18. Wildcard week¶

This week I’ve redesigned the stool made for the “make something big” week. I’ve choosen to make a 3 layers sandwich combining two materials and technique:

- external layers - 4mm plywood - lasercut

- internal layers - 19mm styrenefoam - wirecut

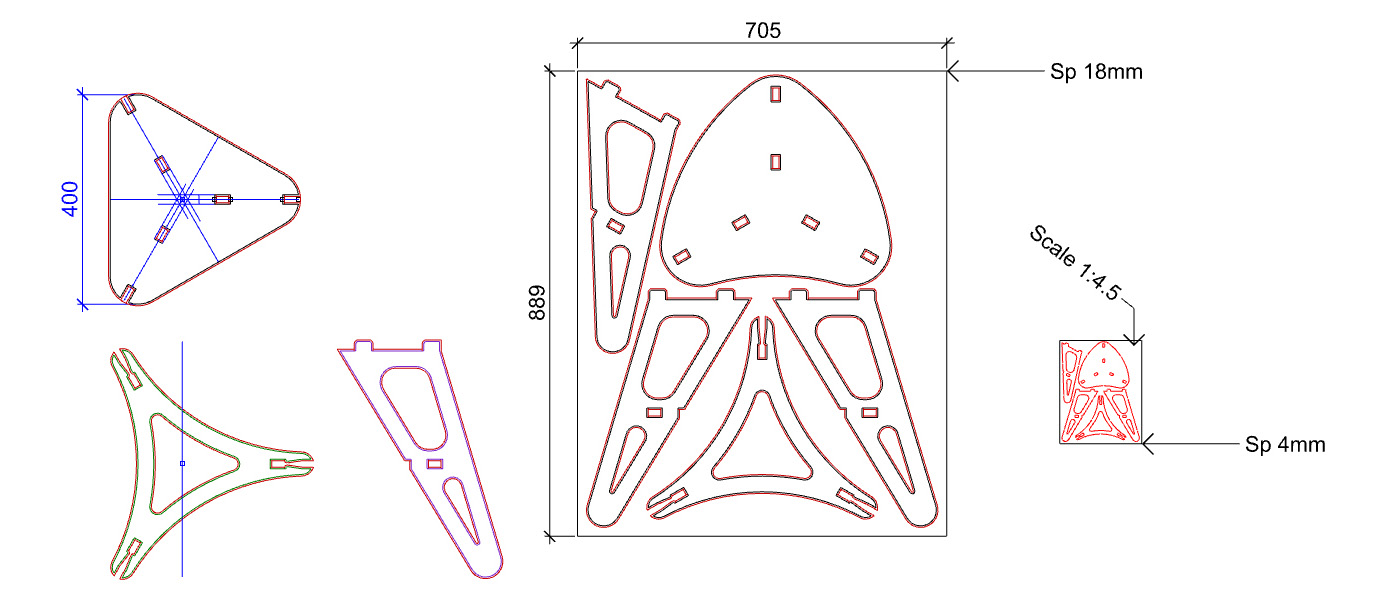

The Stool is 450mm height and 400x400mm LxD, I’ve made it in plywood sheets with a thickness of 18mm and using a flat endmill of 6mm diam.

Design¶

Starting from previous version designed in Rhinoceros v5 CAD.

