4. Computer controlled cutting¶

This week tasks (Finish):

- Group assignment

characterize your lasercutter’s focus, power, speed, rate, kerf, and joint clearance document your work (individually or in group)

- Individual assignments

Design, lasercut, and document a parametric press-fit construction kit, which can be assembled in multiple ways. Account for the lasercutter kerf.

cut something on the vinylcutter

This week task as below:¶

Finish : Design, lasercut, and document a parametric press-fit construction kit, which can be assembled in multiple ways. Account for the lasercutter kerf.

Progress : cut something on the vinylcutter

Individual assignment - Laser Cutting¶

By using FreeCad to create a sketch for a parametric press-fit construction kit.

This is the first time for me to use FreeCad. I have spent time for selecting different software. I have investigating FreeCad, Autodesk Fusion 360 and CorelDraw. Since it is a kind of parmetric design model. I finally choose FreeCad since it look like it’s not difficult to handle.

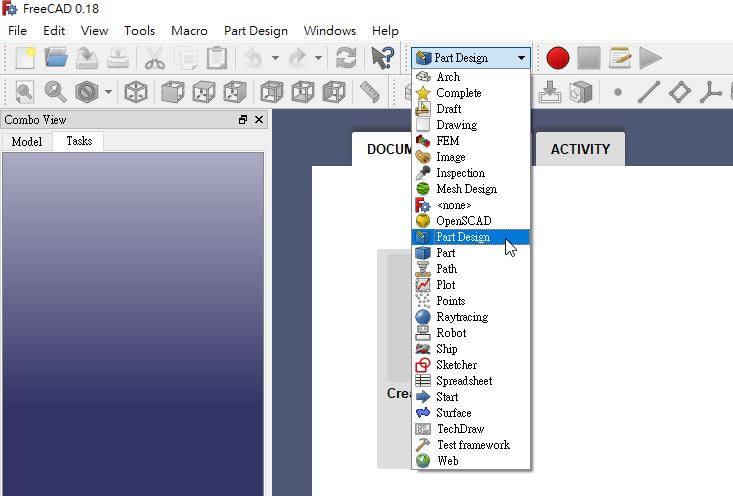

Step 1:

This is my first time to use FreeCad. Also, I learn the concept of parmetric design today. It looks like strange to me. It’s quite challenging for me to design a model like this. The first step is to choose part design in FreeCad.

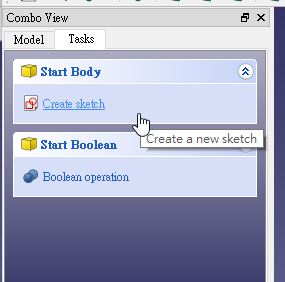

Step 2:

Choose Start body and create sketch

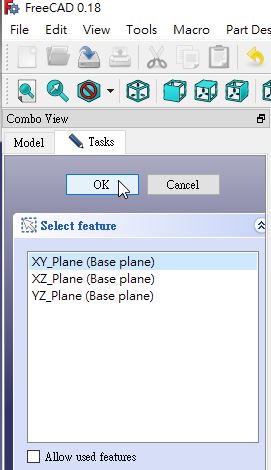

Step 3:

There are three type os base plane. I choose to use XY Plane.

Step 4:

On the top right hand corner, there is a icon for choosing different view point. I choose “Top” as the view point.

