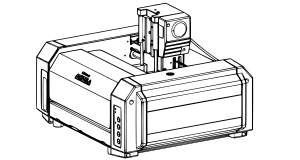

Building a 3d model on rhino5 of an axis head to run some tests

A longtime ago I’ve learned rhino at school and that’s the reason I used it for these task.

First I started by drawing a circle , than using offset curve

, than using offset curve I drew more concentric circles that I copied to a certain distance, by making a line

I drew more concentric circles that I copied to a certain distance, by making a line  and using mirror

and using mirror  in the mid point of that line. From there i made more horizontal and vertical lines using some of the above tools, and used trim

in the mid point of that line. From there i made more horizontal and vertical lines using some of the above tools, and used trim  to take out the some parts off the lines leaving behind just some out lines do extrude my model.

to take out the some parts off the lines leaving behind just some out lines do extrude my model.

Press Fit

I started my press fit task based on a triangle as base material I used some old 3mm acrylic from a store front.

2nd - some basic ideas I already have in mind…( at this point everything is changeable):

Motors - I intend to use dc motors for many reasons, the 1st one being they are more common, then it's easier to buy a used powerful one. And, as I recovered many encoders from hp printers, I can get the proper positioning feedback I need; and the 2nd reason is that I'm going to learn how to read and control input and output devices, nothing better than combine them both on my final project. With hi-torque, both stopped and in motion, good gear reduction, hi-durability and being available as cheap used parts, I found car window and windscreen wiper motors to be apparently ideal for my project…

Final project proposal

5 axis cnc milling machine

As a jeweler I’ve been searching 4 and 5 axis cnc milling machines for a long time, hoping to find one within my small “Portuguese Budget“ with the hi-precision I need.

As I’ve told you that’s what took me to Fab Lab EDP the first place, in there I end up learning that it was possible to build one yourself, and that you could find part of or all the parts you need in ordinary printers and other home and office appliances , beside that you need:

- Dedication

- Persistence

- Designing skills

- Electronics skills

- Programing skills

Since then I’ve been collecting old printers, electronic stuff, and information about components and open source projects and started to design a 5 axis machine of my own. Hoping to get the last two of the above skills during Fab Academy, I propose myself to build a 5 axes milling cnc machine with hi-precision (less than 0.1mm )and as most 360dgrX360dgr-capable as it can. The torque must be as high as possible without affecting any of the previous technical features, as it will be mostly milling molding wax, and I can always build another one later.

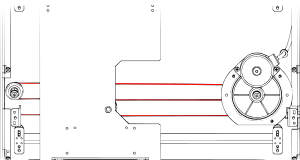

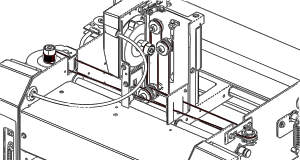

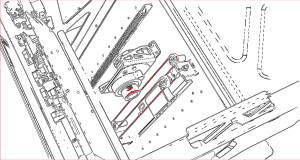

In this machine I intend to use mostly recovered and machined parts, my plan is to use dc motors from car windows and windscreen wipers and optic encoders I recovered from the printers.

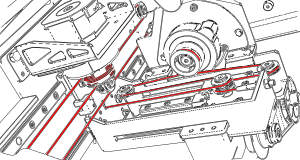

In my search I came across two 3d models, one of them from modela mdx20. Based on them, and knowing to be extremely difficult to build accurate gear systems, I’m thinking on using the same steel cable system used on the machines depicted below.

see https://drive.google.com/folderview?id=0B-zSpF8Sy3QLM0pIZmw4c1lRb1k&usp=sharing for files