Composites

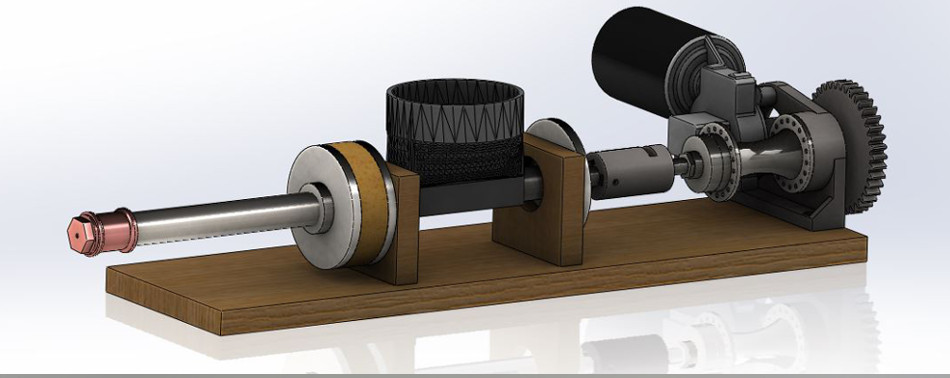

This week we wanted to finish a project that we have already been working on for a while in the fablab: a small horizontal-axis wind turbine.

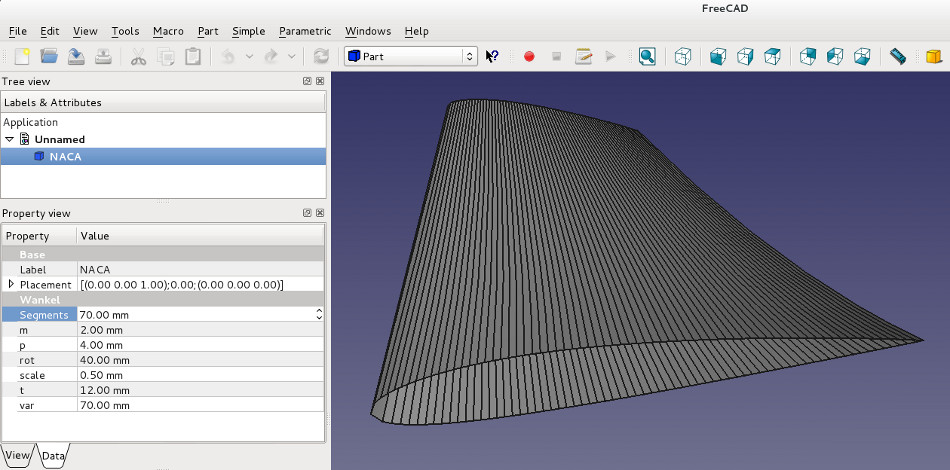

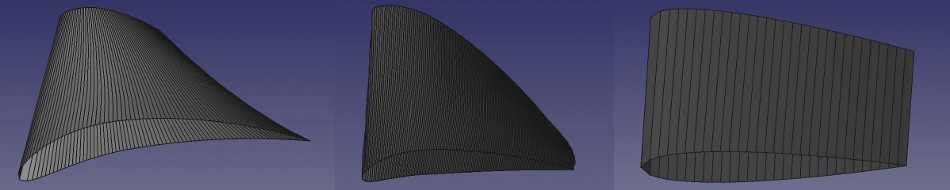

Starting a windmill from scratch was more difficult than I expected. Since we couldn’t find any available CAD-data we decided to start our own model. The only free resource that I found is from the website Warlock engineering, but only the small 500W turbine is for free. There are lot’s of sites with airfoils for windmills like UIUC Airfoil Data Site, NREL or build instructions with airfoil generators like wind and wet, but I wanted something more universal.

We started with the book from Hugh Piggott: Windpower Workshop.

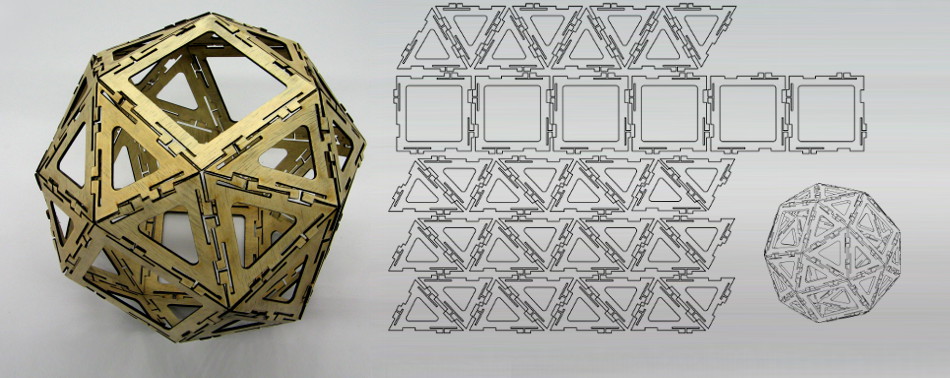

Using the formulae from the book we tried to generate the blades in Grasshopper. After some struggling with the programming we found a NACA-generator for Grasshopper that helped a lot.

