15. Wildcard week

This week we searched different machines and tools. Assignment was to try something new, at least one machine, I was interested to use welding, so to use machine 3D printed two detailes to use as a frame for detailes positioning (leg of my table broke, so needed to weld two parts with exect angle).

Documentation

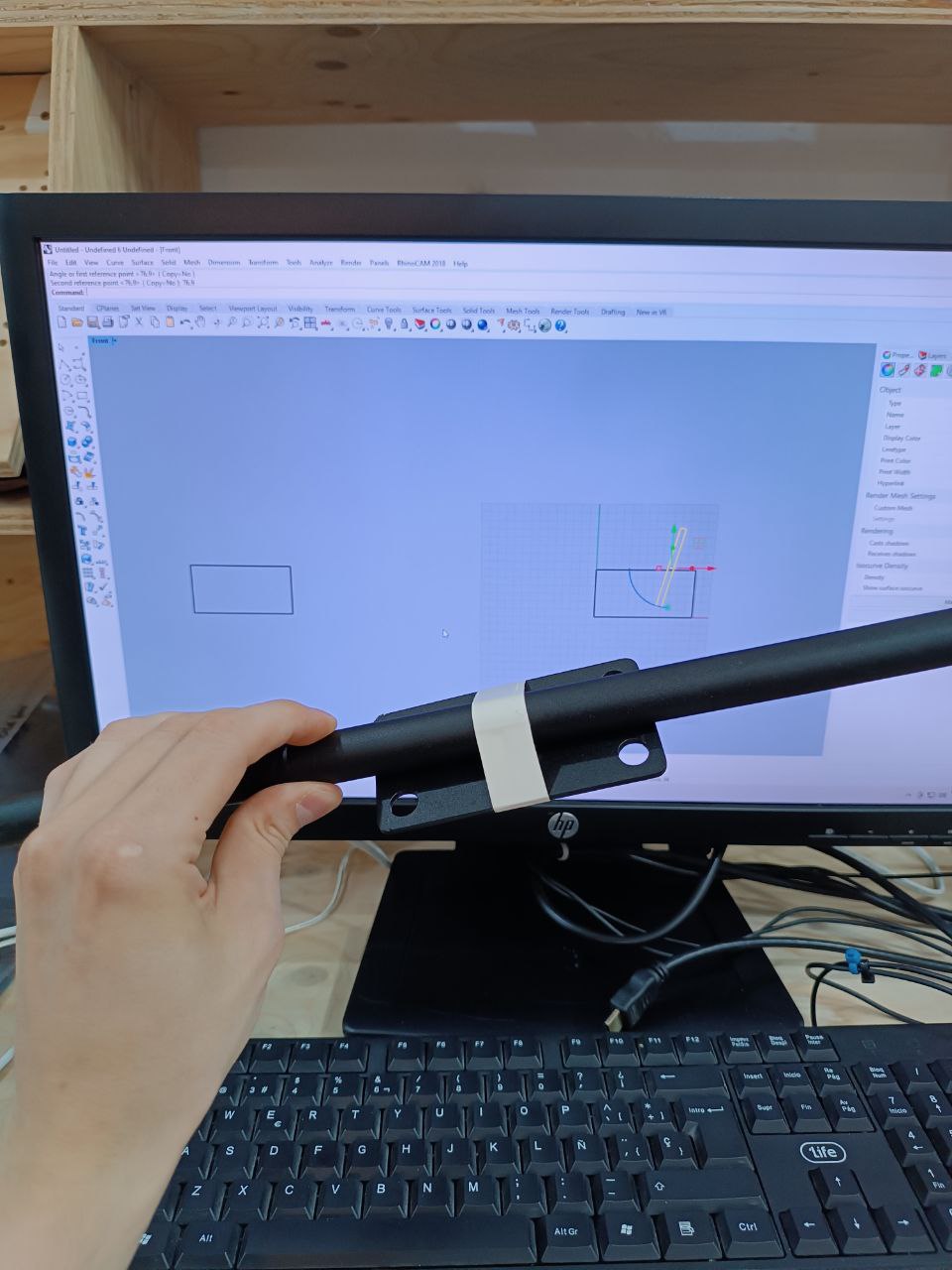

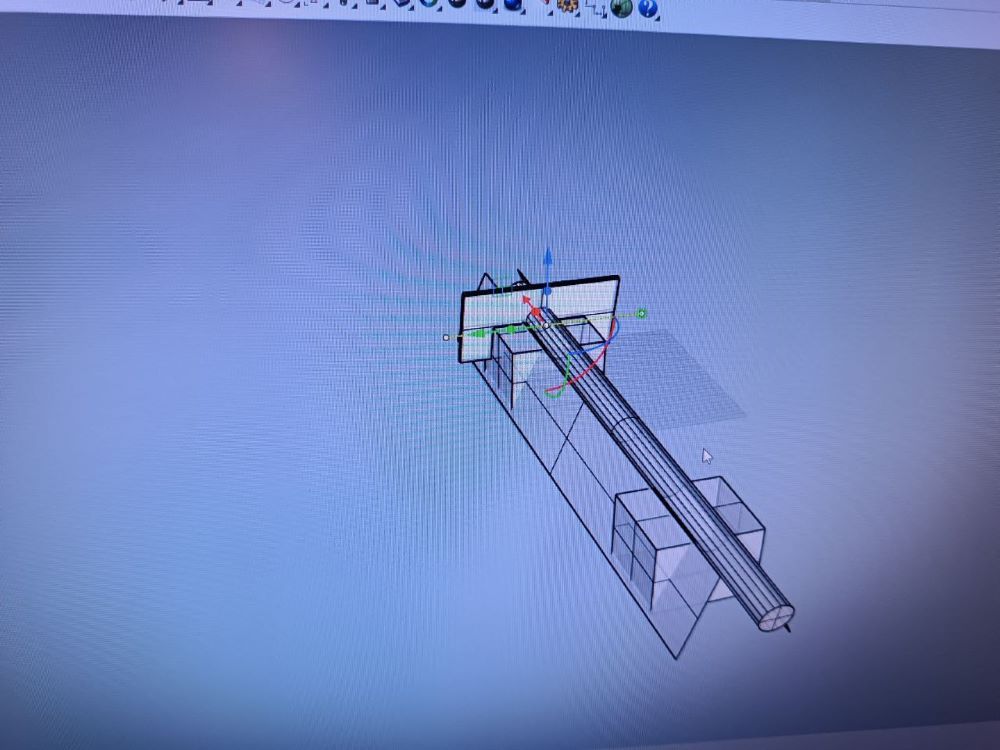

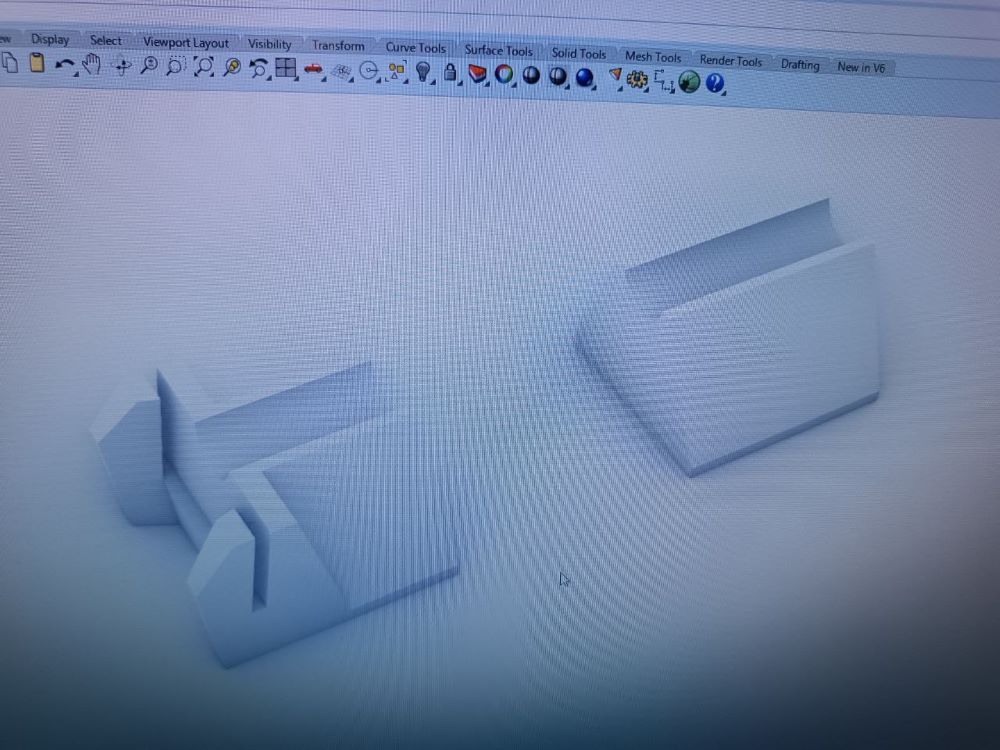

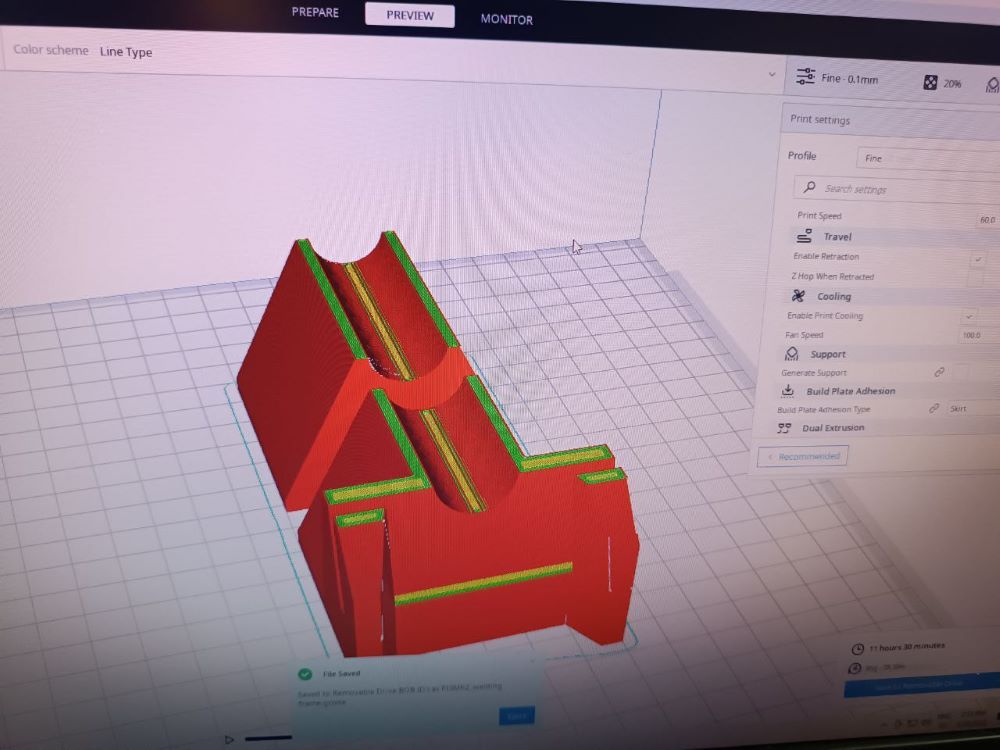

