07 Molding & Casting

There are several ways to prepare molds for your project. One of them is based on milling machine possibilities. Roland Modela or ShopBot ( for bigger objects) can easy carve your project from wax or wooden blocks.

The wax block with dimensions : 3cm, 9cm, 15cm

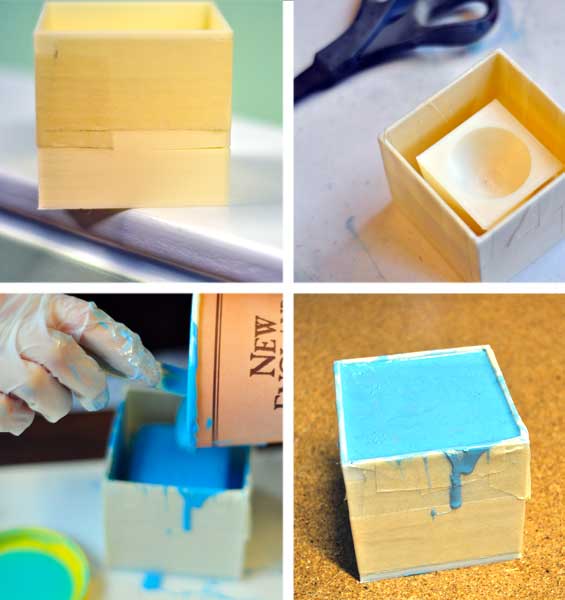

You can also use 3d printer - the choice which way is the best depends of your design. After prinitng or milling you want to get a positive form of your design. Next you will have to prepare a negative. I chosed OOMOO - blue rubber to get a mold. With one negative you can make many quick casts.

During this week I designed egg- holder.

The most common egg's size in USA is large - 4.4cm width.

I again used Rhino to make 3d model and later I imported it to stl. I decided to use 3d printer since milling machine cannot carves tapering shapes. Unfortunetly my print didnt go perfect, had some cracks. I used standard tape to close all holes. Then I prepared a mixture of OOMOO. You have to be very accurate with mixing OOMOO couse bad proportions increases the time for mold to set up. My mixture took many hours but finelly I get the solid blue negative ready for casting.

I needed to destroy my 3d print to be able to get mold out. Now I see I should made a mold which contains two pieces. For casting I chosed hydrostone.

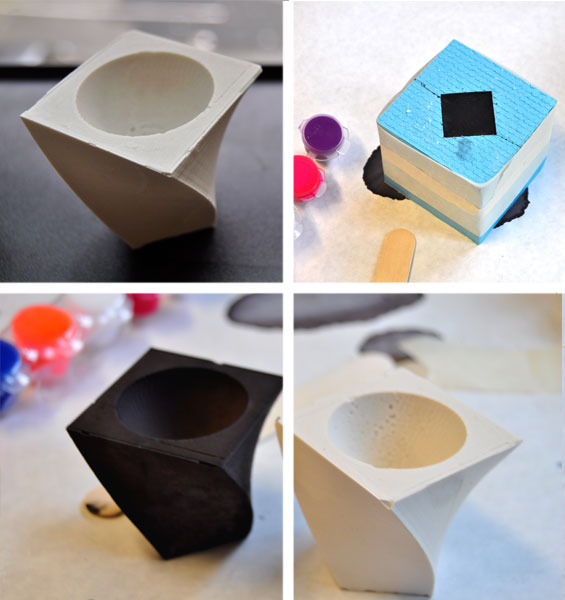

I tried also color pigments.

The hydrostone unfortunetly leaves dirt on the fingers. I decided to wash both forms : white and black to remove dirt. The images below shows egg-holders before ( fisrt) and after wash ( socond image).

Definitly I will make the same object using diffrente mateials - probably plastic. The egg-holder made from hydrostone leaves traces on all surfaces what makes it unwanted in any kitchen!