Lesson 7 - Computer-Controlled Machining

Something big...

The assignment of this week was a little tricky... although the course mix between creativity and fabrication

the challenge was to try to justify the use of the CNC and to use the CAM as a tool that serves out needs, create something big is a very open title..

My first thought was to create a table I have designed years ago, while the real challenge was to use only the CNC machine and to mill it.

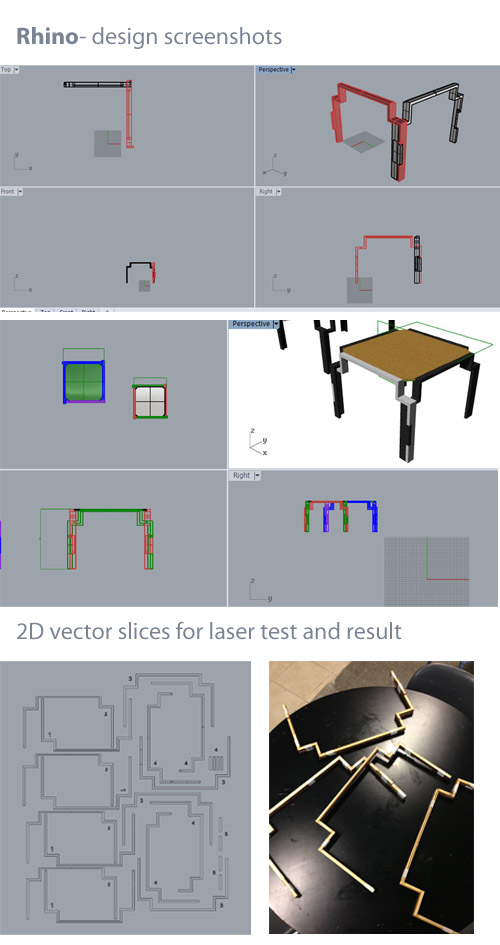

I have taken the old files and created in Rhino the adjustment for the table legs.

I have cut a small scale model of the table in the laser machine in order to understand if it is worth to mill the table in the CNC

...my conclusion was that it is possible but I prefer to challenge myself with a new project

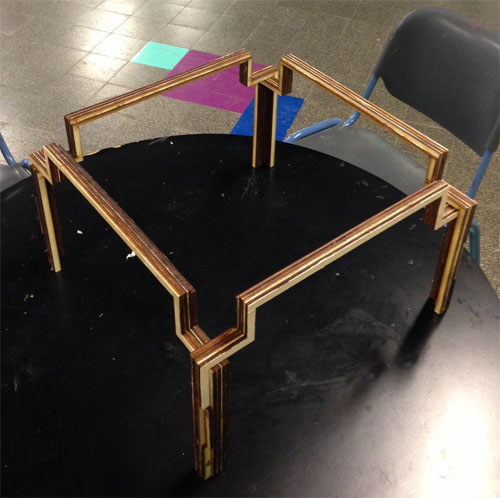

Therefore I have changed course and started to explore about joining two surfaces together in order to get an ornament.

I have been influenced by the

mashrabya which are the Islamic ornaments that are based on mathematic rules, mostly placed on windows.

The reason for two layers attached is the idea to use two different materials in the ornament,

so I had to break the ornmaent I have created to 2 layers.

