A3 - Computer-Controlled Cutting

Group assignment

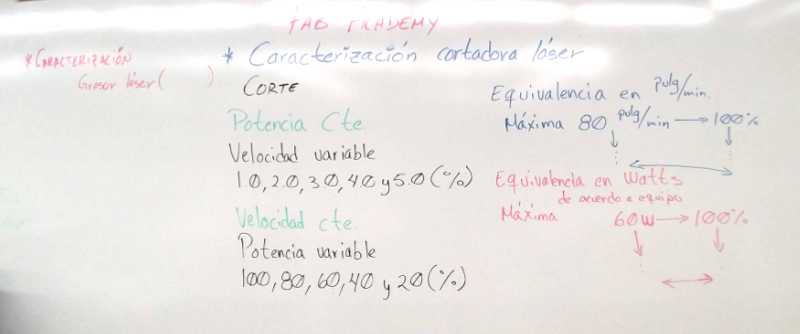

I help characterizing the laser machine with the following steps.

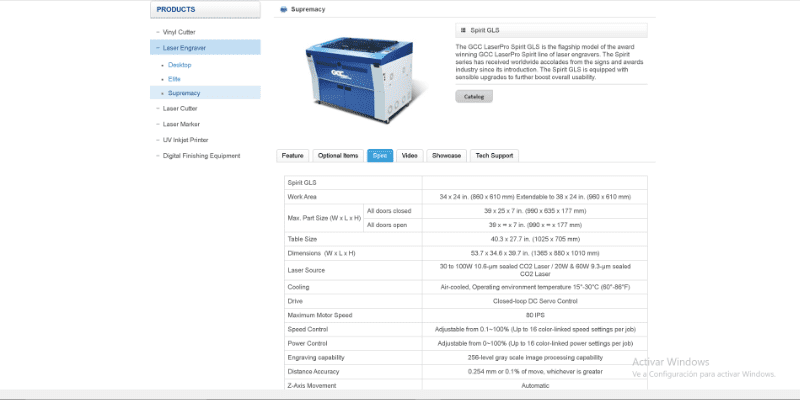

We identify the machine model and specifications.

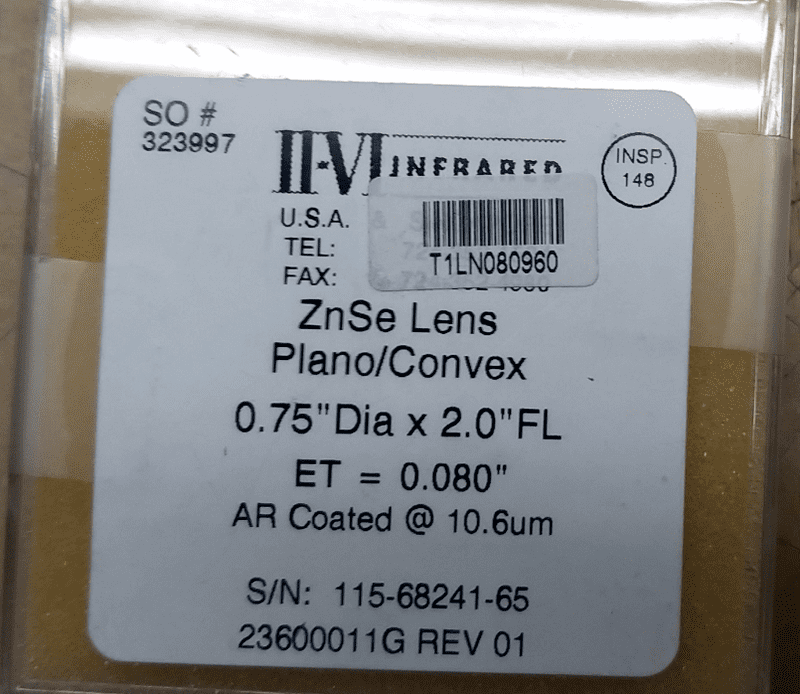

Then we check the lens specification.