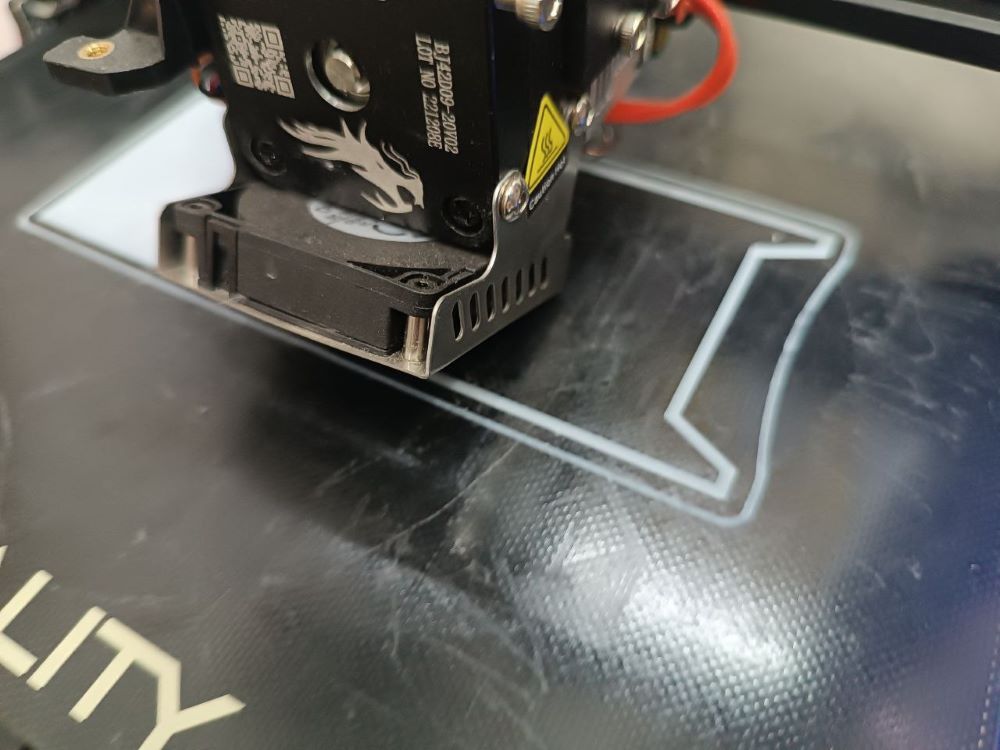

Frame print

- Traced detailes, culculated angle, created model.

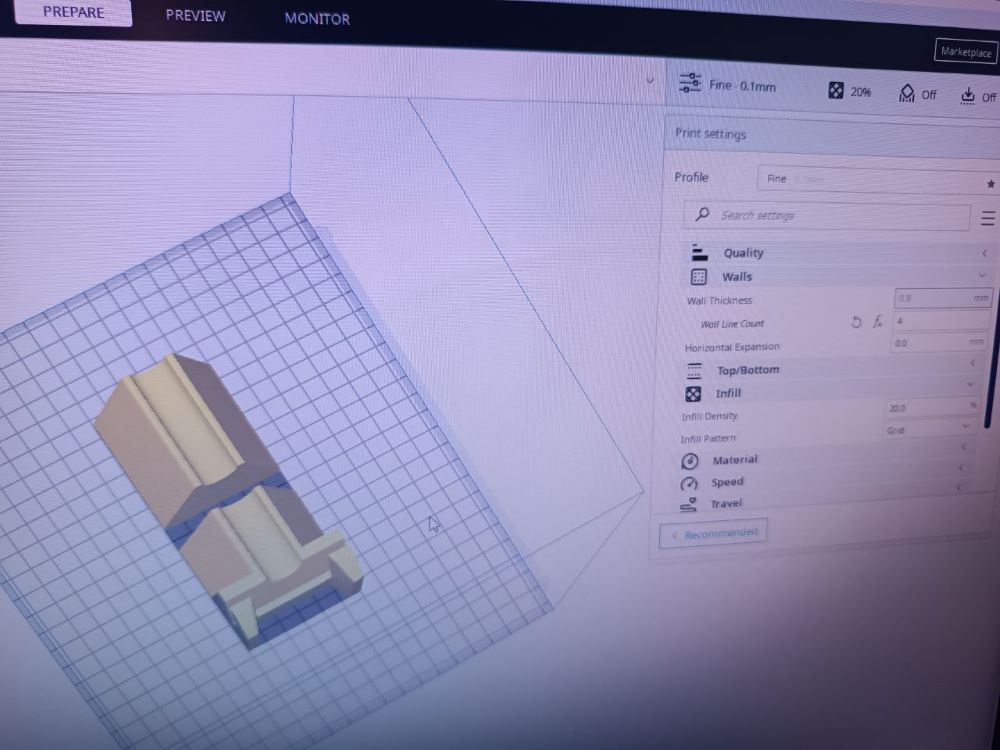

- Set and sliced for 3D print .

