Week05. Electronics production¶

This week, I learn about the following.

-

In the group assignment, investigate the characteristics of the milling machine.

-

Create a writer for the circuit board used in the final project.

1. Research in Group assignment¶

1-1. Envilonment¶

-

Place

-

Participant

- Yuichi Tamiya (Local Instructor)

- Kota Tomaru

- Takayuki Sakai

- Yozi Shimakawa

-

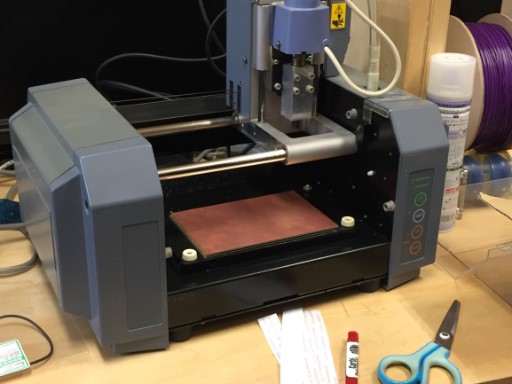

Cut Machine

- MODELA MDX-15

-

Cut Tool

- 1/64 SE 2FL

- 1/32 SE 2FL

- measure is inch

- 1/64 inch = 0.397 mm

- 1/32 inch = 0.794 mm

- SE mean Square End

- 2FL mean 2 blades

- 1/64 SE 2FL

-

Used Software

1-2. Measuring cut line¶

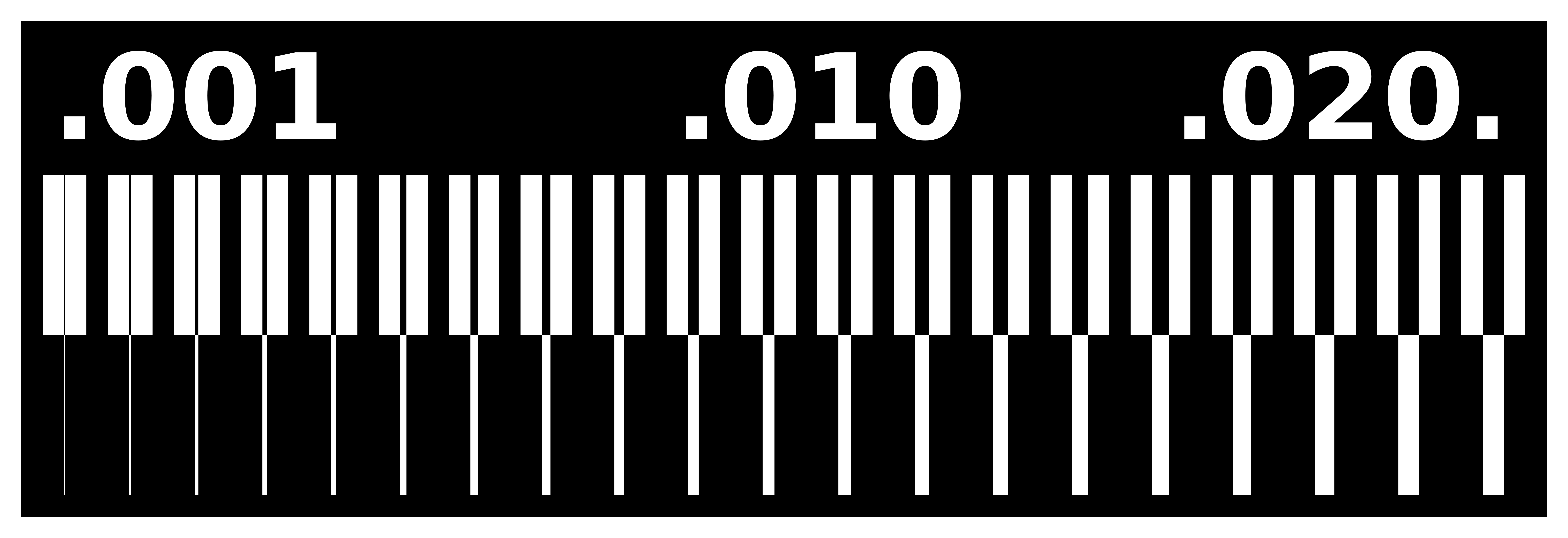

fabmodules generates machining paths from monochrome images.