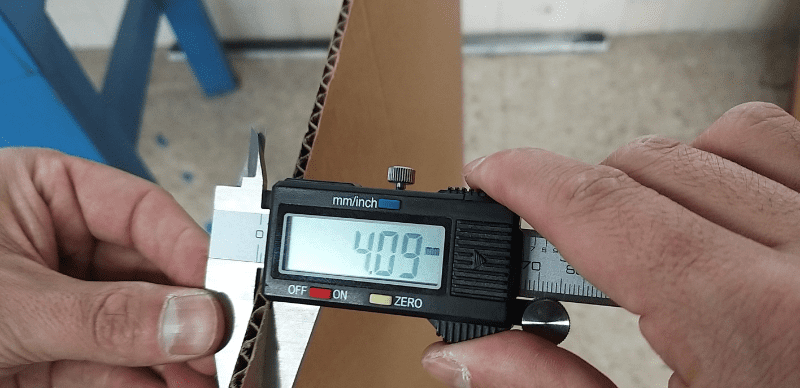

After we measure the material thickness.

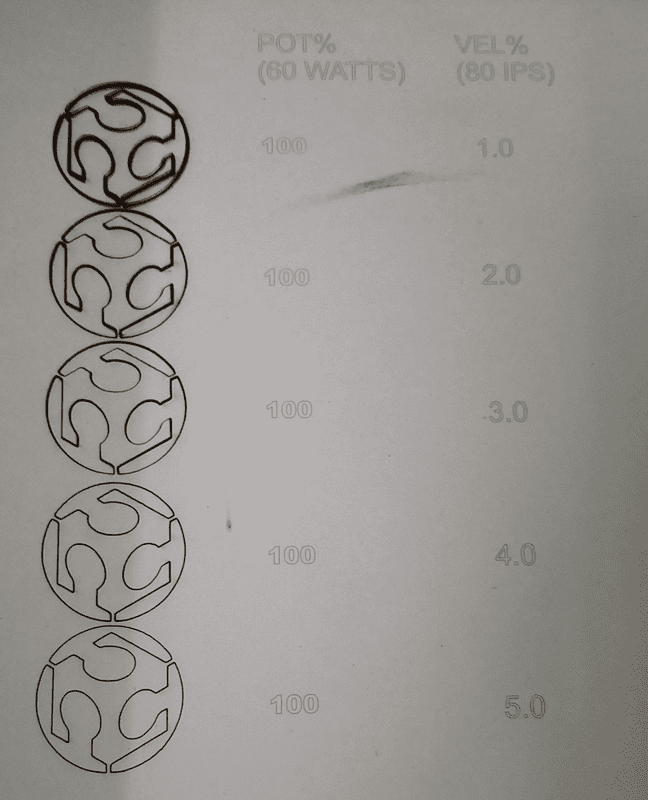

We adjust the power to 100% of 60 Watts and change the values of the speed (max 80 IPS) from 1.0 to 5.0.The 5.0 velocity was the best result.

Parametric Kit

A 3.2 Design, lasercut, and document a parametric construction kit, accounting for laser cutter cutter kerf, which can be assembled in multiple ways, and for extra credit include elements that aren't flat.

