Assignment 11 - Molding & Casting

The Group Assignment for this week is to:

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

The group assignment is done by Ting Kok Eng, Noel Kristian and Yeo Gau Siong

Part (A) Review Safety Data Sheet- Smooth-On Sorta Clear 37

- Smooth Cast 300 & 305

- EasyMold Silicon Rubber

- EasyMold Silicon Putty

In addition, we also review the SDS for Smooth-On mold release agent, a spray that we used together with the above chemicals/compounds.

1. Smooth-On Sorta Clear 37

Image from https://www.smooth-on.com/products/sorta-clear-37/

Sorta Clear 37 is a premium water white translucent silicone rubber (platinum catalyst) which cure at room temperature in 4 hours with negligible shrinkage. It has Shore 37A hardness and features high tensile and tear strength. This product also offers the convenience of a 1A:1B by volume mix ratio, and vacuum degassing is recommended after mixing to eliminate any entrapped air. Sorta Clear 37 is ideal for making prototype, jewelry or other molds of any configuration where model visibility is important (i.e. extracting a model from the mold via cutting).

Materials such as urethane, epoxy or polyester resins can then be cast into SORTA Clear 37 silicone without application of a release agent. Although release agent is not usually necessary but to make demolding easier Ease Release 200 is recommended. Other materials such as wax and low melt metal alloys can also be cast into this silicone. And, SORTA Clear 37 silicone can be pigmented with SILC Pig™ silicone pigments.(2)

SORTA Clear 37 silicone rubber is FOOD SAFE and can be used for culinary applications including casting chocolate and other confections. OSHA and WHMIS classification this material not a hazardous substance or mixture, And, no requirement for GHS label elements and precautionary statements.

to download the full SDS for Smooth-On Sorta Clear 37.

Although there is no information found in SDS Section 11 Toxicological Information and Section 12 Ecological Information, safety exposure and controls are required when using SORTA Clear 37 silicone rubber.

Respiratory ProtectionUse SORTA Clear 37 in a properly ventilated area (room-size ventilation), do not breath in vapours and mists. Respiratory protection is not normally required when using this product with adequate local exhaust ventilation. Where risk assessment shows air-purifying respirators are appropriate, follow OSHA respirator regulations 29 CFR 1910.134 and European Standards EN 141, 143 and 371; wear an MSHA/NIOSH or European Standards EN 141, 143 and 371 approved respirators equipped with appropriate filter cartridges as a backup to engineering controls.

Hand ProtectionWear vinyl gloves only, any liquid-tight gloves such as butyl rubber, neoprene or PVC. Avoid latex gloves, this kind of gloves will inhibit the cure of the rubber. Wash hands after use.

Eye ProtectionWear safety glasses with side shields per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses. Provide eye bath and safety shower.

Other Protective Clothing/EquipmentAdditional protective clothing or equipment is not normally required, to minimize exposure wear long sleeves and provide safety shower.

General Hygiene and protection measuresNever eat, drink, or smoke in work areas. Practice good personal hygiene after using this material, especially before eating, drinking, smoking, using the toilet, or applying cosmetics. Wash thoroughly after handling.

Safe StorageStore material in cool and dry environment at room temperature (73°F/23°C) in approved container, tightly closed and properly labelled. Warmer temperatures will drastically reduce working time and cure time. Storing material at warmer temperatures will also reduce the usable shelf life of unused material. These products have a limited shelf life and should be used as soon as possible. Avoid contamination during storage with any incompatible materials, such as strong bases, strong oxidizer and acids.

Proper Disposal

Waste treatment methods at the time of disposal should be in full compliance with the local laws, waste of this material should not be mixed with other wastes. Use waste container with vented bungs.

First Aid Measures- For inhalation, remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

- For eye contact, flush eyes with plenty of water. If irritation persists, seek medical attention.

- For skin contact, wash thoroughly with soap and water.

- For ingestion, do not induce vomiting unless instructed by a physician. Never give anything by mouth to an unconscious person.

