Molding and Casting

Week 10

In my tenth week I was allowed to work with molding and casting. First of all, safety was the topic of the group assignment. In the individual part I was allowed to translate my own idea into a form. Wax milling - that has something!

Prepare

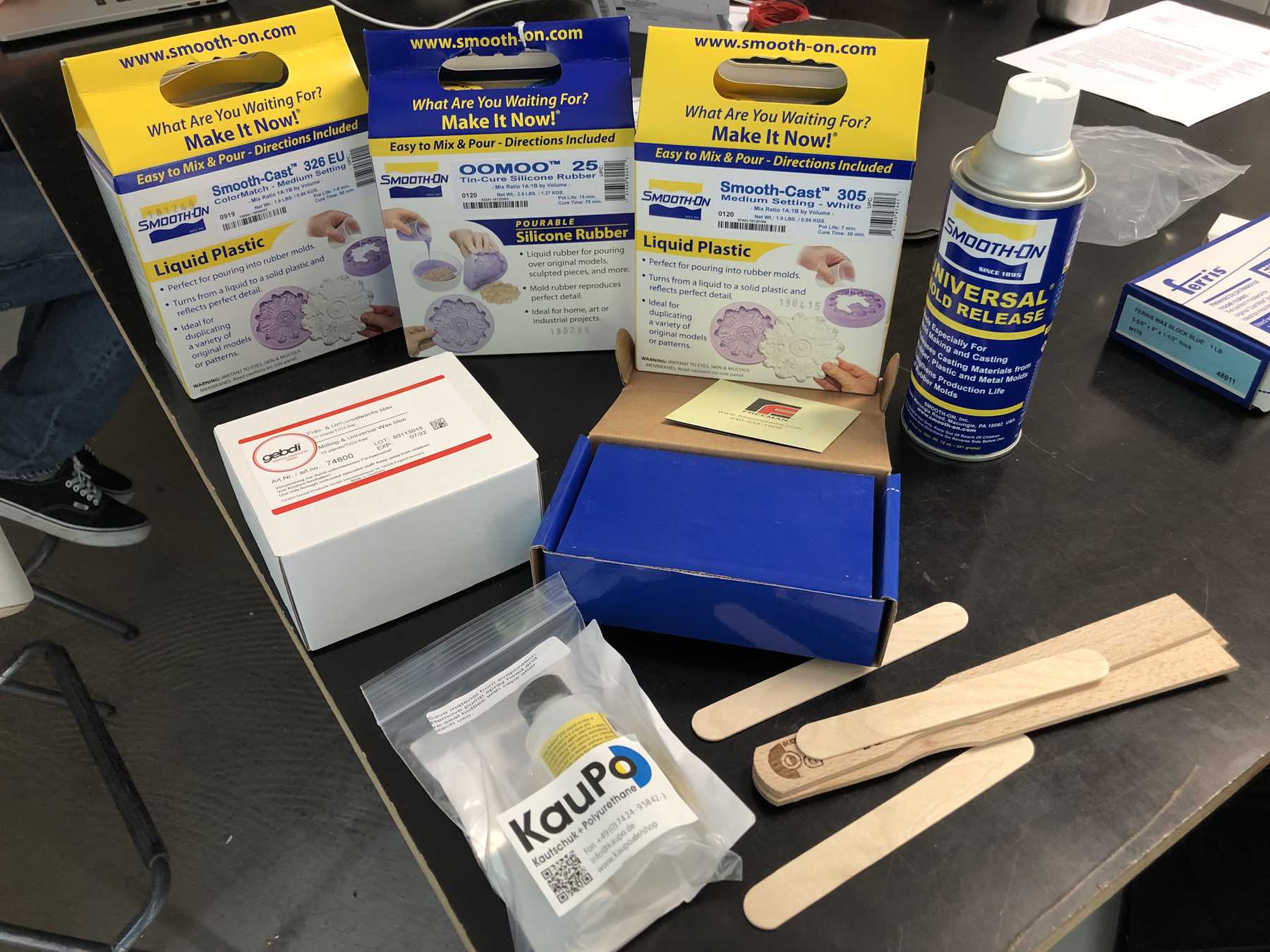

It took me a while to find a supplier for the materials in Germany. Fortunately, there was a distributor who could deliver the components quickly. With the Wax it looked however differently. I could find milling wax at a few suppliers. I decided for two different waxes, but in my opinion the costs for the wax blocks are very high. Below is a photo of the purchased material:

Group assignment

Safety Data Sheets

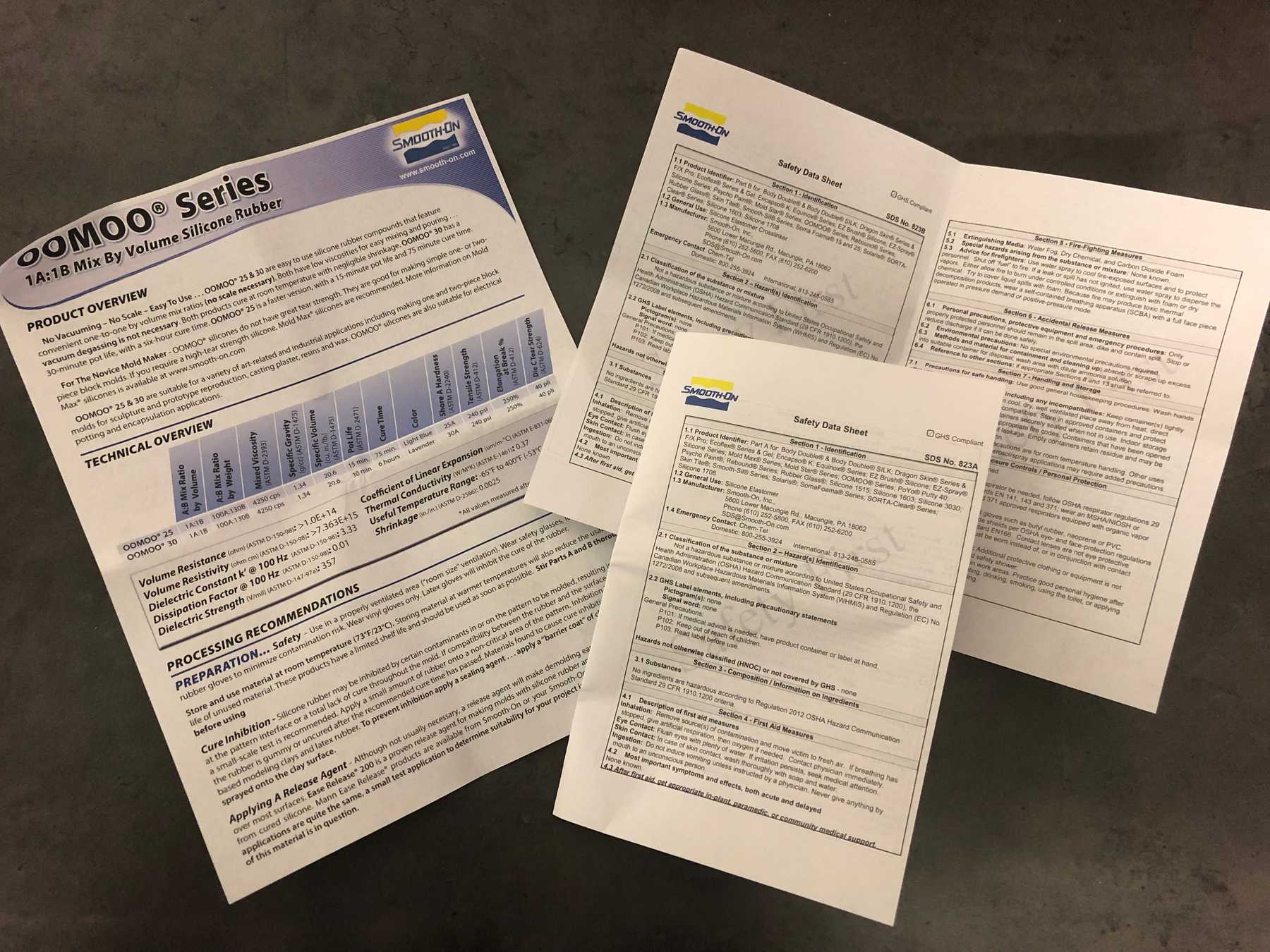

For my individual assignment I used the following products: Oomoo® 25, Smooth-Cast® 305 and Ease Release® 205. I would like to take a closer look at those products with regard to their safety.

Oomoo® 25 is a low cost silicone for condensation curing castable silicones. It is mixed in a mixing ratio of 1:1. According to the manufacturer, this is a low-viscosity agent that can be used to cast moulds with as little air bubbles as possible. The special thing about the Oomoo® 25 material is that it can be used without the need for a vacuum. Compared to Oomoo® 30, Oomoo® 25 is the version with a shorter pot life and shorter curing time, with 15 and 75 minutes respectively.

Eye contact should be avoided with regard to the EC Safety Data Sheet for this product. Normally silicone polymers are harmless to the eyes, however the eyes should be washed with water for 15 minutes after contact. Use soap and water to remove it after contact with the skin.