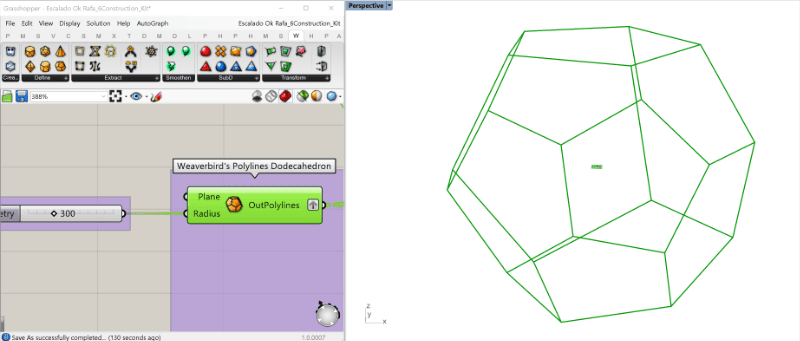

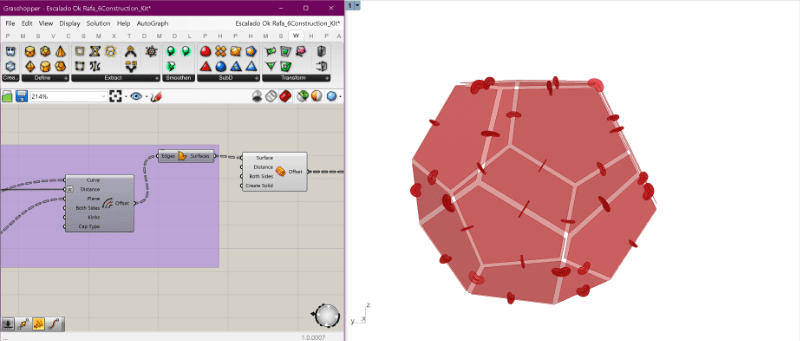

I utilize Rhino with Grasshopper to make my assembly kit

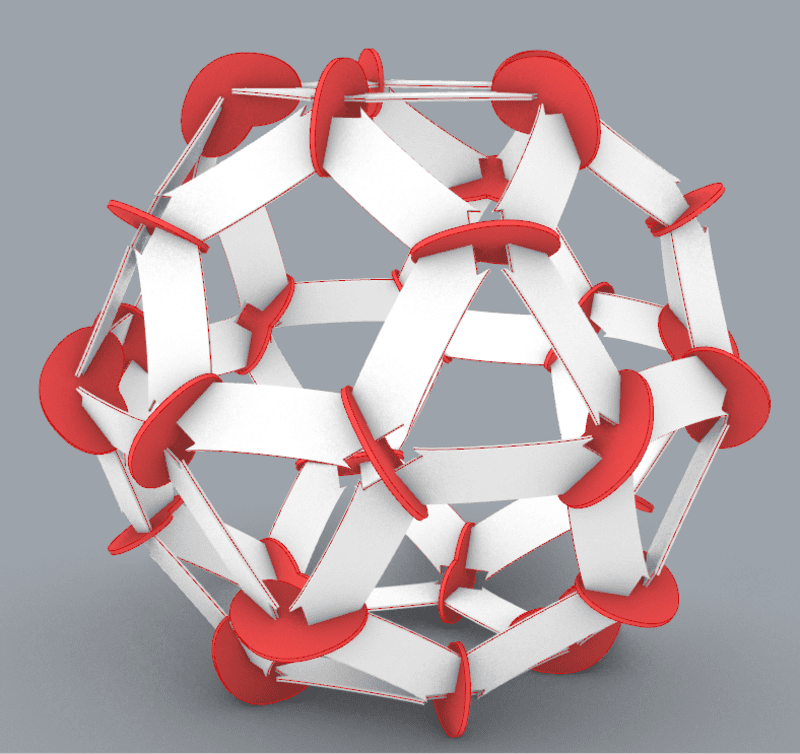

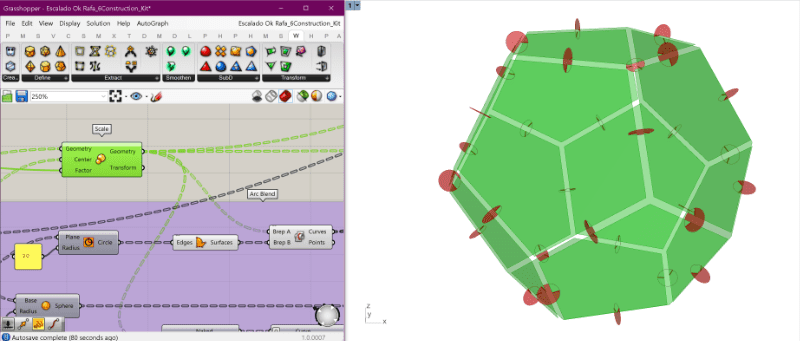

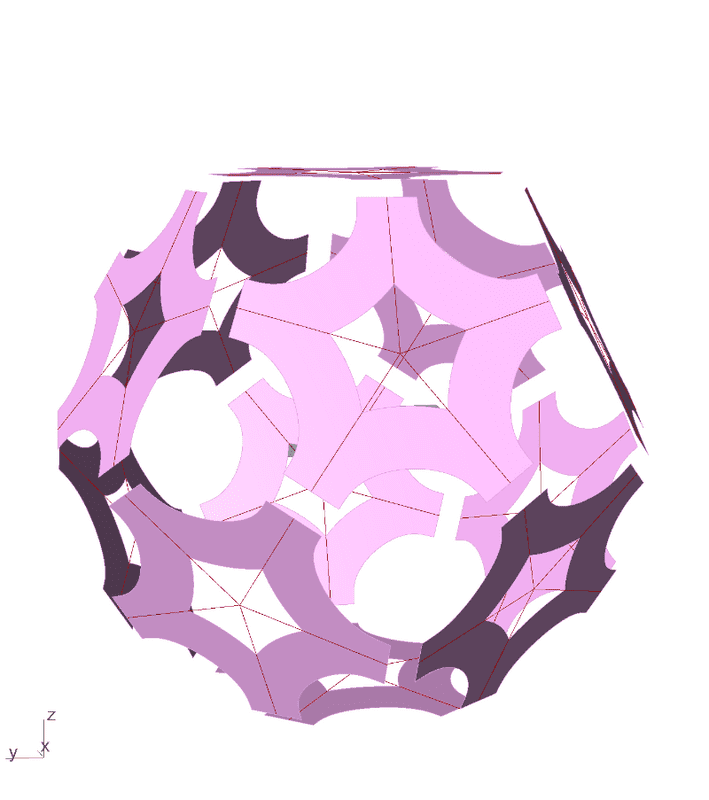

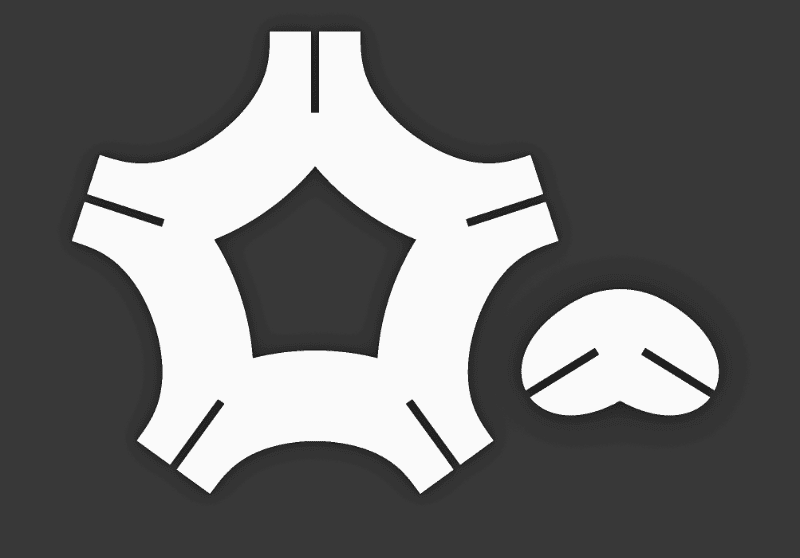

I used the Weaver´s Bird Dodecahedron out lines to make the main frame

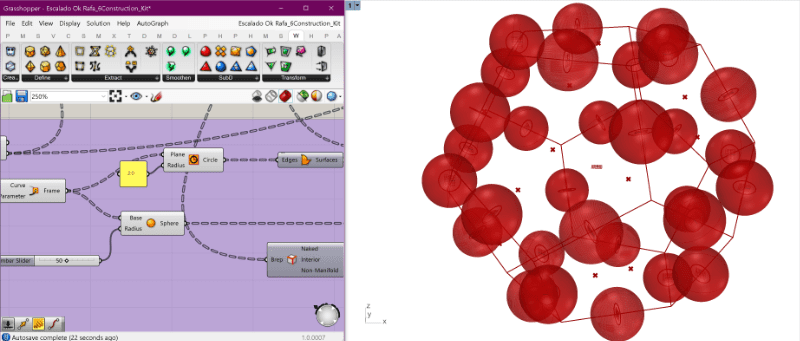

Then I find the perpendicular planes for each border edge

I generate an area of inclusion of the points that were inside the sphere to generate the intersection between the faces and the perpendicular frames

