Assignment 1

This website contains the documentation and write-up for Group Assignment 1 - Computer Controlled Cutting.

For the

characterization, 3 different materials namely, corrugated

cardboard, clear acrylic and plywood were used.

a squares each measuring 25.0 mm by 25.0 mm were first

created on CorelDraw X8.

The line colors

for the four squares were set as Red, Green, Blue and

Magenta and the line thickness was as “hairline” to enable

the cutting mode. Using

4 line colors allow 4 different combinations of Power, Speed

and Frequency (PPI) to be set so that each square can be cut

with a different set of parameters. This will hasten the

characterization process substantially.

Corrugated Cardboard

The

first material used was a 3.5 mm thick corrugated cardboard.

A group of four squares were cut and the specimens were

examined carefully for cut marks on both sides of the

materials. Based on the results obtained, the parameters

were adjusted and a new group of 4 squares are cut.

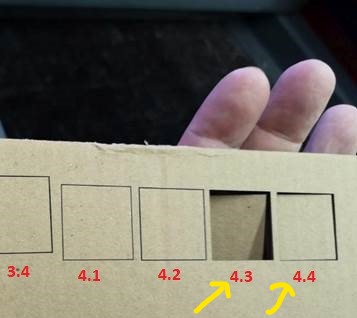

4 groups of 4 were run.The first three groups of

parameters did not managed to cut the squares. For the

fourth group, the last 2 settings were able to produce

nice clean cut-out on the cardboard.

The settings and

results are tabulated as follows:

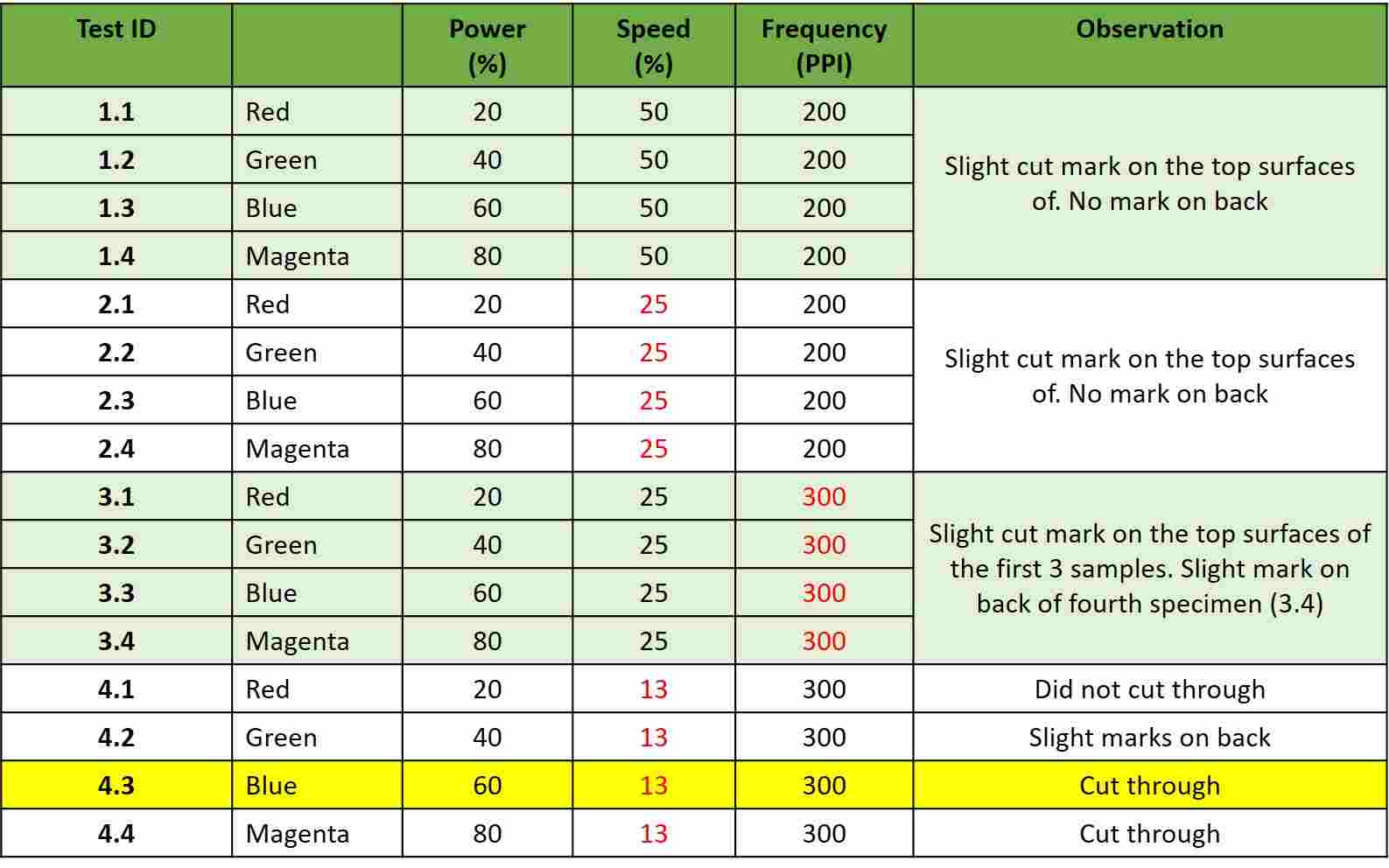

Table 1: Test Details and Results for

3.5 mm Corrugated Cardboard

Clear Blue Acrylic

The next material

tested was a 2.9 mm clear blue acrylic sheet. Similar test

method as above was adopted. A total of 16 squares were also

cut in groups of 4 and the settings as well as results are

tabulated as follows:

Table

2: Test Details and Results for 2.9 mm Clear Blue Acrylic

Sheet

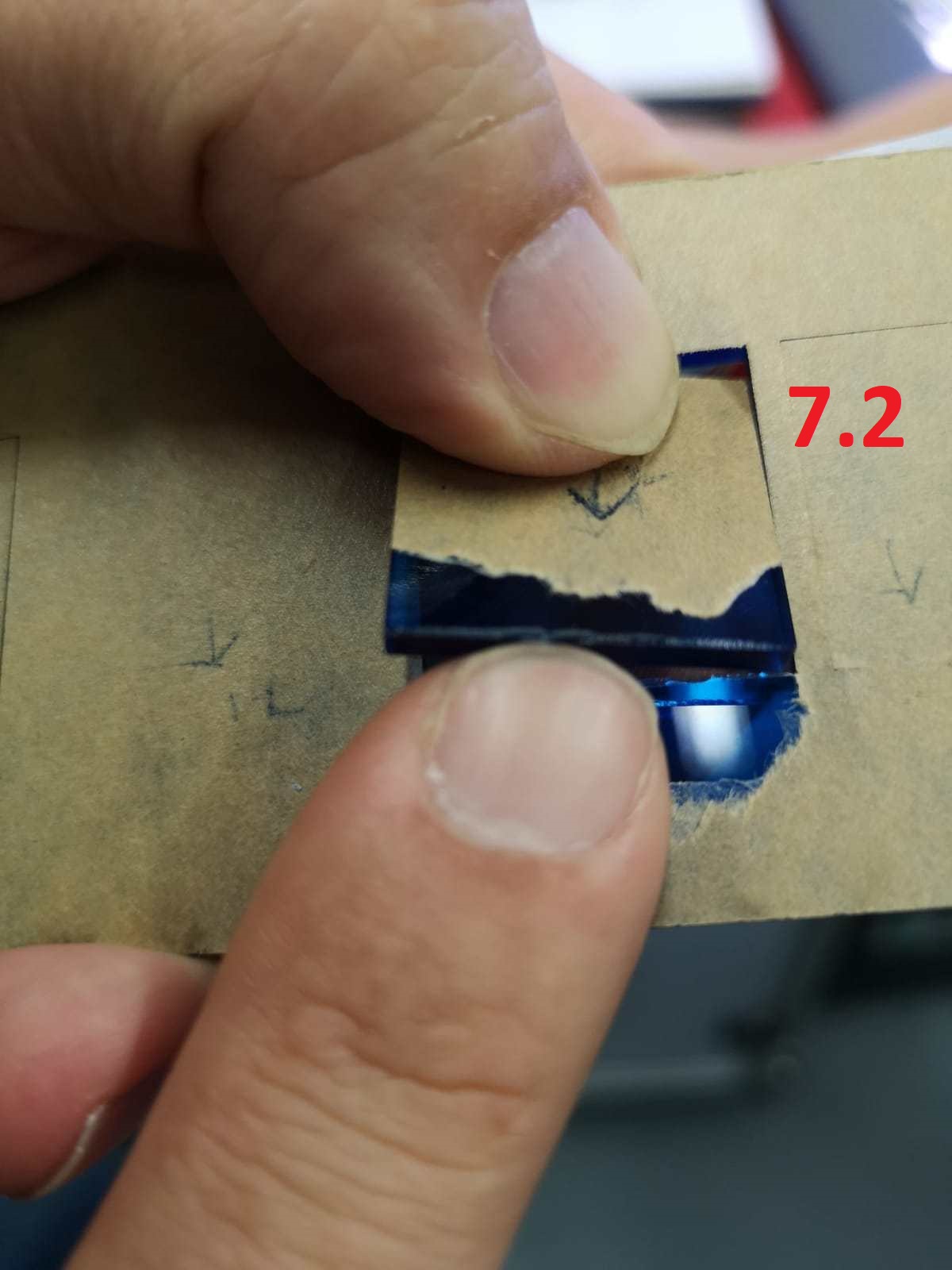

For the third set onward, the laser can

partially (see image below) or wholly cut through the

acrylic sheet.