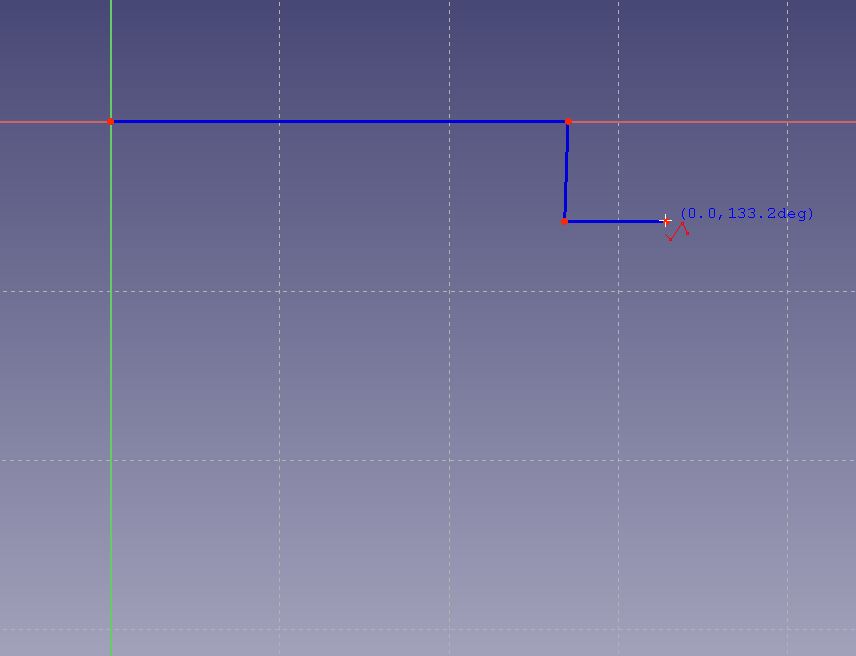

Step 5:

I have to choose polyline. This is a important feature that I can draw the whole design by using this feature.

Step 6:

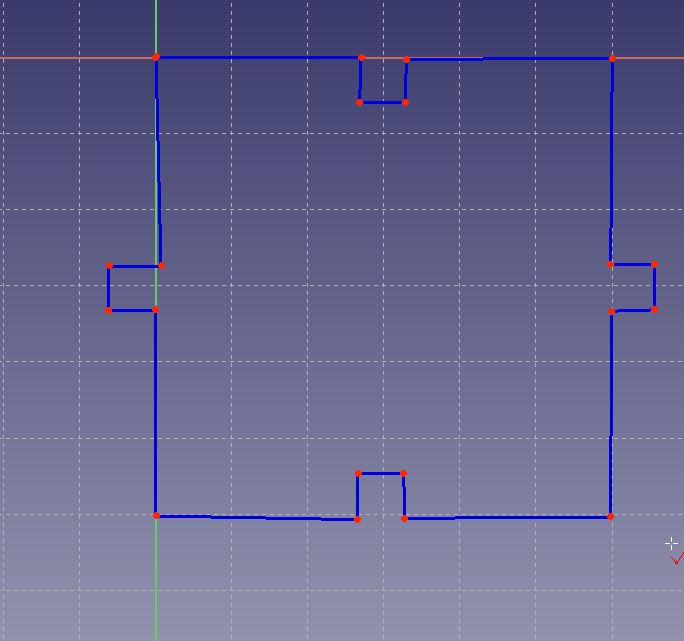

I started the drawing of the whole sketch step by step.

Step 7:

After for a while, I have completed the drawing of the whole design. However, it is not accuracy.

Step 8:

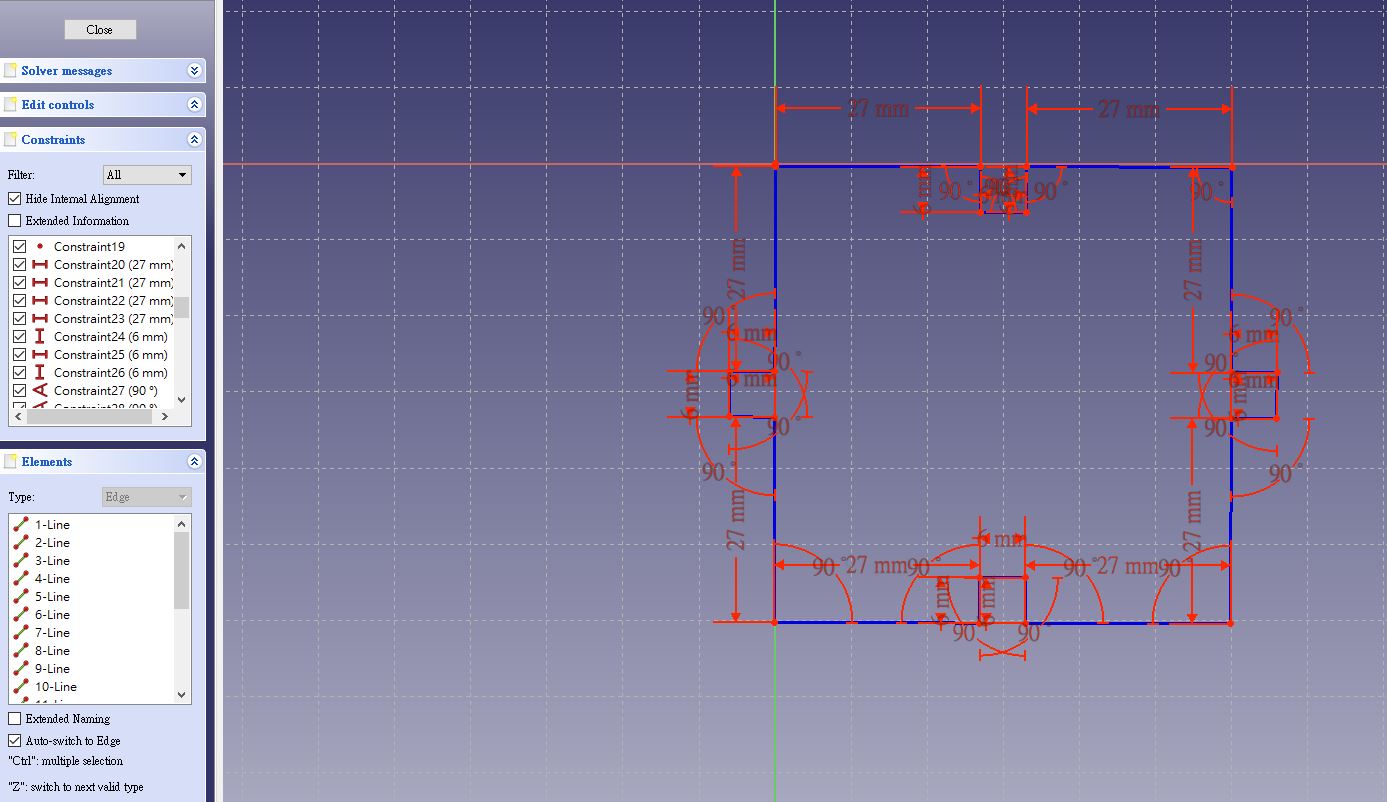

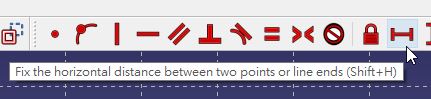

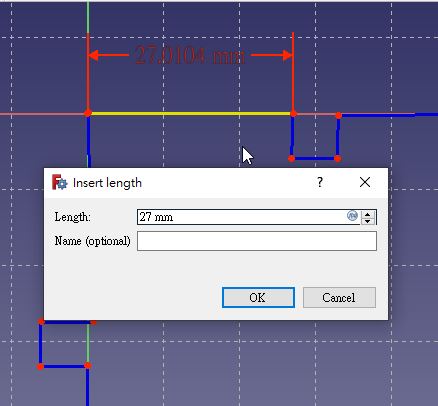

Horizontal distance constraint is a important feature that I can setup the horizontal distance between two points. It is used to fix the distance.

Step 9:

I set the length of the first line to 27mm.

Step 10:

Also, setting up the vertical distance

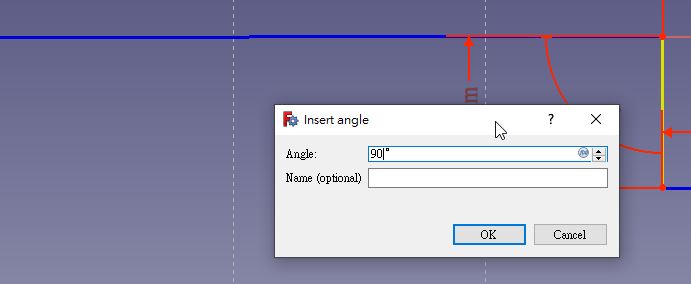

Step 11:

Setting angle as 90 degree is important to ensure my design is a right square shape.

Step 12:

This is the final product. Also on the constraints area, there are many constraints appeared. This is what we call parametric press-fit construction kit.