With the perpendicular frames I intersect the faces

This give me two lines for each intersection

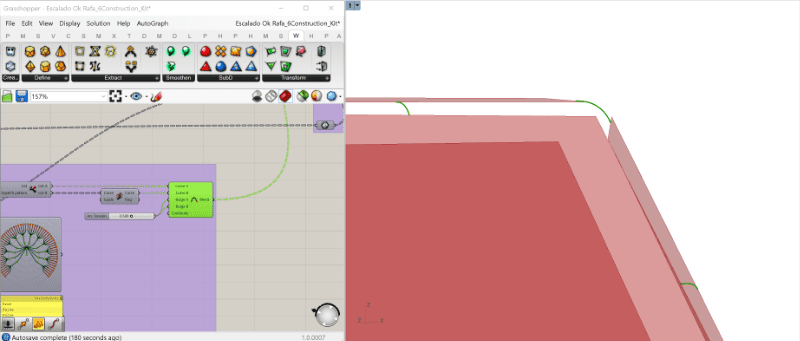

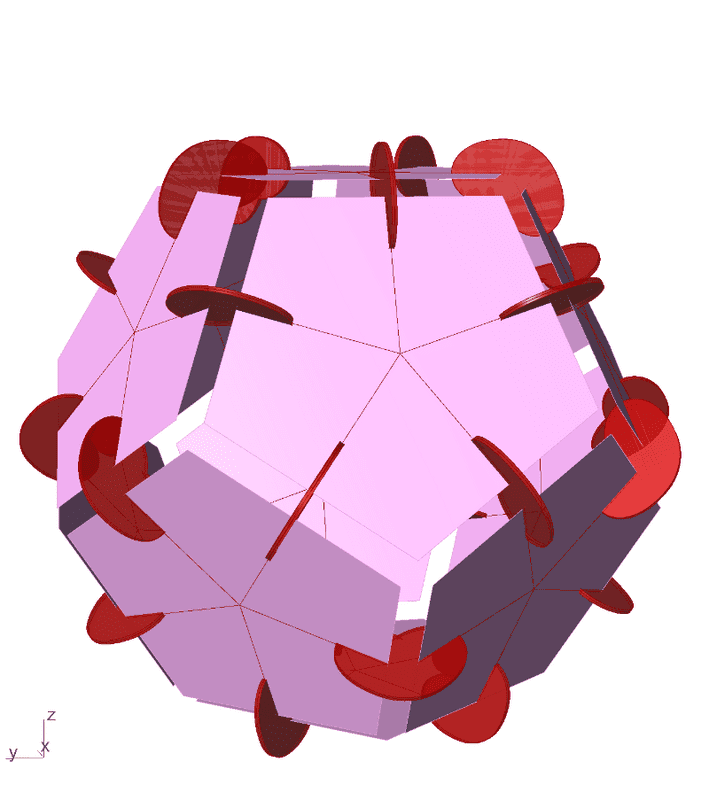

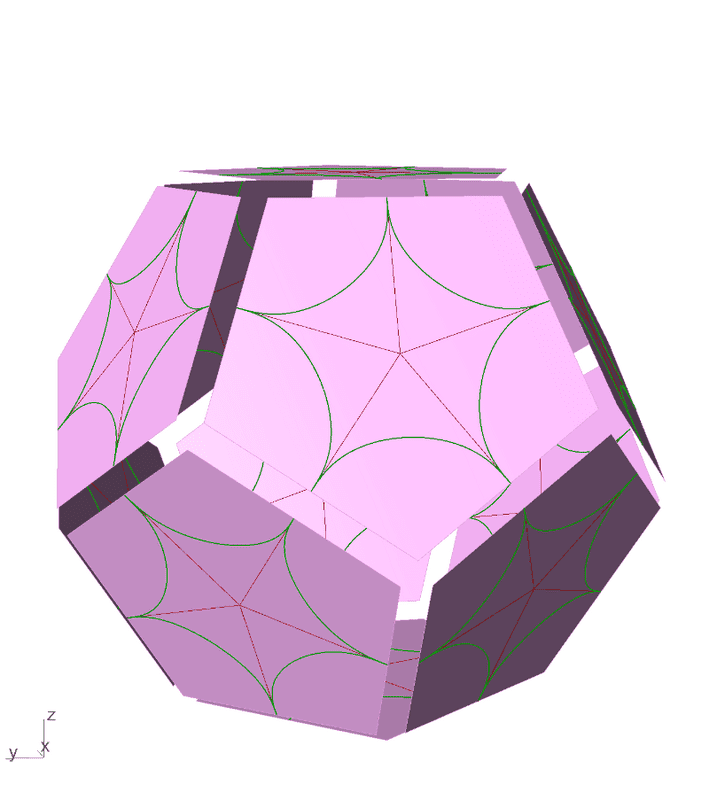

I use the blend curve command in Grasshopper to generate the conection blend

I offset two sides and blend each end of the offsets with each other

I scale the ribbs and make the a solid with extrude

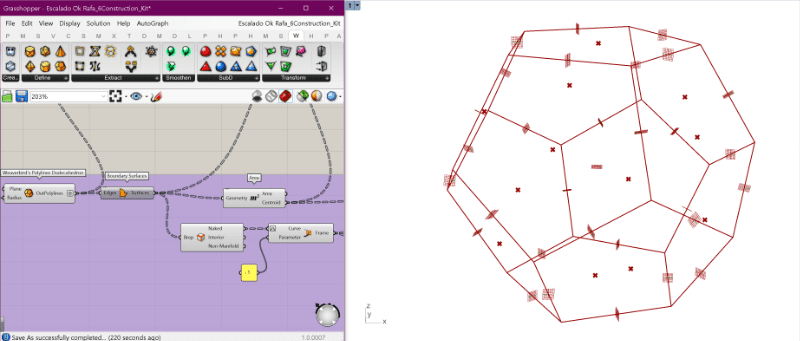

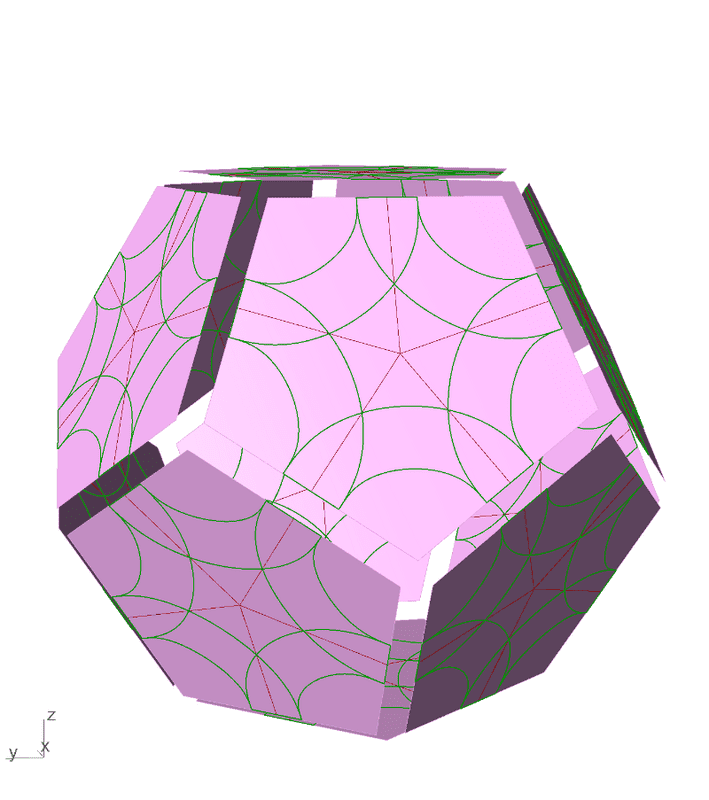

From the same intersection lines I blend each medium side of the face

