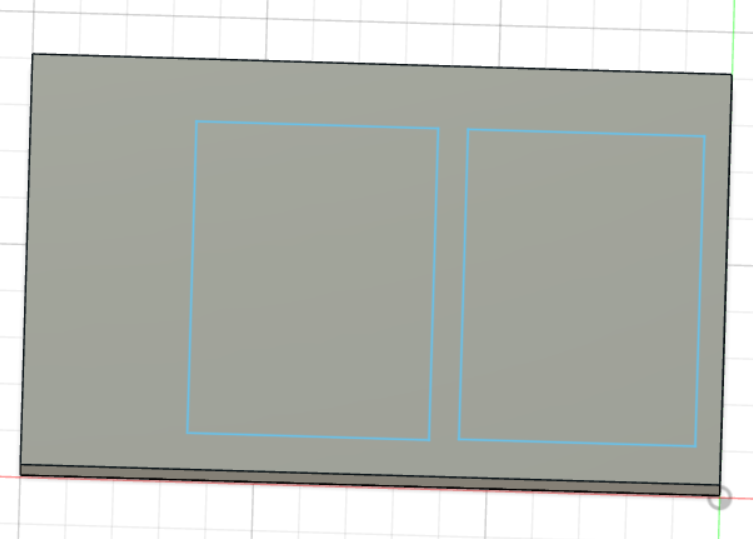

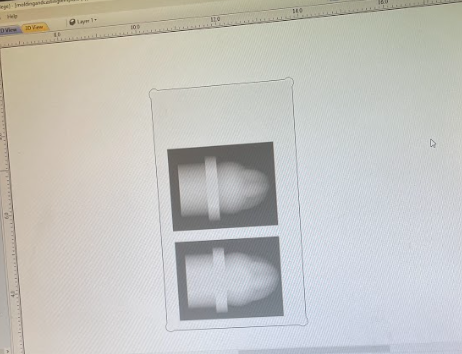

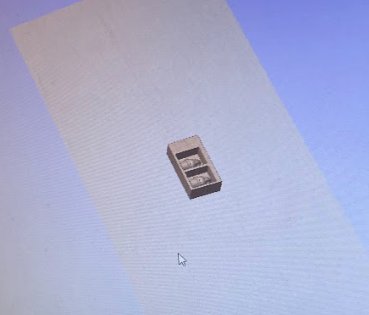

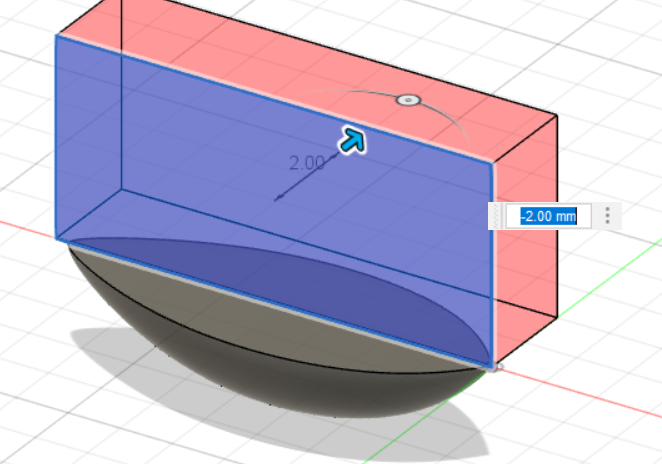

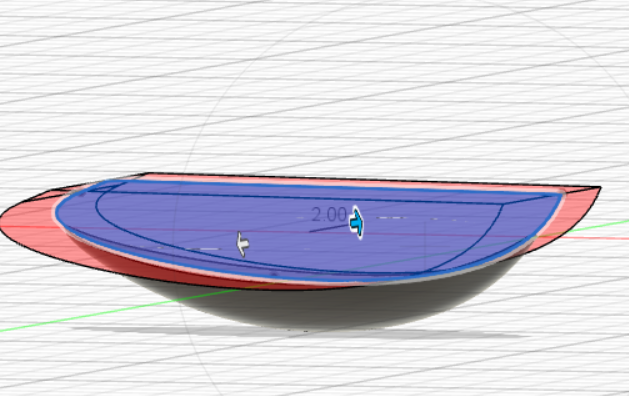

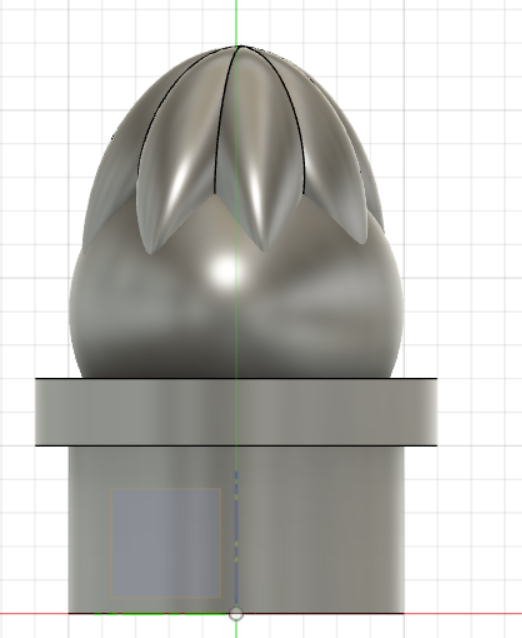

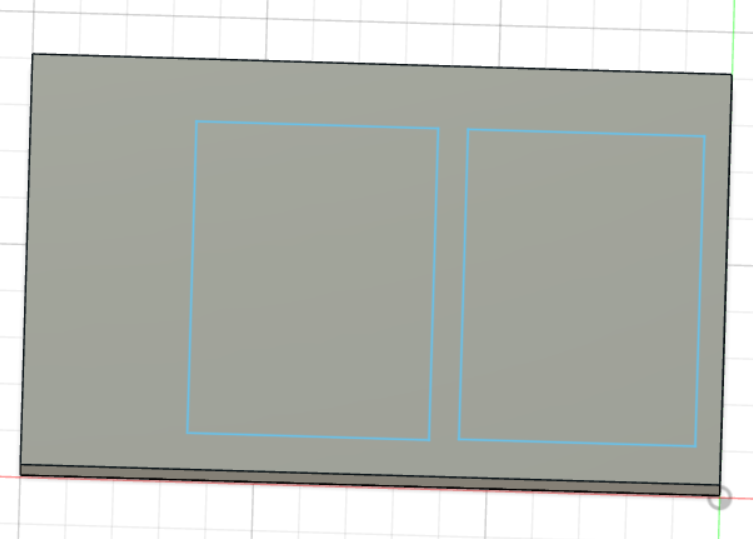

I split the design in half in order to prepare it for the mold block unfortunately there were openings in the design that would have caused issues for the milling process so I painstakingly extruded until The inside was completely solid. After that I made a sketch of the dimensions of the block and extruded until I had the correct length, width, and height. With that I extruded further to open up the mold for the design.