Please click here to download the FreeCad file

Step 13:

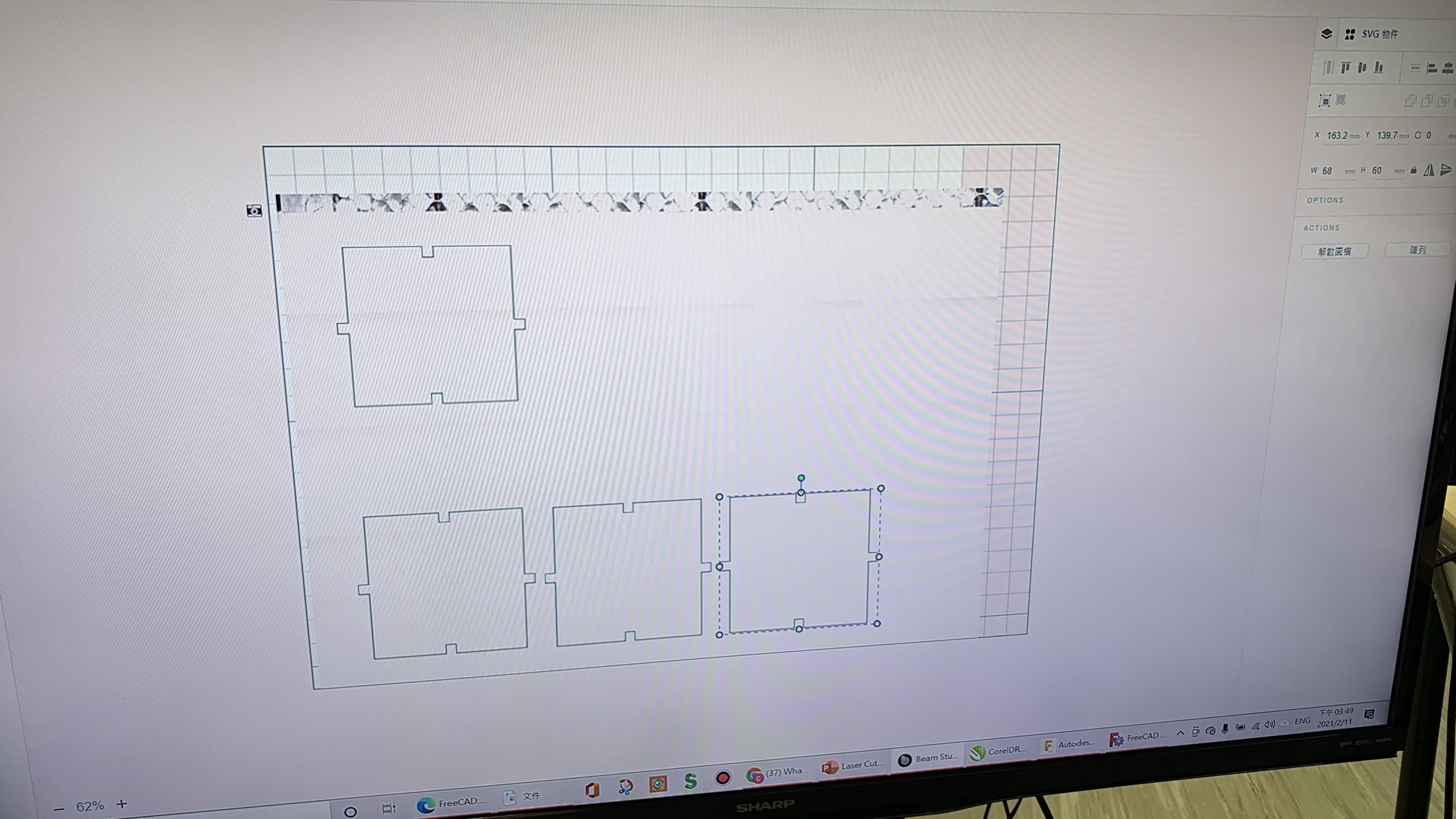

And then I move the design file to my laser cutter software. As you see from the screen capture, there are four picture.