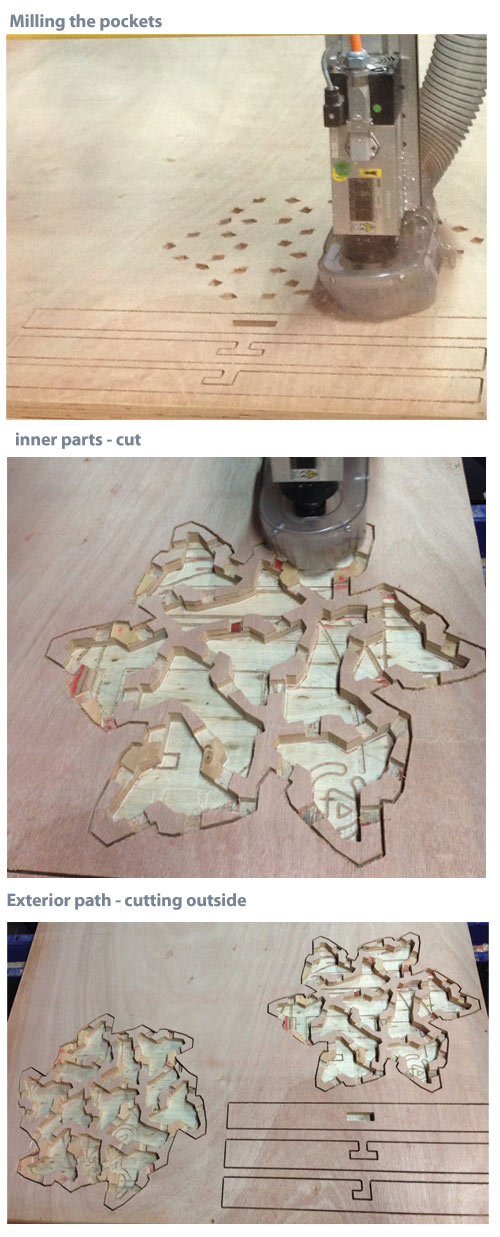

Planning the ornaments surface

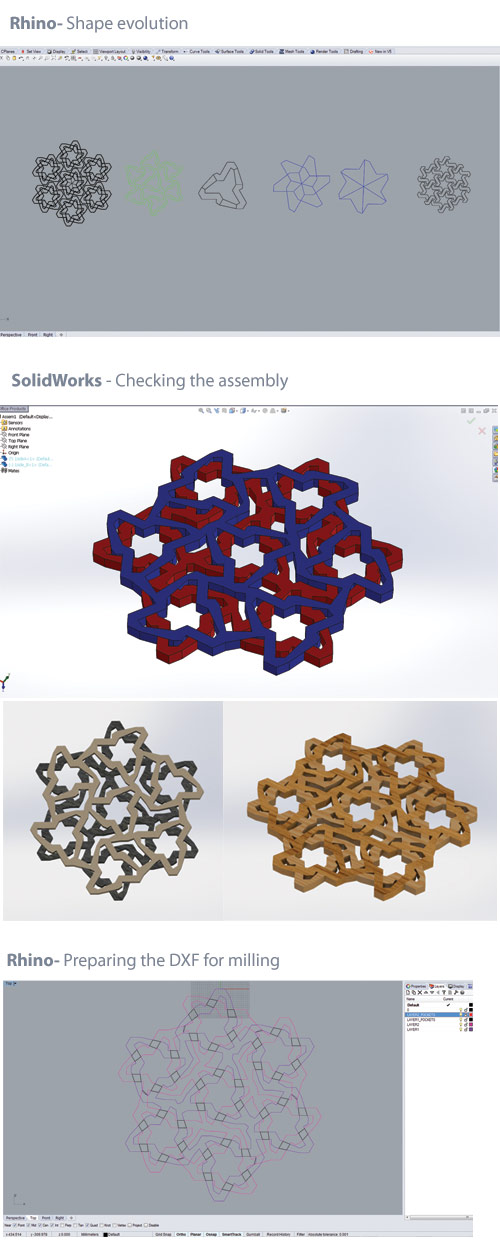

The first steps were the planning , I have created the ornament and designed it using Rhino and Solidworks, I was 3D model the outcome in order to Boolean difference between the surfaces,

than I had the "pockets" to be milled from both surfaces.

I have created a DXF file while keeping 4 layers:

The 2 surfaces to be milled out and the 2 pocket files - one for each surface.

I was working with PartWorks 3.5 that I finf very user friendly and easy to learn.

when I approached to the machine I had to create 3 files for each surface -

1.POCKETS

2.IN

3.OUT

It was working fine...

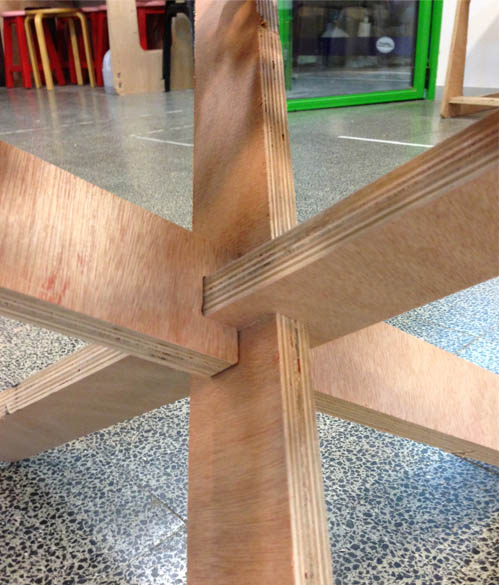

Legs

I always wanted to understand the geometric locking systems and this was a great opportunity to do so,

while searching over the internet I have found many methods and locking systems in wood.

Many of the systems have required a diagonal cutting, which in our case was hard to establish with the CNC we had.

so I was touring for a nice locking that fits the requirements,

I was creating a few trials in different size in laser and 5mm wood ,

afterwards I have calculated the relations to the desired legs for the table.

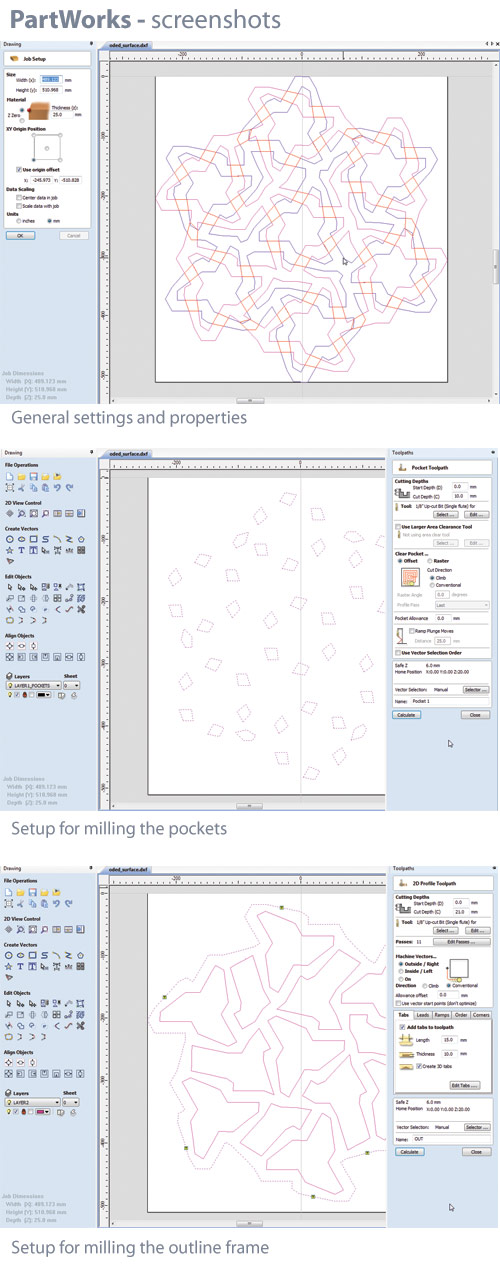

I was very pleased with the outcome

Outcome

At the end I had a kind of a table,

which I have few more things to work on in Order to complete it.

download files for mashrabiya HERE (right click and save as)

download files for table legs HERE (right click and save as)