Therefore, what kind of path is generated when actually used is examined.

Also, confirm the actual processing result.

trace & interior image to be processed were prepared.

- used trace

-

used interior

-

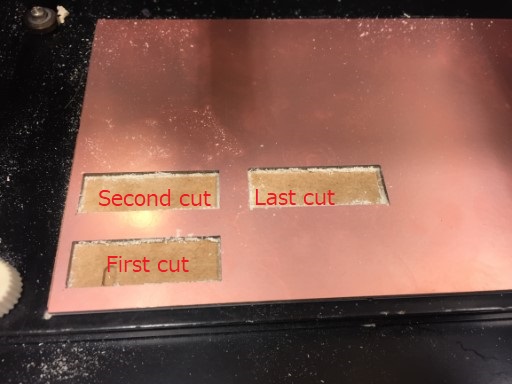

When setting fabmodules and machining at a depth of 0.3 mm,

it was only able to scrape the surface as it scratched. -

When it was set to 0.4 mm, it was scraped.

However, whether the processed surface was tilted, the left side was not yet scraped. -

So we decided to process on the right side.

The result was beautifully scraped. -

The cut position is like this

The result is as follows.¶

- It seems good to scraped with 0.4mm.

- Be careful as it may not be possible to shave depending on the position.

- The position is recommended in the center.

- Concave machining pass is generated from 0.016 inch.

- Processing of convex surfaces is almost done well, but it is better to leave as much as concave.

2. Electronics Prduction¶

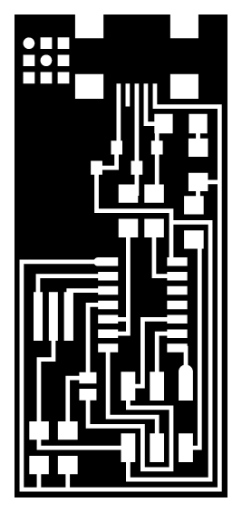

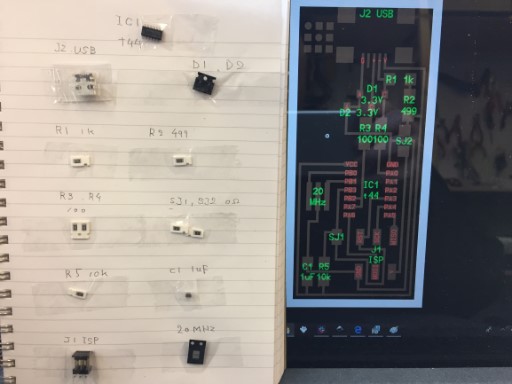

I decided to create Hello.ISP.44.res.cad with Electronics Production.

FabTiny ISP was recommended, but I heard that it is not stable.

- used trace

-

used interior

-

machine & tool is same used in group assignment

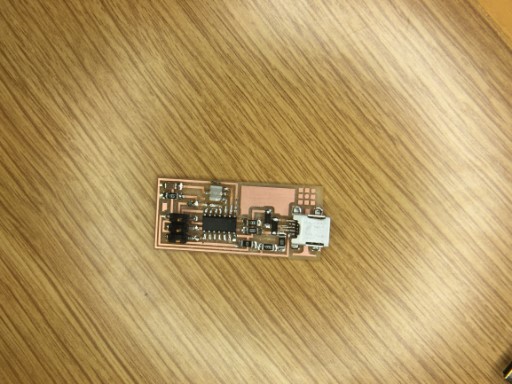

2-1. Substrate processing¶

-

fabmodules setting (trace)

- cut depth = 0.4mm

-

fabmodules setting (interior)