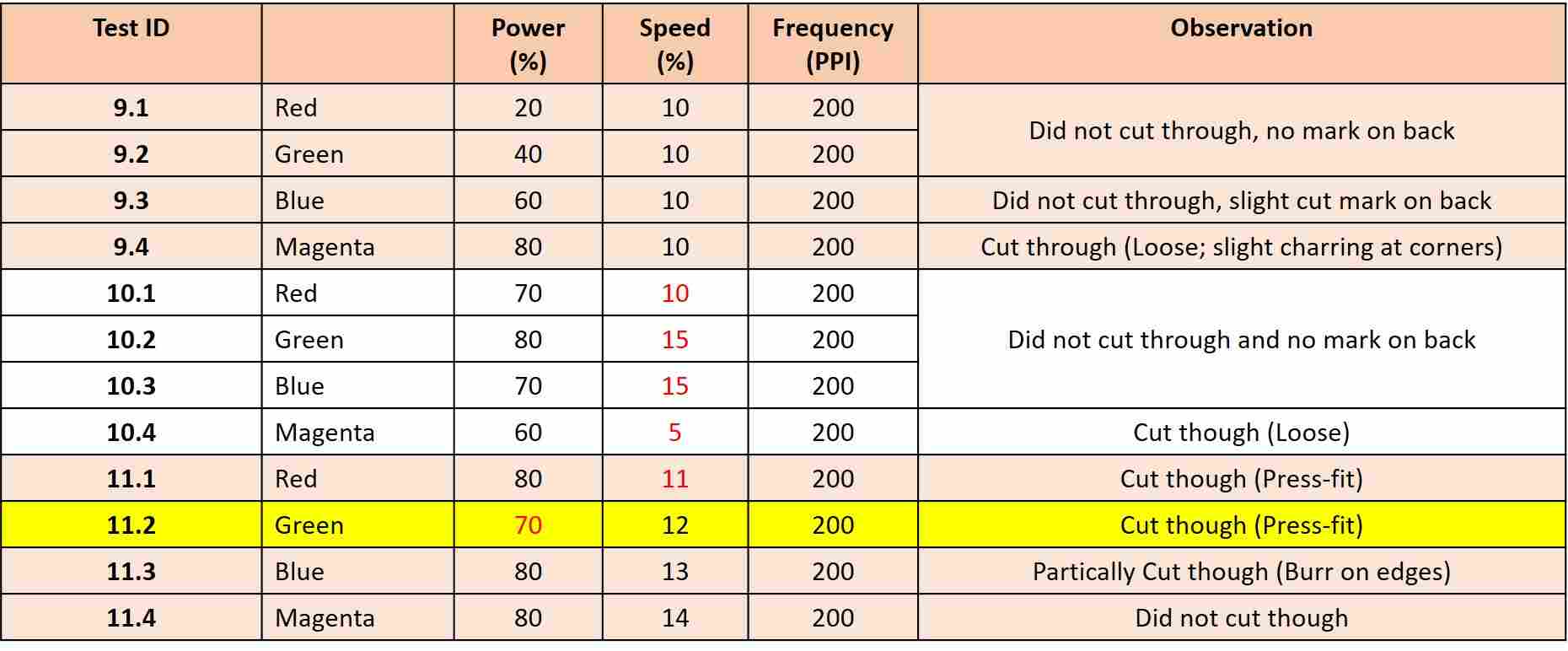

Plywood

The third material tested was a 2.4 mm plywood sheet. A total of 12 squares were cut in groups of 4 and the results are tabulated as follows. For Plywood, there are several specimens exhibiting partially cut. Uneven material thickness is believed to be the cause.

Table 3: Test Details and Results

for 2.4 mm Plywood

The summary of

the optimum settings for the three materials are as below:

After completing

the characterization, the next step is to determine the

kerf for each material.

Table

4: Kerfs for different materials

(All dimensions

in mm)

During

the measurement, we observed that the thickness of the

corrugated cardboard is very inconsistent, as such, the

team decided to use plywood (2.4 mm thickness) for our

construction kit. We decided to make a test gauge to

determine the best fit. The test gauge was a comb,

where the cut-off width is varied from the thickness of

material and gradually decreases by 0.05 mm. When the

cut-off was set at 2.3 mm (shown in the below picture),

the plywood (2.4 mm thickness) can fit tightly into the

cut-off part, hence the kerf is 0.5 x (2.40-2.30) = 0.05

mm. The result showed that the kerf is actually 0.05 mm,

quite different from our test finding earlier of 0.01 mm

and 0.02 mm. We used 0.05 mm for our parametric press-fit

construction kit and the results were tight fit.

We decided to

use a kerf of 0.05mm for our laser cutting.