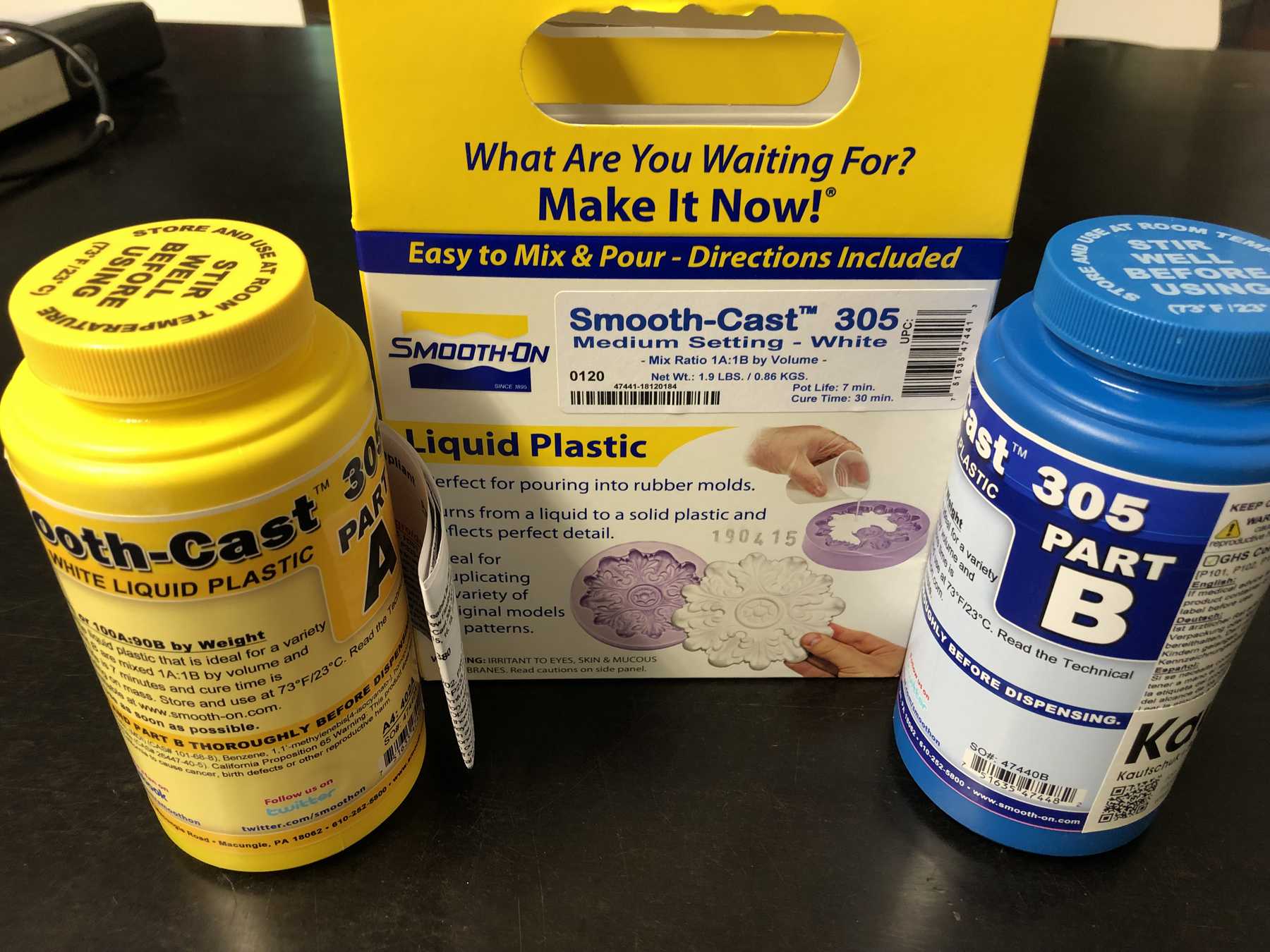

Smooth-Cast® 305 is a pure white polyurethane casting resin. It corresponds to the Smooth-Cast® 300 series and is a very viscous material with a white colour. The advantage of this series is that it can be bubble-free and without the application of a vacuum vent. With a mixing ratio of 100 parts by weight A to 90 B it is a casting resin with a very short drip time.

As far as safety is concerned, a distinction must be made between two cases. Component A with the yellow sticker contains methylene diphenyl diisocyanate. The vapours produced by heating may cause irritation or damage to the lungs. This should only be done under ventilation. Contact with the eyes can cause severe irritation and a doctor should be consulted. Eyes should be washed immediately for 15 minutes. It can be removed from the skin with soap and water. For component B, with the blue sticker, the same applies to contact with the eyes. If a mechanical treatment is carried out, a breathing mask should be worn.

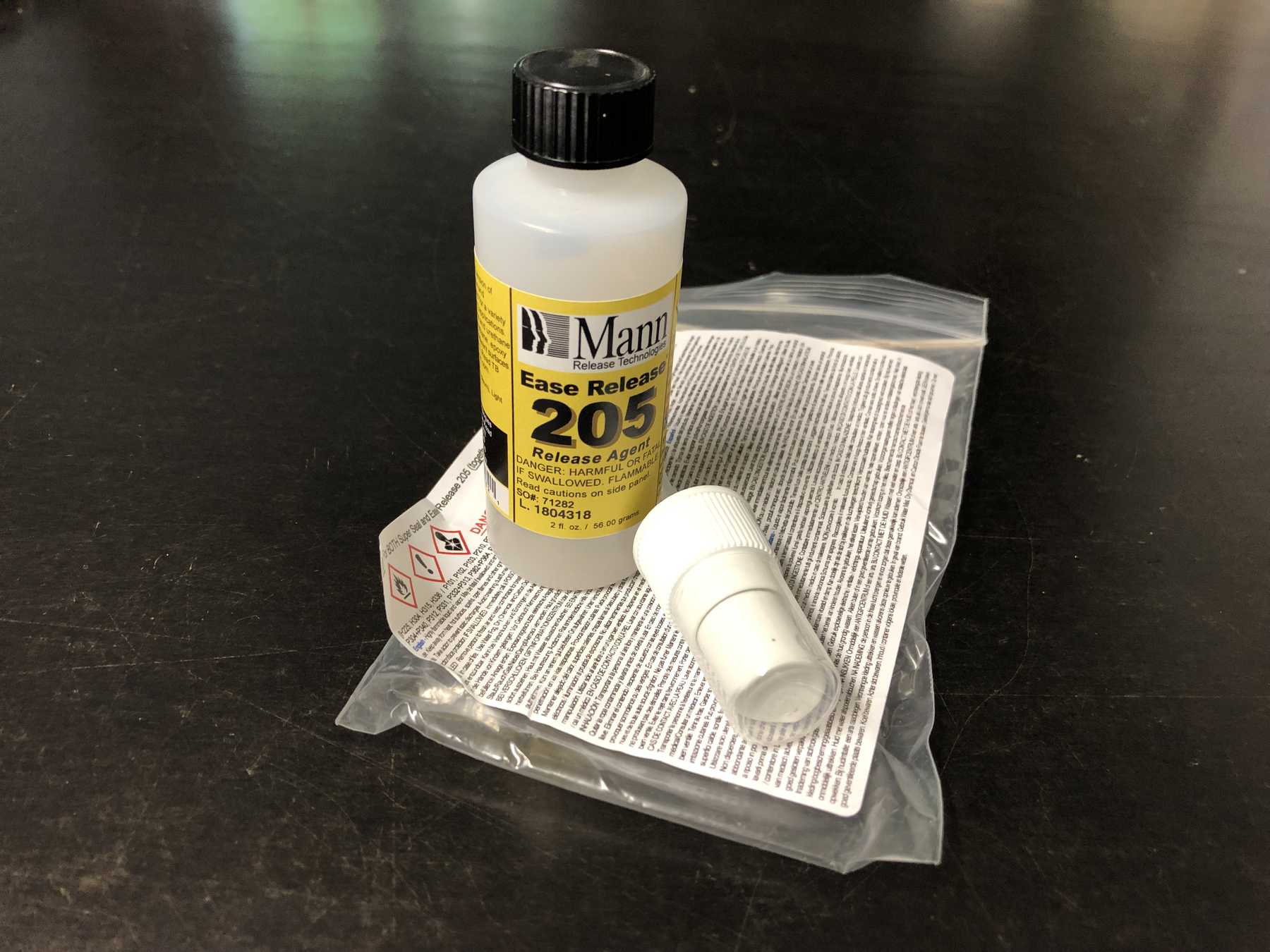

Ease Release® 205 is a silicone release agent which is specially produced for mould making. It separates various materials such as polyurethane elastomers, epoxy resins, silicones etc. from each other. Before use, the mould should be cleaned and freed from residues or dirt. Then there are two possibilities for application. The first is the use of a brush and a regular application on the layer. The second is to spray on the mould from a distance of 30 cm. Before further processing of the casting it is advisable to clean the surface again with 2-propanol or acetone.

In terms of safety, skin contact can cause dehydration. Safety glasses should be worn to avoid eye contact. Sufficient ventilation should also be ensured during use.

Model waxes should not be used or come into contact with unqualified persons of the subject, such as children. Contact between skin surface and hot wax should be avoided.

Individual assignment

Design a mold

Next, I thought for a long time about what I would like to do this week and what would benefit my final project. In this case I couldn’t think of a useful application for my final project. Unfortunately, I decided to create a meaningless, but optical design, which we already printed in 3D. For this I used our beloved FabLab logo DEZENTRALE:

I have exported this to Illustrator as an SVG file, which can be downloaded below:

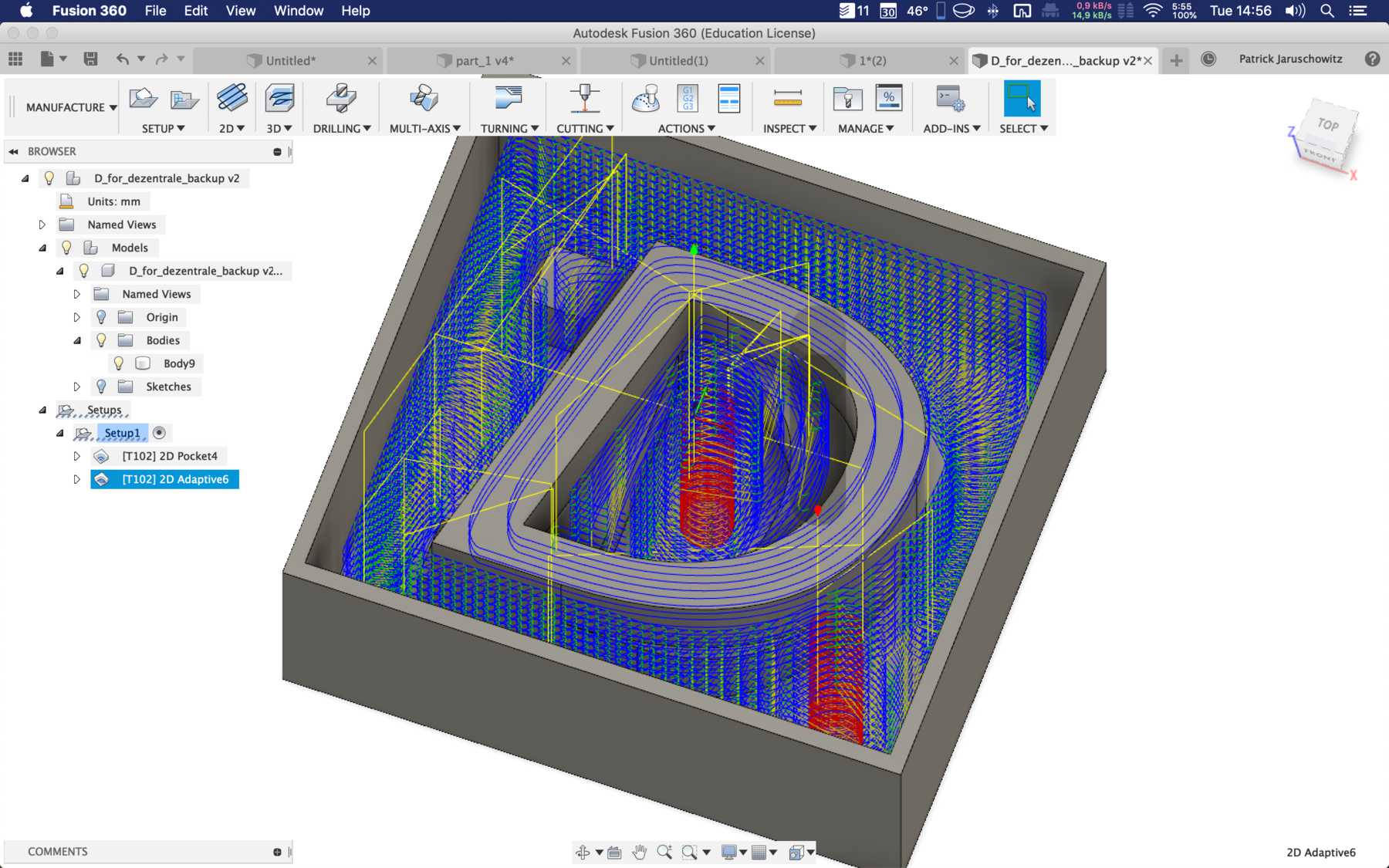

In Autodesk Fusion 360, I first inserted the SVG file and then thought about milling the whole logo or just a letter. The first draft looked like this:

But then I decided against it, simply because it would have to be a too big wax block and the suitable milling cutter would not have been there. For this reason I changed the letters again and the whole thing looked like this:

Mill it

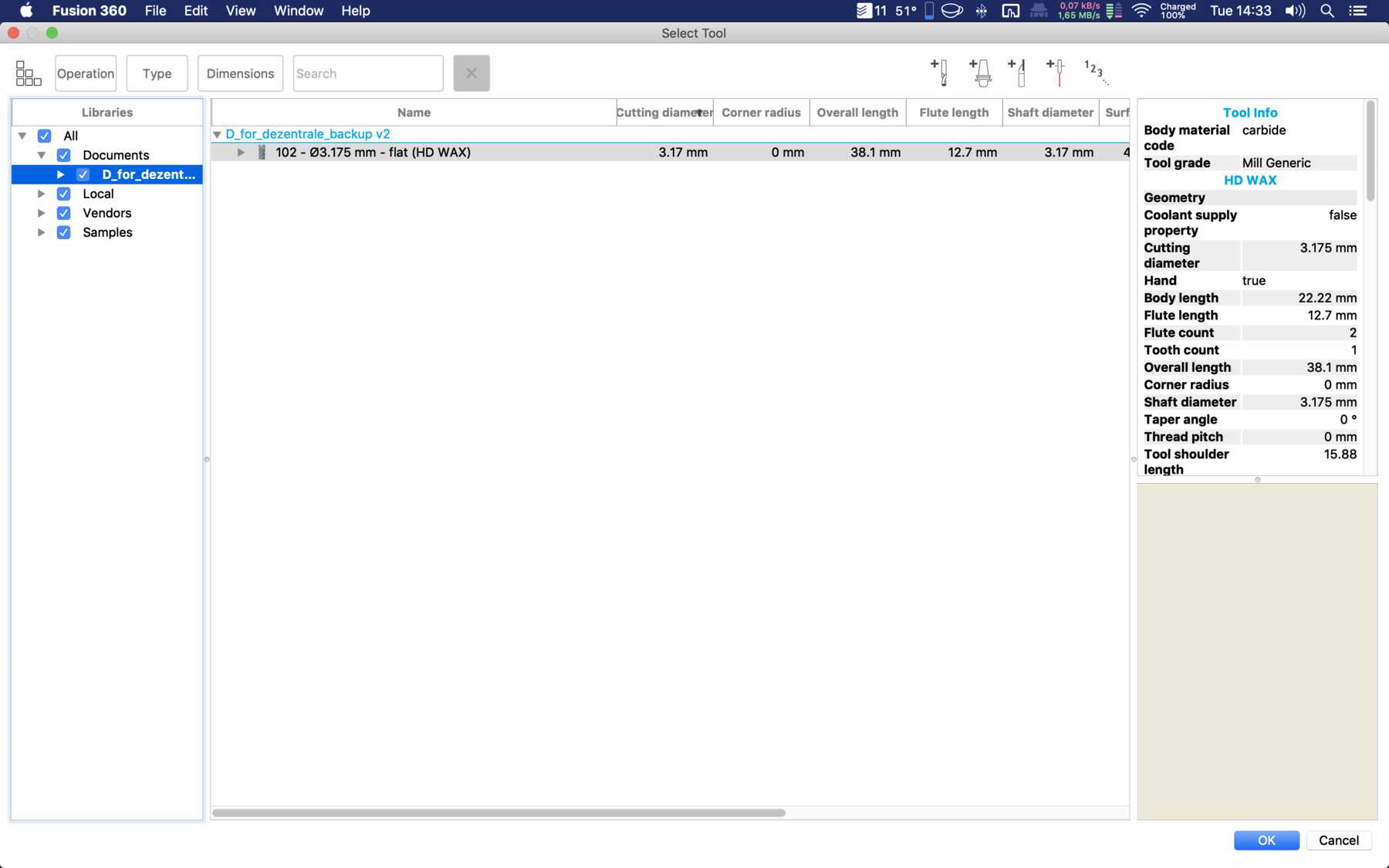

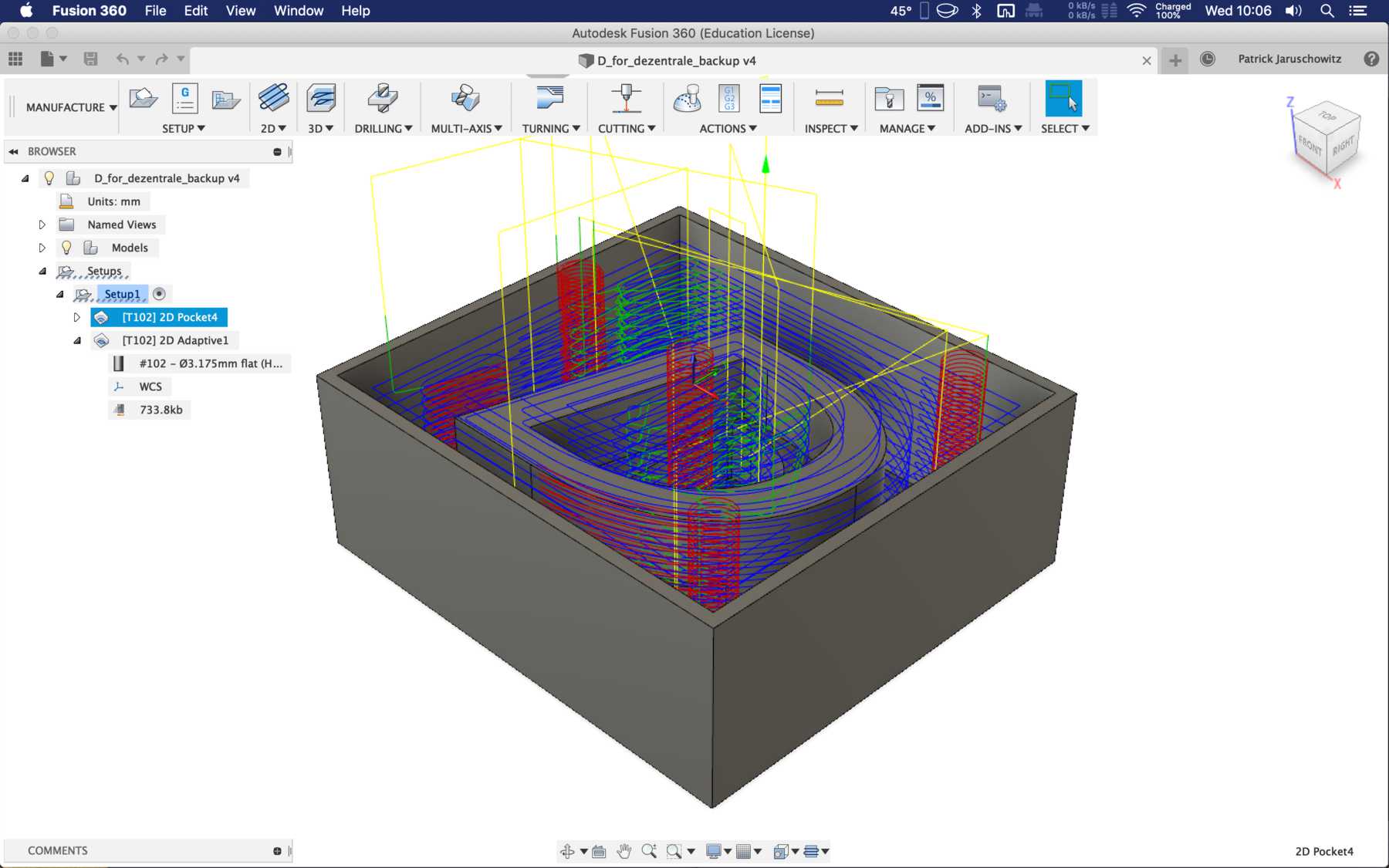

Next I have set the steps for milling with the Nomad 833 Pro. The parameters for the mills are adjusted and the parameters for wax milling I have from Carbide 3D their Wax milling videos:

I transferred the data to the Nomad 833 Pro and started the first milling process. With the following video I want to share some impressions I made - as always it was a lot of fun to watch the CNC-milling machine cutting.

Then I changed the milling settings from pocket clearing to adaptive cearing. You can see the difference while the process in the following video. I hope that it will be easy to see what kind of movements take place in this milling process, like making a lot of circles. This circular movement should save some temperature, but in a later exact comparison it rather led to an increase in temperature during wax milling.

