Assignments

1. Principles and practices

2. Project management

3. Computer Aided design

4. Computer controlled cutting

5. Electronics production

6. 3D Scanning and printing

7. Embedded programming

8. Computer controlled machining

9. Electronics design

10. Output devices

11. Input devices

12. Molding and Casting

13. Networking and communications

14. Interface and application programming

15. Wildcard week

16. System integration

17. Applications and implications

18. Invention, intellectual property and income

19. Project development

4. Computer controlled cutting

Assignment: Design, lasercut, and document a parametric press-fit construction kit, which can be assembled in multiple ways. Account for the lasercutter kerf. cut something on the vinylcutter.Vinyl Cutting

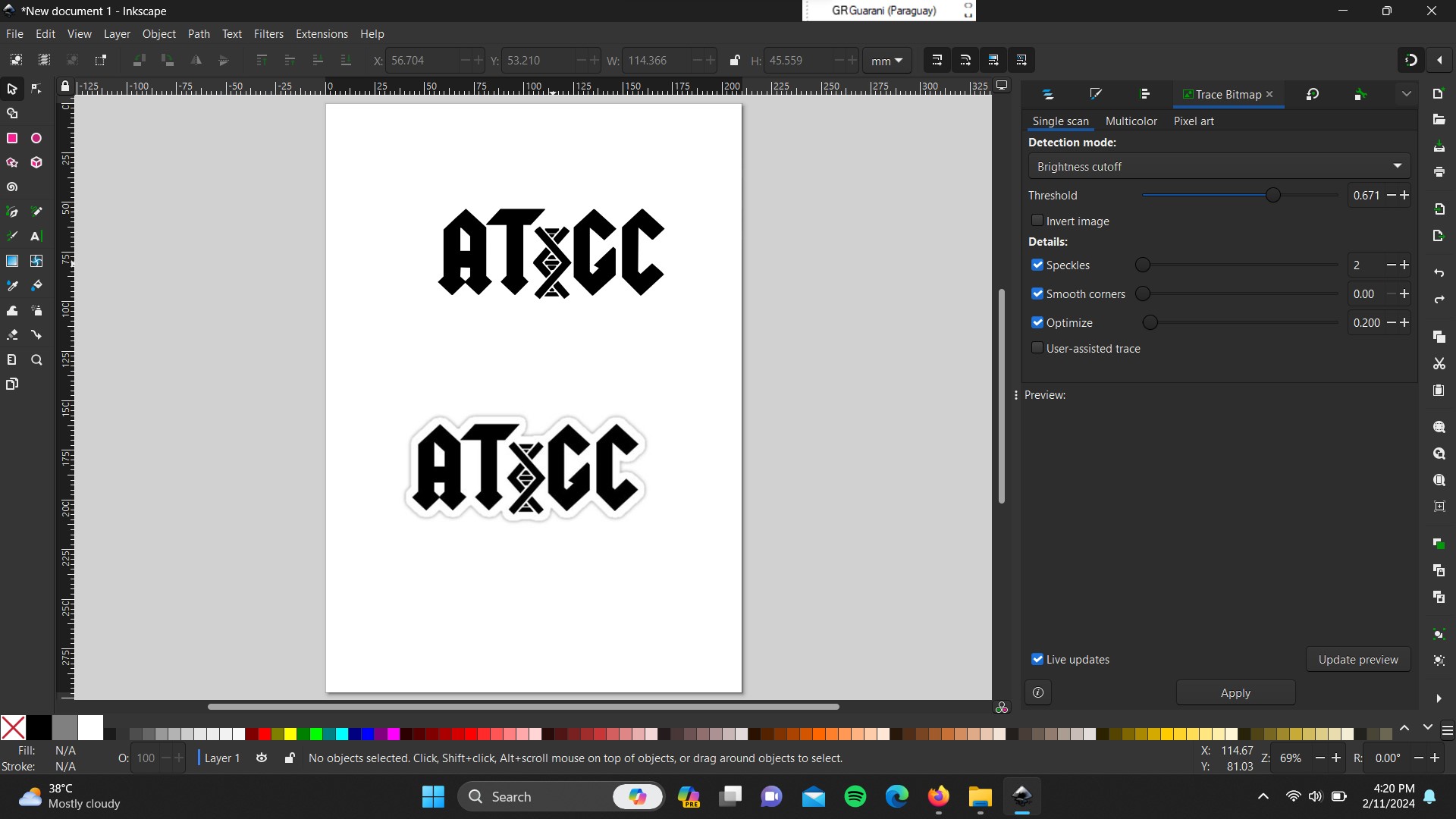

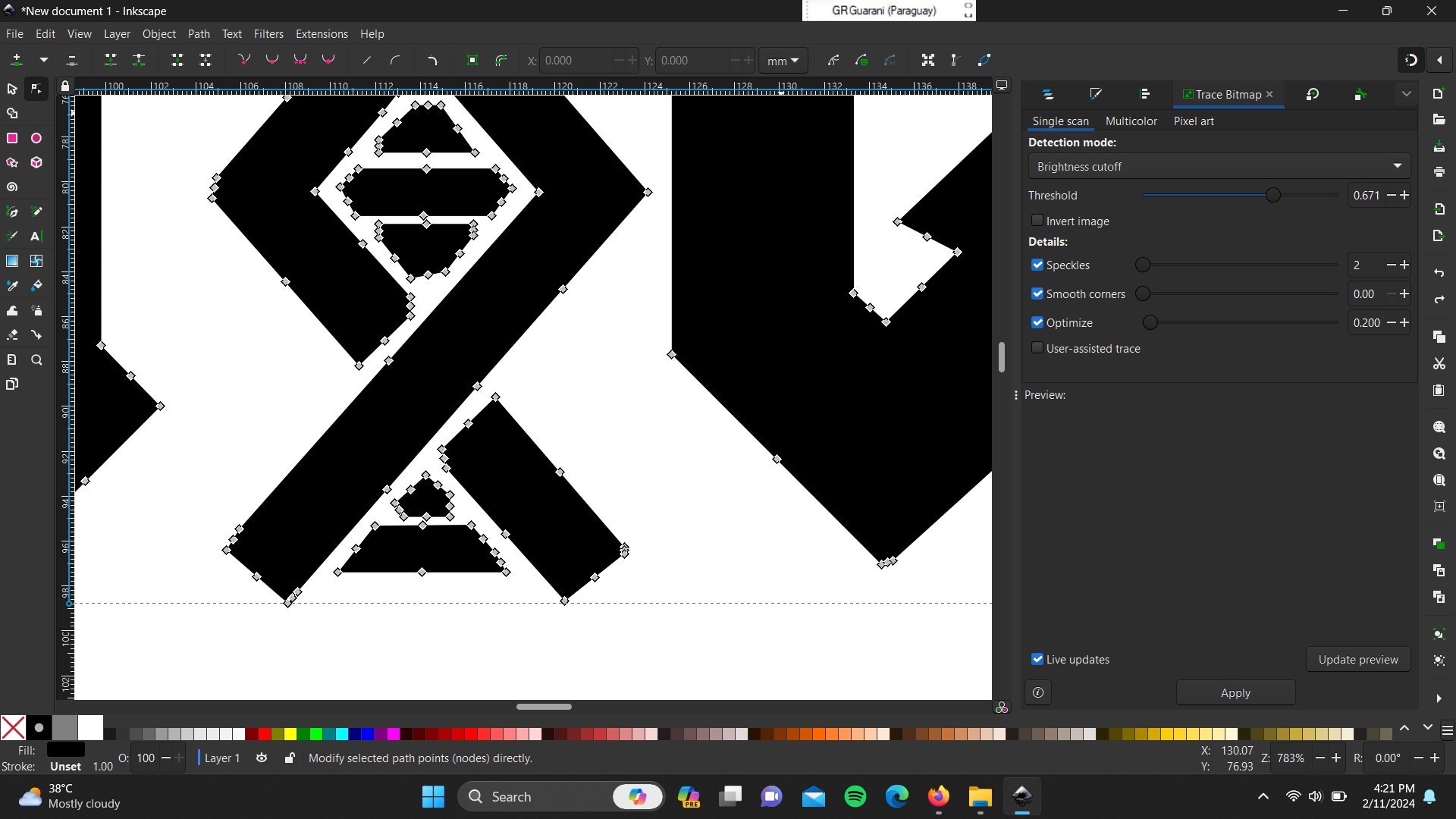

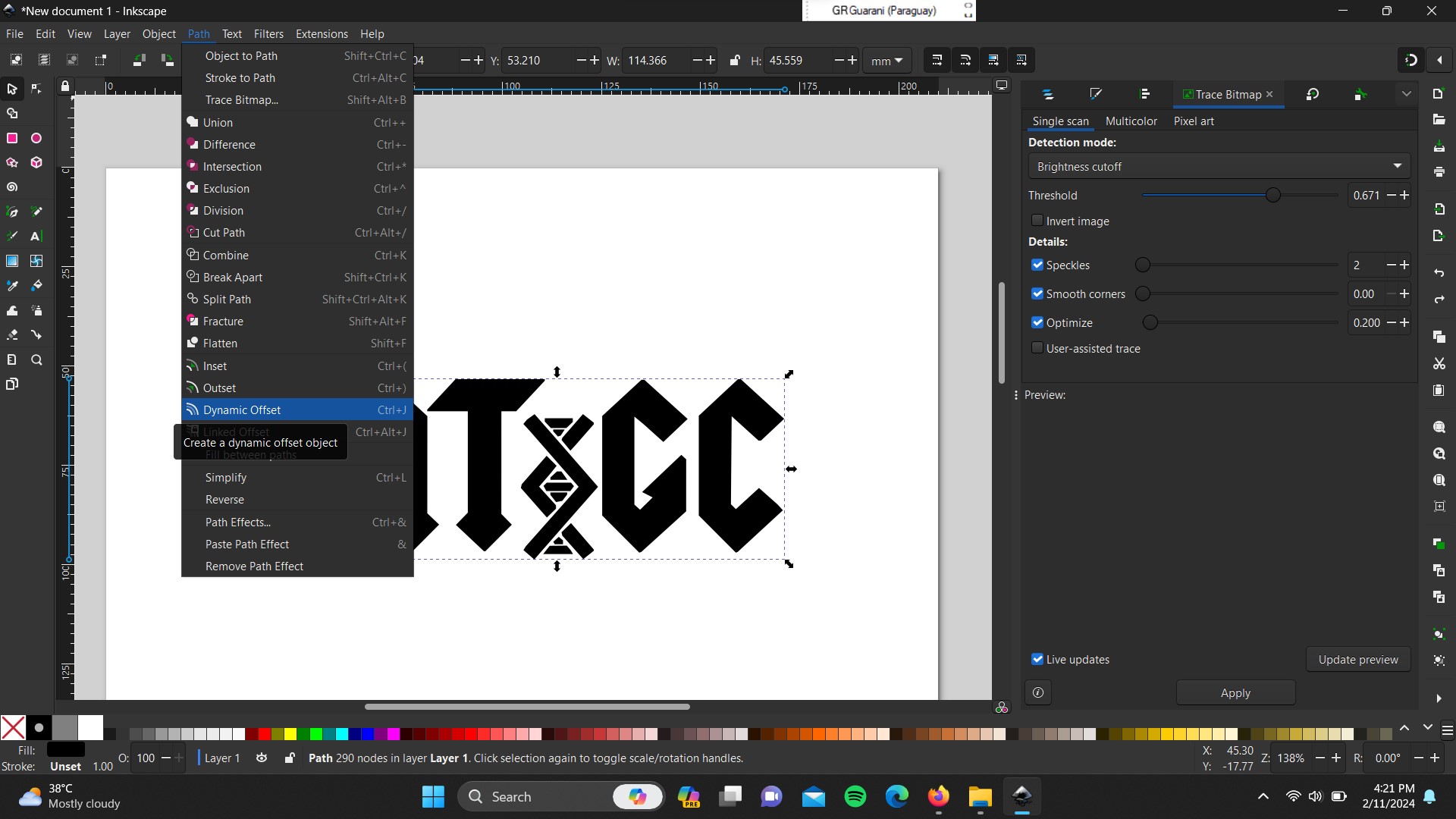

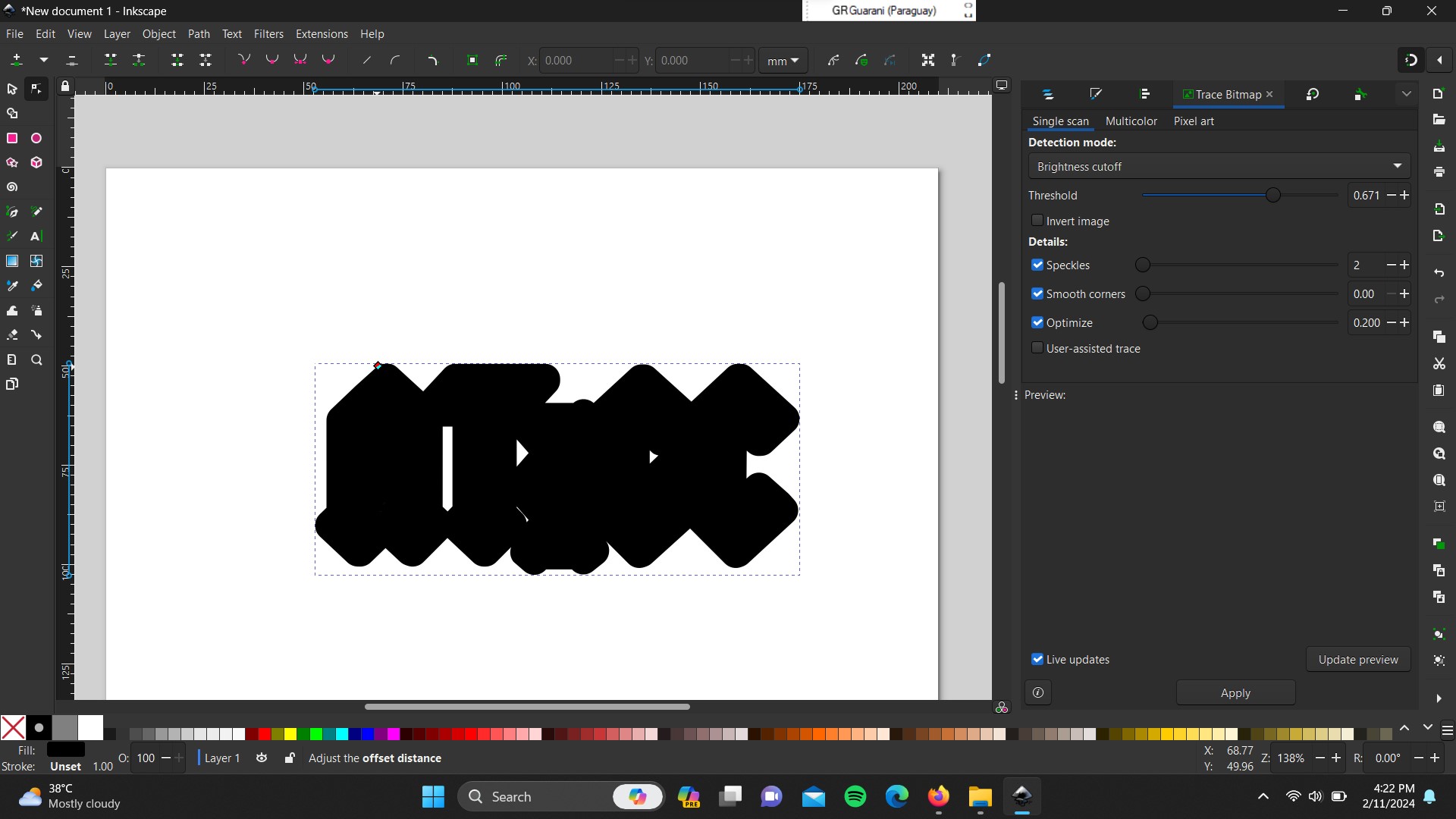

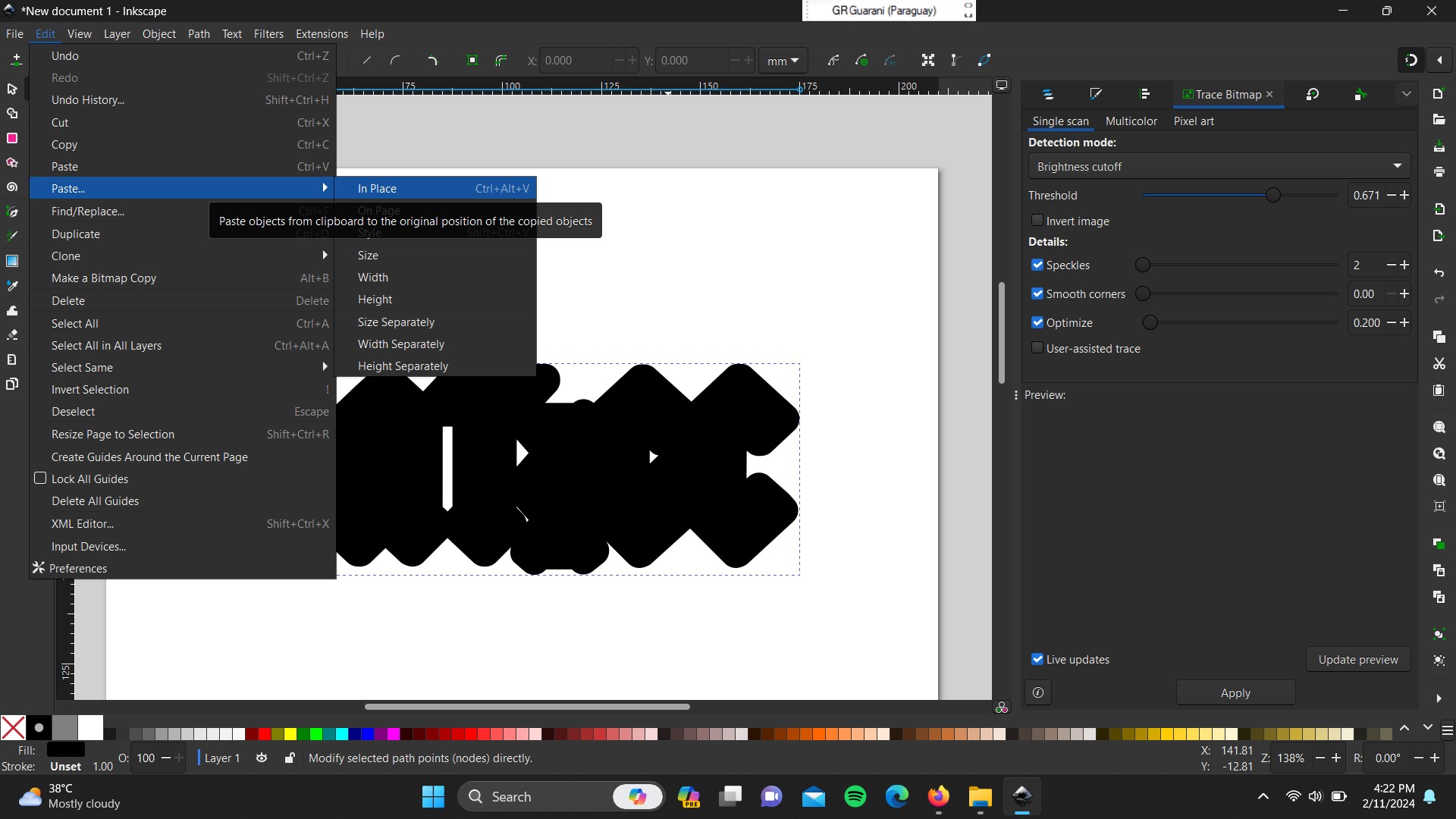

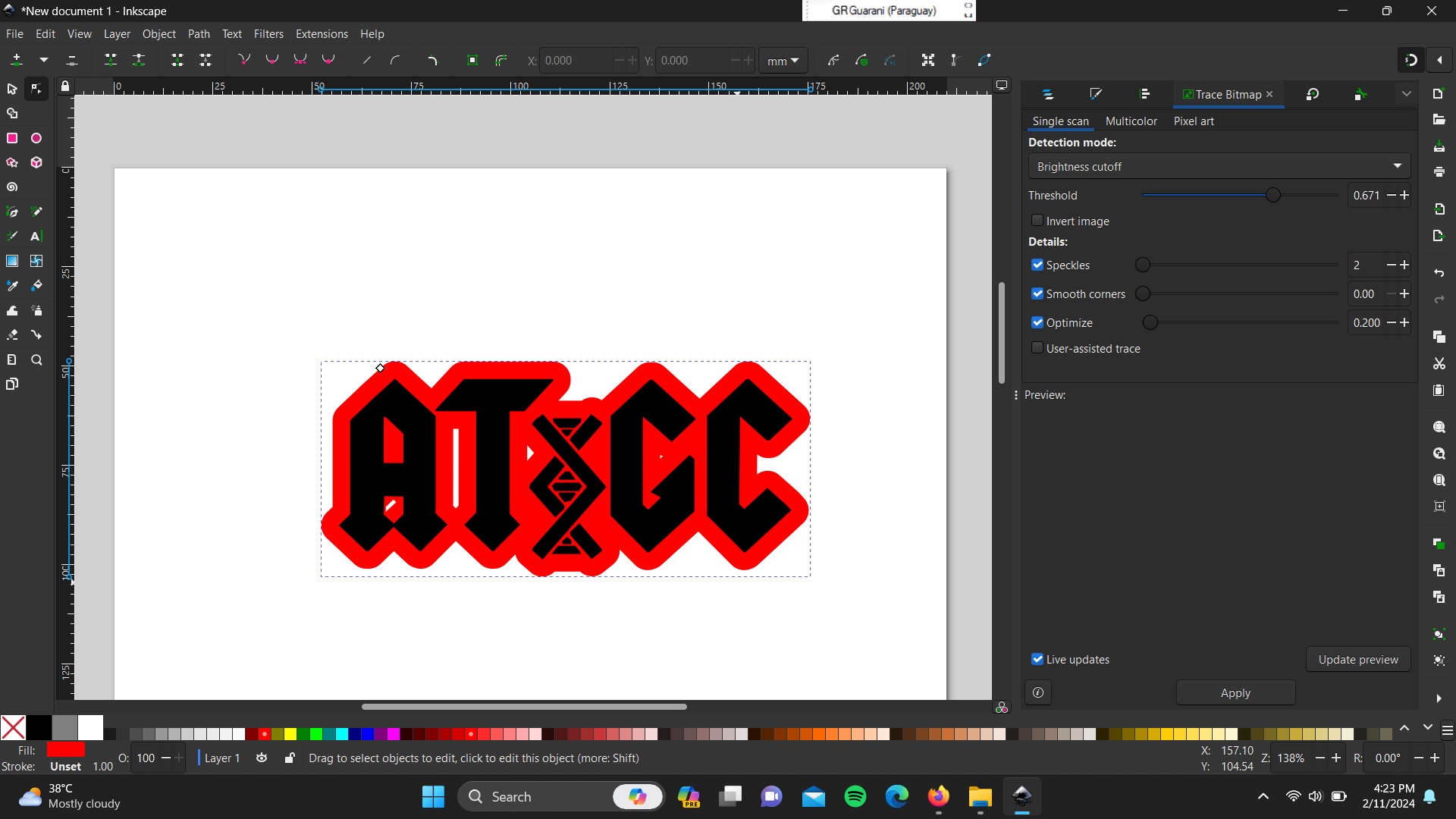

For the vinyl cut, I first did a search on Pinterest and selected the following image as the design. I downloaded the image in jpg format and then vectorized it using Inkscape.