After first aid, get appropriate medical support. There are no known symptoms and effects for both acute and delayed.

2. Smooth-Cast 300 & Smooth-Cast 305

Smooth-Cast 300 & Smooth-Cast 305 are parts of of the Smooth-Cast 300 series manufactured by Smooth-On Inc.

They are ultra-low viscosity casting resins that yield castings that are bright white and virtually bubble free. Because they are bubble free, vacuum degassing is not necessary, hence make them easy to process for casting without sophisticated tooling.

They also offer the convenience of a 100A:90B by weight or 1A:1B by volume mix ratio, making it extremely easy to composition right even without a weighing balance.

Before starting to use any of the molding and casting chemicals, we need to read their Safety Data Sheet to comprehend their physical and chemical properties, safe handling and storage and other information relevant to the safety of people that will be exposed to these chemicals.

to download the full SDS for Smooth-Cast 300.

The file is also available from the manufacturer website.

to download the full SDS for Smooth-Cast 305.

The file is also available from the manufacturer website.

The chemical and physical properties of both are very similar hence the hazards and the handling and storage are also similar. Some key information to take note are below:

1. Safety:

- IRRITANT TO EYES, SKIN & MUCOUS MEMBRANES.

Contains Methylene Diphenyl Isocyanate. Do not breathe fumes. - CAUTION: HOT!

Combining Parts A & B will generate heat in excess of 100°C which could cause burns to the skin.

Handling Smooth-Cast 300/305

- Let cured plastic cool before handling.

- Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.

- Use in well-ventilated working environment.

2. Preparation:

- These products have a limited shelf life and should be used as soon as possible.

- Materials should be stored and used in around 23-25°C environment.

- All liquid urethanes will absorb and react with moisture in the air, causing bubbles to form, hence should be used in a low humidity environment.

- Mixing tools and containers should be clean and made of metal, glass or plastic.

- Stir or shake both Part A & Part B thoroughly before dispensing.

3. Pouring and Curing:

- Pouring - Pour the mixture in a single spot at the lowest point of the containment field and let the mixture seek its level. This will help minimize air entrapment.

- Best results are obtained using a pressure casting technique. After pouring the mixed compound, the entire casting assembly (mold, dam structure, etc.) is placed in a pressure chamber and subjected to 60 PSI (4.2 kg/cm2) air pressure for the full cure time of the material.

- Curing - Important: Use this product with at least room size ventilation or in proximity to a forced outlet air vent and do not inhale/breathe fumes.

- Applying a Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (Smooth On Universal Mold Release).

Smooth-Cast 300 & Smooth-Cast

They are both polyurethane-based resins, the main differences between Smooth-Cast 300 & 305 are indicated below:

Pot life

Pot life is defined as the amount of time it takes for an initial mixed viscosity to double, or quadruple for lower viscosity products (<1000 cPs). Timing starts from the moment the product is mixed, and is measured at room temperature (23C).

Cure Time

Mixing epoxy resin and hardener begins a chemical reaction that transforms the combined liquid ingredients to a solid. The time it takes for this chemical transformation from liquid to solid is called cure time. As it cures, the resin passes from the liquid state to a solid state. Cure time dictates how long we should wait before going on to the next step in the project, like removing clamps or sanding, for example.

3. EasyMold Silicone Rubber (Liquid)

Image from https://www.eti-usa.com/easymold-silicone-rubber

EasyMold Silicone Rubber is a easy to use, odor free, non-toxic, two component parts A & B silicone rubber (liquid) that cure easily to create blanket, glove or block molds. It is FDA Compliant, Food Grade.

EasyMold Silicone Rubber is ideal for a wide range of mold applications, including Castin Craft Clear Casting Resin, EasyCast Clear Casting Epoxy, wax, baking, chocolates, ice cubes, soap, plaster, air dry clay, concrete and low melt metals.