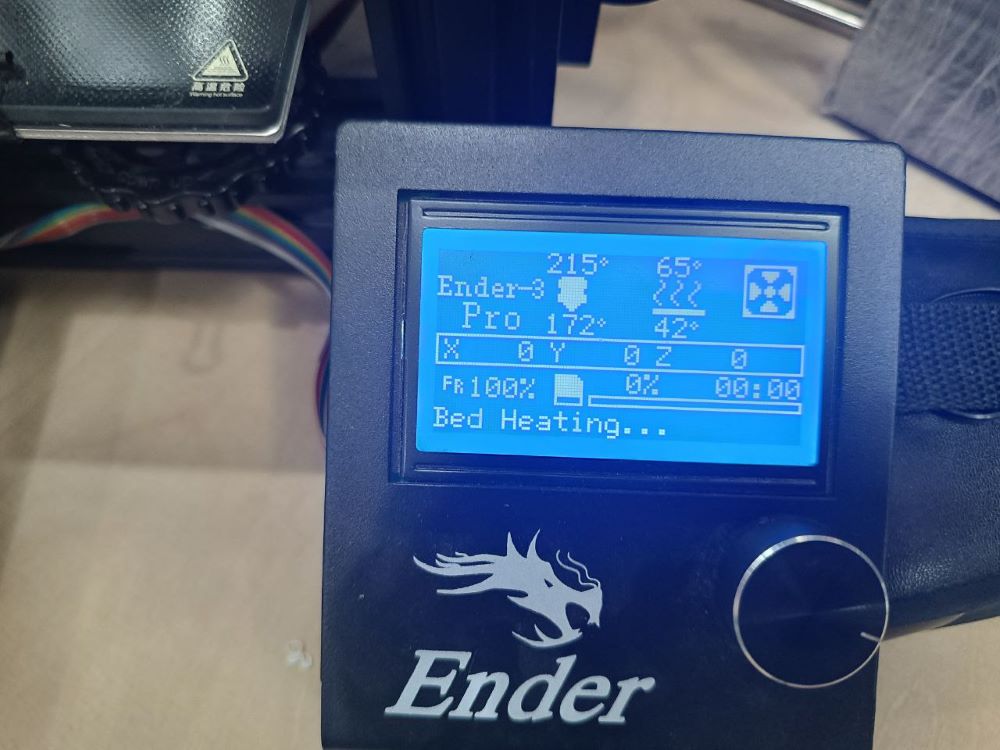

- Auto homed extruder, it started to heat, but this exact printer have glitch, some times can not get exact temperatute, jupmping above and below, so changed temoerature setting on machine, it started to print, then changed temperature again to needed.