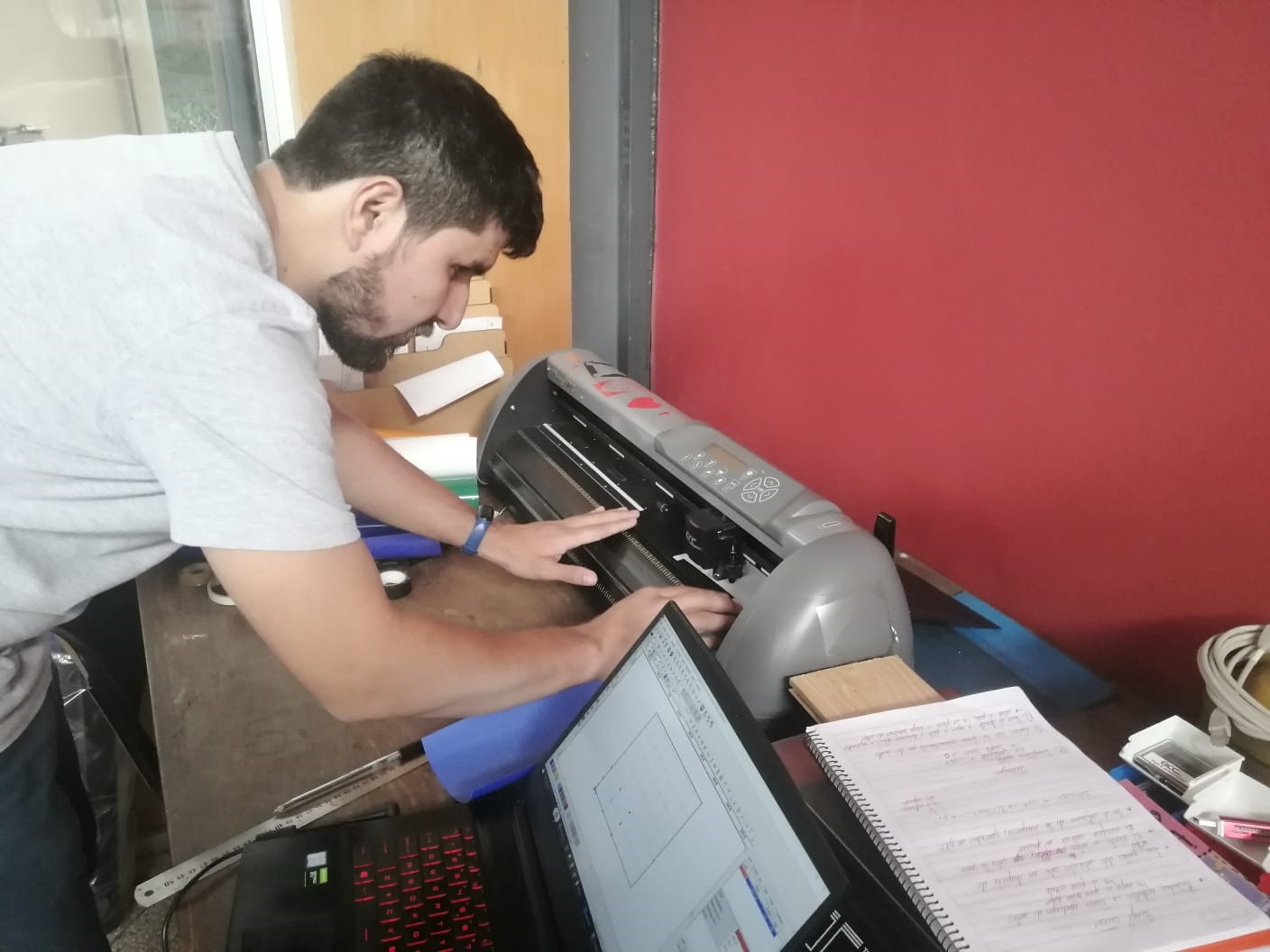

I exported the vectorised image in dxf format, this format is recognised by the machine software (GCC Puma IV LX vinyl cutter). Once the image is loaded in the machine software, we select and place the appropriate knife, place the heat transfer vinyl, set the origin of the cut, and finally make the cut.