- cut depth = 1.8mm

- cut each 0.6mm

- cut depth = 1.8mm

-

check & cleaning

-

Preparation for soldering

- Search

- Line up

- Search

-

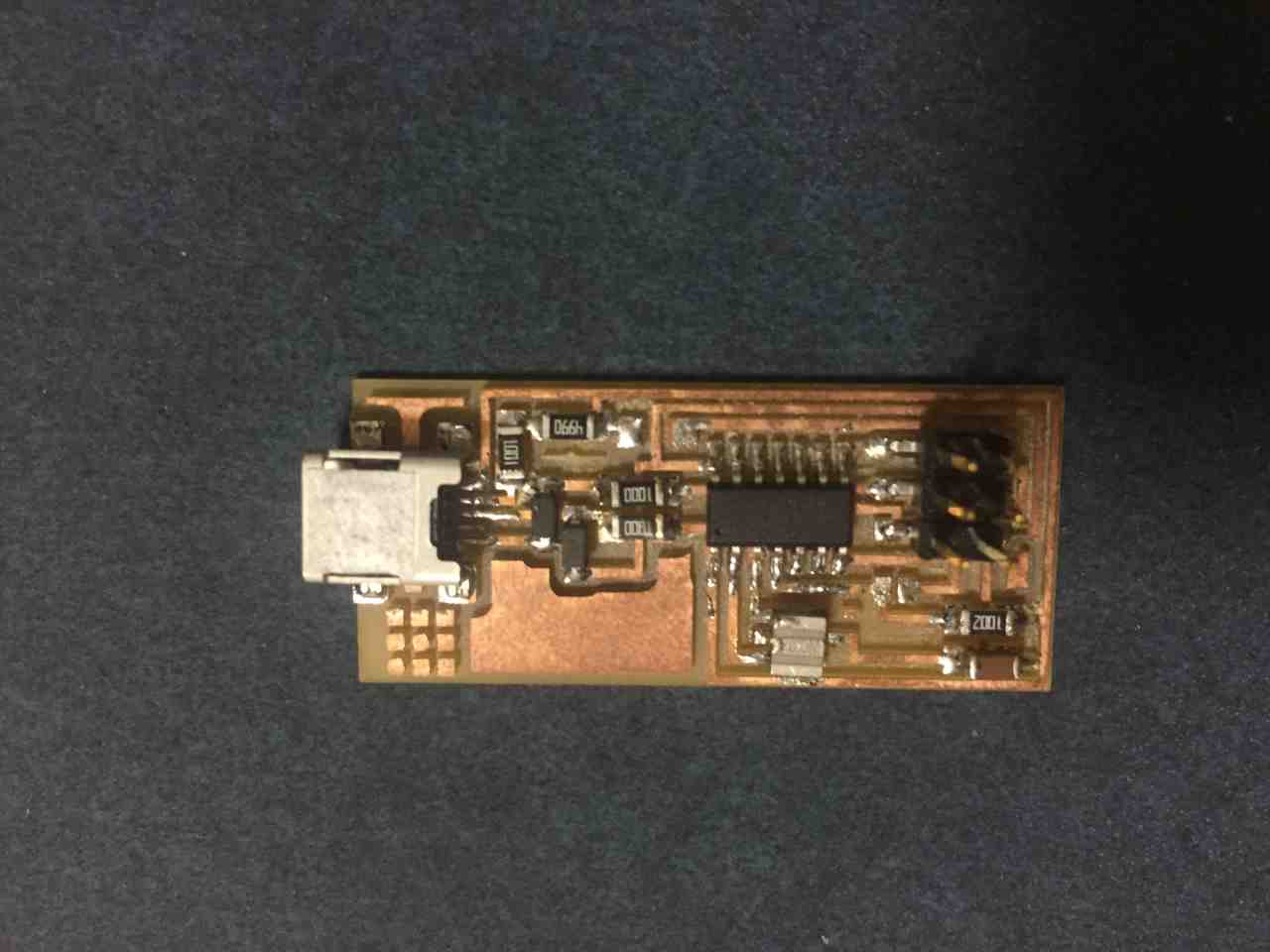