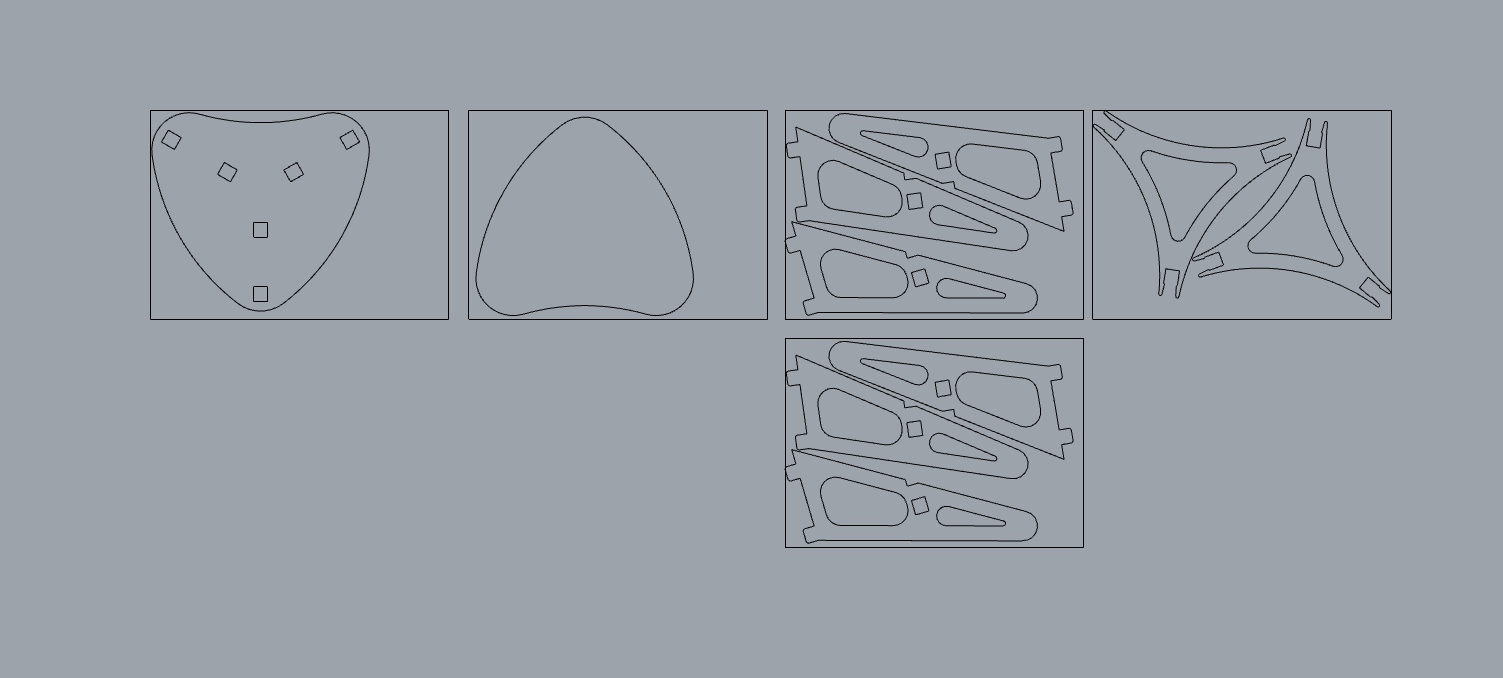

I’ve separated every piece in three layers: two external for 4mm plywood (black colored) and one internal for styrenefoam 19mm.

This stratification gives the new name to the project: OreoStool, because similar to the famous cookies brand.