Finally we carry out the heat transfer process so that the design remains attached to my t-shirt.

this is the final result.

Parametric Press-fit Construction

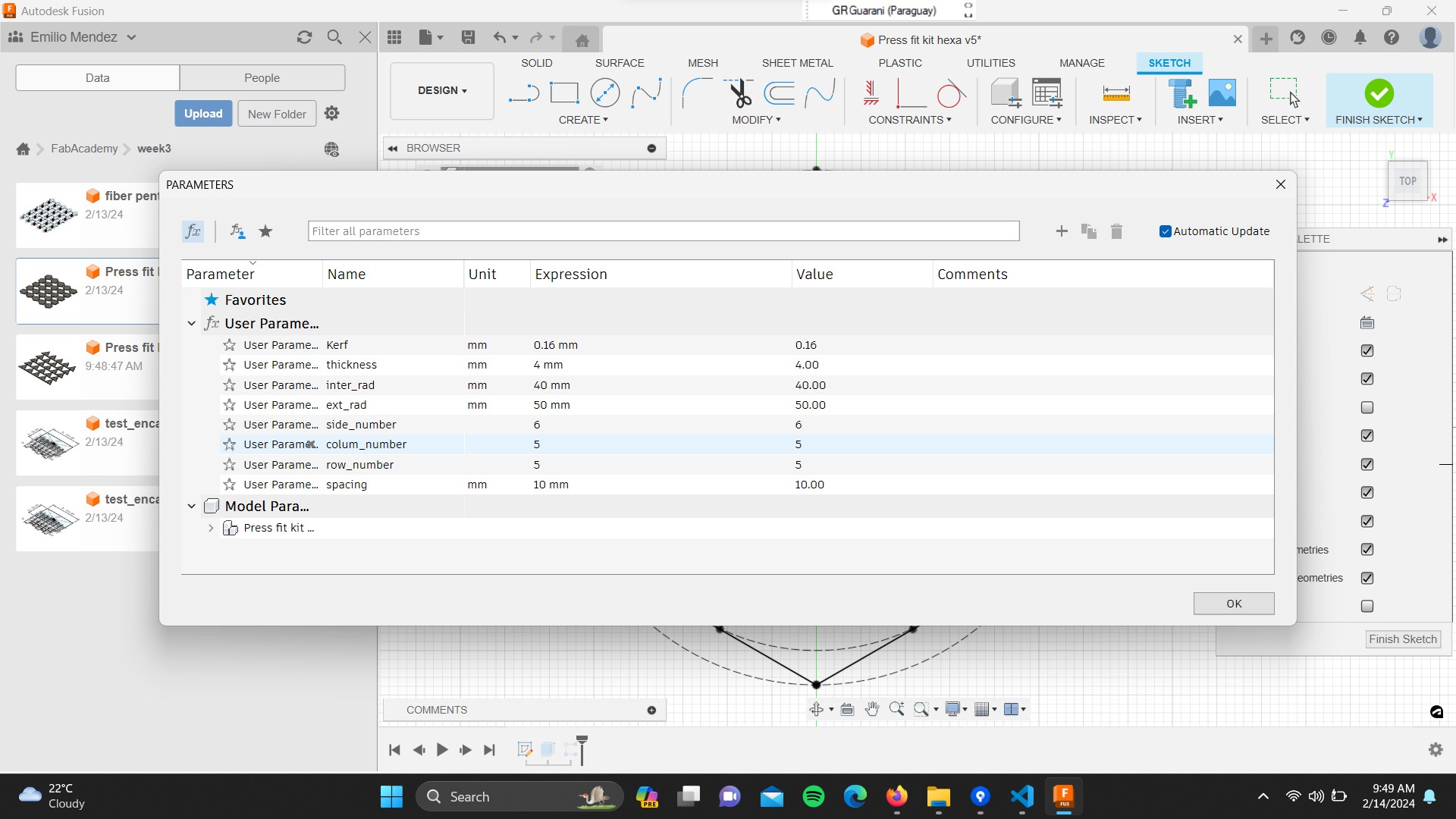

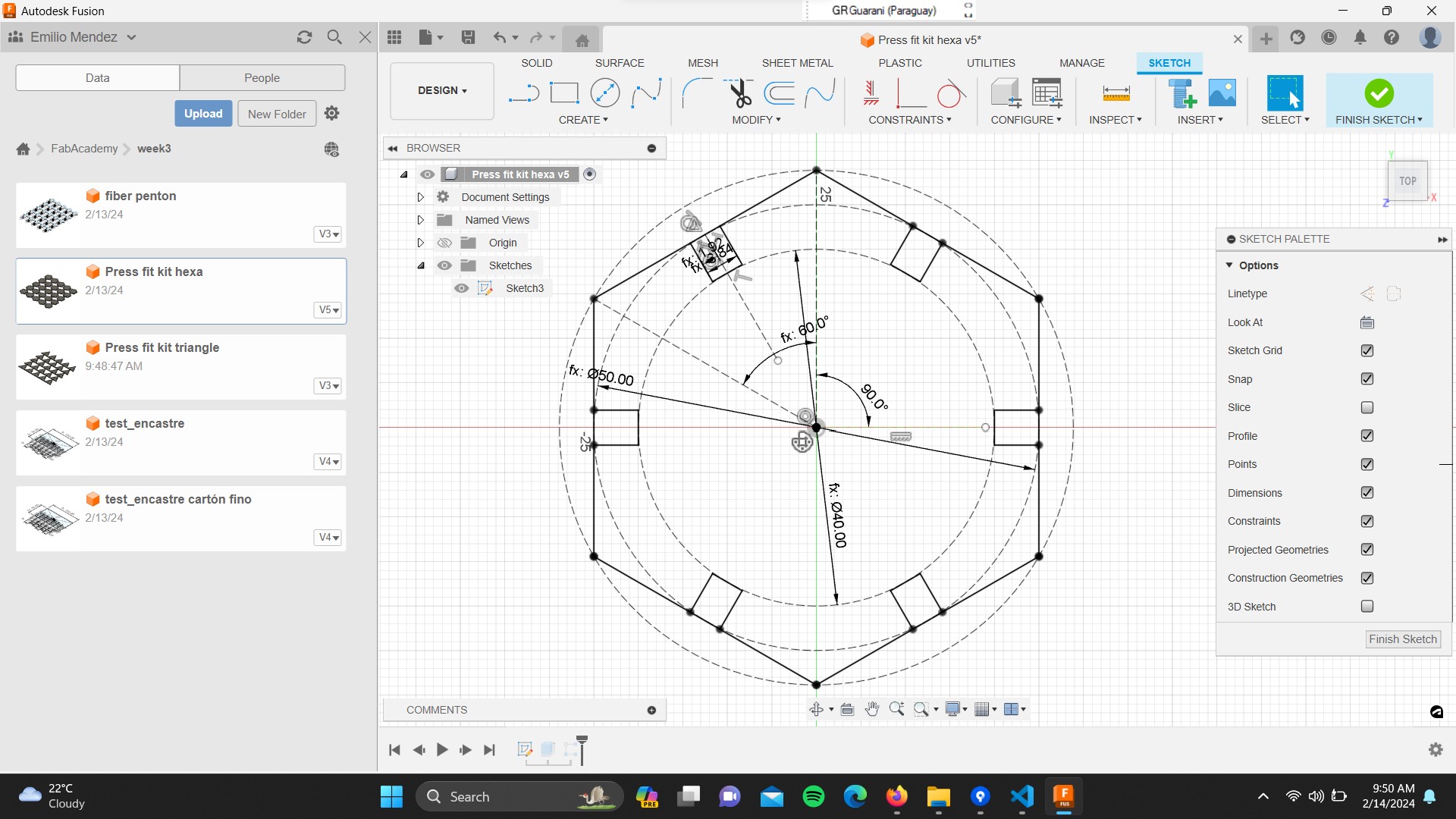

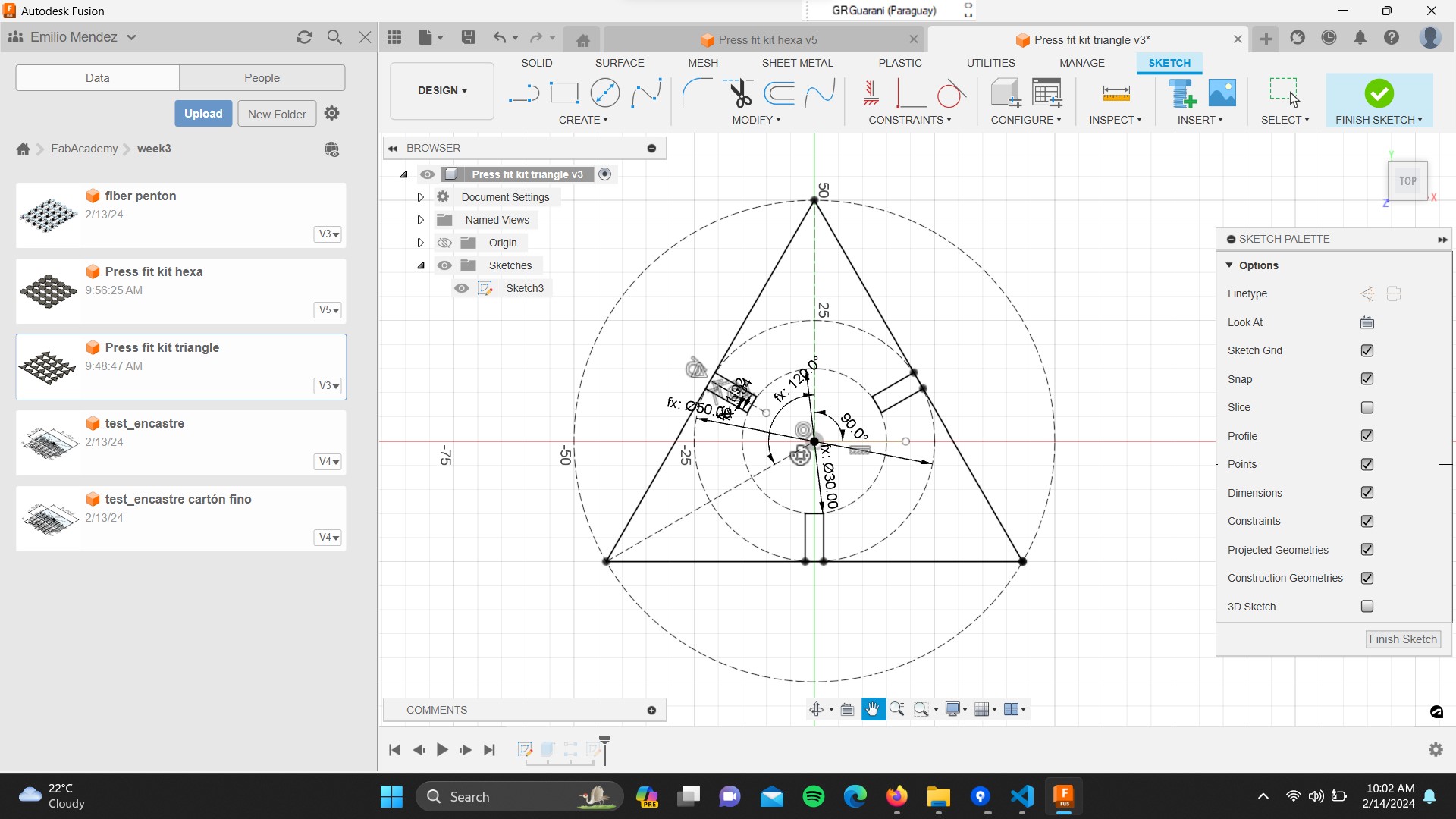

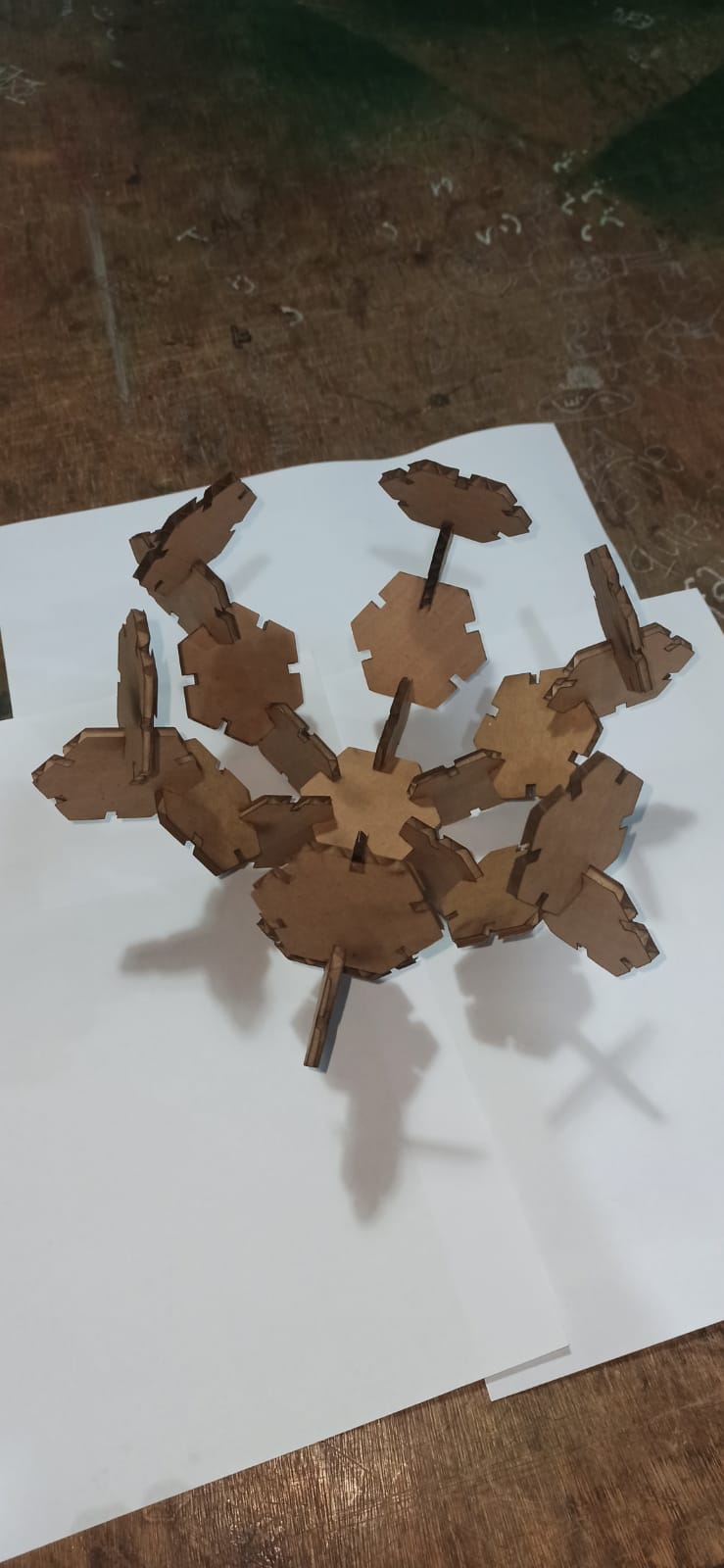

For the parametric design I used Autodesk Fusion 360, and I decided to work with cardboard. At first, I had the idea of making some interesting designs of my interest, but due to my limited knowledge and skills in this area, I decided to only design something similar to a block or puzzle that would allow me to learn and apply what corresponds to parametric design, at the same time it allows me to show if the design was made correctly after laser cutting.With the help of the instructors I parameterized the hexagon that could fit between them. The parametric design was carried out in a way in which depending on the number of sides assigned, it was adjusted to the corresponding polygon. In this way, I designed hexagonal and triangular blocks. Some important parameters that were taken into account during the design are the Kerf and the thickness of the cardboard, which were 0.16 mm and 4 mm respectively. The two final designs were as follows.