Molding and casting

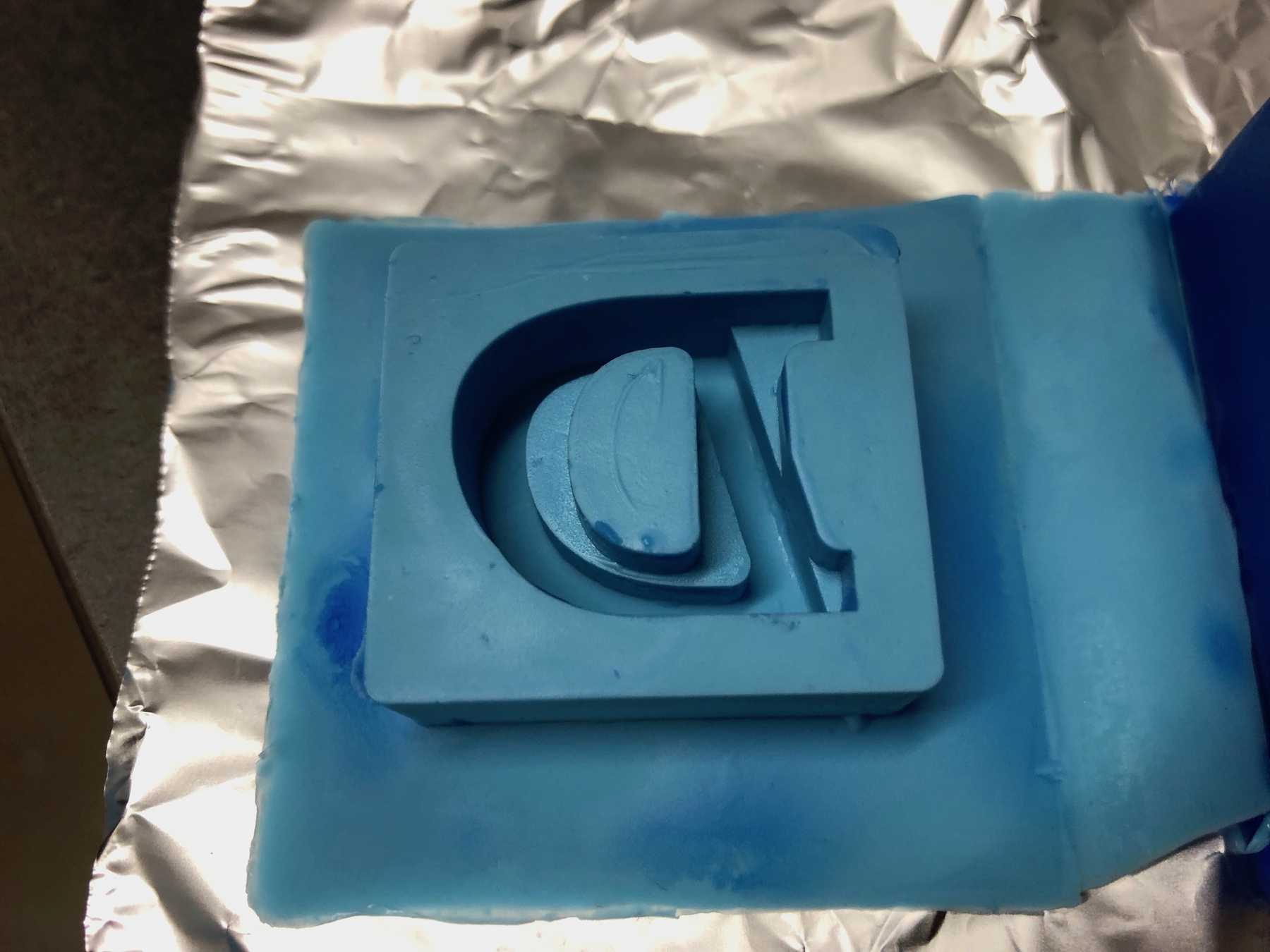

After some cleaning of some wax residues in the form of chips by the milling process, finally two original forms were finished:

First I sprayed it with Ease Release® 205 as release agent from a distance of 30 cm, so that an easier later removal of the silicone mould should be possible.

