Building a 3d model on rhino5 of an axis head to run some tests

A longtime ago I’ve learned rhino at school and that’s the reason I used it for these task.

First I started by drawing a circle , than using offset curve

, than using offset curve I drew more concentric circles that I copied to a certain distance, by making a line

I drew more concentric circles that I copied to a certain distance, by making a line  and using mirror

and using mirror  in the mid point of that line. From there i made more horizontal and vertical lines using some of the above tools, and used trim

in the mid point of that line. From there i made more horizontal and vertical lines using some of the above tools, and used trim  to take out the some parts off the lines leaving behind just some out lines do extrude my model.

to take out the some parts off the lines leaving behind just some out lines do extrude my model.

Press Fit

I started my press fit task based on a triangle as base material I used some old 3mm acrylic from a store front.

2nd - some basic ideas I already have in mind…( at this point everything is changeable):

Motors - I intend to use dc motors for many reasons, the 1st one being they are more common, then it's easier to buy a used powerful one. And, as I recovered many encoders from hp printers, I can get the proper positioning feedback I need; and the 2nd reason is that I'm going to learn how to read and control input and output devices, nothing better than combine them both on my final project. With hi-torque, both stopped and in motion, good gear reduction, hi-durability and being available as cheap used parts, I found car window and windscreen wiper motors to be apparently ideal for my project…

mecanic comcept

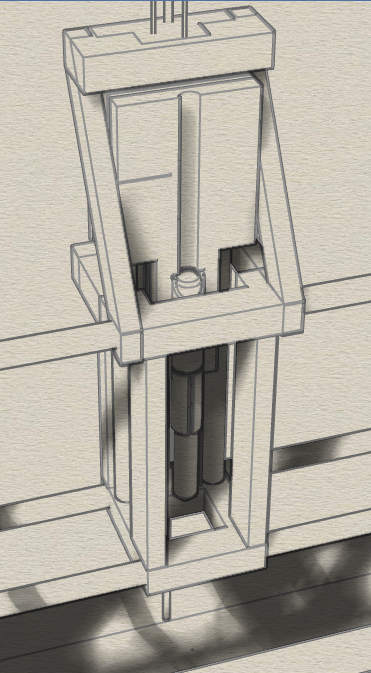

This is z-axis. It was conceived to have the better reach I could envisage and so made the longest and as less cumbersome as possible.

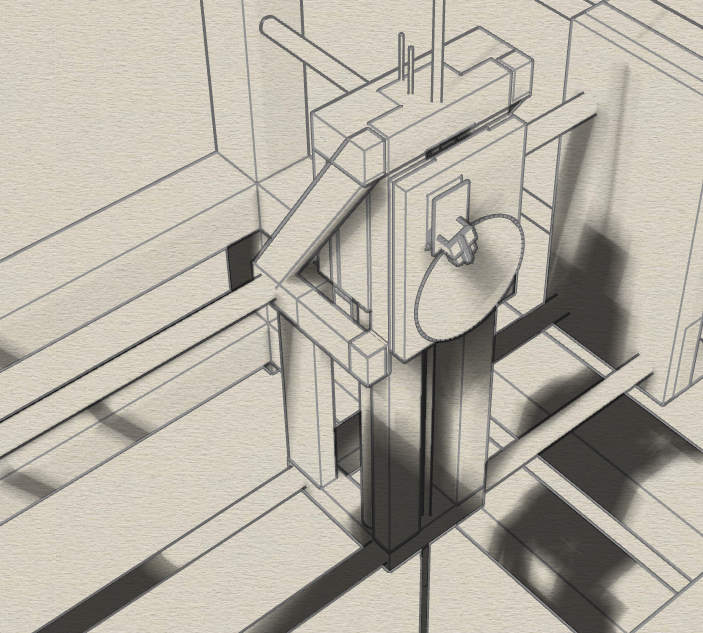

The encoder location and setting.

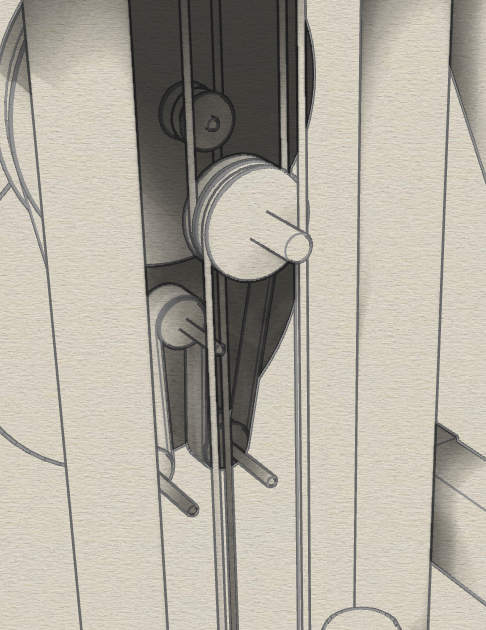

Inside cut of axis by the encoderside showing some of the cogs behind it.

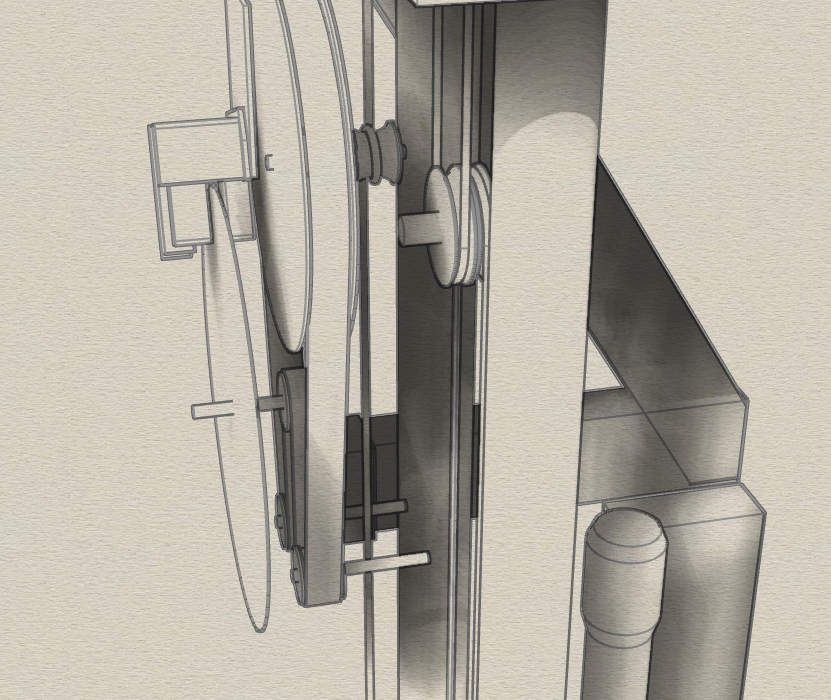

Cut view showing the support and the pulleys and the attachment to the spindle.

The pulley system, axis mouvement and encoder. (Front and side view)

see https://drive.google.com/folderview?id=0B-zSpF8Sy3QLM0pIZmw4c1lRb1k&usp=sharing for files

Guilherme Moreira | 18-01-2014 | 04:46 AM | Lisboa | Portugal | para Fab Academy 2014 (pt)