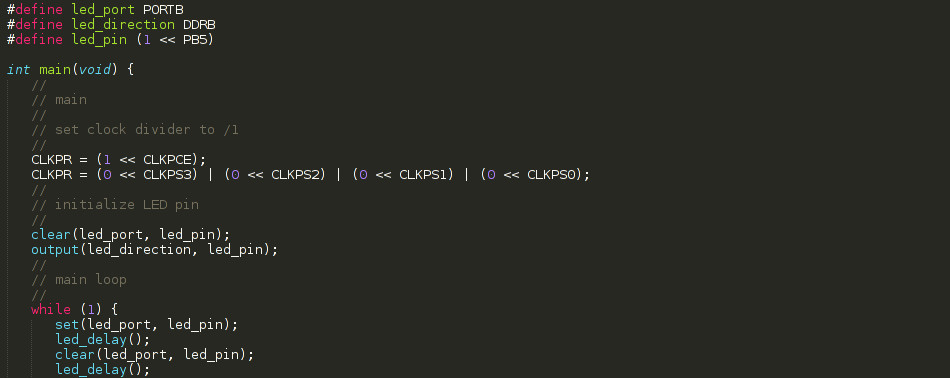

I also started a script in FreeCAD to generate the blades.

Here you can find the freecad macro for generating the wing. To use it, copy the script to your Freecad Macros (Macro—> Macros… —> Macro destination), start a new document in Part Design and execute the Macro. In Property View —> Data you can adjust the parameters in realtime.