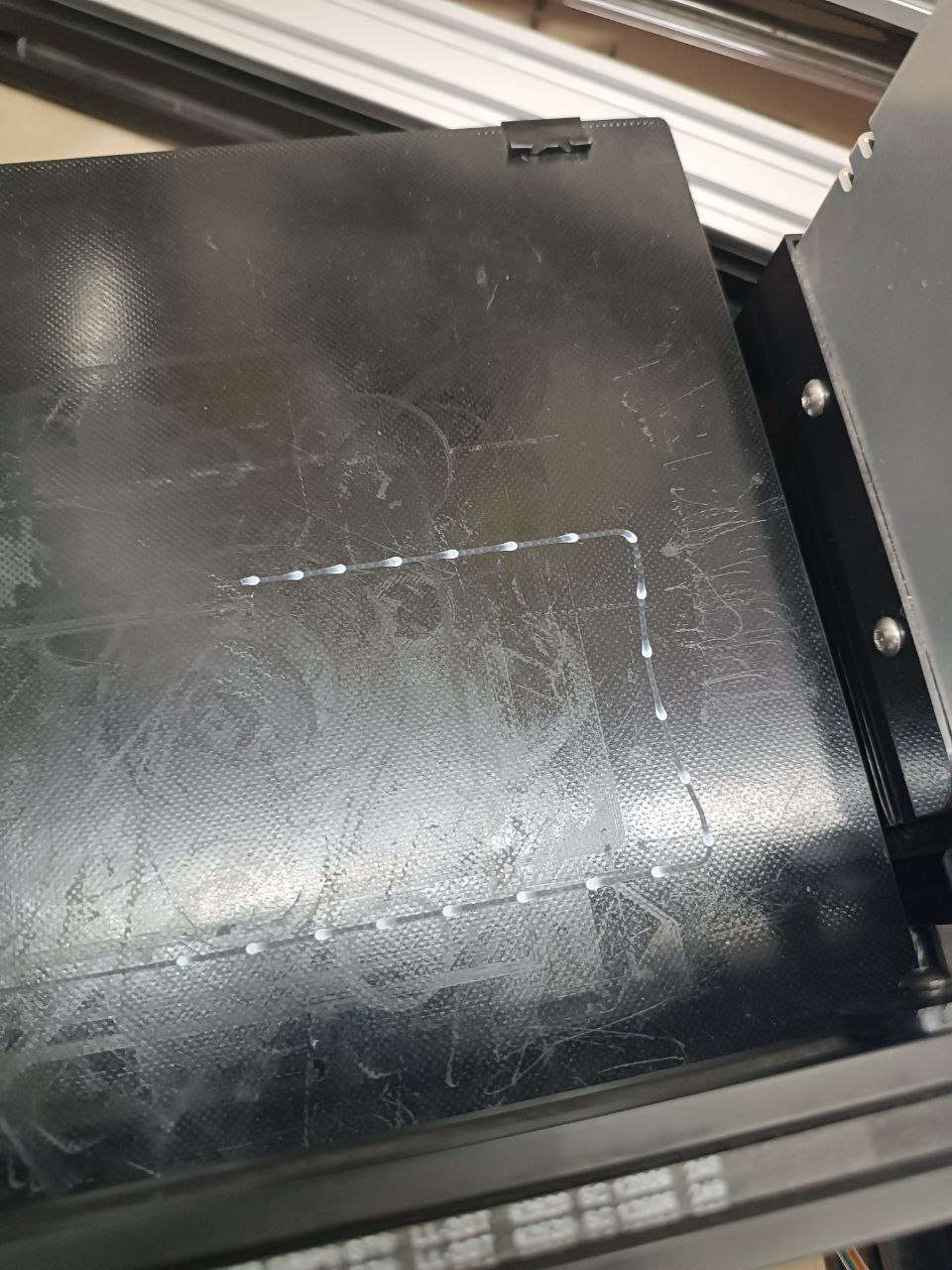

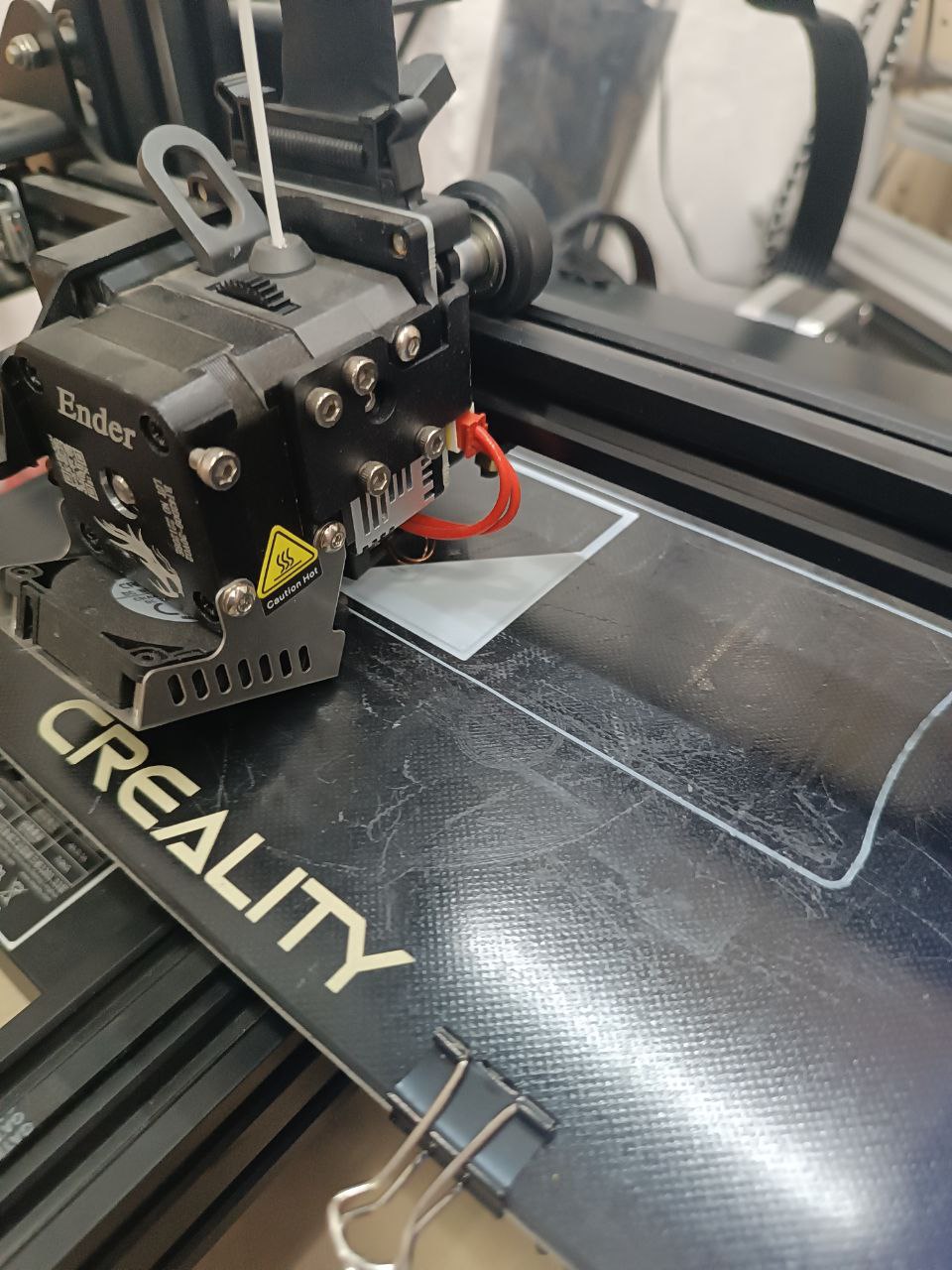

- It started to print dotted line, so I decided that table too low and adjusted it higher, but during printing extruder were melting upper layer creating "waves".

- So the point was that table needed to be push down, not up, after adjusting and restart of print, line became continious. Printed well, little bit tight (despite tolerance), but thats beter then loose.

- So first needed to clean black powder coating, clean metall need to be welded.

- It was some programm final presentation, so can not use grinding tool with sending tool, it is too loud. So started sending manualy.

- First cleaned just small area, but after cleaned more, to be sure that weld will connect enough far and would be possible welding from both sides.

- Base part had weld inside hole, interfere align detales, tried send manualy, but it was impossible, so used more quiet rotation tool, worked well (even too well, fortunately did not sended too much).

- Creaned base detail from both sides.

- Alignewd detales.

