Lesson 5 - 3D Scanning and Printing

By nature, the world of 3D printing is not new to my profession, I meet the models on my everyday work as an Industrial designer,

and since we started to create models and print them, the world of hand sculpturing models of small scale products became faster and simple.

3D printing - design

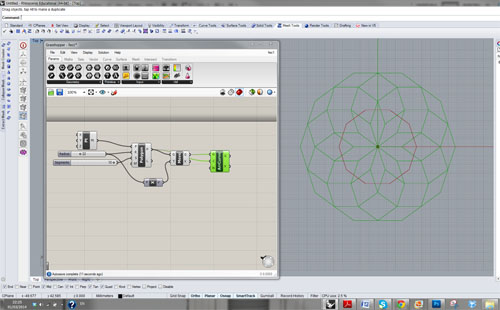

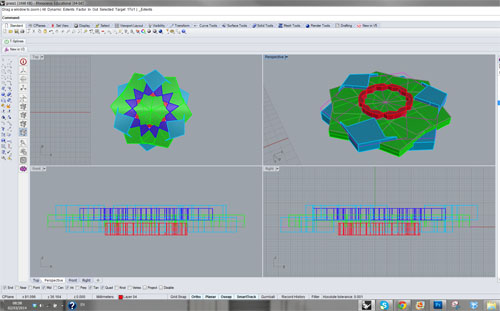

I have tried to use Rhino and Grasshopper to design my 3D object,

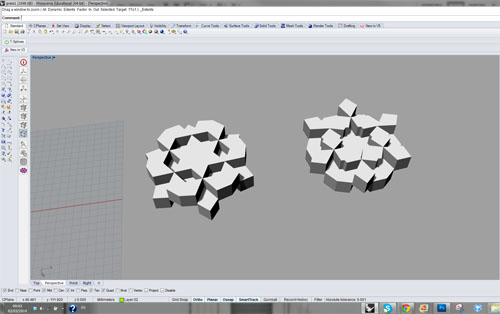

and after few runs I came out with a 3D pattern that i liked.

The Grasshopper was creating many possibilities to play with, I had to stop playing at some point...

Then I was exporting in STL format and optimized the polygons to try to cover the design with no missing triangles.

There are many tools to repair the polygons. I have used Rhino, Netfabcloud, minimagics, and meshmixer