I offset the two sides of my center curves

With a region union I take out the main face shape and I extrude it

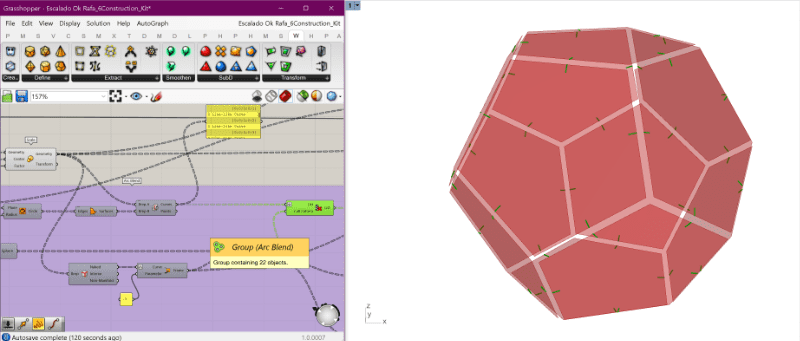

I made the booleans from the middle of the intersection of the rib with the face

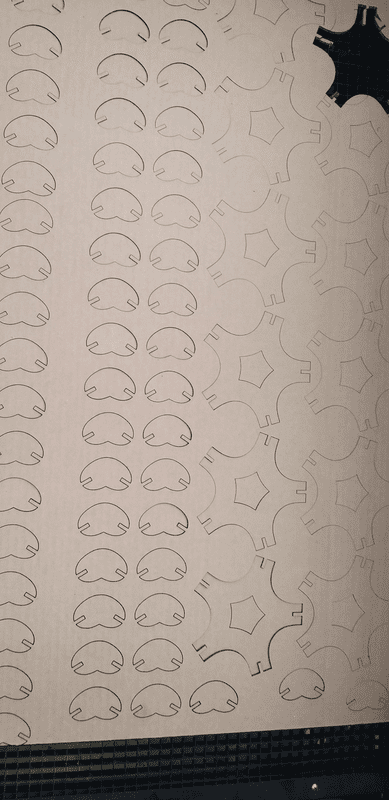

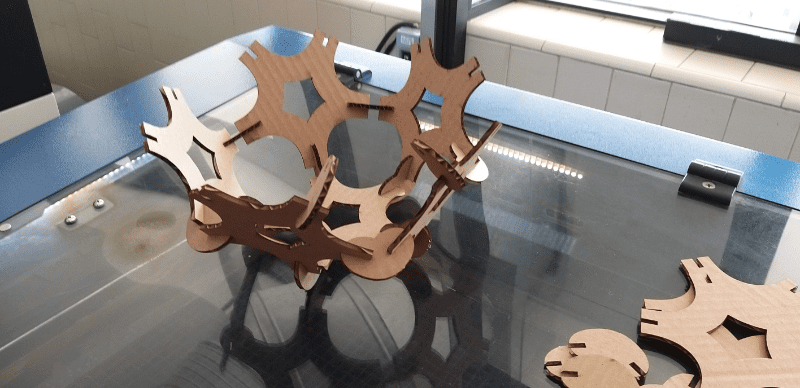

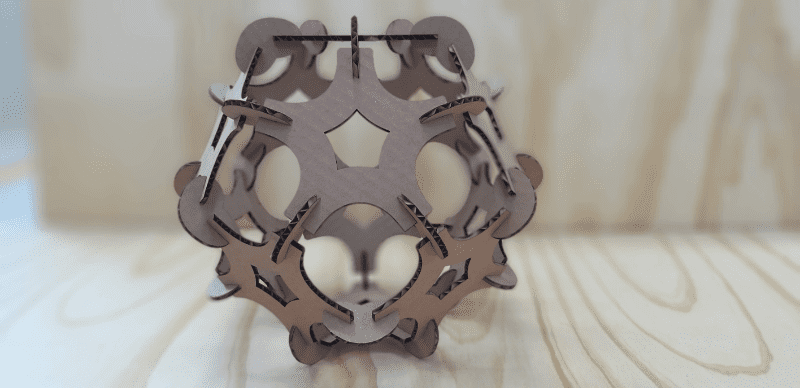

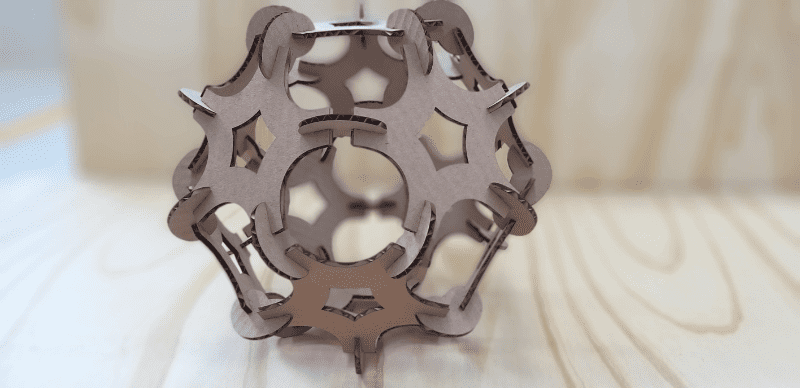

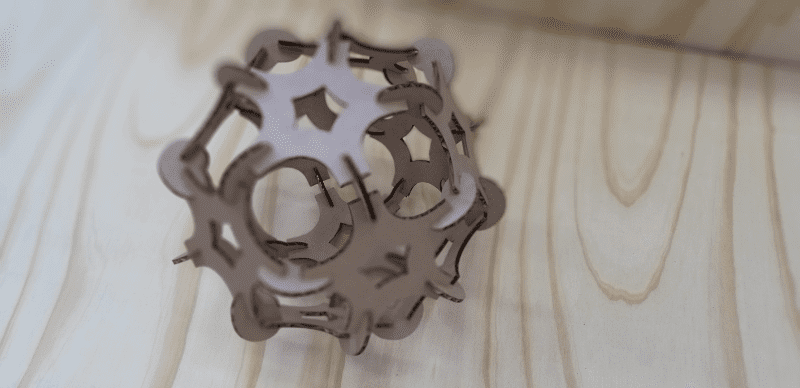

This is the lasser cuttin result

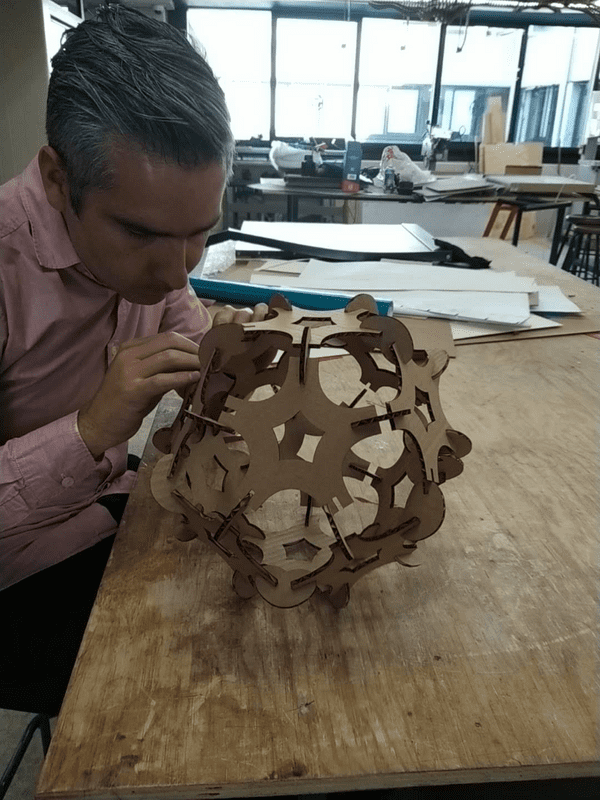