Soldering

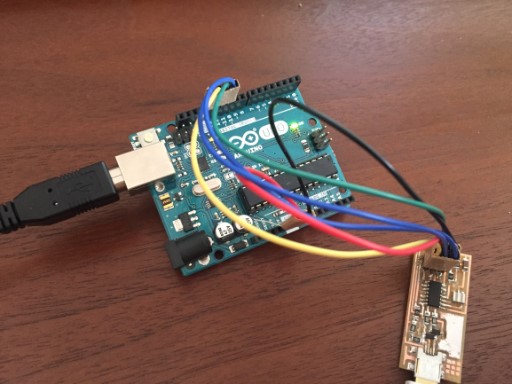

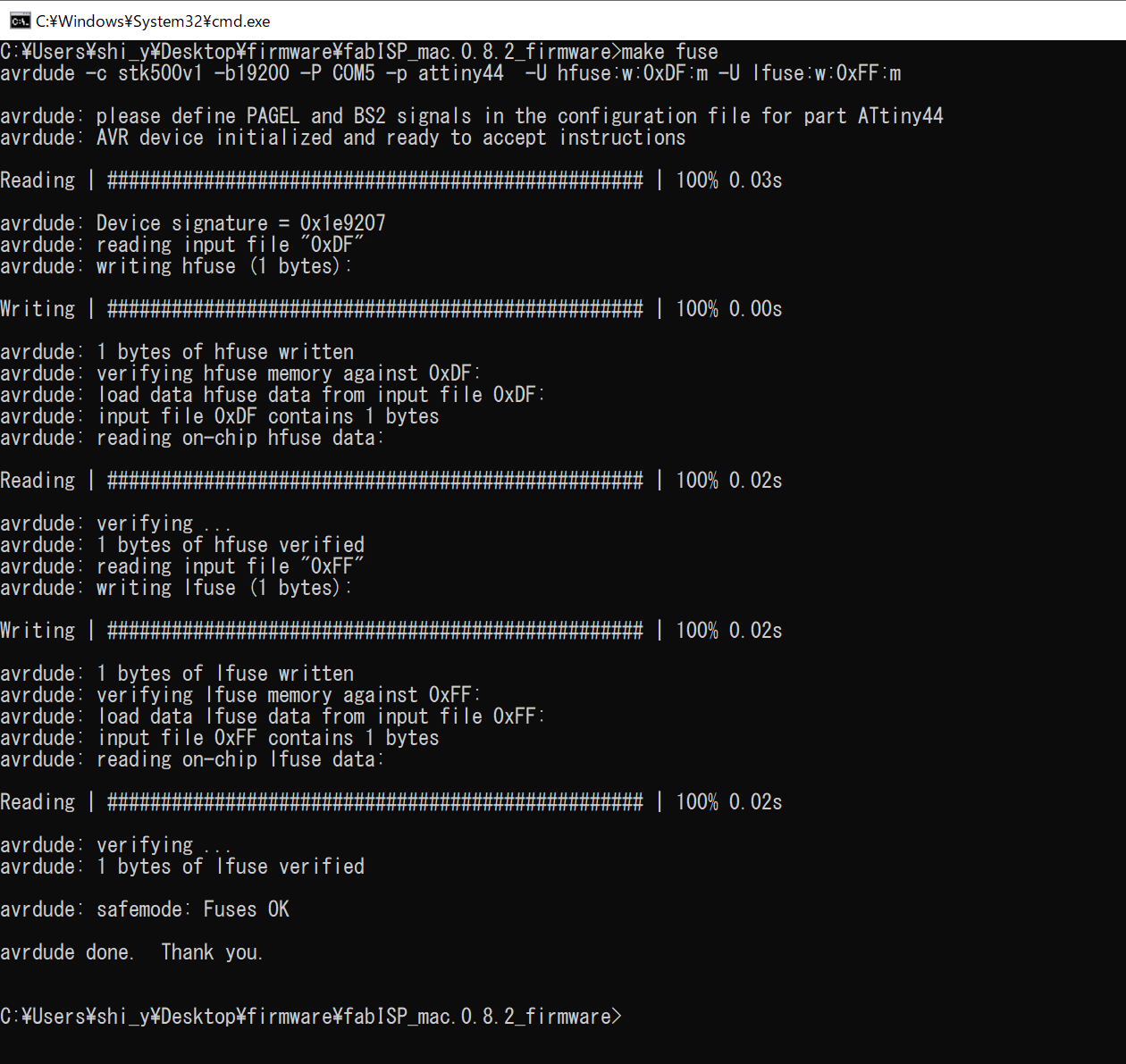

2-2. Programing Writer¶

-

I made the settings according to Tutorial(for Windows).