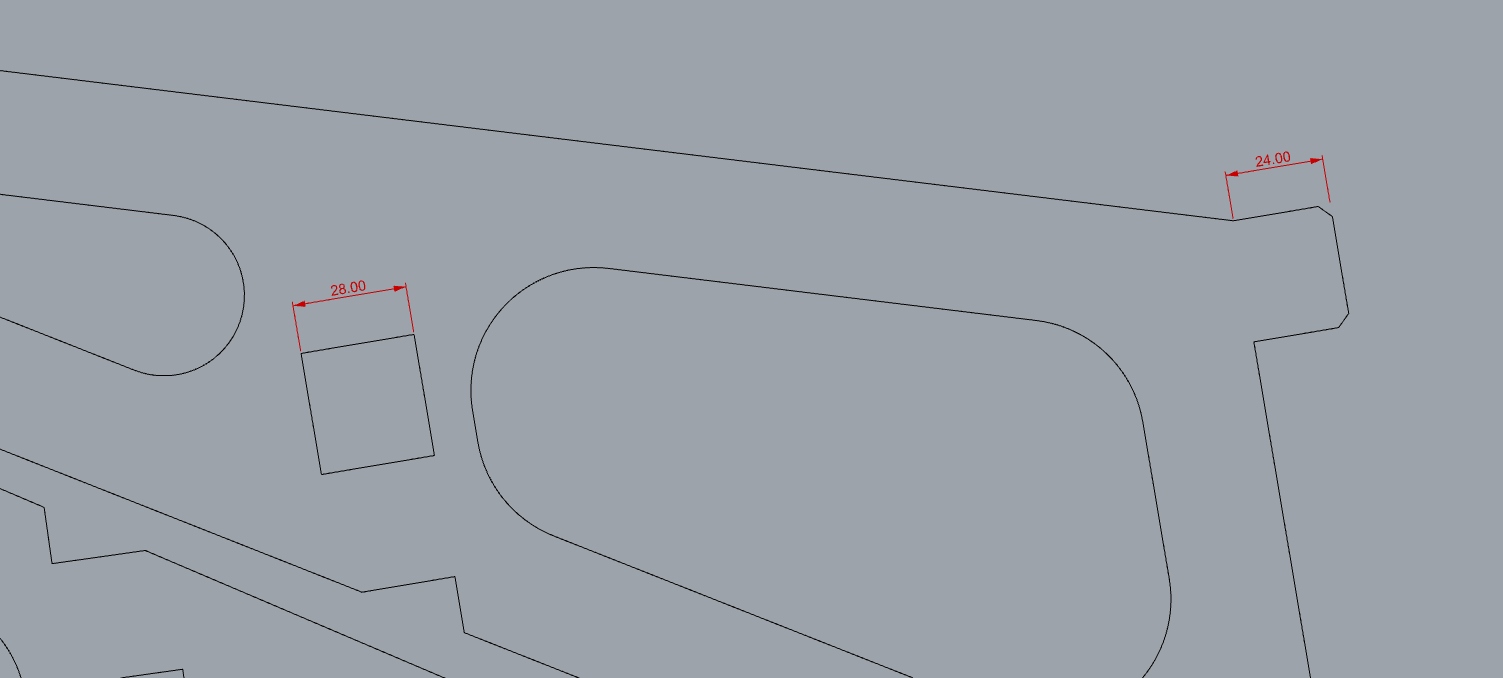

To adapt to the new thickness given by the layering (mm 4+19+4 = 27mm), I redesigned the joints, widening the slots and lengthening the pegs, but not up to the upper surface, so as to keep the upper layer of the seat clean.

download the original files.¶

Production¶

Laser Engrave¶

As mentioned above, I want keep the upper layer of the seat clean. So I decided not to pierce the joints and first of all I colored the whole surface with black acrylic paint and then I sent the engrave to my epilog laser to remove the black layer and get the plywood color below.

Laser Cut¶

At this point I’ve cutted the top layer and than the others 4mm plywood pieces.