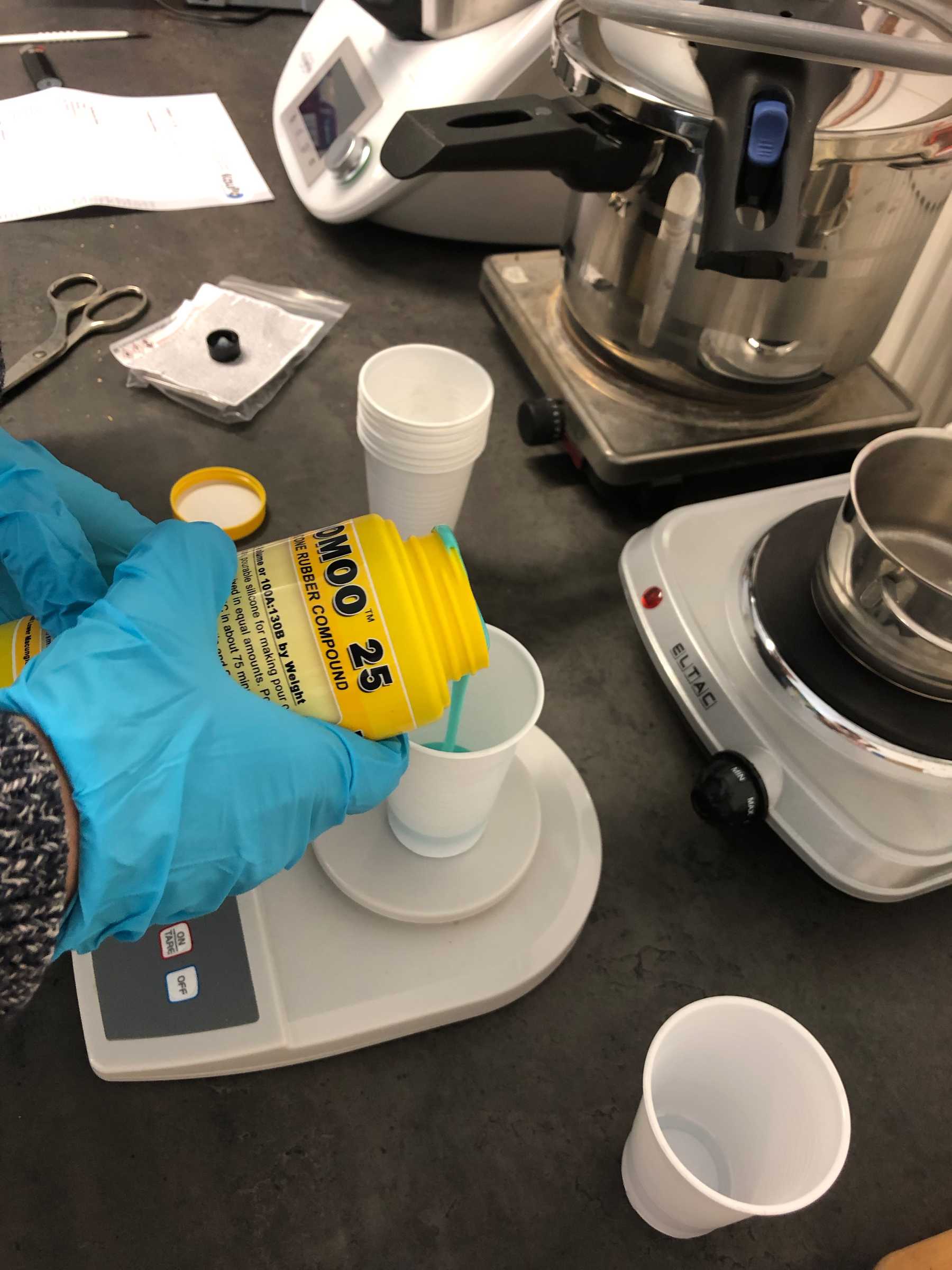

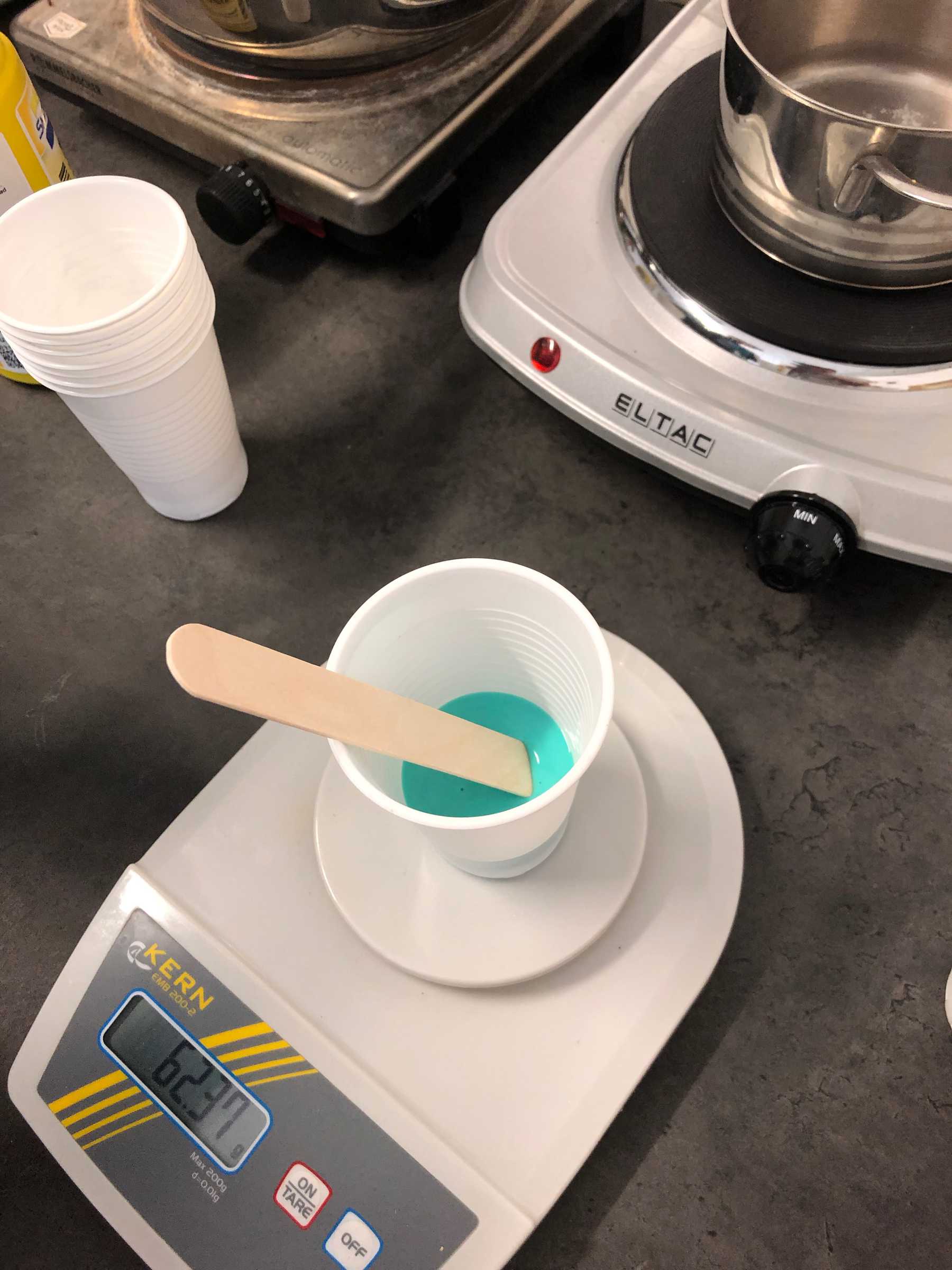

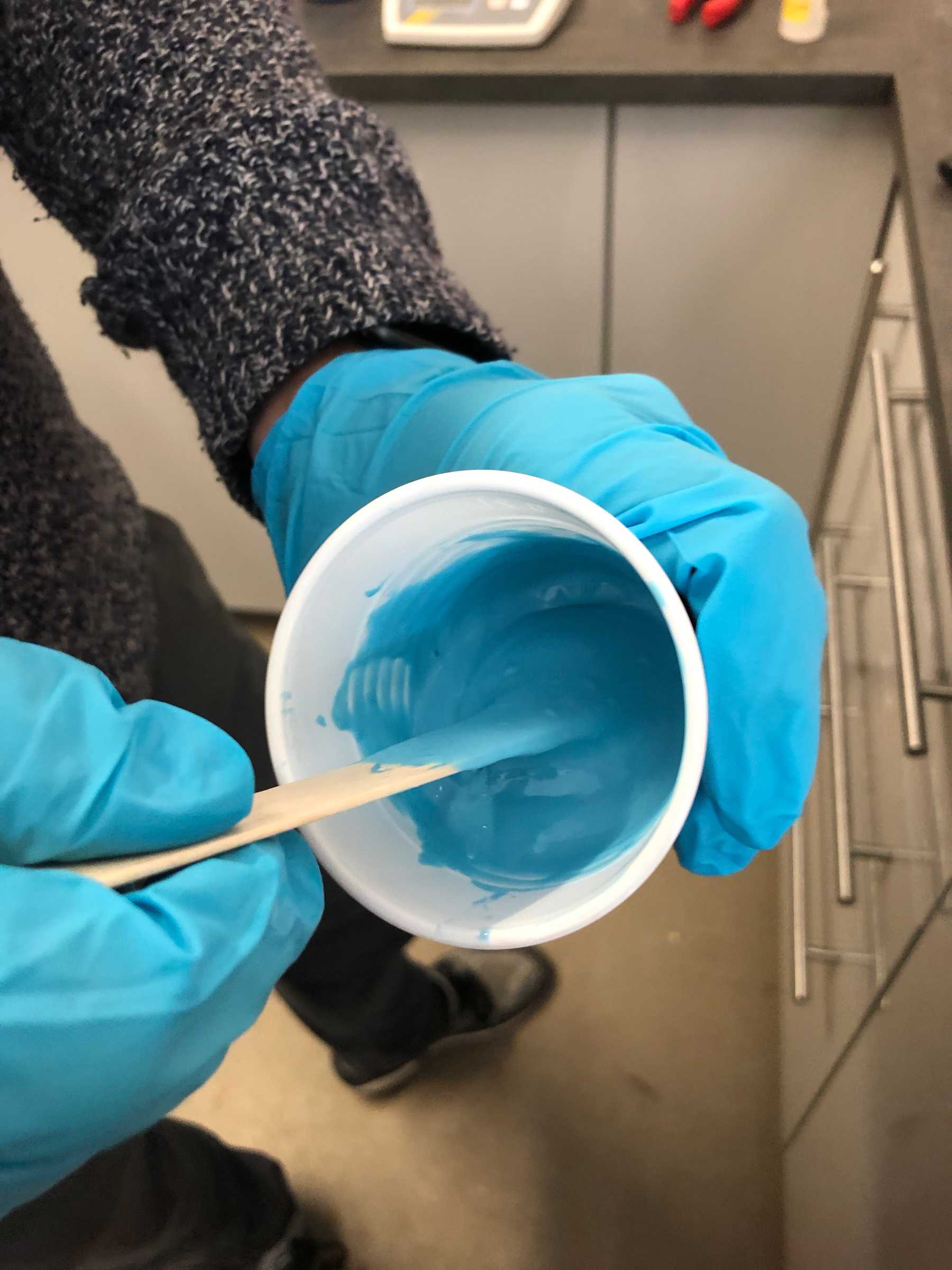

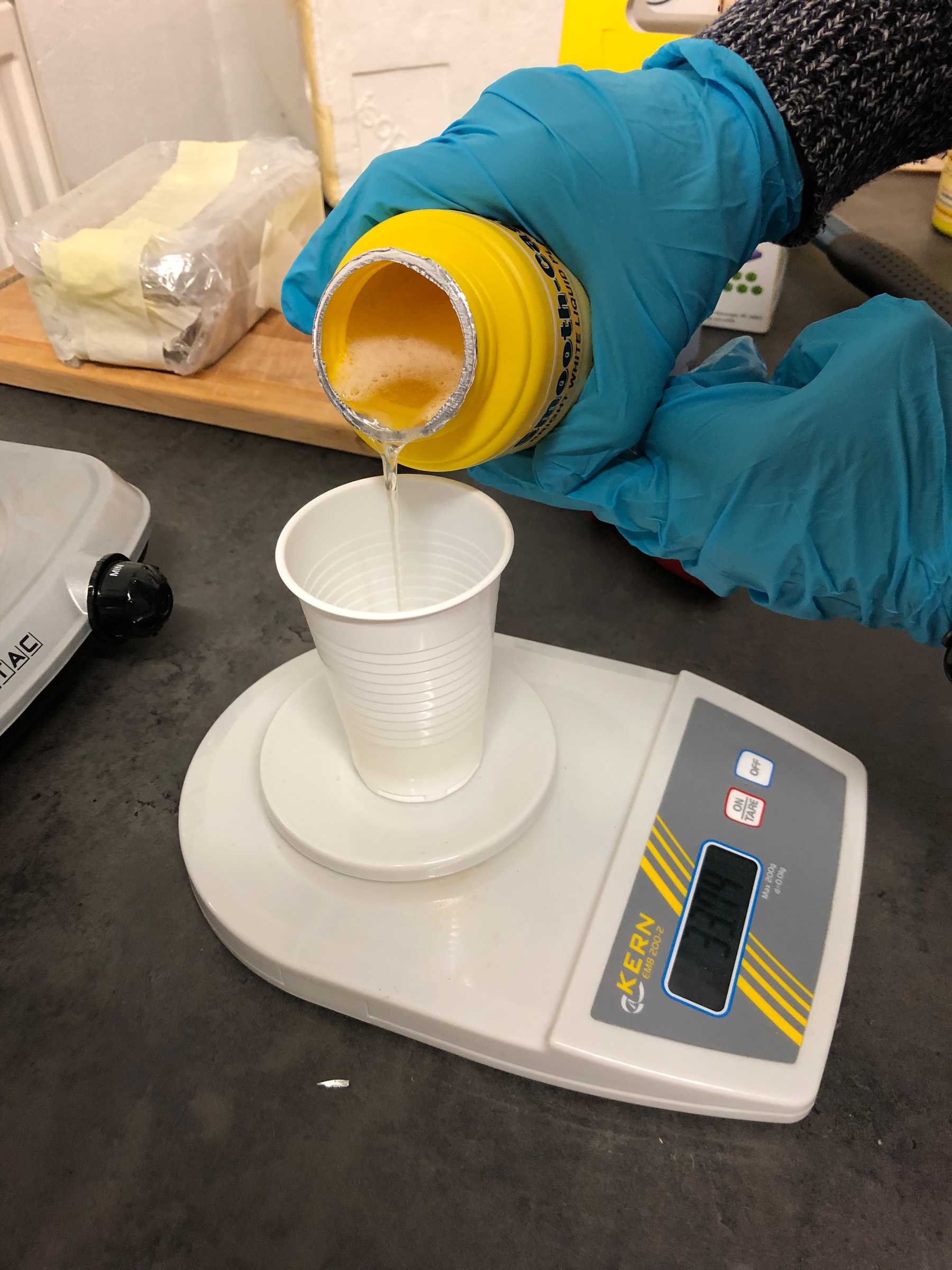

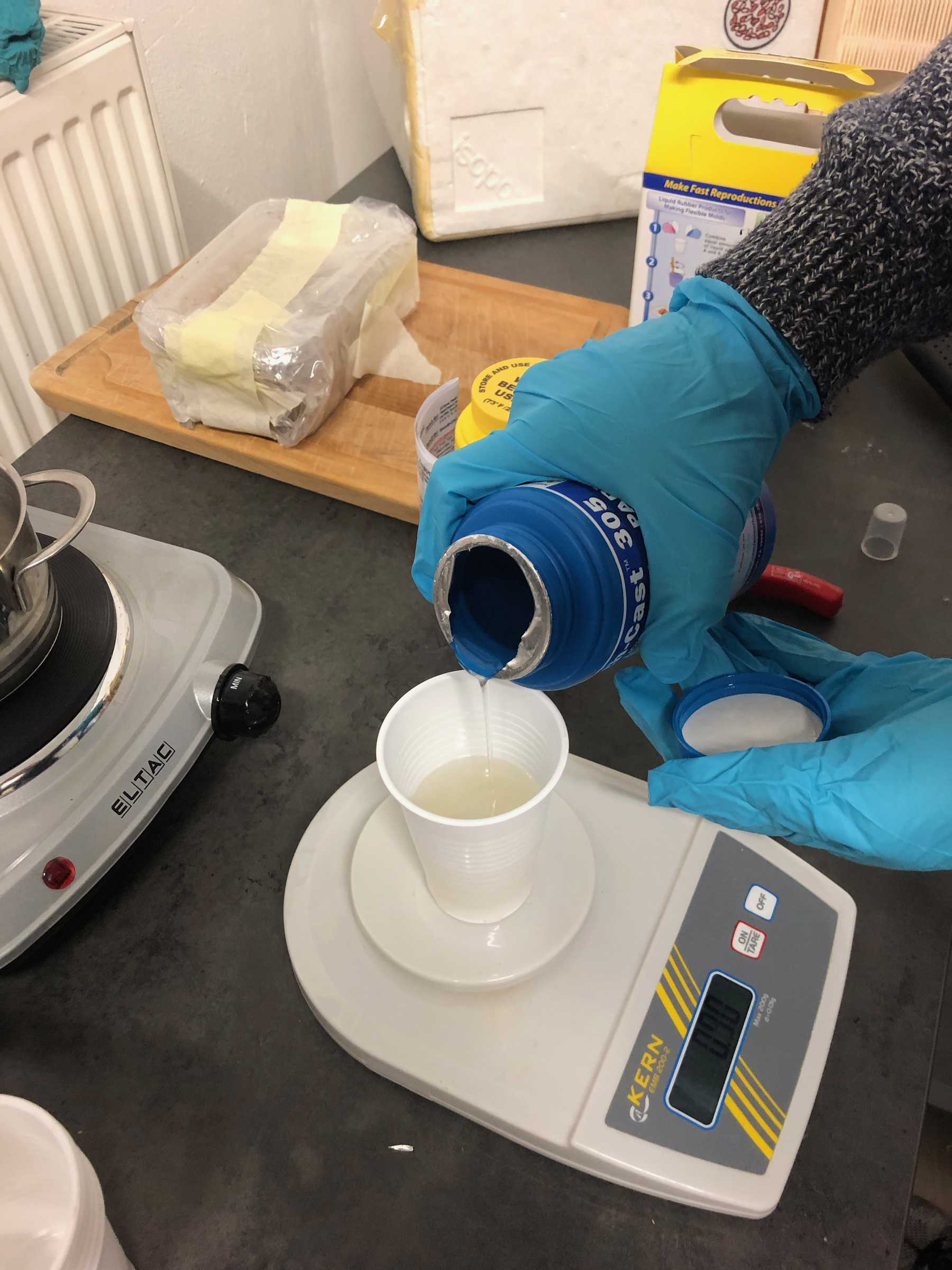

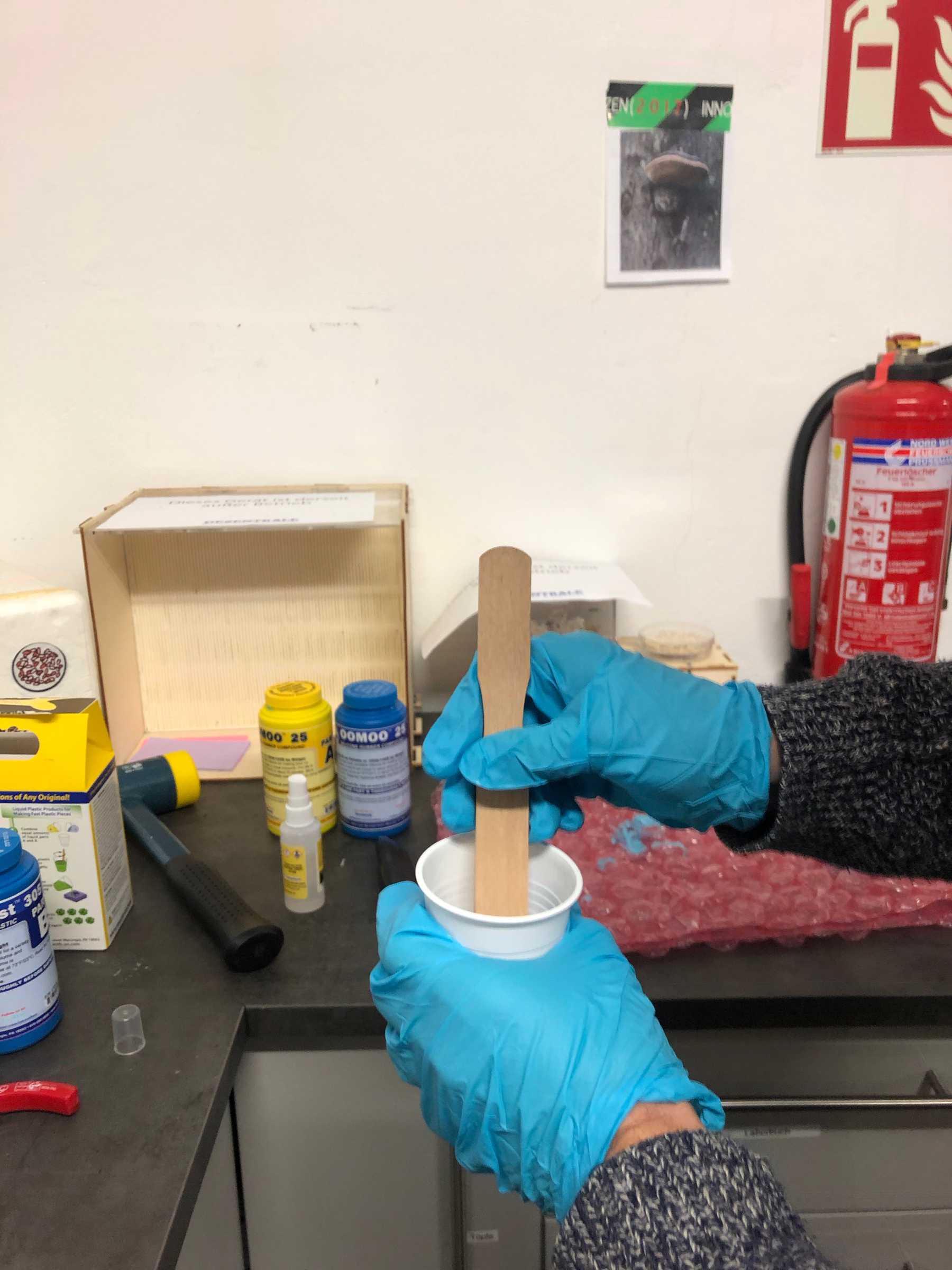

