Guilherme Moreira

Growing up with a Philosophy and Arts and crafts Teacher and an Electronic Engineer soon I started to feel some difficulty on focusing my interests on some specific area or subject, always with the certainty that I love to get my hands dirty, understanding and building things. Therefore, I found myself in a big dilemma when having to choose between arts and science on high school. Following the 1st one I entered the best Specialized Arts high school in the country (Escola Secundaria Especializada no Ensino artistico Antonio Arroio), where I had the opportunity to experience each semester one of the 6 professional classes they had: ceramics; textile; audiovisuals; graphic design; product design and jewelry with which I fell in love and stuck to this day.

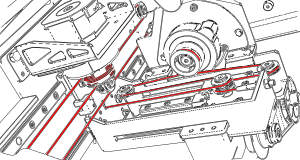

Building a 3d model on rhino5 of an axis head to run some tests

A longtime ago I’ve learned rhino at school and that’s the reason I used it for these task.

First I started by drawing a circle , than using offset curve

, than using offset curve I drew more concentric circles that I copied to a certain distance, by making a line

I drew more concentric circles that I copied to a certain distance, by making a line  and using mirror

and using mirror  in the mid point of that line. From there i made more horizontal and vertical lines using some of the above tools, and used trim

in the mid point of that line. From there i made more horizontal and vertical lines using some of the above tools, and used trim  to take out the some parts off the lines leaving behind just some out lines do extrude my model.

to take out the some parts off the lines leaving behind just some out lines do extrude my model.

Press Fit

I started my press fit task based on a triangle as base material I used some old 3mm acrylic from a store front.

2nd - some basic ideas I already have in mind…( at this point everything is changeable):

Motors - I intend to use dc motors for many reasons, the 1st one being they are more common, then it's easier to buy a used powerful one. And, as I recovered many encoders from hp printers, I can get the proper positioning feedback I need; and the 2nd reason is that I'm going to learn how to read and control input and output devices, nothing better than combine them both on my final project. With hi-torque, both stopped and in motion, good gear reduction, hi-durability and being available as cheap used parts, I found car window and windscreen wiper motors to be apparently ideal for my project…

Guilherme Moreira

who's that guy …

Growing up with a Philosophy and Arts and crafts Teacher and an Electronic Engineer soon I started to feel some difficulty on focusing my interests on some specific area or subject, always with the certainty that I love to get my hands dirty, understanding and building things. Therefore, I found myself in a big dilemma when having to choose between arts and science on high school. Following the 1st one I entered the best Specialized Arts high school in the country (Escola Secundaria Especializada no Ensino artistico Antonio Arroio), where I had the opportunity to experience each semester one of the 6 professional classes they had: ceramics; textile; audiovisuals; graphic design; product design and jewelry with which I fell in love and stuck to this day."

To pursue this passion of mine I went on to two professional schools. The first one was more directed for author jewelry, so they were less focused on technical skills that on design and conceptual ones. That made me transfer to the second professional school (C.I.N.D.O.R.) which was created to prepare new specialized workers for our national jewelry industry, becoming one of the best Jewelry Schools in Europe and the only one in all the world with my speciality that is Portuguese filigree. In there I met my second love in life with whom I made my ultimate master piece, my daughter who taught me it was possible to take love to new heights and gave me more energy to continue my quest.In my way to leave the author jewelry market and throw myself on a small serial production micro family business, talking about CNC ( Computer Numeric Control ) machines with a friend (designer), she told me that she had heard about a place where I could work with them. But there was more about that place she had not told me. That unthinkable place was more like a hall with endless unlocked doors full of challenging knowledge and building skills to be learned, to help open these doors there were three interesting and enthusiastic nice guys who, in the process, challenged me to help them open a few more. More recently I have opened the big door of Fab Academy that I intend to use to open all other doors ...

Global idea

Let's a build cnc milling machine

1st - what do I intend it to be:

Number of axis – in my working area I need one with at least 4, obviously 5 would be great. If you are looking to design one yourself I advise you to start with the pictures on this webpage. They give you a good idea of almost all the possible machine configurations as well as the name usually used to define the axis http://www.cnc-toolkit.com/support.

htmlFast – yes but I will happily give up on speed to increase precision and accuracy-Precise and Accurate – yes as much as can build it, they are the most relevant features in my projected Heavy-duty – of corse it would be great to build an all-in-one but I will mill mostly lost wax, so let's see what I can do…

4th and 5th axis working angle - these are for me the 2nd on the most important features.

Final project proposal

5 axis cnc milling machine

5 axis cnc milling machine

As a jeweler I’ve been searching 4 and 5 axis cnc milling machines for a long time, hoping to find one within my small “Portuguese Budget“ with the hi-precision I need. During Fab Academy, I propose myself to build a 5 axes milling cnc machine with hi-precision (less than 0.1mm )and as most 360dgrX360dgr-capable as it can. The torque must be as high as possible without affecting any of the previous technical features, as it will be mostly milling molding wax, and I can always build another one later.

Press Fit

I started my press fit task based on a triangle as base material I used some old 3mm acrylic from a store front.

With this 2 limitations and with some inka inspiration I start dreaming about a modular lamp that is still a work in progress but as press fit was the the real task at hands let's try the press fit i design for the modules

At first i drew a snap fit, but I realize it was too small and easy to break, so I change it to a more conventional press fit and add it a little security deformation at the edge.

see https://drive.google.com/folderview?id=0B-zSpF8Sy3QLM0pIZmw4c1lRb1k&usp=sharing for files

Guilherme Moreira | Lisboa | Portugal | para Fab Academy 2014 (pt)