- Brushable/Pourable

- 45 Minute to 1 hour working time, 24 hour cure. Cure rate can be adjusted by applying heat

- Produces extremely fine detail from original, no shrinkage

- Self releasing, no mold release agent required for most applications. However, molds used repeatedly may overtime experience a build up or residue from various casting mediums such as plaster or concrete. Castin Craft Mold Release/Conditioner will help to prevent this build up and restore your molds natural releasing properties. Note: Casting abrasive materials such as plaster or concrete repetitively can wear away mold detail. Do not use Castin Craft Mold Release/Conditioner for food type applications.

- High heat range, up to 400°F

- Strong flexible re-useable molds

- No vacuum equipment required

- No special treatment for inhalation

- For skin contact, wash off with soap and water. Get medical attention if irritation develops and persists.

- For eye contact, flush eyes with water for 15 minutes. Get medical attention if irritation develops and persists.

- No special treatment for ingestion.

- EasyMold Silicon Rubber

- EasyMold Silicon Putty

Although EasyMold Silicone Rubber is FDA Compliant, Food Grade and there is no hazard information found in SDS Section 2 Hazard(s) identification, safety exposure and controls are required when using EasyMold Silicone Rubber.

to download the full SDS for EasyMold Silicone Rubber (Liquid)

Respiratory Protection and Ventilation

Respiratory protection and special ventilation are not normally required, just use with adequate ventilation. And due to the physical properties use in Part A of EasyMold Silicone Rubber, particulate inhalation exposure is not possible.

Hand ProtectionWear vinyl gloves only, any liquid-tight gloves such as butyl rubber, neoprene or PVC. Avoid latex gloves, this kind of gloves will inhibit the cure of the rubber. Wash hands after use.

Eye ProtectionWear safety glasses with side shields or chemical safety goggles per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses. Provide eye bath and safety shower.

Other Protective Clothing/EquipmentAdditional protective clothing or equipment is not normally required, to minimize exposure wear long sleeves and provide eye bath and safety shower.

General Hygiene and protection measuresNever eat, drink, or smoke in work areas. Practice good personal hygiene after using this material, especially before eating, drinking, smoking, using the toilet, or applying cosmetics. Wash thoroughly after handling.

Safe StorageStore material in cool and dry environment at room temperature (730°F/230°C) in approved container, tightly closed and properly labelled. Warmer temperatures will drastically reduce working time and cure time. Storing material at warmer temperatures will also reduce the usable shelf life of unused material (maximum temperature allowed during storage is 1220°F/500°C). These products have a limited shelf life and should be used as soon as possible. Avoid contamination during storage with any incompatible materials, such as acids, basic substance (e.g. alkalis, ammonia, amines), alcohols, water, moistures, strong oxidizing agents, catalyst. Reaction causes the formation of hydrogen, therefore ensure adequate ventilation when storing this material.

Precautions against fire and explosionEasyMold Silicone Rubber can release hydrogen, keep away from sources of ignition, heat, sparks and electrostatics charging. Provide well ventilation place.

Proper DisposalWaste treatment methods at the time of disposal should be in full compliance with the local laws, waste of this material should not be mixed with other wastes. Use waste container with vented bungs.

First Aid MeasuresAfter first aid, get appropriate medical support. There are no known symptoms and effects for both acute and delayed.