Wire Cut¶

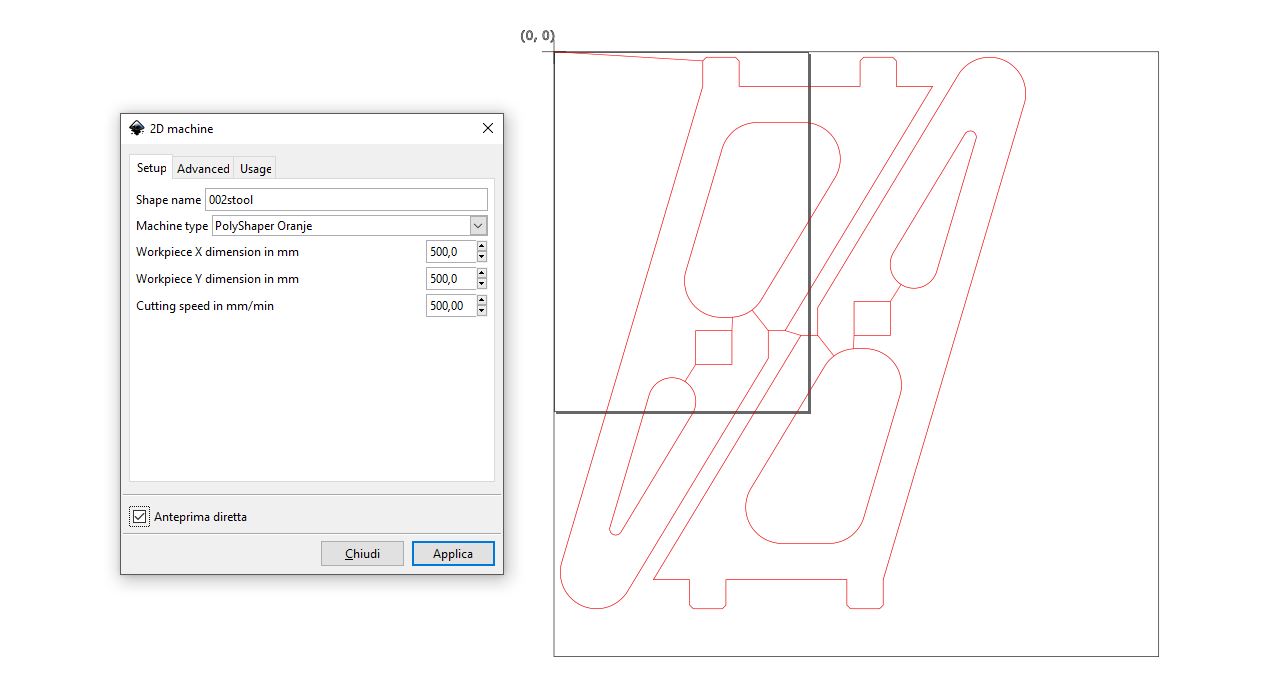

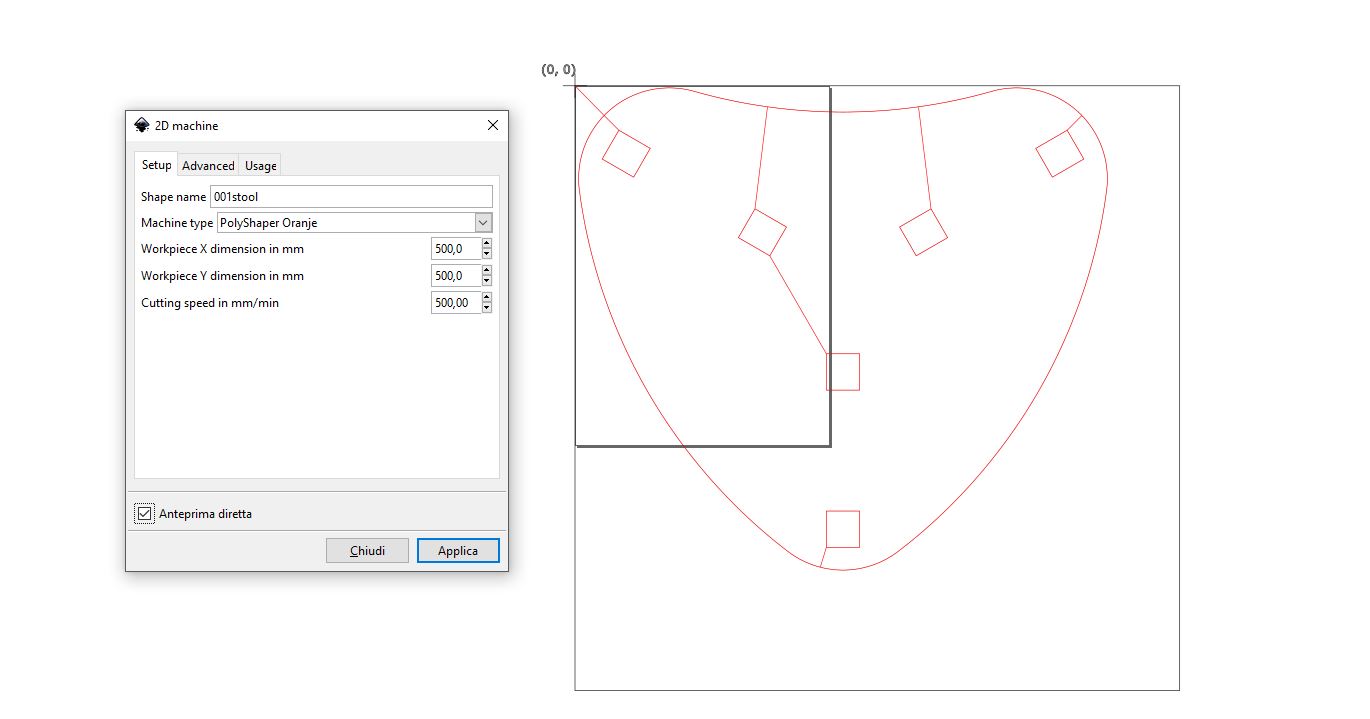

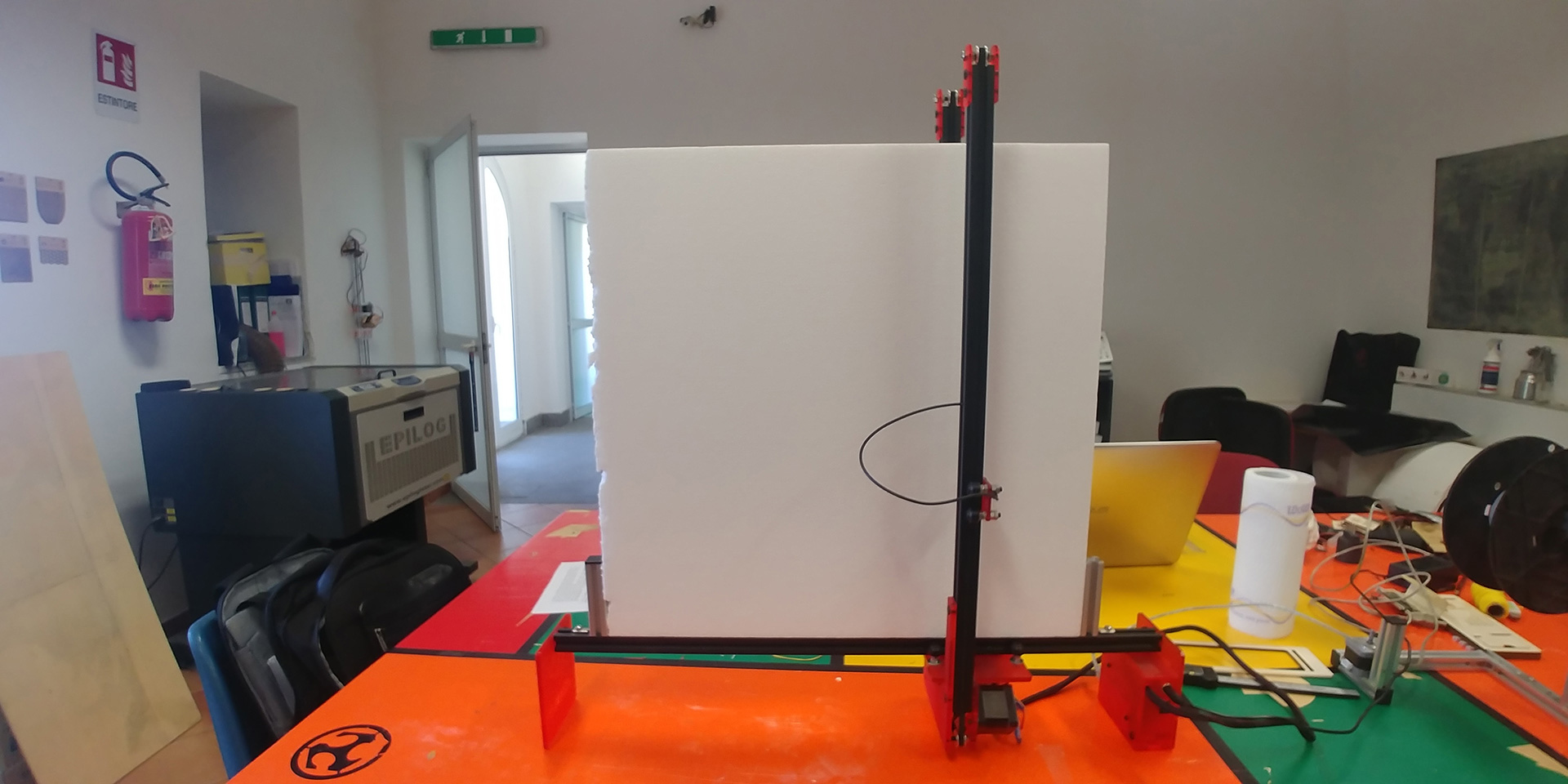

Using PolyShaper Oranje I’ve imported the vector paths in Inkscape, converted the imported objects in paths and than I’ve generated the GCode, GRBL flavour, through by PolyShaper plug-in for Inkscape.

Once obtained all GCodes for the pieces I need, I’ve sent them through ShaCo GCode Sender to the wirecutter.

Assembly¶

Once painted the rest of plywood pieces in black, I’ve glued the sandwiches through polyuretane glue and then I assembled them together.