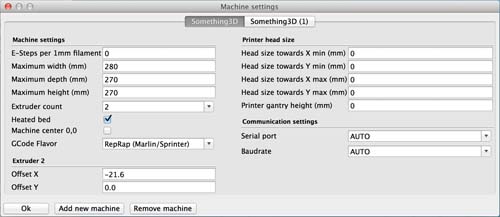

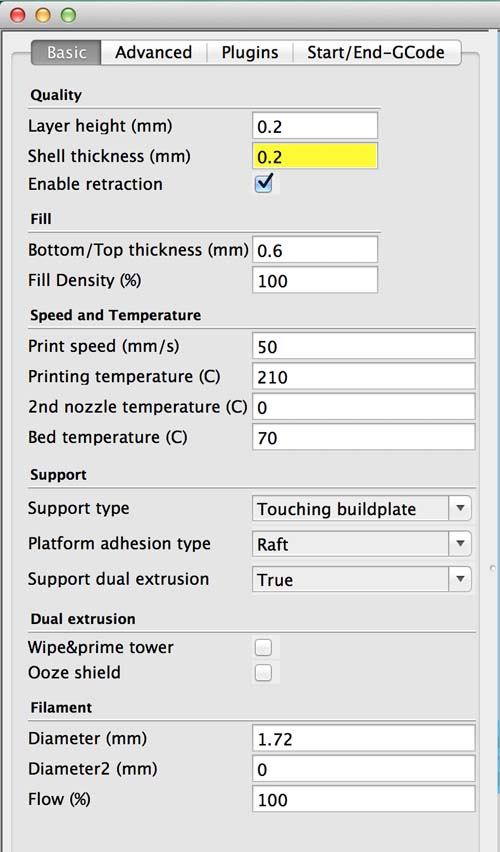

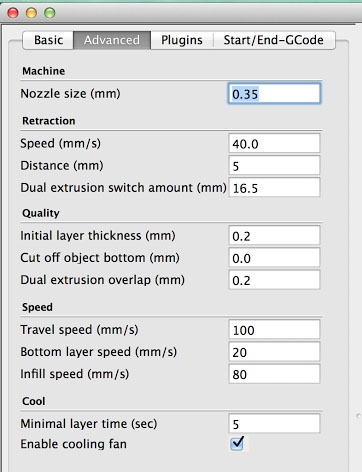

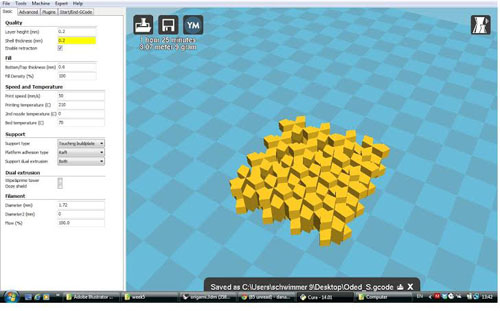

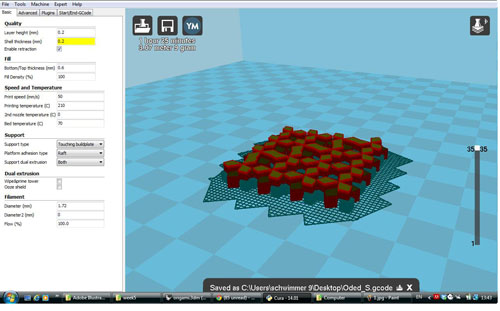

The repaired STL we have opened in CURA, at this point we had to optimize the file for printing and the printer values.

The next screen was dealing with the way we would like to print and mechanical definitions of the extruder.

(how fast and how hot the extruder will process the material).

The Cura also shows the model on the bed, angel of printing and supports in a graphic way.

Printing

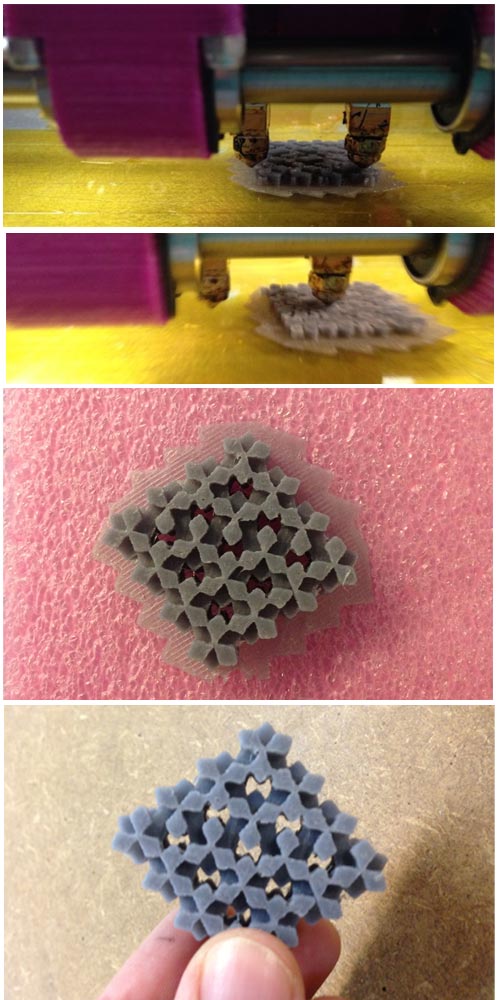

This file was inserted to the machine - from the machine (pointer face) we have opened the Gcode.

The printer was pre-heated to the both - base and extruser right temperature, we have checked the ABS fiber and its connectivity,

we did a check up and we saw that the ABS is responding well, than..it was just a matter of waiting while the printer finish to work.

In the middle of the printing, the ABS string was breaking and we had to relaunch the printing, so I have changed the color...

We had to re-launch the printing...Now it went fine.