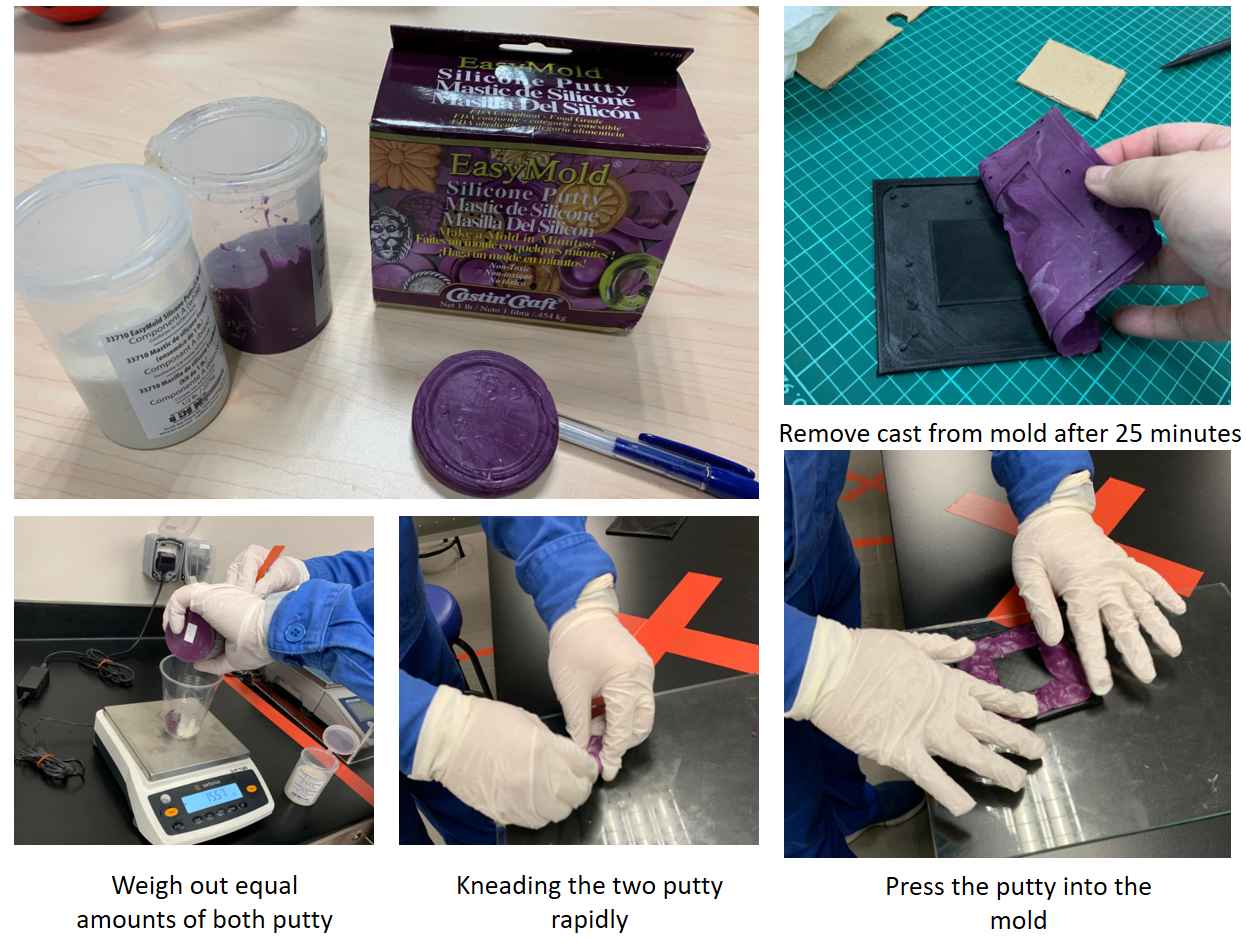

4. EasyMold Silicone Putty

Image from https://www.eti-usa.com/easymold-silicone-putty

EasyMold Silicone Putty is a two component silicone putty that is easy to use and is ideal for a wide range of impression type mold applications. The EasyMold silicone putty is odor free, non-toxic and FDA compliant. It has a 3-minute working time and 25-minute cure time. The properly kneaded putty is soft and suitable for small molds giving excellent detail from original. The mold is strong, flexible and reuseable. It can withstand high Heat range, up to 200 degree C and has virtual no shrinkage.

Like the liquid counterpart, EasyMold Silicone Putty is FDA Compliant and Food Grade and there is no hazard information found in SDS.

to download the full SDS for EasyMold Silicone Rubber (Liquid)

Respiratory Protection and Ventilation

Respiratory protection and special ventilation are not normally required, just use with adequate ventilation.

Hand ProtectionWear nitrile gloves only, as latex material can inhibit the curing of the silicone putty and should be avoided. Wash hands after use.

Eye ProtectionWear safety glasses with side shields or chemical safety goggles per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses. Provide eye bath and safety shower.