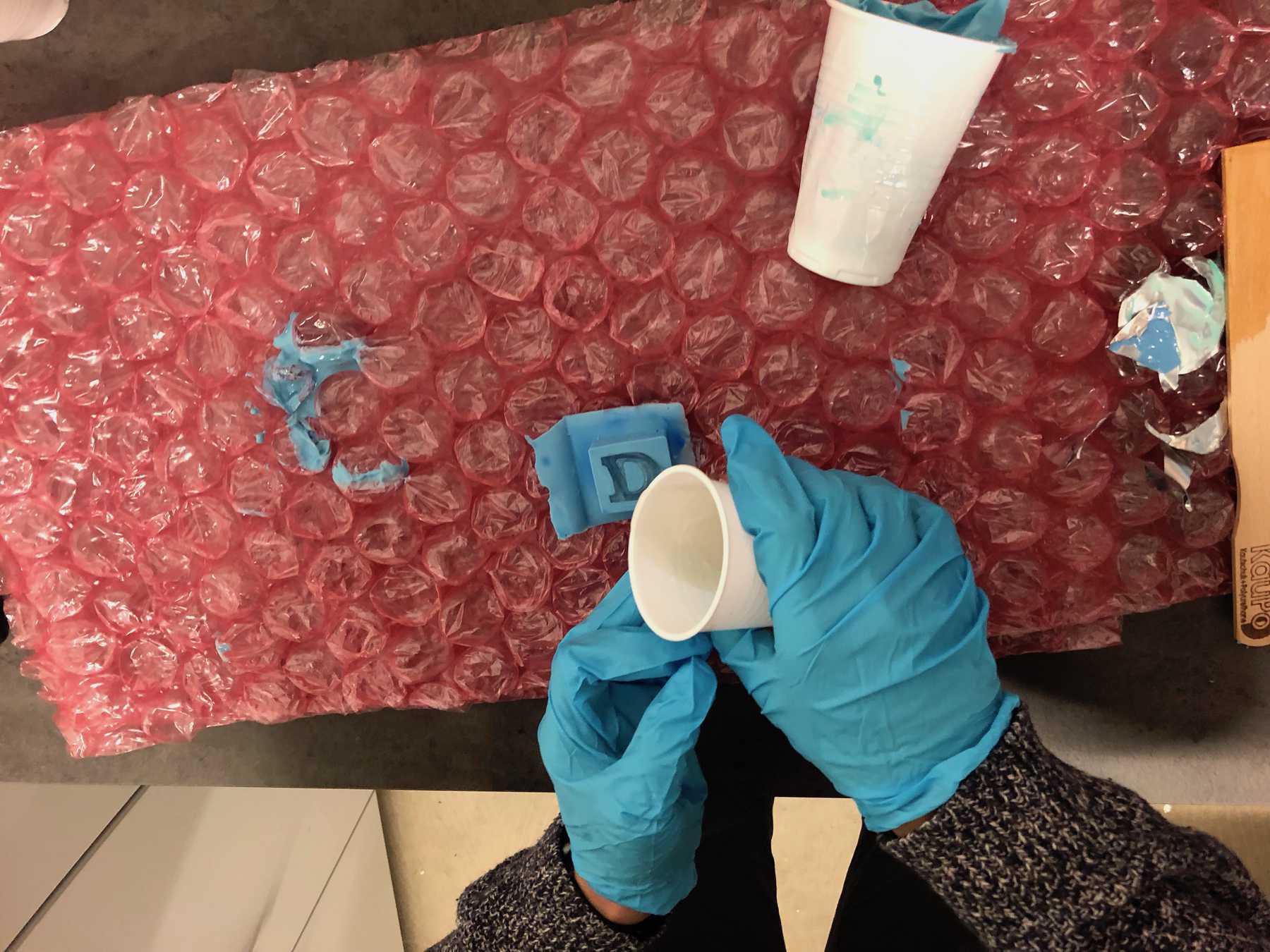

In the meantime, when the release agent should dry a little, I mixed the pourable silicone with the name Oomoo® 25. In a mixing ratio of 1A to 1B it had a pot life of 15 minutes, so I had to hurry. Weighed and then stirred for several minutes.