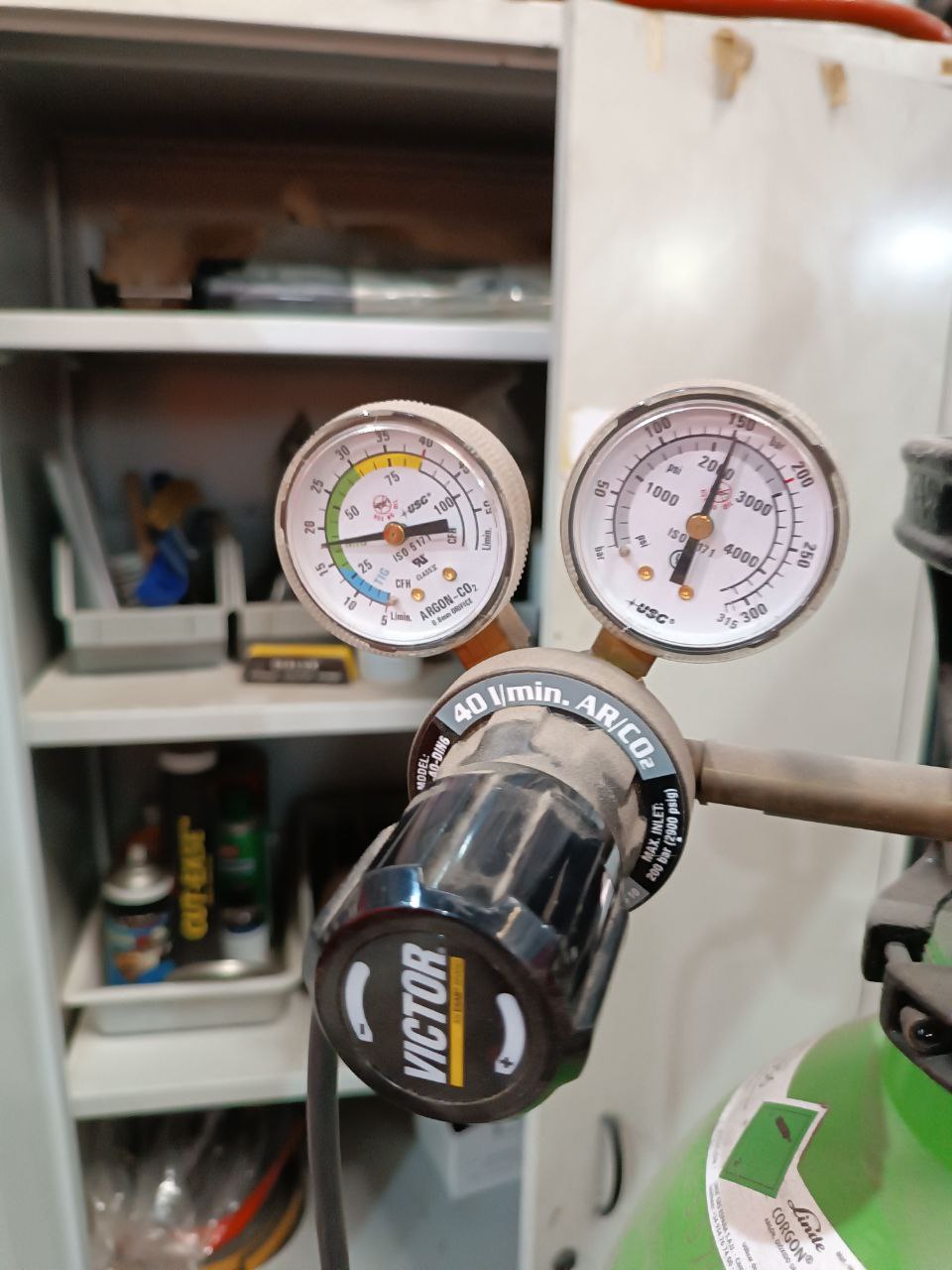

- Tested settings of welder machine (also little practice), they were convinient enough.

- More voltage - more heat, more spead - faster weld coming out.

- Gas (Argon + CO2 - inert gas (framing electric arc)) have to comeout with pressure refering to green zone, adjusting by valve.

- Grounded detailes (that need to create attraction and deffusion of welder (+) with target metall(-) ) .

- First point (of three, to not melt 3D printed part, metall heating very mach) .

- When connection points was ready, tookout from PLA frame (melted just little bit) and fixed at vise, grounded.

- Welded from both sides.

- Grinded (far from perfect also as welding, but ok).

- Little bit black paint and it will looks better (better to grind it more, but did not have appropriate tool).