Other Protective Clothing/EquipmentAdditional protective clothing or equipment is not normally required, to minimize exposure wear long sleeves and provide eye bath and safety shower.

General Hygiene and protection measuresNever eat, drink, or smoke in work areas. Practice good personal hygiene after using this material, especially before eating, drinking, smoking, using the toilet, or applying cosmetics. Wash thoroughly after handling.

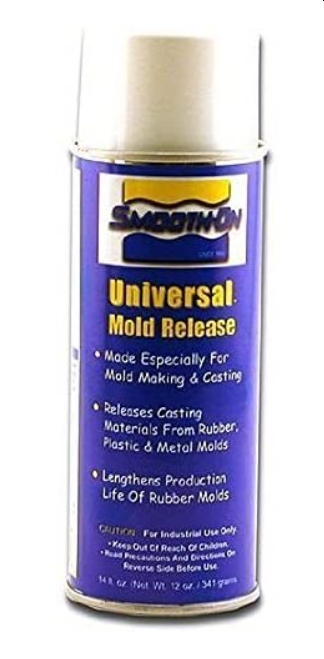

5. Smooth-On Universal Mold Release Agent

Image from https://www.smooth-on.com/products/universal-mold-release/

The Universal Mold Release Agent is a special formulation for mold making and casting and works well with most liquid rubber and liquid plastic products. It will release mold rubbers (such as polyurethanes and polysulfides) from properly prepared models. By "properly prepared", it means that porous surfaces such as wood, plaster or concrete surfaces must first be sealed using a sealer so that the relase agent may work properly. that's enable the casting to be removed easily from the mold.

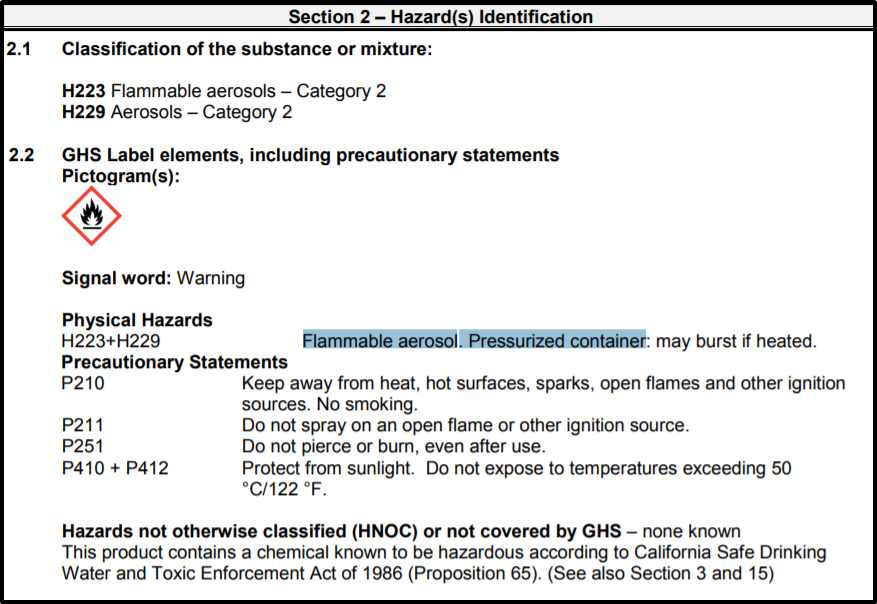

Since this product comes in a aerosol spray can, special care must be observed when using the product as it is stored under pressure and is likely to be flammable. Referring to Section 2.0 of the Safety data Sheet (SDS), this product is classified under H223 and H229 as 🔥flammable🔥 and should not be exposed to any form of heat. Thus before using, it is important to ensure that there is no hot object in close proximity.

From Section 3, the product contains predominately 1,1-difluoroethane (CAS No. 75-37-6 ) and Dimethyl ether (CAS No. 115-10-6). 1,1-difluoroethane (DFE) is used as the propellant for the aerosol spray, while Dimethyl ether functions both as a propellant like DFE as well as a solvent for the active ingredient which is usually a natural or synethic silicone oil such as Polydimethylsiloxane (PDMS). These two chemicals are highly volatile but are generally low in actue toxicity. PDMS also has low on acute toxicity.

