18 Project Development

Gold energy - solar tracking panels

Anna Niespielak and Mathew Owen

The idea is to build our own modular component which will include 4 solar tracking panels. We are planning to build working prototype until end of June and use it during our road trip this summer from Providence to San Francisco. Sun energy will be converted to charge our notebooks in the middle of a desert or a corn field :)

first sketch

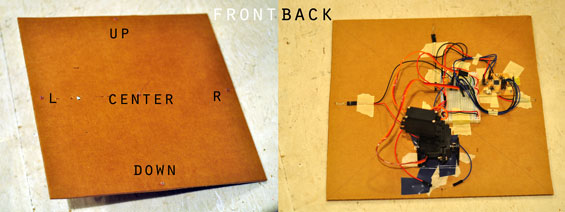

Solar tracking concept is based on 5 photoresistors placed on the panel and called UP, DOWN, CENTER, RIGHT, LEFT. They are code in the way that CENTER is always the brightest otherwise arduino sends message to move servo motors.

To built a first quick version of the panel we used:

cardboard for prototyping which is easy to cut through and adjust

breadboard with our arduino

bought 2 axis servo motor

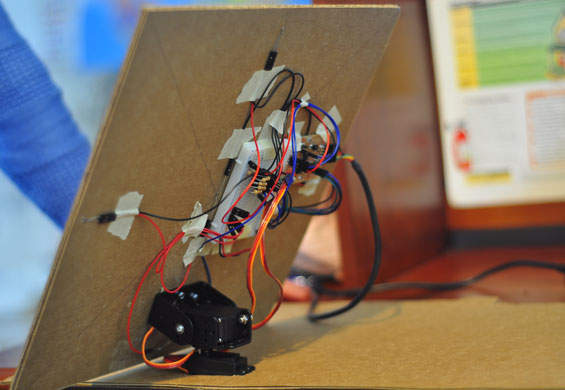

We run a code. Sensors dint follow light as smooth as we expected. We found that ldr's wires were connected in some places. We checked twice all connections and added a stand to support motors. We run code again this time with a better result.

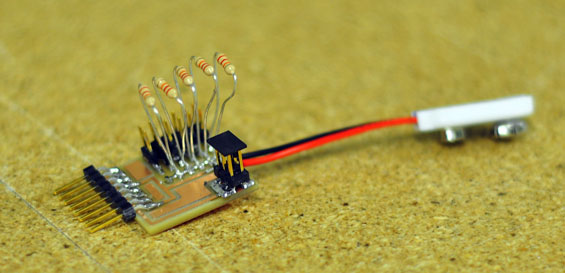

We designed and milled new circuit based on the working breadboard. New board is much lighter and connections works much better.

Right now we have working circuit. Code needs still some improvements, we are trying to set endpoints for the servos to avoid them going to far.

We are waiting for solar cells and servo motors to come. We are going to 3d print on wednesday our own brackets for dual servo axis what will lower cost of the prototype.

Rhino model of servo bracket.

Rhino model of the concept.

Wednesday 5/22/2013 - 7 days to go

Today we are working on:

- panels - design

One panel includes 4 solar cells. Each cell is 6" x 6". Thats give us dimension which is too big for our laser cutter. We scaled down panel just for testing and to laser cut it on the Epilog.

We scaled down original size of the panel to be able to cut it on a laser machine. We placed sensores in drilled holes.

We used dark blue paper instead of solar cells for testing prototype number 2. Looks much better than plane cardboard.

- servo brackets, we are planning to use array of 4 / 6 panels per one component.

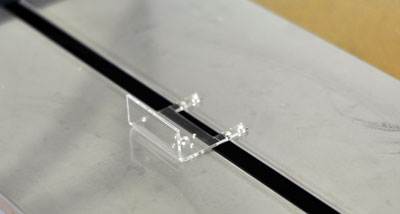

Assembled 3d printed bracket

After some testing 3d printed bracket broke. We decided to try laser cutter for this job.

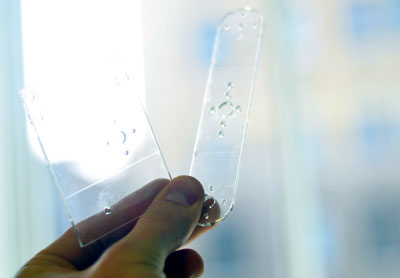

Transparent acrylic profiles before bending process.

To bend acrylic we used heater donated to the lab by Larry, one of the members.

- motor stand ( 3d printed )

- circuit, we are going to try combine all boards on one ( arduino, sensor board and regulator board)

Thursday 6/22/2013 - 6 days to go

We are studing how works solar cells and how we can connect them with each other. We were working on a sample made with paper and silver vinyl to find a laout for soldering.