Here is the final result

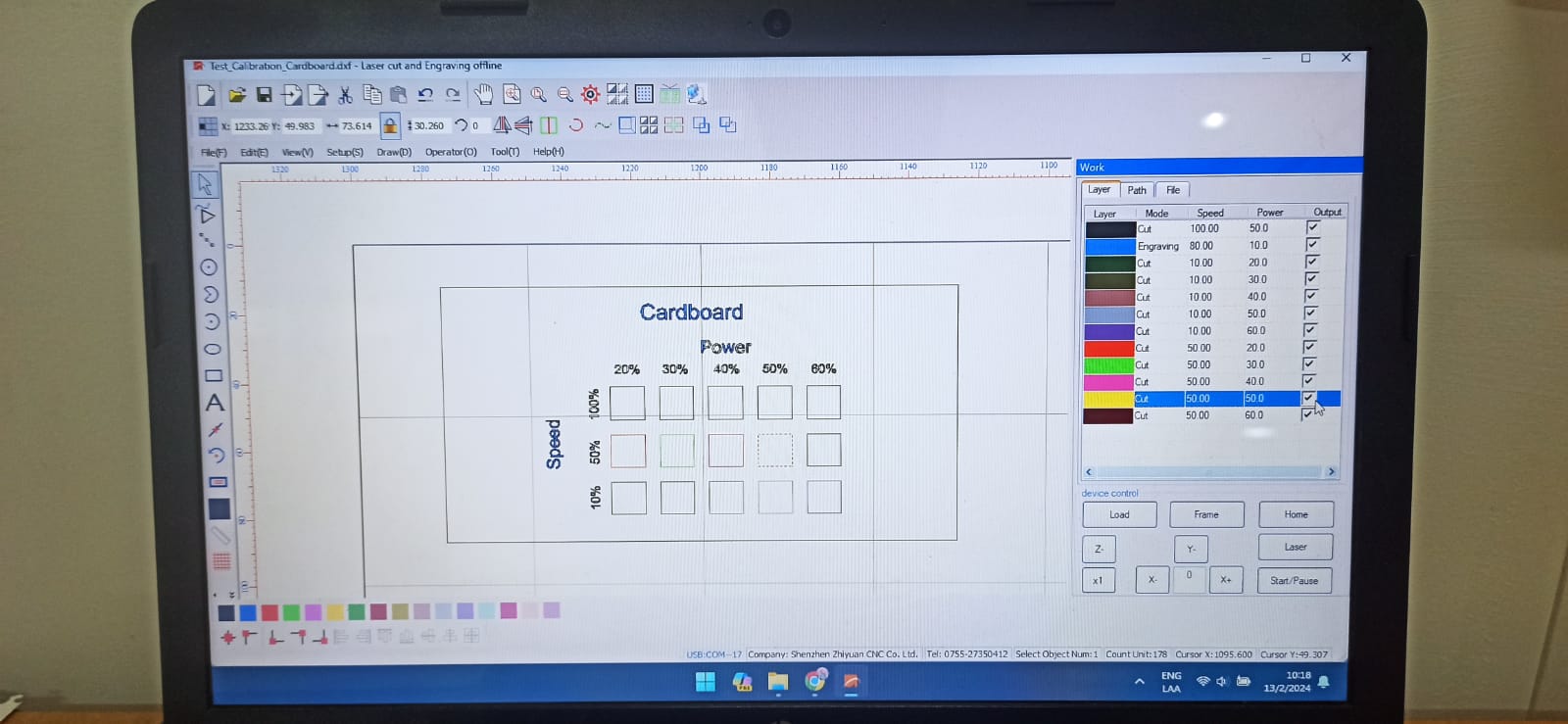

Group Assignment

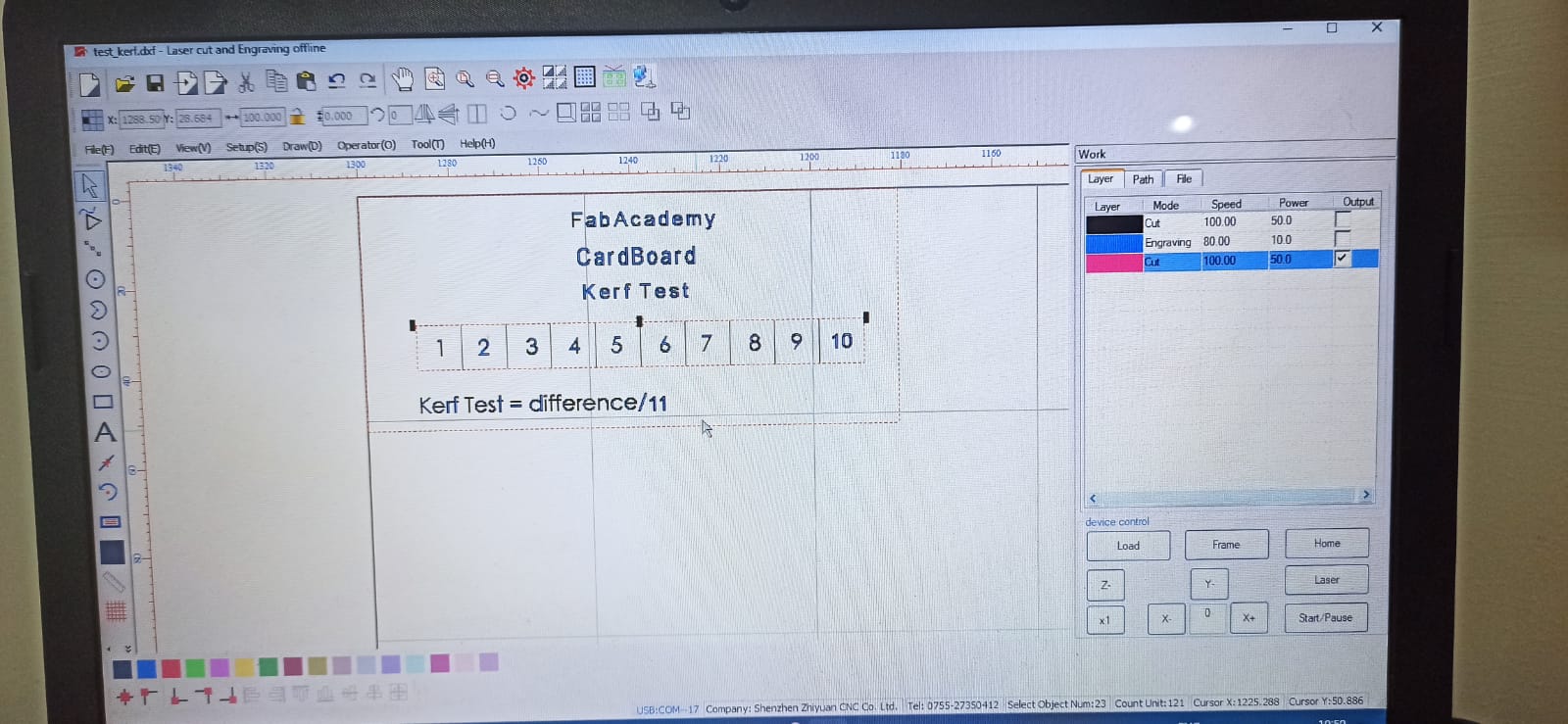

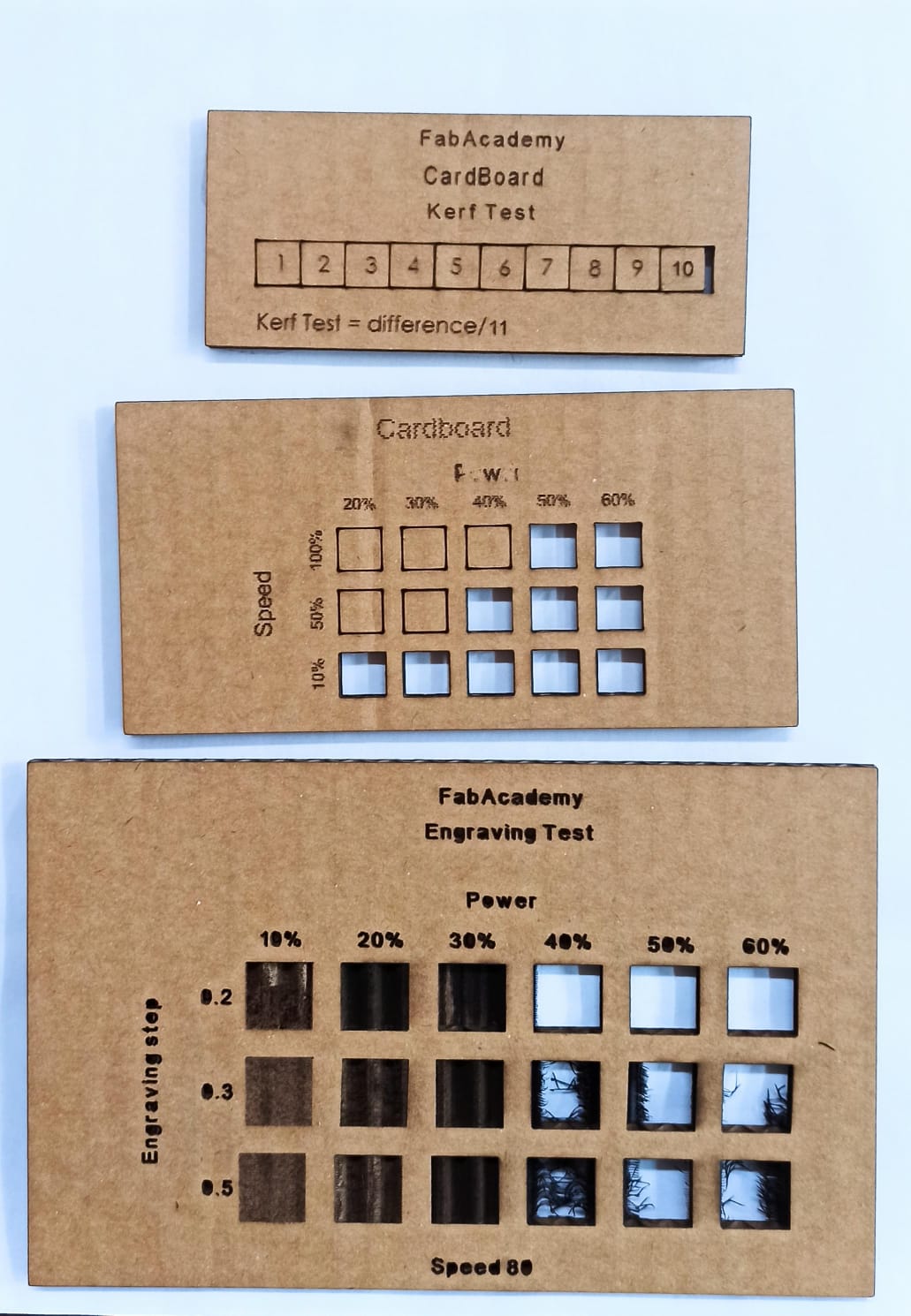

For the group assignment we characterize our laser cutter. After learning the basic functions of the machine, each member of the group characterized the cut with a specific material, in my case I used cardboard and defined the different parameters (kerf, power, speed, engraving test). I finally got a 0.16mm kerf. The speed and power used for cutting were 100 and 50 respectively.

There is the link of the groupal assignment