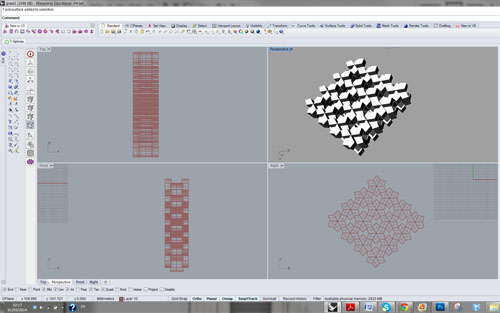

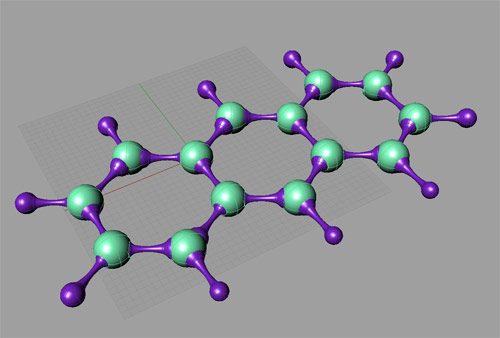

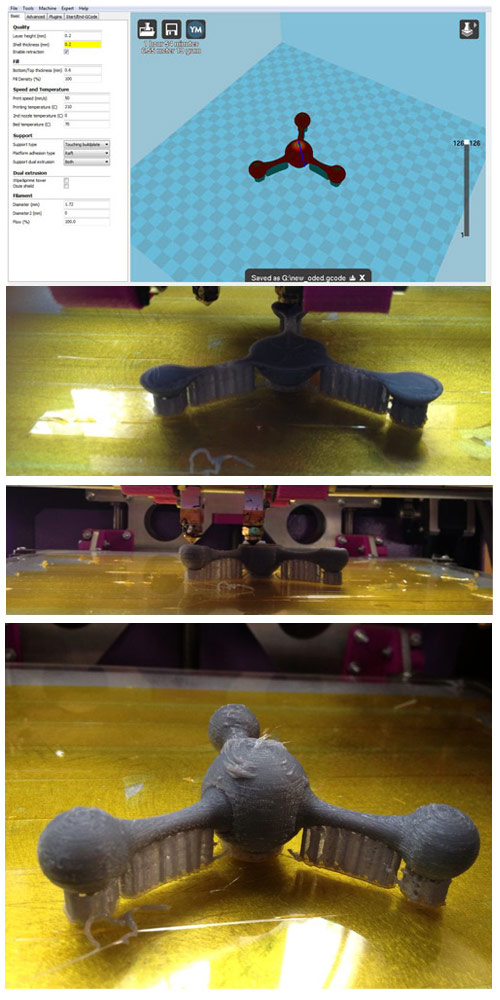

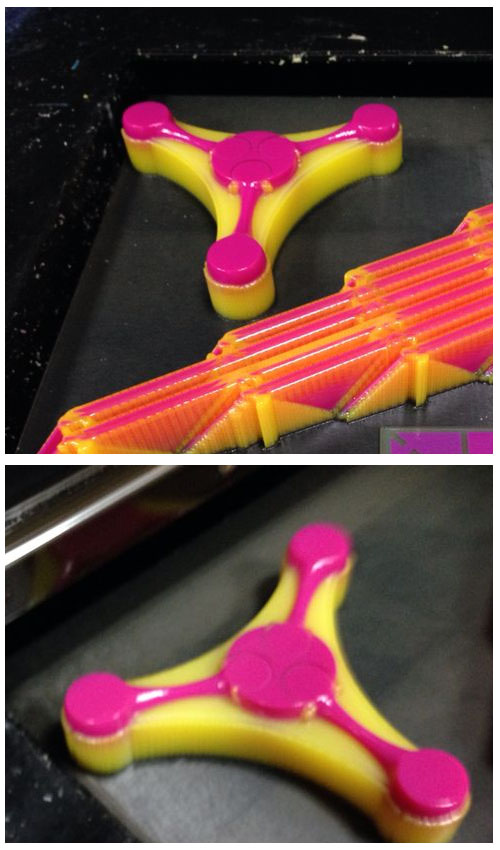

Later on..I have tried to design with Dana a triple hinge arms from 1 print,

in order to examine the base detail for a continuous flexible net by multiple the object.

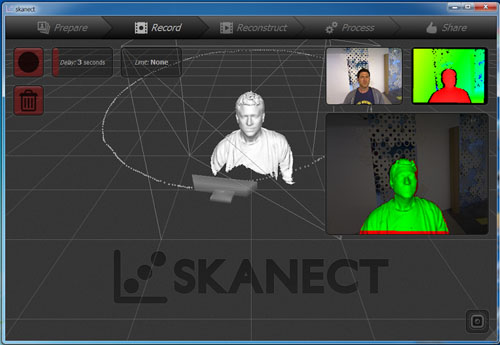

3D scan

We have scanned with the kinect camera - by primesense.

The software we used was Skanet and we had fixed the polygons later on with the Meshmixer

We had to do several trials in order to define the best position and speed to be scanned. (6fps)

Thanks to Ohad and Stratasys education department and Daniel Dikovsky - A manager at Stratasys R&D,

We had the great opportunity to design an object that will carry 2 materials. One of the materials is a flexible polymer, while the other is hard.

The printer has the ability to print products as if they were co-injection molded.

File-wise - the materials should be divided into as many files as materials,

The Extruder contains the two materials and release each time the right material accordingly and accurately. This was printed in Connex printer

download the file here (right click - save as )

you can see it in thislink