- FabISP Tutorial

- Local Instoructors Site (Week4)

- Wiring etc. when using Arduino are listed in detail

-

Wireing

-

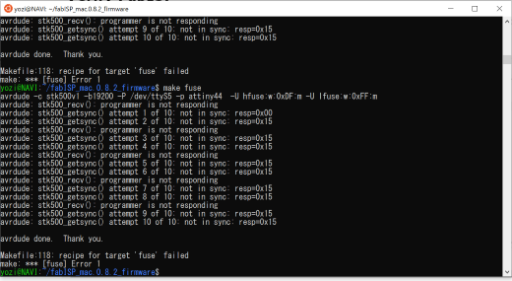

It does not work

- I also tried Ubuntu on Windows, but I could not do it.

- I also tried Ubuntu on Windows, but I could not do it.

-

Recheck

- There was a part that was not soldered.(no image)

-

Resoldering

-

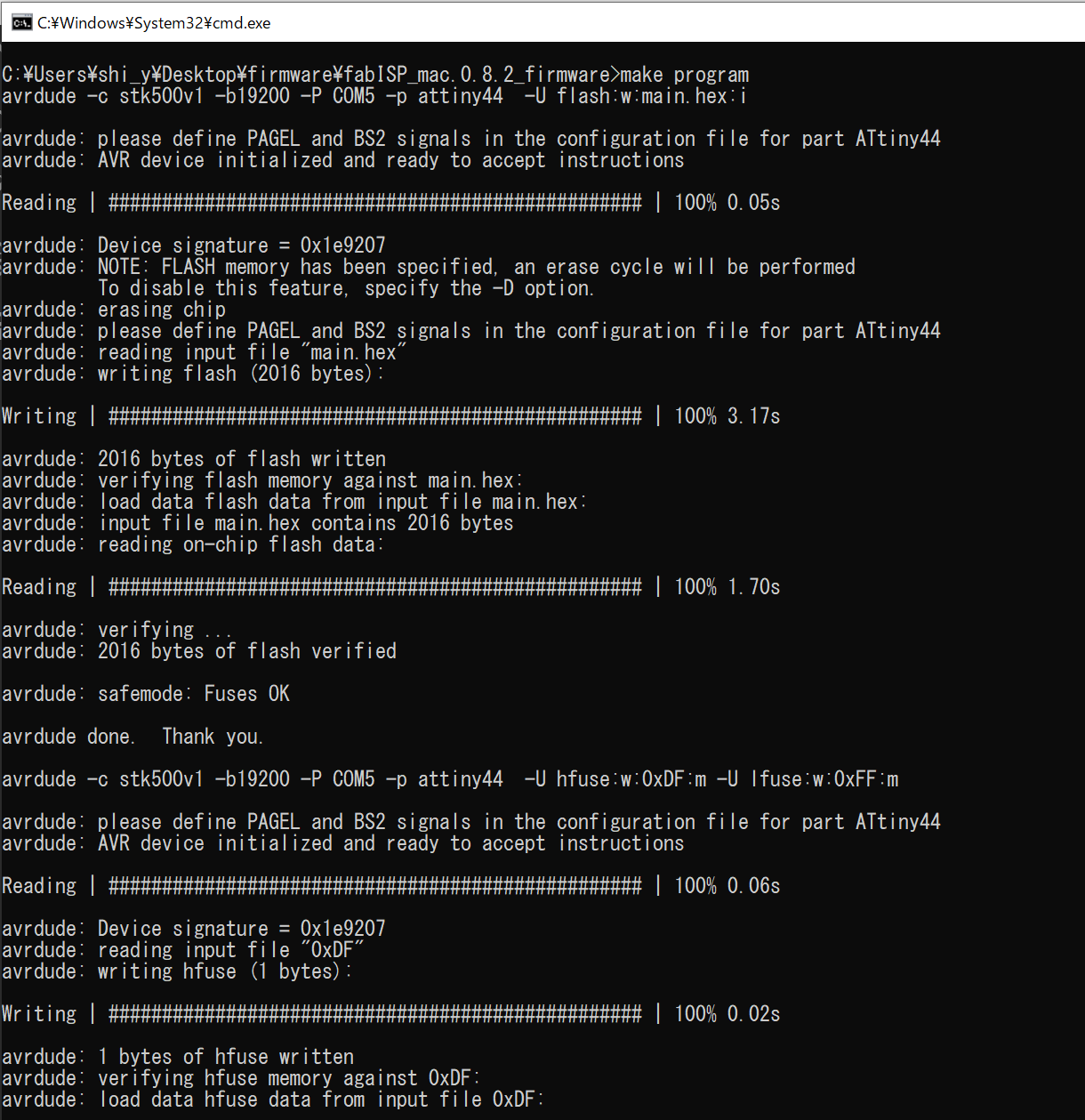

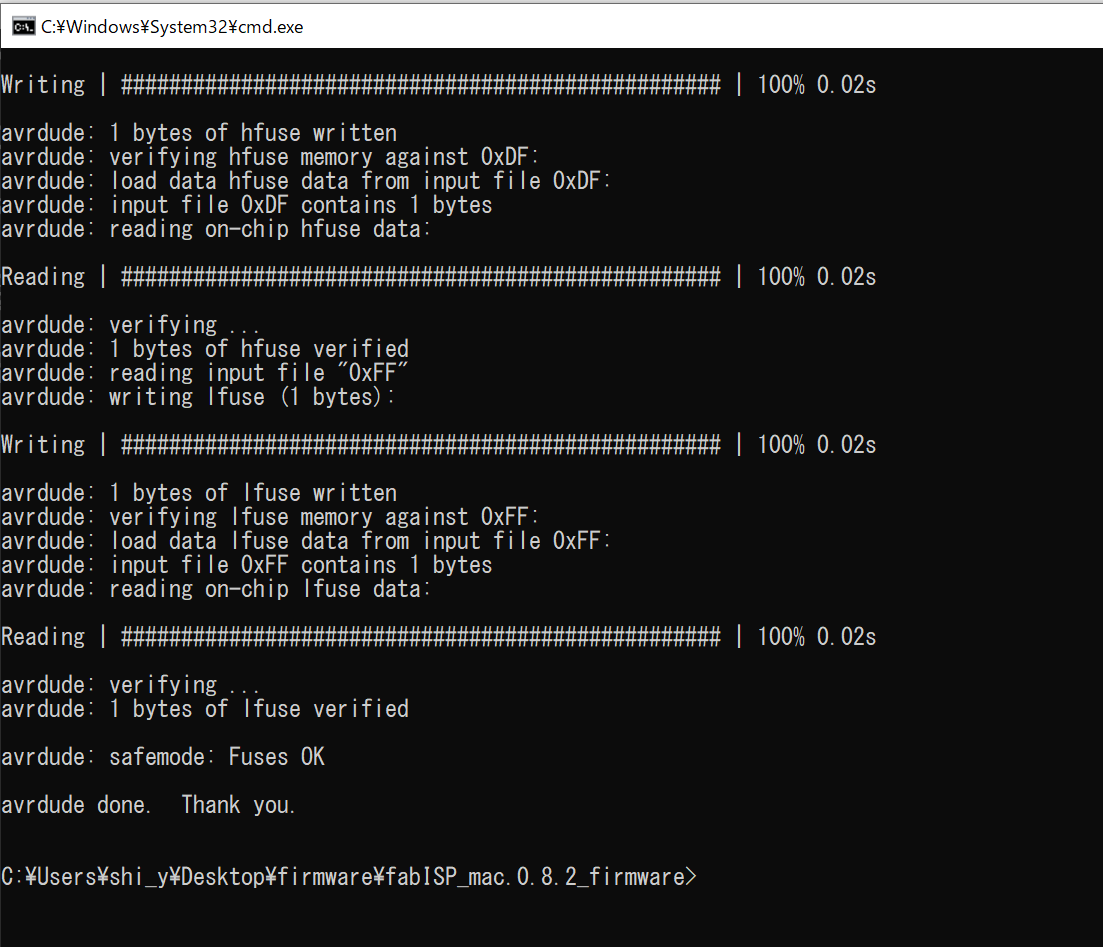

Resetting

- I finally succeeded by making a Make from the Windows command prompt.

