A11 - Molding and Casting

Checando..

Checando..

Moulding and Casting :confused: Not yet updated for 2020 evaluation standards

Group assignment

Review the safety data sheets for each of your molding and casting materials Make and compare test casts with each of them Individual assignment

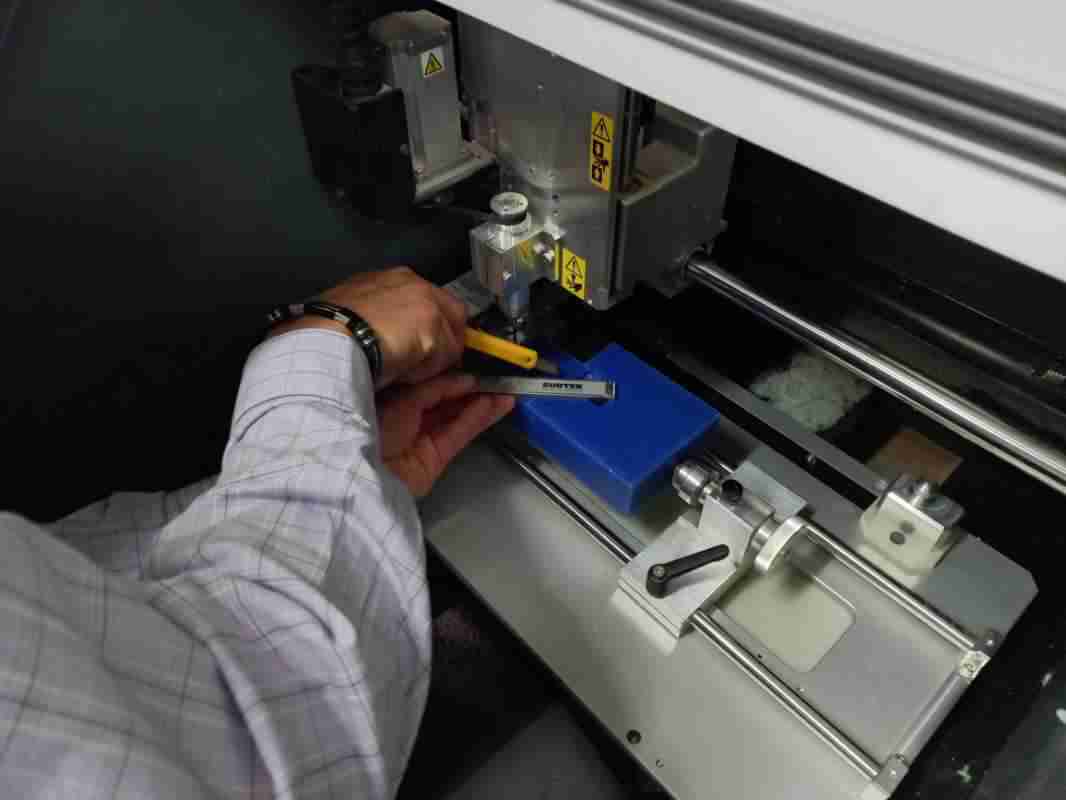

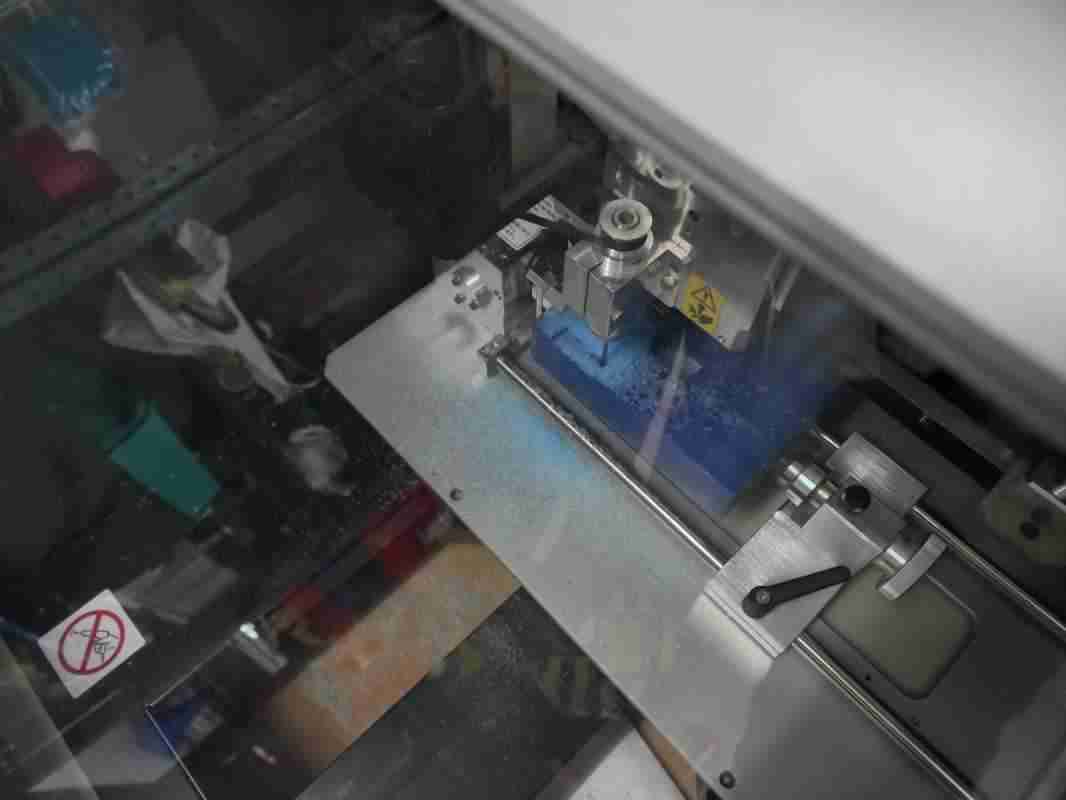

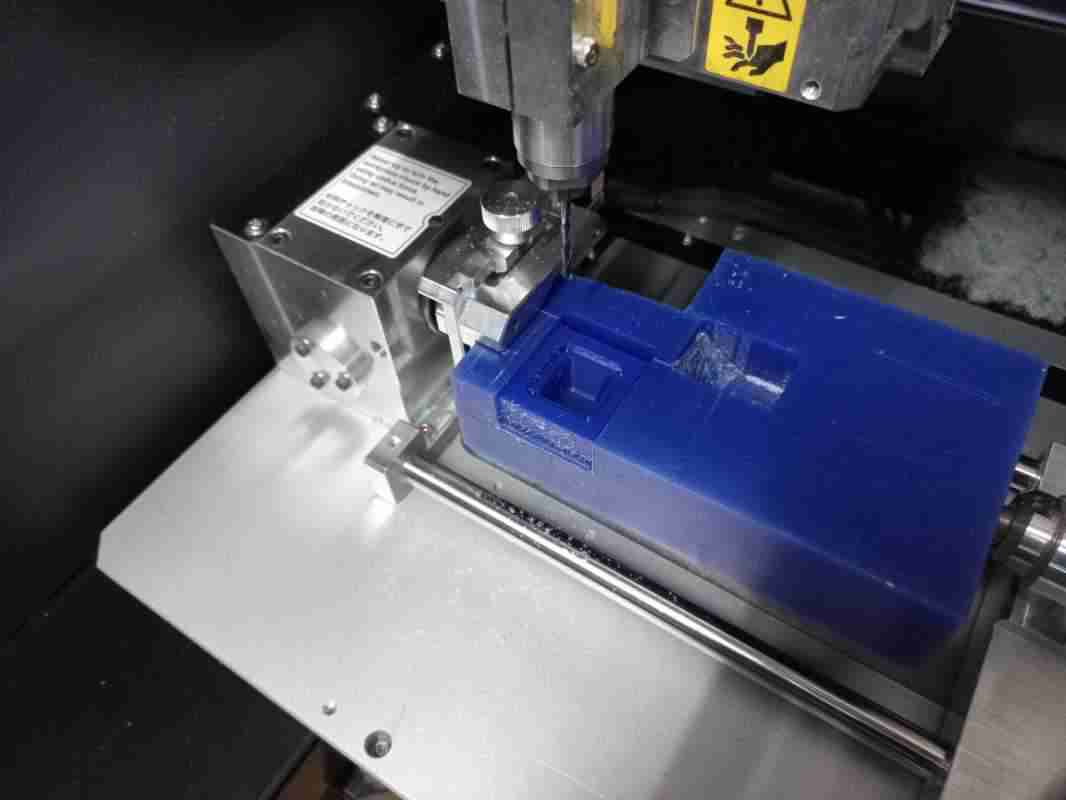