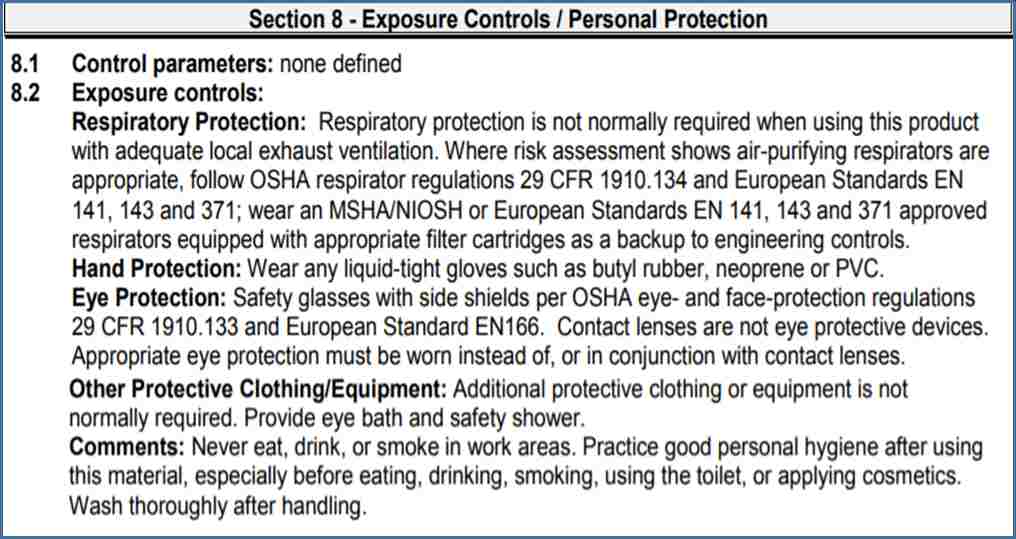

As the amount used is unlikely to be large and SP Fablab does not purchase this product in bulk, many sections of the SDS pertaining to accidental release, handling, transportation and storage are less relevant in our context and are not discussed here. Section 8 however is relevant to the average user. According to the SDS, respiratory protection is not normally required when using this product with adequate local exhaust ventilation. Since the ventilation at SP Fablab (T11C) is good, there is no need for the user to wear any respiratory protection when using the product. The SDS however recommends that liquid-tight gloves and eye protection be worn when handling the product.

to download the full SDS for Universal Mold Release Agent.

The file is also available from the company websitePart (B) Make and compare test casts

Due to Covid-19 situation, delivery schedules were badly affected and only 2 different types of molding and casting materials are available to the team.The group hence carried out test casting on these 2 materials.

The two were compared on the working time, curing time, ease of handling as well as the properties of the completely cured mold.

EasyMold Silicon Rubber (Liquid)

The liquid EasyMold Silicone molding compound has a working time of about 1 hour. This enables the user to measure the 2 components properly and mix them thoroughly. The thorughly mixed silicone mixture is light blue in colour and flows easily, allowing it to be poured into the mold easily. The curing time is a long 24 hours. When completely cured. The mold is strong and flexible.

EasyMold Silicon Putty

The EasyMold Silicone putty molding compound has a working time of ONLY 3 minutes! The weighing and kneading together the 2 putty components must hence be carried out rapidly. After kneading for a few minutes, the silicone putty turned warm and started to hardened. The user must hence immediately press the putty onto the mold. Thankfully the kneading putty also became softer and made filling the mold easier. The curing time is only 25 minutes, but after 3 minutes, the putty is actually hard enough to be removed from the mold. After 25 minutes, the completely cured silicone mold can be easily removed from the mold. Mold releasing agent is not required at all. The cured silicone mold is stretchy but strong. It is also softer than the fully cured liquid version.