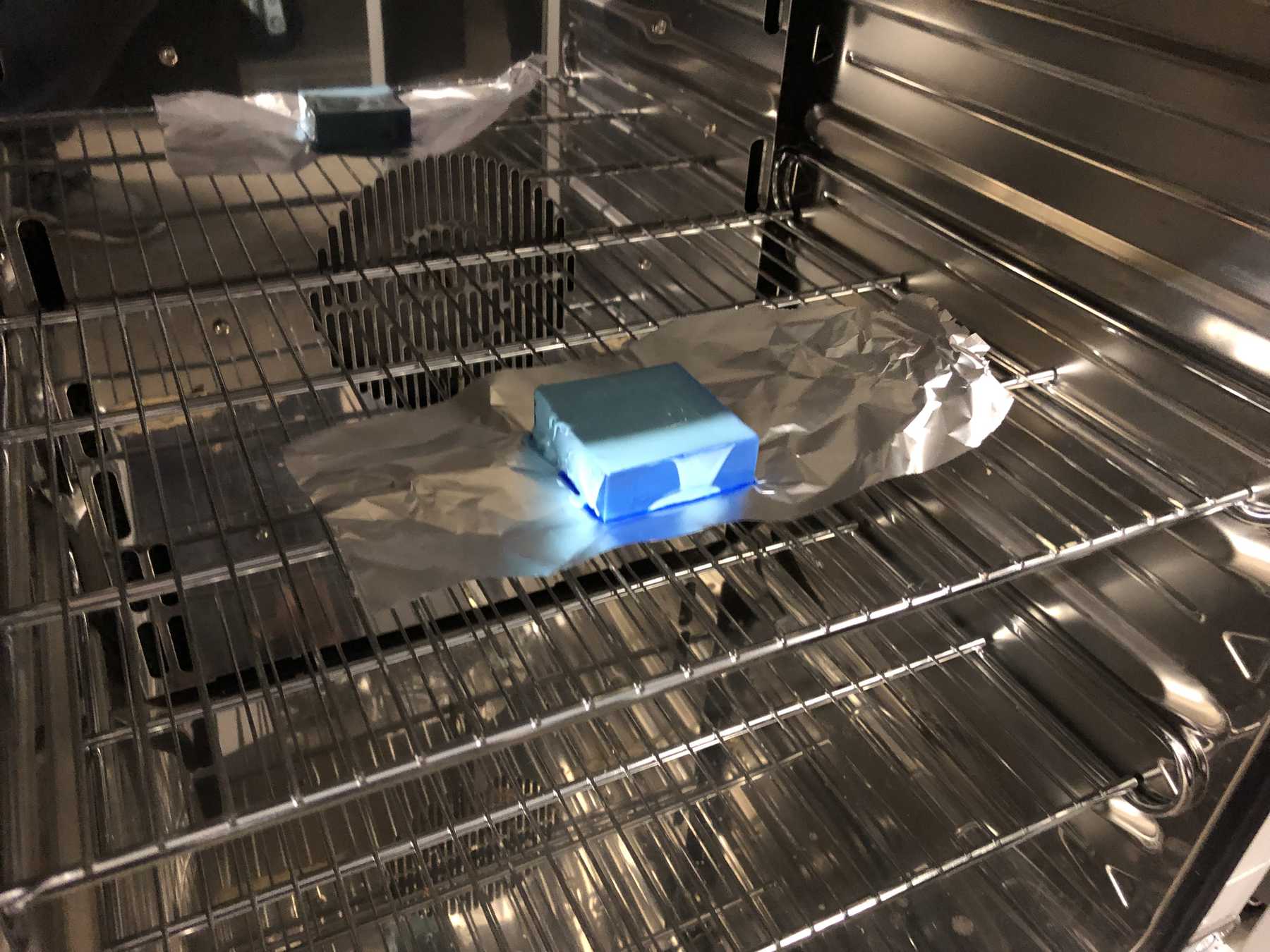

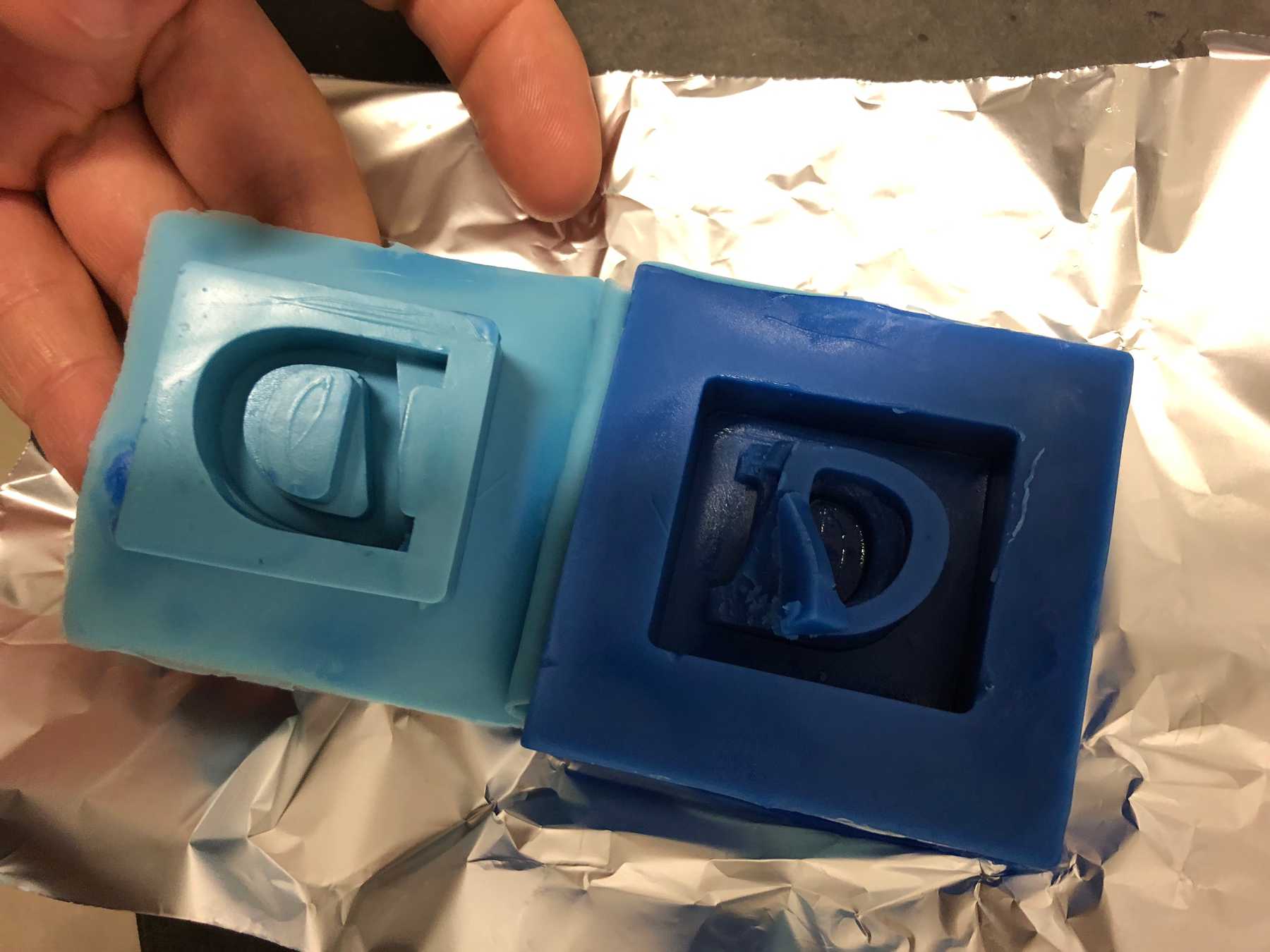

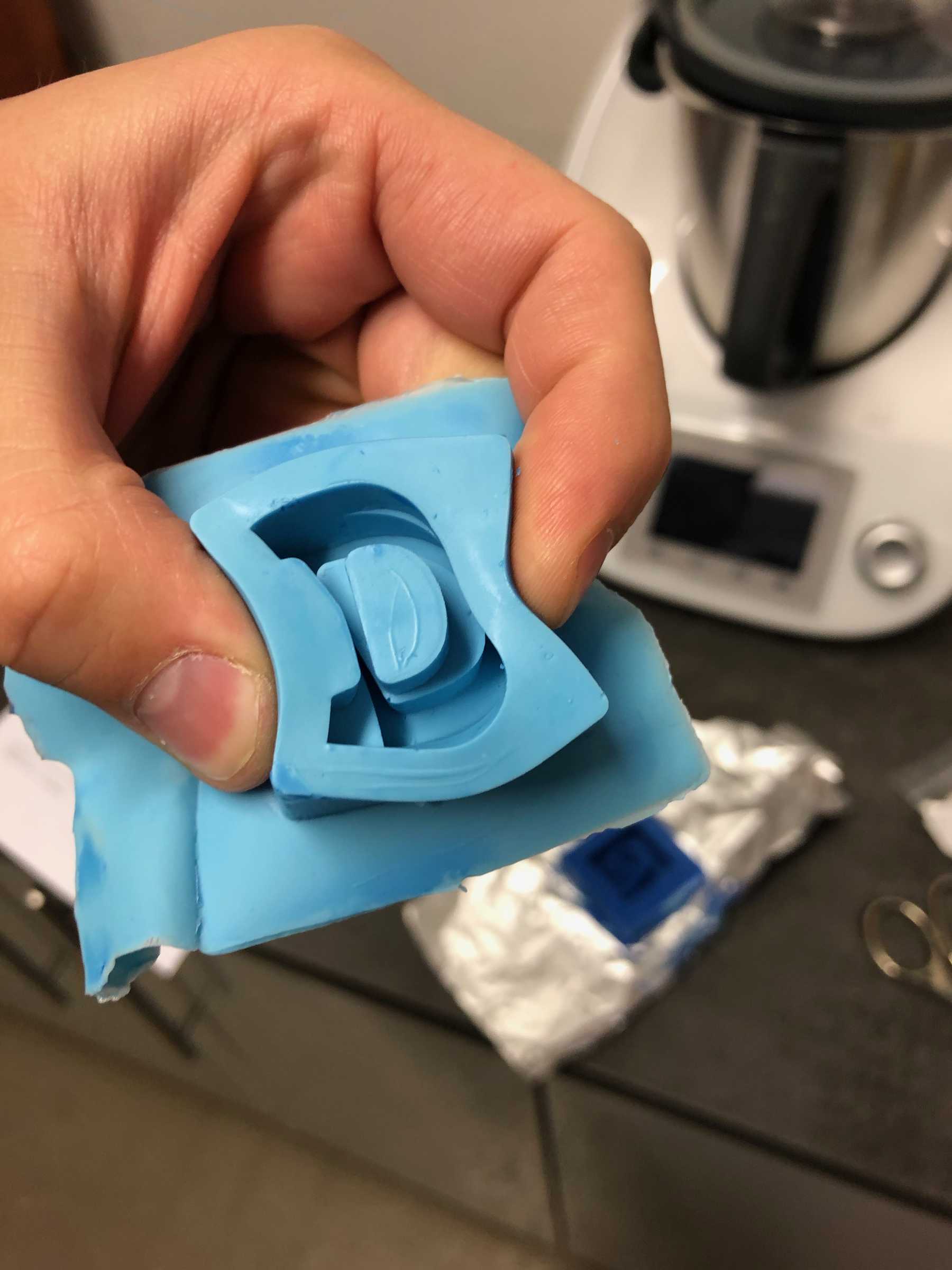

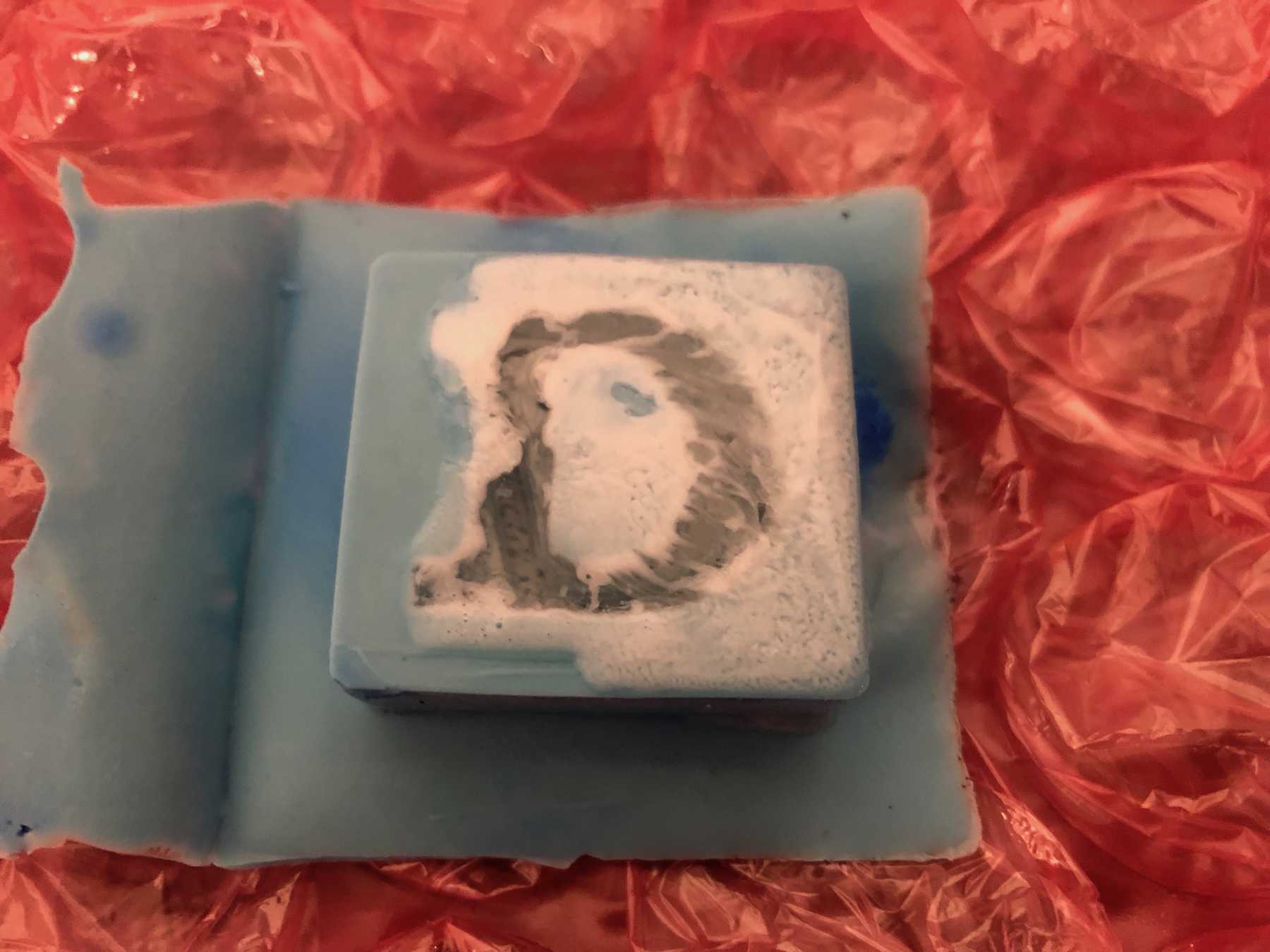

Then I poured them into the original mould, and stored them for at least 75 minutes, which is the same as the demoulding time. It was recommended to let the mould harden in the oven at 50°C for another 4-5 hours so that residual moisture and residual alcohols evaporate away. The result looked as shown below:

I was thrilled with the result! The surface is wonderfully flexible, the feel remarkable. I didn’t expect the result in this form. My test copy was ready and now came the next step.

As a casting resin I had the white Smooth-Cast® 305. I mixed it in a mixing ratio of 100A to 90B and then stirred it for about three minutes to get a homogeneous mixture. But this doesn’t seem to have been really successful, as you could see from the later result.