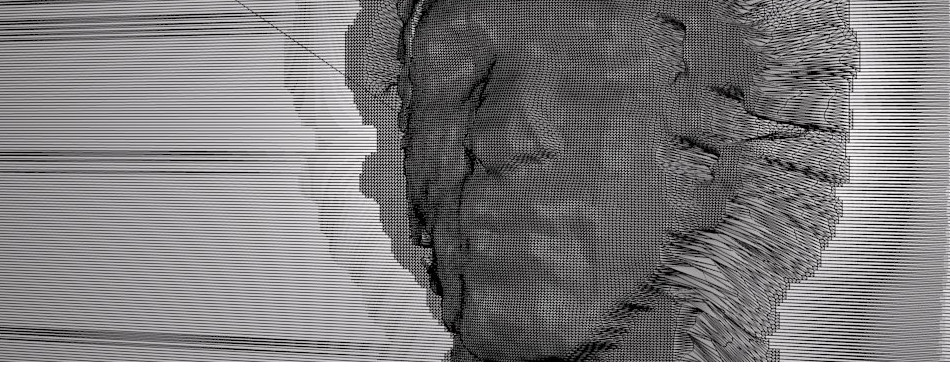

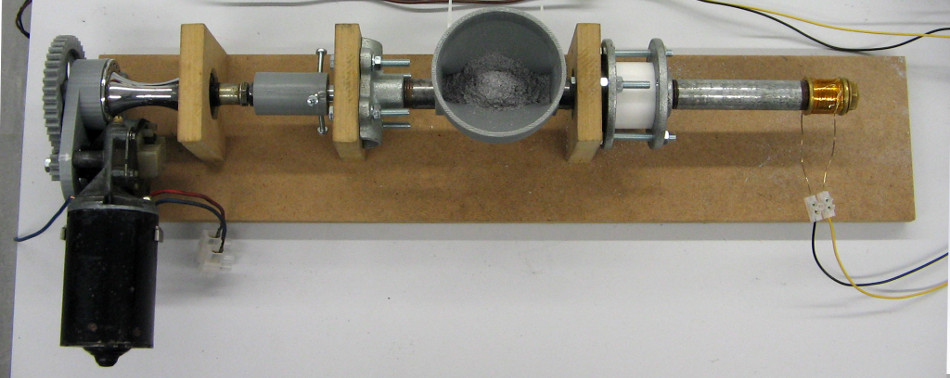

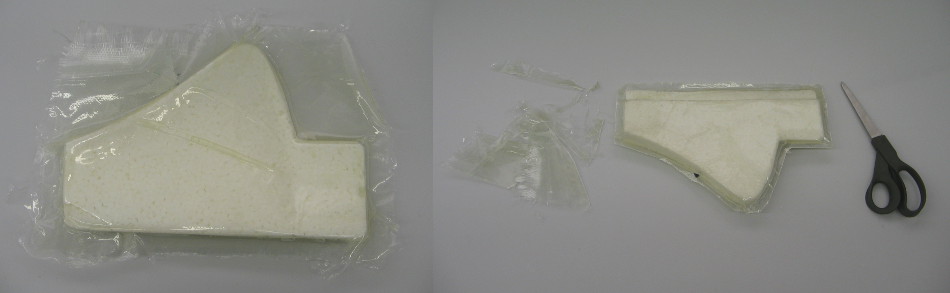

We milled one of the blades out of Styrofoam,

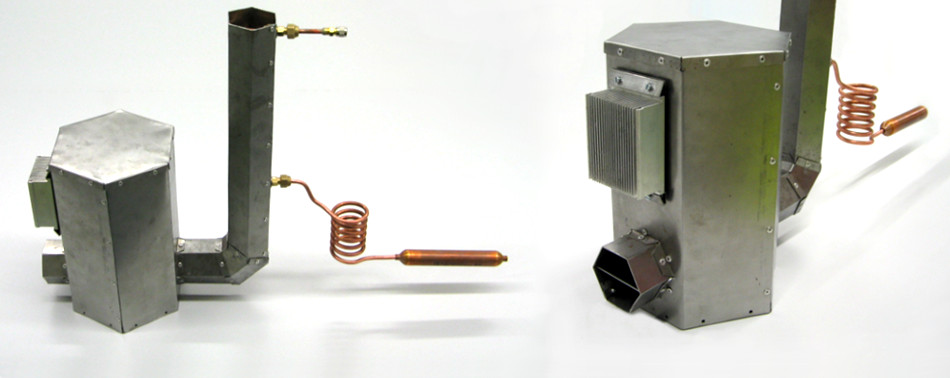

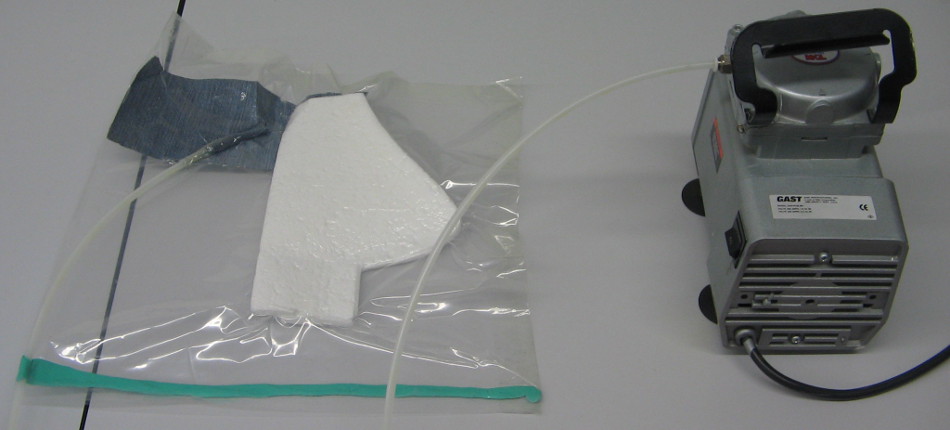

but before risking a lot of money for glass-fiber we decided to do some smaller tests. Our vacuum-bagging setup is still missing some materials like the release fabric and the breather layer, but our improvised version seems to be working more or less.

After doing some tests with different materials to see if the epoxy sticks to them or not, we started the first part with glasfiber and jeans-textile:

As a breather layer I used some textile separated with some thin plastic film.

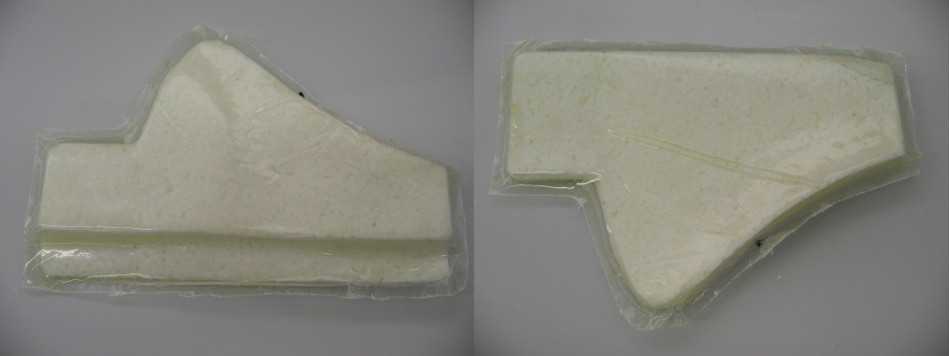

The resin reached all the places it was supposed to go and the foam piece turned to a very hard and rigid piece with just one layer of fibre.

The vacuum wasn’t as strong in all places as I would have wished, so there are some air-bubbles in one corner and some excess resin in another. The bag also made a little fold on the back-side while wrapping around the curved shape which is now visible as extra resin.

For the next try I bought some better breather material and a bigger vacuum bag.