Step 14:

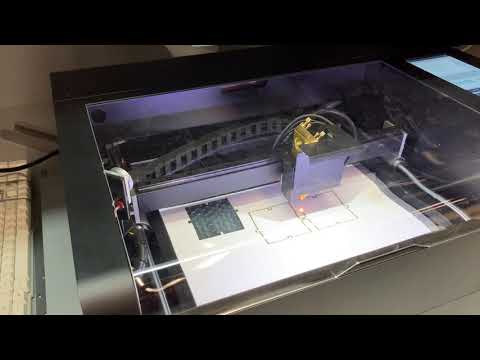

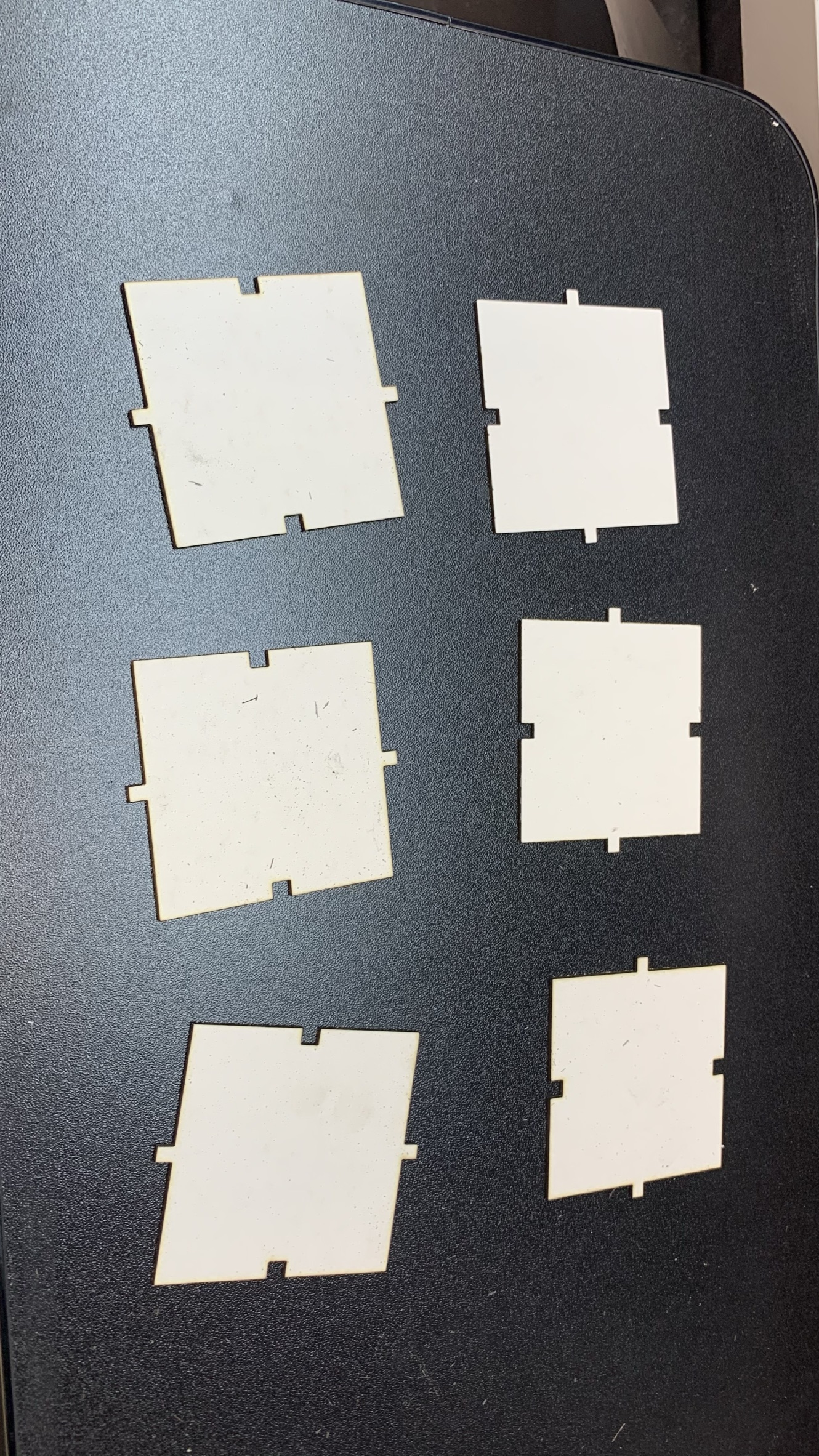

laser cutter is now processing to cut a press-fit construction kit by using a hard paper.