My firend Rodrigo Shiordia helping me to assambly the kit

This is the final result

A 3.1 Individual assignment - Cut something on the vinylcutter

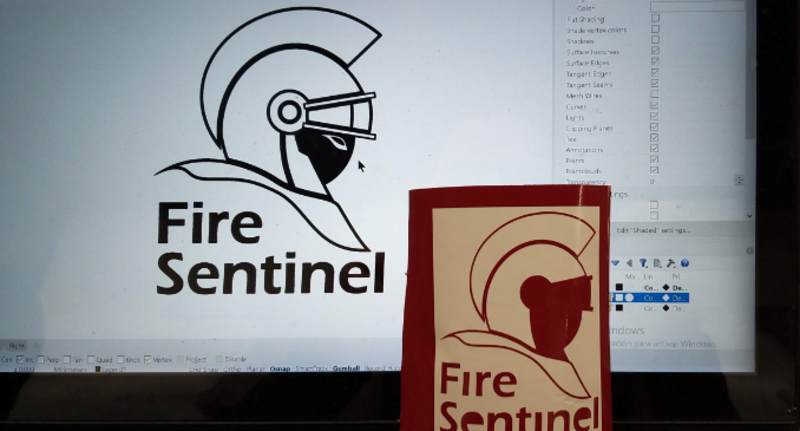

I vectorized my fire sentinel logo, the problem was that I used Affinity Design and it use a EPS old algorithm that it´s hard to translate to vector, I have to use Free Ink to translate to vectors that can be read in illustrator or in the laser cutting machine.

After the Free Ink vectorization I use Rhino to make the solid regions, because it has the _CurveBooleann Command that enables you to choose between solid and empty spaces.

The Fab Lab has a GCC Puma IV Cutting Machine.

With a cutter I removed the empty spaces

I decided to use red vynil because my logo it´s about fire

This is the final vynil cut

Checklist

- [X] linked to the group assignment page

- [X] Explained how you parametrically designed your files

- [X] Documented how you made your press-fit kit

- [X] Documented how you made your vinyl cutting

- [X] Included your original design files

- [X] Included your hero shots