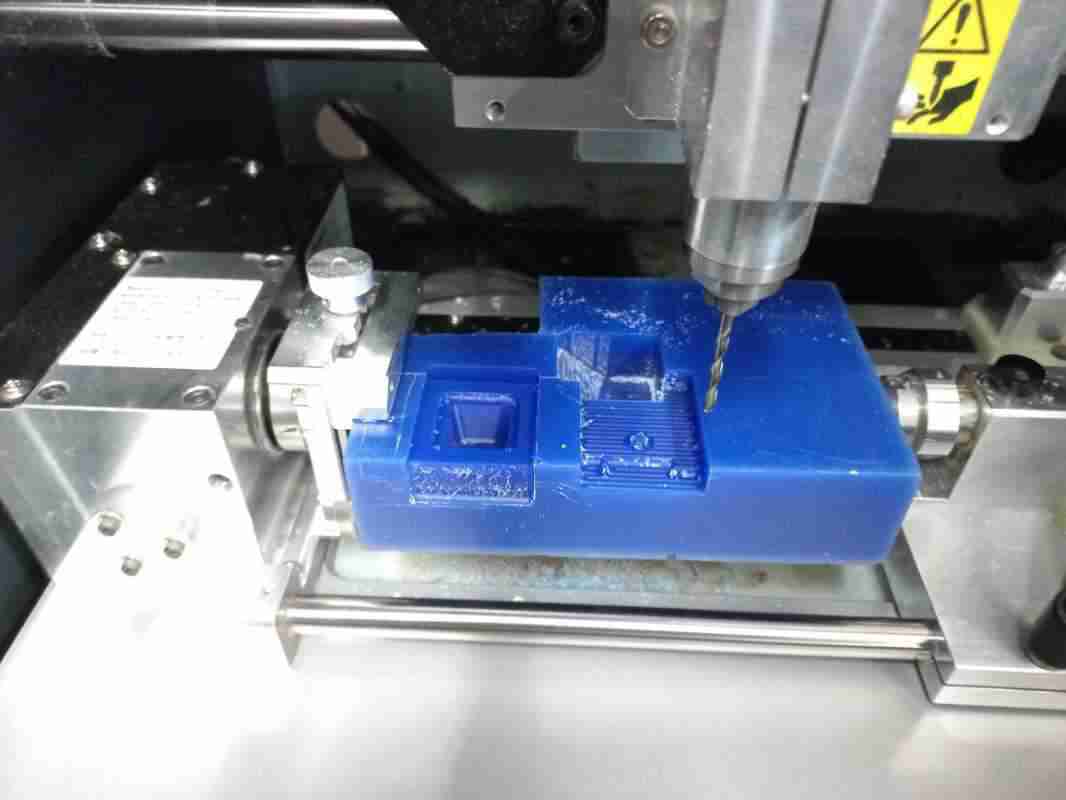

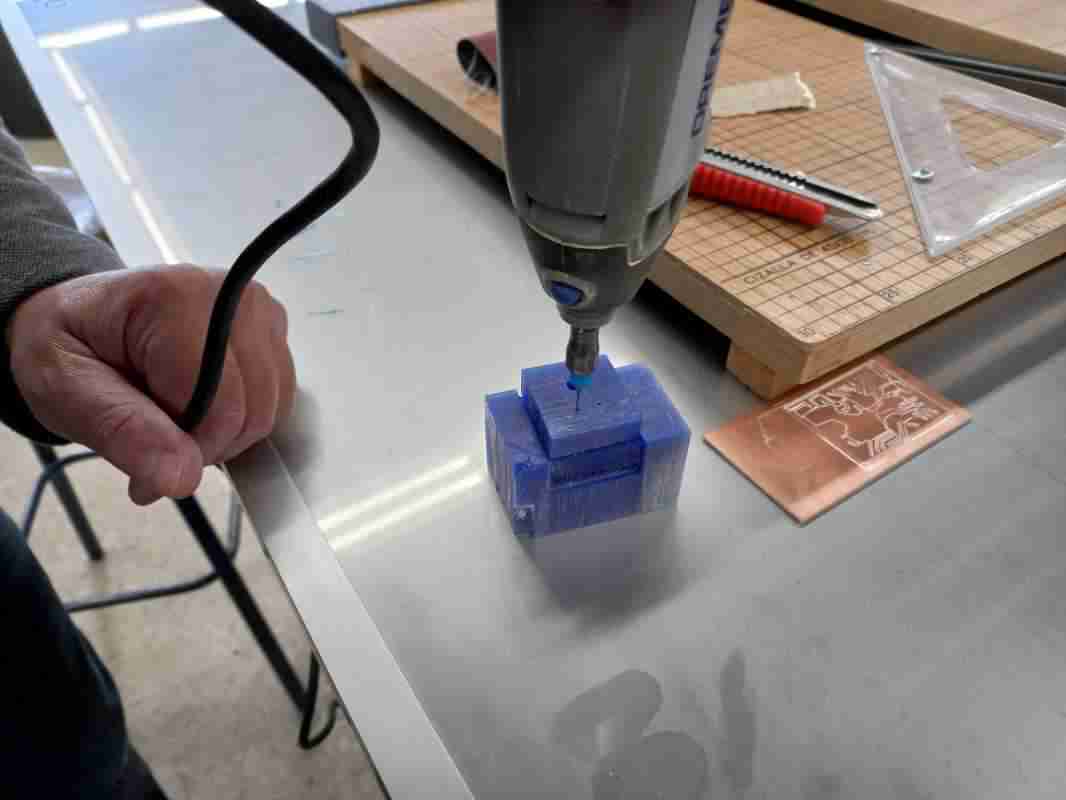

Design a 3D mould around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts. Learning outcomes

- [ ] Design appropriate objects within the limitations of 3 axis machining

- [ ] Demonstrate workflows used in mould design, construction and casting

Have you? * [ ] Explained how you designed your 3D mould and created your rough and finish toolpaths for machining * [ ] Shown how you made your mould and cast the parts * [ ] Described problems and how you fixed them * [ ] Included your design files and ‘hero shot’ photos of the mould and the final object * [ ] Reviewed the safety data sheets for each of your molding and casting materials, then made and compared test casts with each of them

FAQ Should I read the MSDS and TDS this week? Answer: Yes, always.

I want to only make a wax mould, and cast something in it. Is that acceptable? Answer: Only after you learn and go through the 3 step process. To break the rules, you have to master the rules.

Can I 3D print the mold? Can I do a lasercut? Answer: No, for this assignment you must mill the mould using a CNC milling machine. After fulfilling the requirements, please go ahead and experiment other techniques for fabricating moulds.