Week's Assignments

Group Assignment:

● Actuate and automate your machine.

● Document the group project and your individual contribution.

Group Assignment:

● Actuate and automate your machine.

● Document the group project and your individual contribution.

For this week’s assignment, we continued working in our group of five:

Gleb,

Marjo,

Perttu,

Lukasz and me.

We designed and built a tablet dispenser, whose shared work page can be found from here.

The user puts a cup of water in the machine and pushes the button.

The machine drops a tablet in the water, preparing a ready drink.

This week we automated the machine whose mechanical design week we had done in Mechanical Design week.

Our target was to automate our machine.

For this week’s assignment, we programmed an Arduino UNO to control a servomotor

(in the upper part of the machine for tablet dispenser) and a 4-phase stepper motor

(for moving the cup holder). The stepper motor needed a motor driver,

since Arduino UNO could not supply the power it needed.

We also engraved a logo on the machine’s the front panel. It was Gleb’s idea to name the machine VitaFab

(multi-vitamin pills!).

For this part, Marjo drew a picture of a cup with tablets and did the engraving.

Some small mechanical issues still needed to be figured out

from previous week that we fixed together. We added an On/Off button for the machine.

There was a continuity issue with the stepper motor position record.

In the early version of the code, the position of the stepper motor (cup holder position)

was followed by saving its position to EEPROM after every step that it took.

This would lead to a problem in cases that the motor is disconnected from power supply

and moved by physical force from its recorded position in EEPROM.

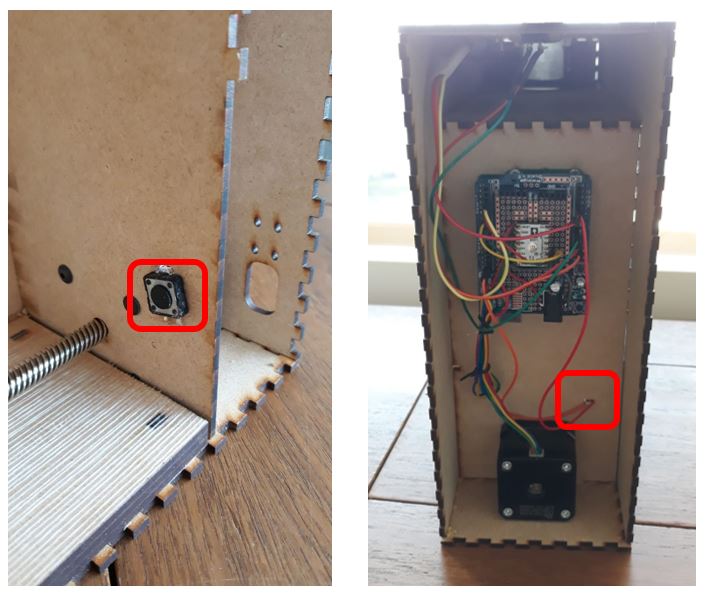

I suggested adding a button to the far end of the step motor’s route.

Fig. 2 shows the button and its connection to the electronics.

Then, we changed the code in a way that every time that the machine powers up,

the stepper motor automatically starts moving to its left until it pushes the button.

When the button is pushed, the position is recognized and the stepper motor stops.

I also helped in and assembling the final design. The files are added to the group page.

We had a fun couple of weeks working on mechanical and machine design as a group. We had a few redesigns and remakes to get everything working. I learned that in designing the physical part of a project, great attention to detail is needed, and if the work is done in a group, good communication and support. Finally, we got the VitaFab working and Perttu edited a video about it!