Please click the below link in order to play this video by using youtube!

Step 15:

This is the final product.

Step 16:

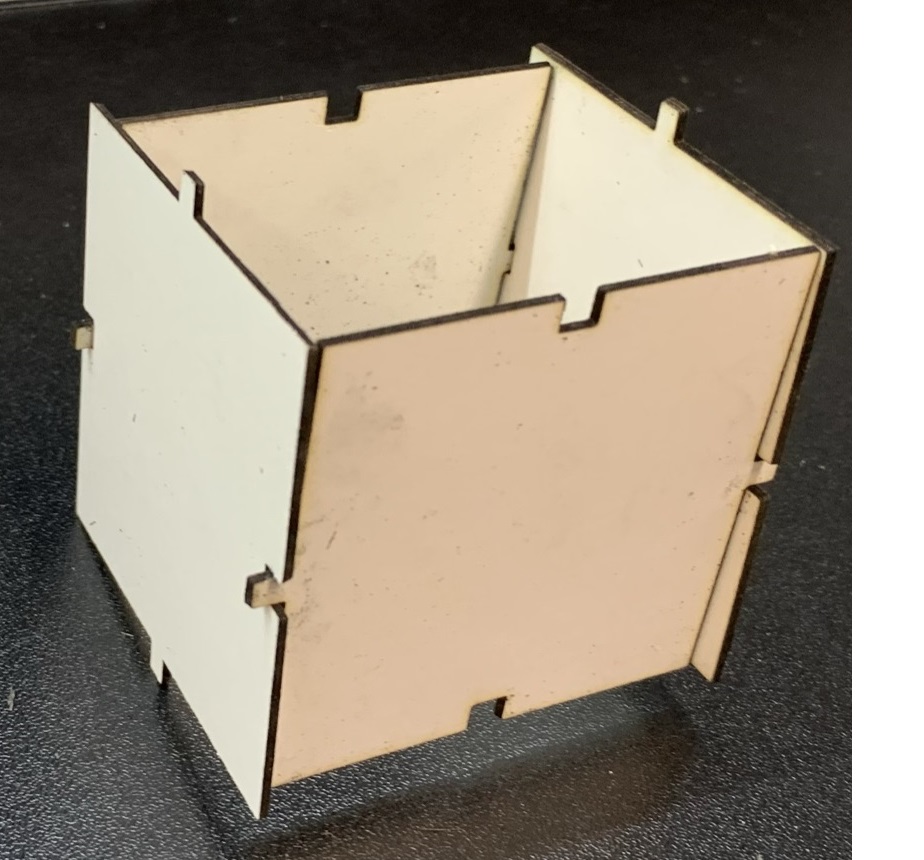

This is the final product. I try to assembly them to form a 3D model.

Step 17:

The following is the file of this 3D model by using Coreldraw

Please click here to download this file

Individual assignment - Vinyl Cutter¶

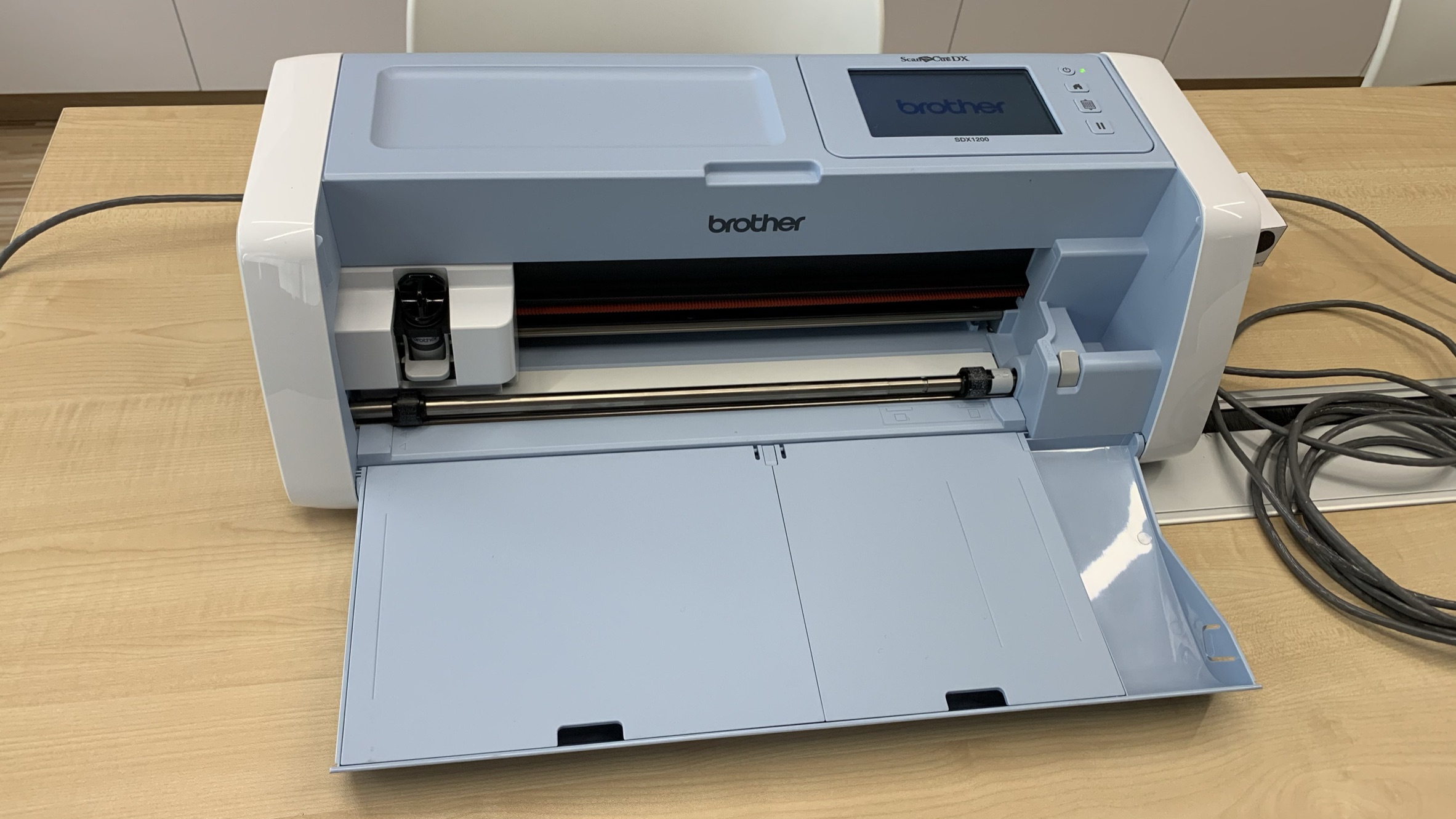

I also have a Vinyl Cutter it is from Brother.

Step 1: We have purchased a brother scan and cut. it is used to made a 3D press-fit construction kit.

Step 2:

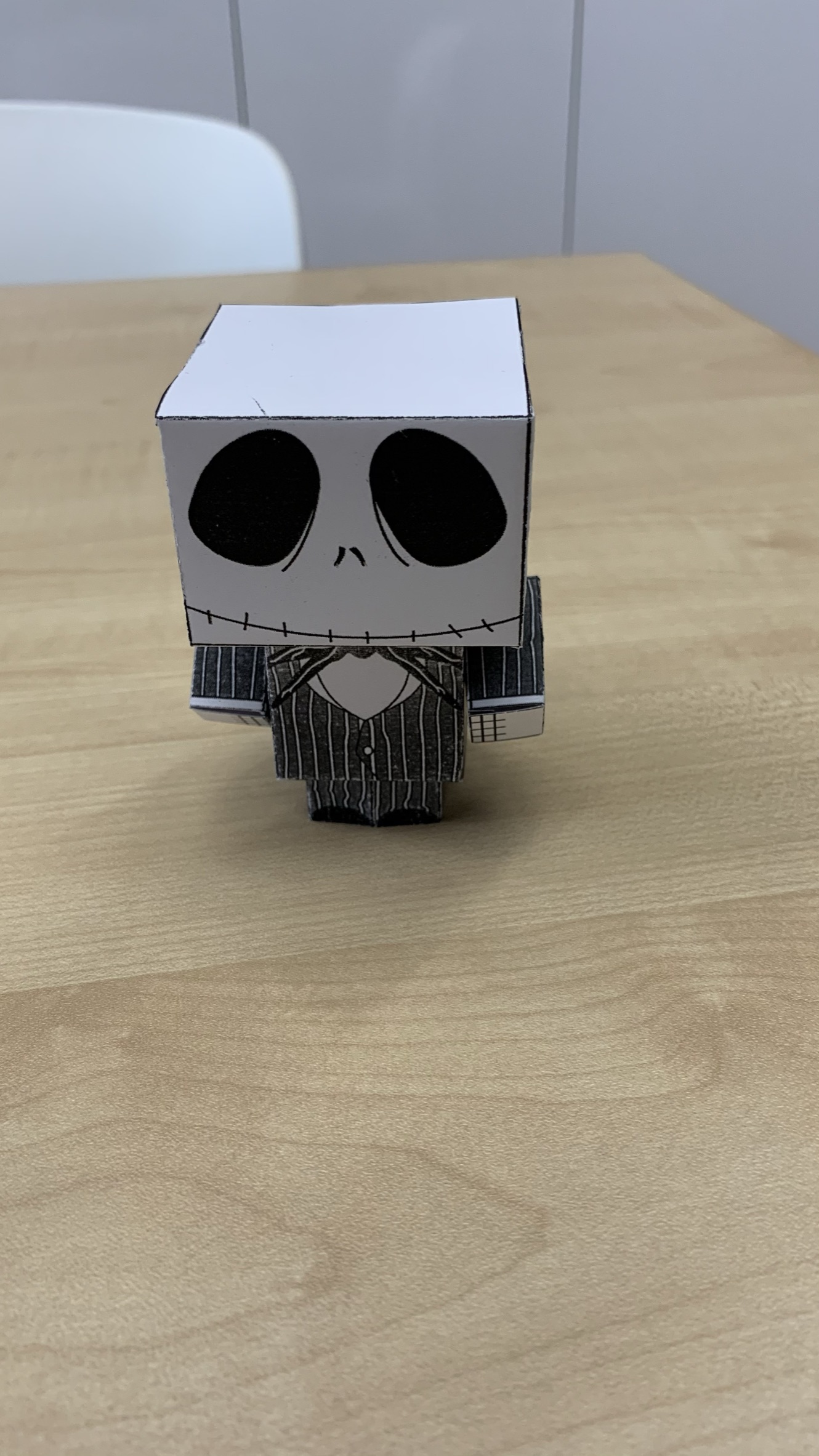

This is the final product.

Step 3:

Please click above link to view this 3D model by clicking the above youtube link!

It is created by using Vinyl Cutter - press-fit construction kit by software a 130 Gram paper

Group assignment -¶

Here is the link of the group assignment .

Characterize your lasercutter’s focus, power, speed, rate, kerf, and joint clearance document your work (individually or in group)

Principal The laser cutter we used is called Flux Beamo.

It used 30W CO2 laser. This laser cutter can cut and engrave different kinds of materials.

Matericals that can be handled.

-

wood

-

leather

-

Acrylic

By using this laser cutter, we can easier create many kinds of products. It is a useful tool for Fab Lab.

As you read from the above information. It can be used to handle hundres of materials.

Also, it is used to handle by using cutting with different thickness.

Connection

This laser cutter uses Wifi as a connection with the computer. It is really convenience for us to connecting the device.

Focus

This laser cutter have the ability to auto focus. As a user, I dont need to take care the problem of focusing. Therefore I can concentrate on the product creation itself.

Reference from the website :¶

https://www.fluxlasers.com/beamo.html