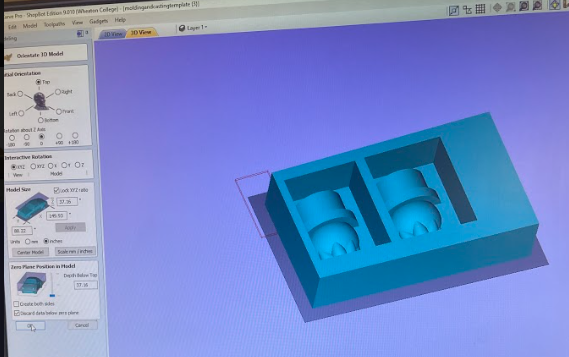

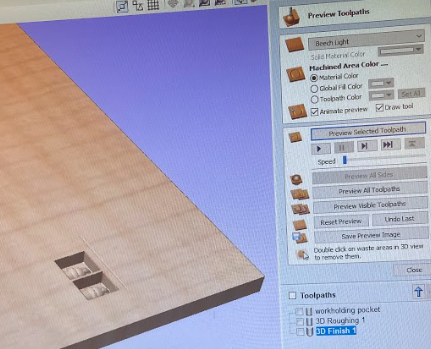

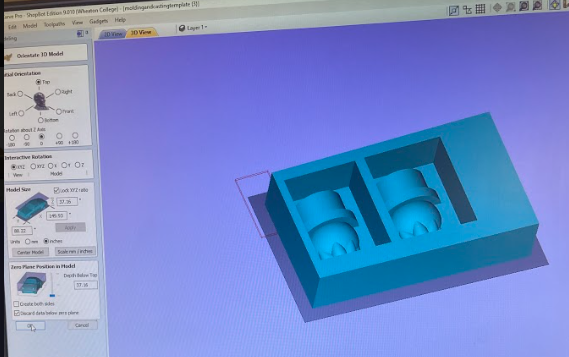

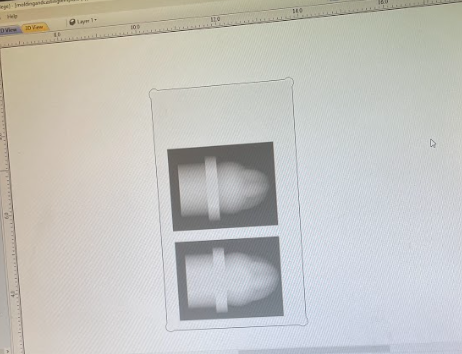

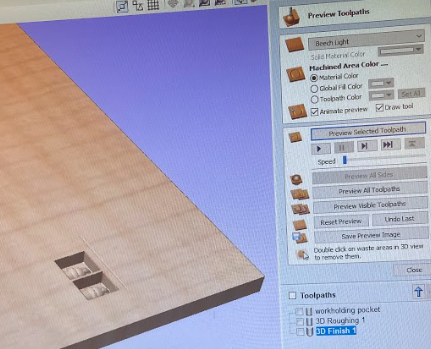

I transferred the file to Vcarve and set it up for the CNC machine.

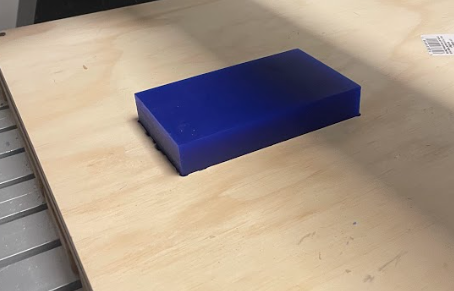

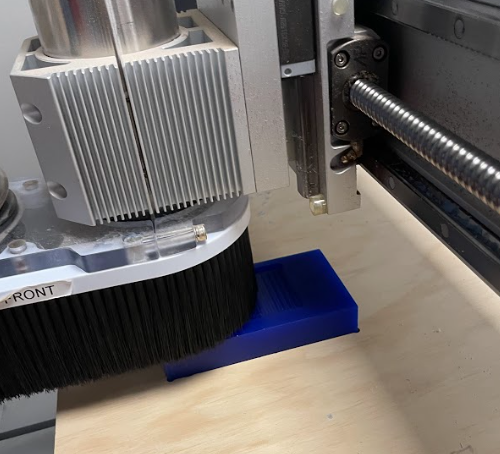

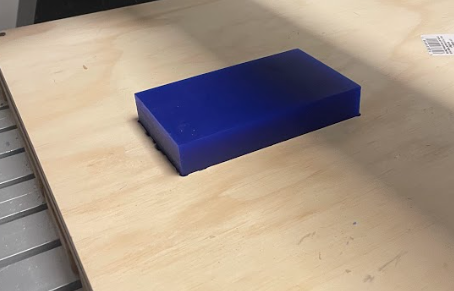

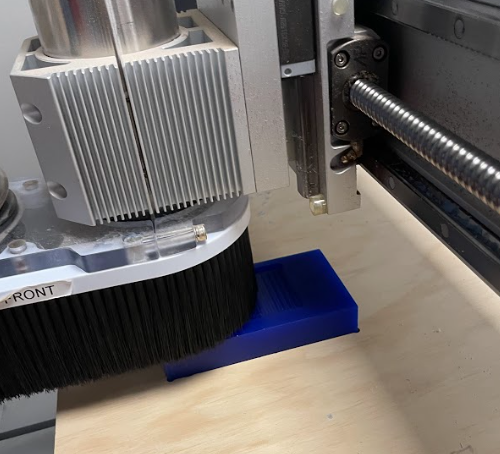

I then exported the file to USB and uploaded it to the CNC machine. The method used to keep the wax block in place was to utilize a plank of wood with an opening the size of the block and keep it in place with double sided tape. The cutting process was rather successful so the next step was to mix chemicals together to create a mold.

I then exported the file to USB and uploaded it to the CNC machine. The method used to keep the wax block in place was to utilize a plank of wood with an opening the size of the block and keep it in place with double sided tape. The cutting process was rather successful so the next step was to mix chemicals together to create a mold.