-

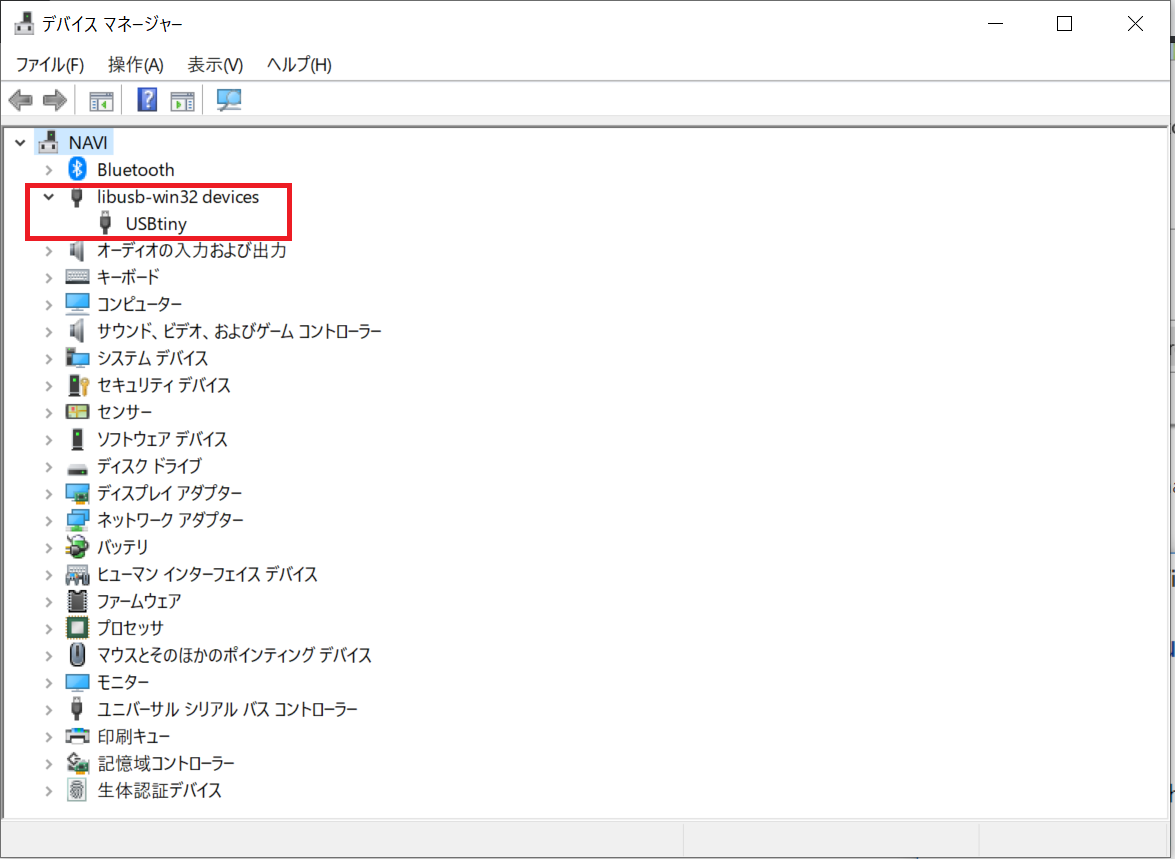

Looking for USBtiny in device manager

-

Hero shot

I do too many things on the way and I do not know how I came this way.

I would like to keep track of what I did, so that it will not happen from the next time.

2-3. Probably the necessary application¶

- Adafluit Driver

- GNU Make

- avrdude

- need setting system path

- WINAVR

- Windows USBtinyISP signed driver