03 Computer-Controlled Cutting

In the Fab Lab in Providence you can find great computer - controlled cutting tools : vinyl and laser cutter. First machine uses a knife for cutting designed shapes. It's a great tool which is able to cut vinyl ( for stickers) and a copper for flexible cicuits. More about the vinyl cutter you can find under this link.

JUMP TO LASER CUTTNG

VINYL CUTTING

Since I have moved to Providence just 4 weeks ago I needed to mark my post, vinyl cutter was quite helpfull :)

You can basicly make sticker from almost any shape and picture. I found cameras icons on the web and I simply opened them in the Inkscape and converted to the vector graphics.

Next step was more complicated since I've tried to make a sticker from one of my projects. I was working in Photoshop to change colofrull picture into black and white graphic which is easy to trace in Inkscape.

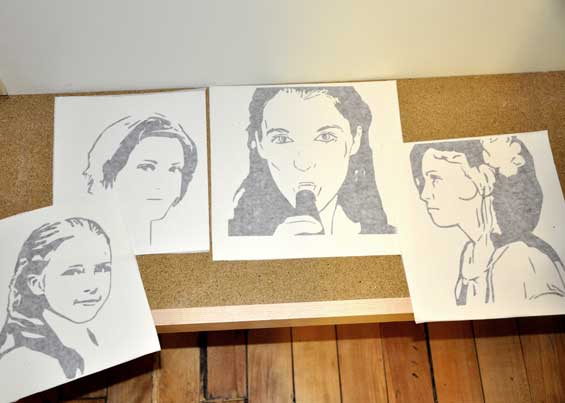

My sisters also got personal stickers:)

LASER CUTTING

Our first assignment with a laser cutting machine was to make a press - fit contruction kit. Parametric design is essential, our work should be able for future modifications. One parameter which describes thickness of the material should be easy to update.

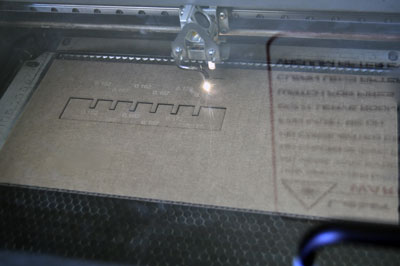

Test of cardboard ( 0.177 inch width )

The idea was to find a perfect width of joints for a 0.177 inch width cardboard. Press fit contrsuction need a really tight friction fit to work. Since my cardboard has 0.177inch I started test from much lower value : 0.152, 0.157, 0.162, 0.167, 0.172, 0.177.

I draw the "joint ruller" in a cad program.

I made another version of the Ruller with chamfered edges

The thigthest width - 0.152 was the best.

I did also test with playwood 0.174 in and the best joint width is playwood is 0.161.

Wine holder

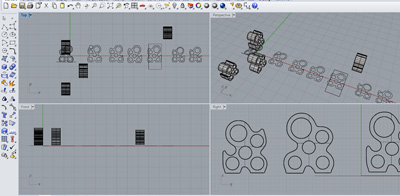

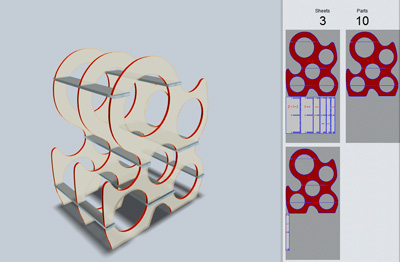

To make my own wine holder I designed a solid form in Rhino.

Then I saved my file as a stl. and I opened it in the 123D Make Autodesk program. It's a great free software which prepares cutting layouts for a laser cutter. According to materials which you are going to use you can change width of the joints what is really helpfull. I set up file with two diffrente settings, for cardboard with joints 0.152 and for playwood with joints 0.161.

And here is a result in cardboard.

The first version needed some improvements: one opening is to small for standard size of wine bottle. I was working on the model and finally second version made me happy.

Parametric design

I had some problems with this task to code by myself a kit which is parametric. I found that 123D Autodesk Software is great for it and this program prepare cutting pieces where you can control width of joints. I tired though made kit manualy with Inkscape. I used clone tiles commend.

Then I switch to Rhino. I used block commend to create box with joints easy to modify.

To get perfect press kit contruction for the box made from the cartboard I set joints in way that inputs are wider than the outputs of the 0.03 in.

For the playwood inputs are 0.25 in width when the outputs are 0.225 in width. So the difference is a smaller than in cardboard press-fit construction.