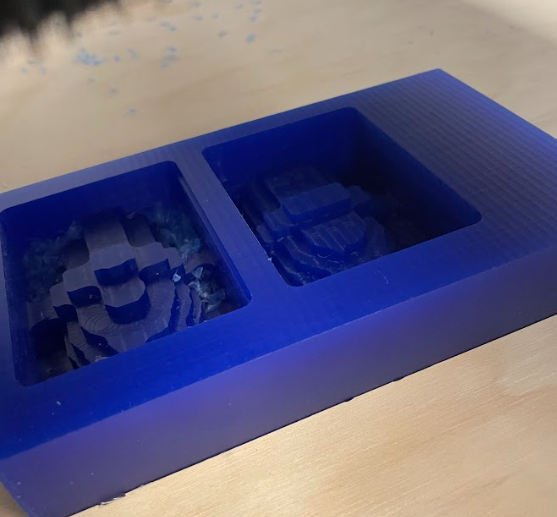

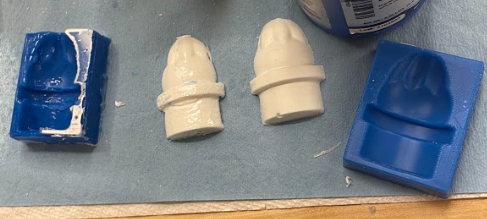

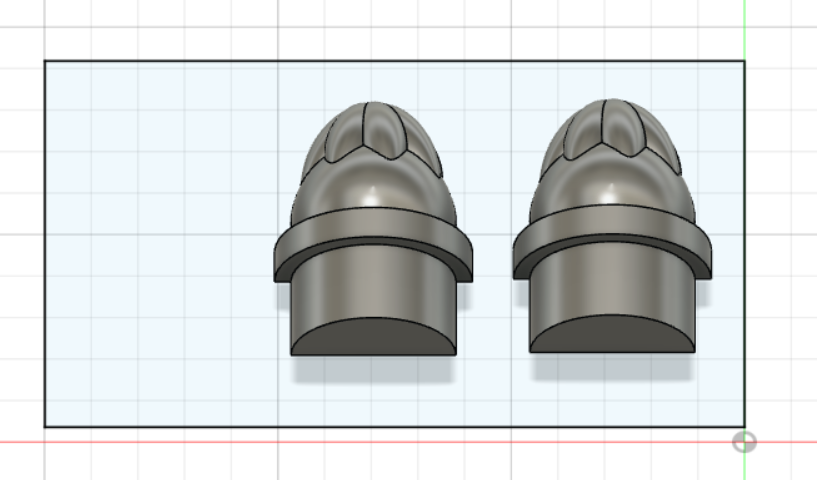

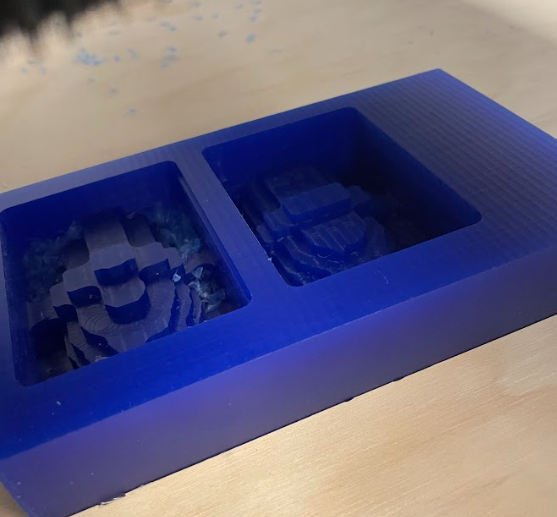

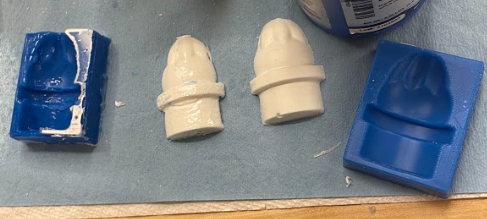

The two chemicals I used were fast acting and only had roughly 30 seconds to mix and be added to whatever it will be molding until the solidification process begins. I was able to mix and set the solution in time so I just had to wait for the mold to set. I came back roughly 24hrs later and one of my molds was perfectly solidified (the left) while the other was a little unfinished (the right) . I just let that one sit for a few more hours until removing it once more. It was slightly warped but it worked. After that was finished I made another mold out of the two casts. This next solution wasn’t as fast acting as the other but all I had to do was pour in the solution into an almost sealed cast and let it sit with a slight air opening to let the solution expand.

The two chemicals I used were fast acting and only had roughly 30 seconds to mix and be added to whatever it will be molding until the solidification process begins. I was able to mix and set the solution in time so I just had to wait for the mold to set. I came back roughly 24hrs later and one of my molds was perfectly solidified (the left) while the other was a little unfinished (the right) . I just let that one sit for a few more hours until removing it once more. It was slightly warped but it worked. After that was finished I made another mold out of the two casts. This next solution wasn’t as fast acting as the other but all I had to do was pour in the solution into an almost sealed cast and let it sit with a slight air opening to let the solution expand.

Unfortunately there was too much air so the solution ended up seeping out. I instead opted to create the two casts separate and seal them together.

Unfortunately there was too much air so the solution ended up seeping out. I instead opted to create the two casts separate and seal them together.

Last update:

July 14, 2022