The pot life in this case was 7 minutes, even less than before. I sprayed the silicone before with Ease Release® 205 as release agent and afterwards, perhaps too early, used it. After the Fab Academy I’ll try this even more closely and probably more often, because it was a lot of fun! I poured this into the silicone mould.

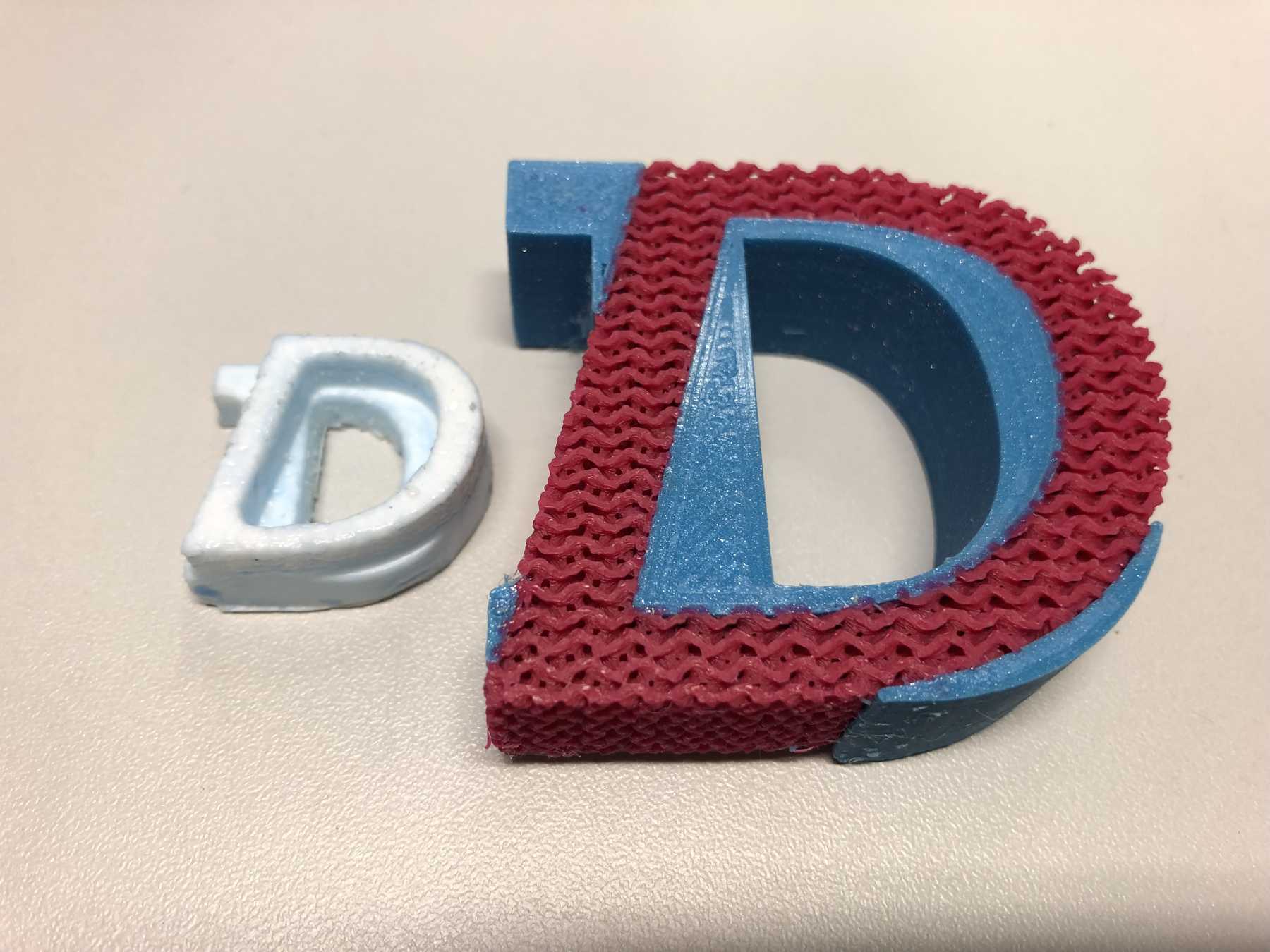

After a demoulding time of 30 minutes and a subsequent curing time of 4 hours at 65°C, I had the following result:

Conclusion: My final result still has potential! But I will deal with it more in the future, because it was a lot of fun!

Here you can download the files mentioned above:

Step file of the D from DEZENTRALE

SVG file of the DEZENTRALE logo