17. Machine design¶

15. Mechanical design¶

Assignment Requirements:

.Mechanical Design (part 1 of 2) .Group assignment:

-Design a machine that includes mechanism + actuation + automation -Build the mechanical parts and operate it manually. -Document the group project.

Individual assignment:

-Document your individual contribution.

Machine Design (part 2 of 2)

Group assignment:

-Actuate and automate your machine. -Document the group project.

.Individual assignment:

-Document your individual contribution.

Learning Outcomes: .Work and communicate effectively in a team .Design, plan and build a system. .Analyse and solve technical problems. .Recognise opportunities for improvements in the design.

Introduction

laser cutter/engraver machine

Laser cutter/engraver is a type of laser machine with CNC (Computer Numerical Control) system that adopts Fiber/UV/CO2 laser beam to cut & engrave 2D letters, numbers, texts, patterns, photos, pictures, signs or logos on the surface of the materials.Laser has four main characteristics: high brightness, directivity, monochromaticity and coherence.so it has been widely used in industrial processing.

Application Laser engraving machine is an intelligent laser engraving device for personal or enterprise applications. It can be used to perform specific tasks i.e Used for carving pictures, words, tracks or cutting the surface of general non-metallic materials! Suitable for all kinds of DIY artworks.

Automation Automationdescribes a wide range of technologies that reduce human intervention in processes.

Automation – specialist in power transmission and motion control We supply slewing ring bearings, oscillating mountings, addition we also select and offer the right components and systems for motion control solutions, such as stepper gear motors, linear stepper actuators and complete XY cartesian systems.

Actuation Actuation. An actuator is a component of a machine that is responsible for moving and controlling a mechanism or system.it is mover.

From the point of view of machine design, Actuators are the parts of the machine that operate in its environments ( to affect it/change it, in some way), while the limit sensors are the parts that receive information from its environment. In terms of actuation, our machine has a moving laser beam, whose tip can be arbitrarily positioned in any position in the operating space/volume.

For all intents and purposes, however the laser beam will only occupy 2 planes in space:

The paper plane: when the tip of the laser beam is touching the surface below the machine. This setting can be used to write, draw on it or mark it in some way.

The hover plane: when the tip of the laser beam is held away from the floor/paper/whiteboard. This position allows us to freely move the laser beam without leaving marks or painting anything.

Mechanism Mechanism, rigid bodies connected by joints in order to accomplish a desired force and/or motion transmission

The machine that we have built has various mechanisms to operate and perform action in all 2 spacial dimensions:

-

mechanism to operate on the X axis using 1 stepper motors.

-

mechanism to operate on the Y axis using 2 stepper motors.

The mechanisms allow the machine to have an operating area of approx: 60mm * 30mm = 180mm.

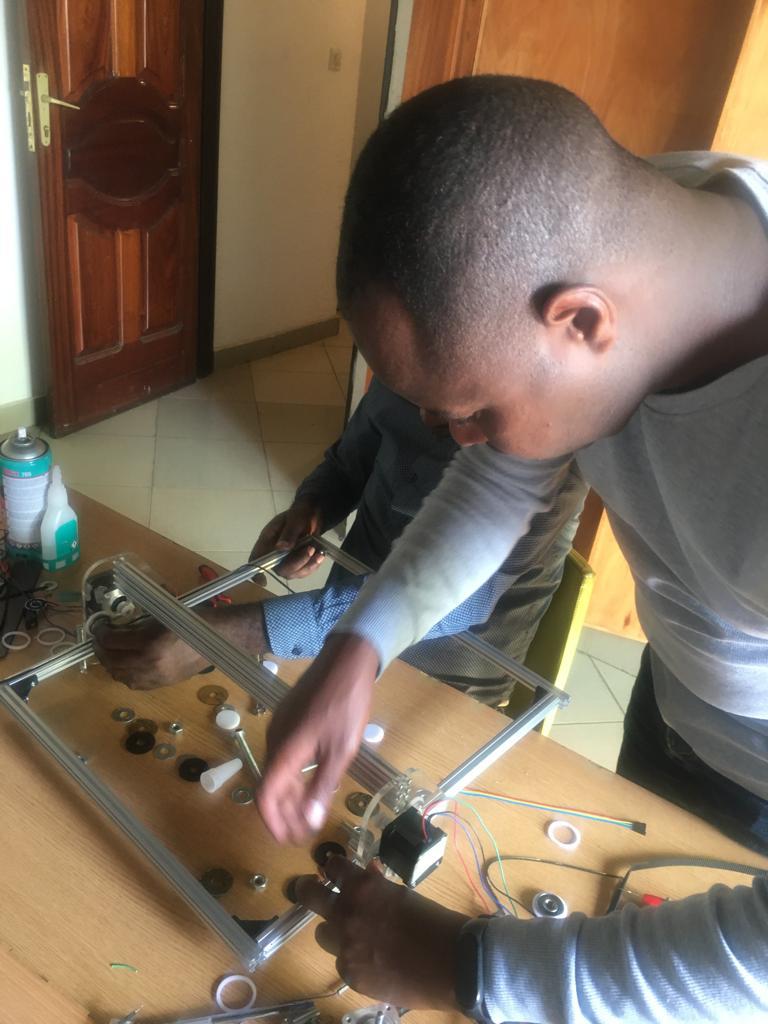

My contribution in this machine design was assembling the components as you can see in the following screenshots: