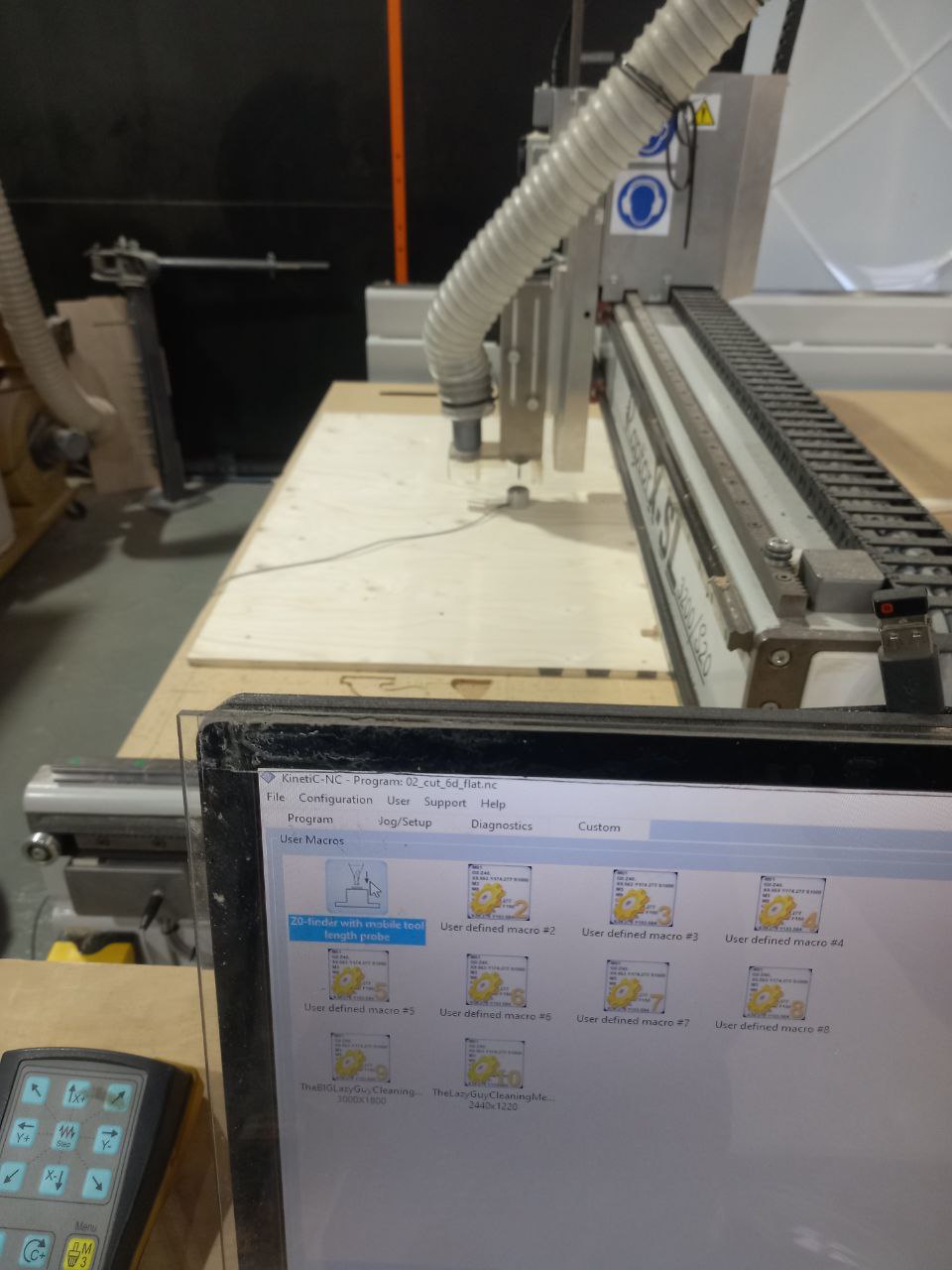

3. Computer controlled machining

This week we used CNC milling machine to cut something big from plywood. Cut CNC test together.

Documentation

Creation

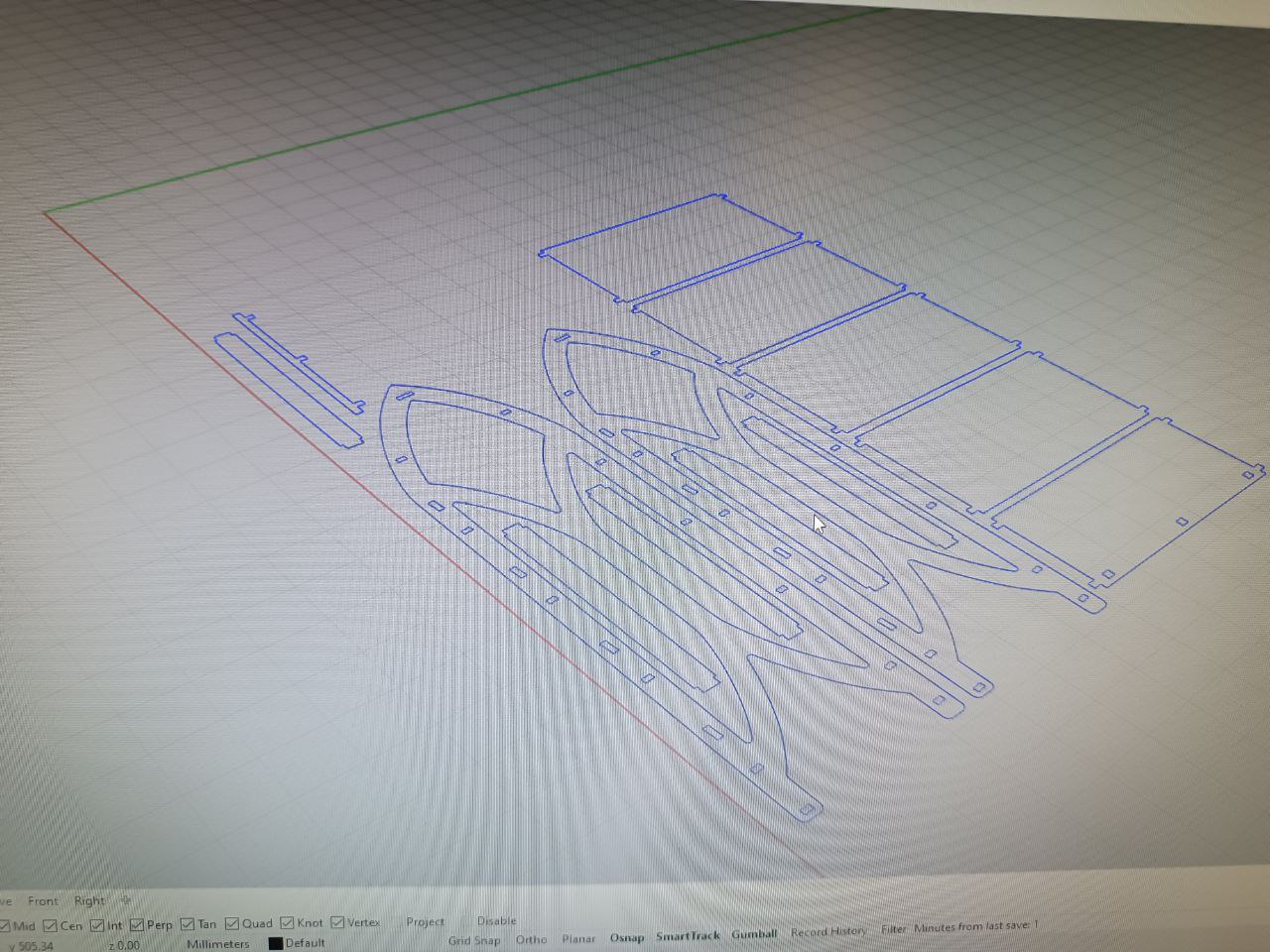

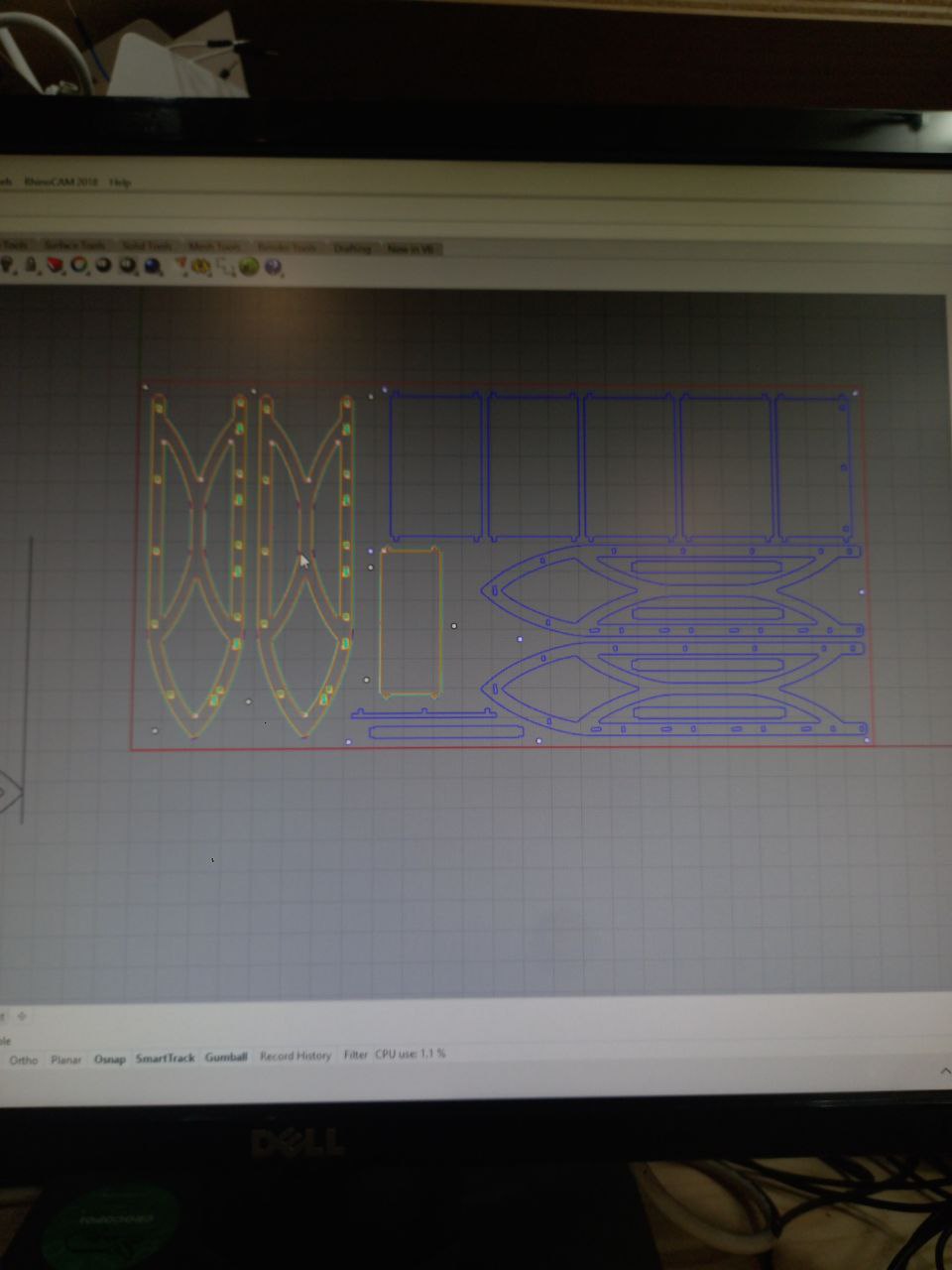

- Designed using Rhinocerous, inspired by gothic arc.

- Used usual Rhino commands: polyline, fillet edge, extrude, move, 1D scele and so on.

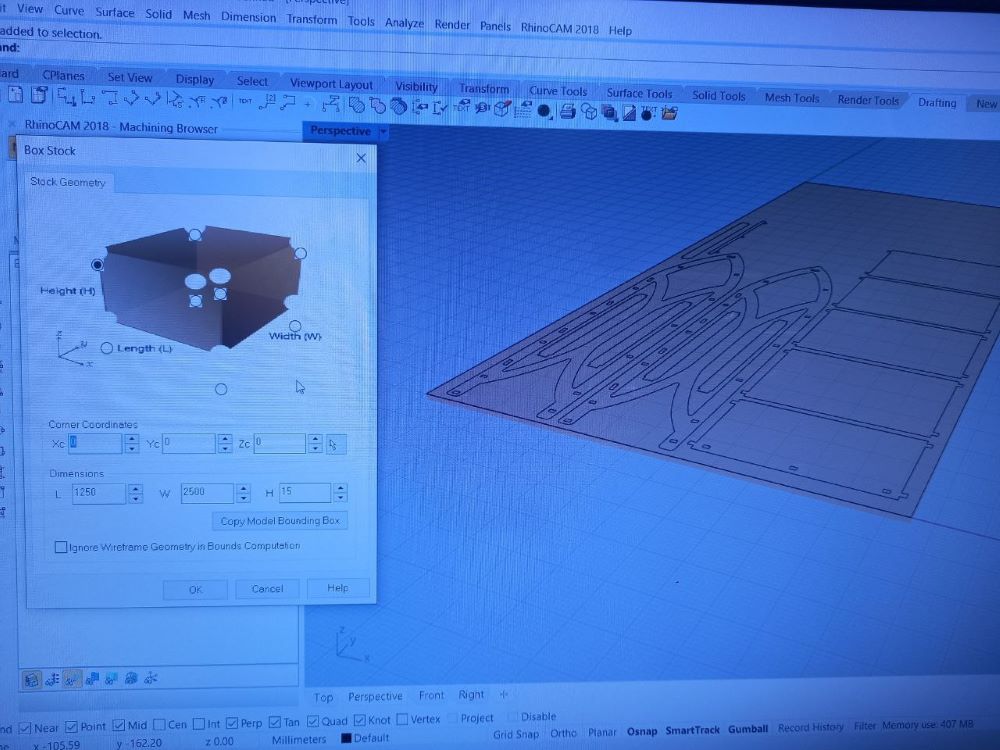

- Set matetrial sizes and Z-axis origin referring to material.

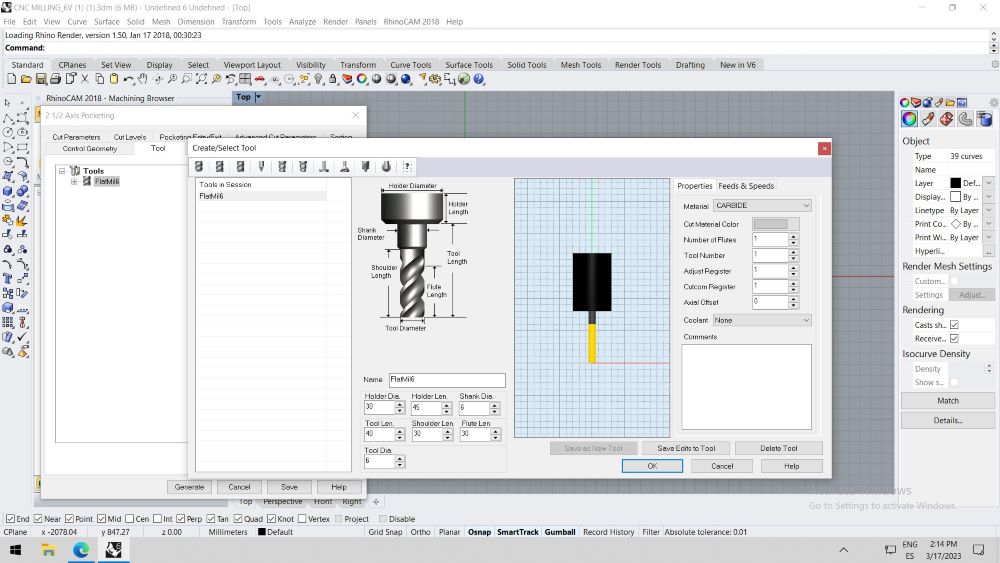

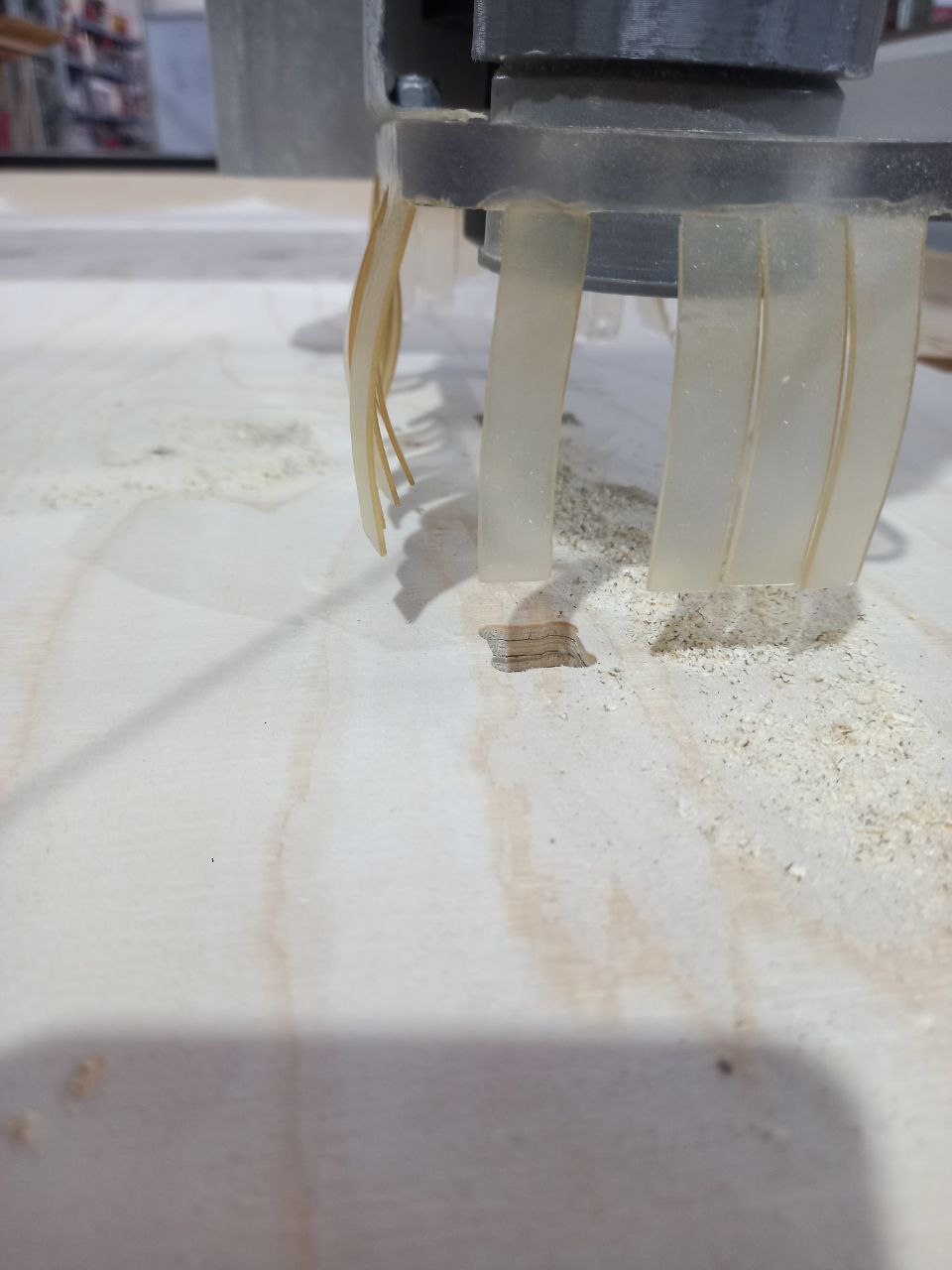

- Setting tab for 6mm diametre flat tool (for plywood using down cutting milling cutter).

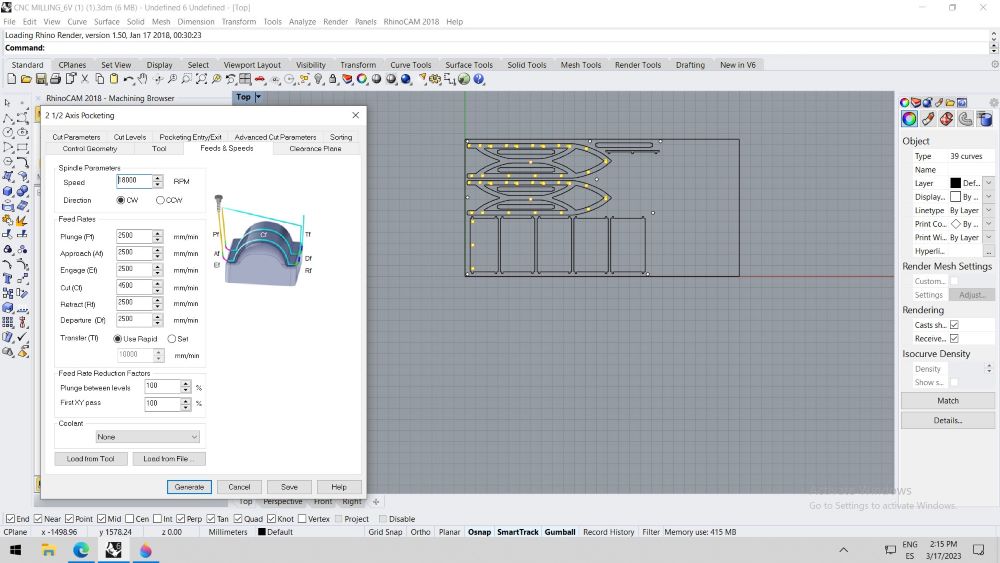

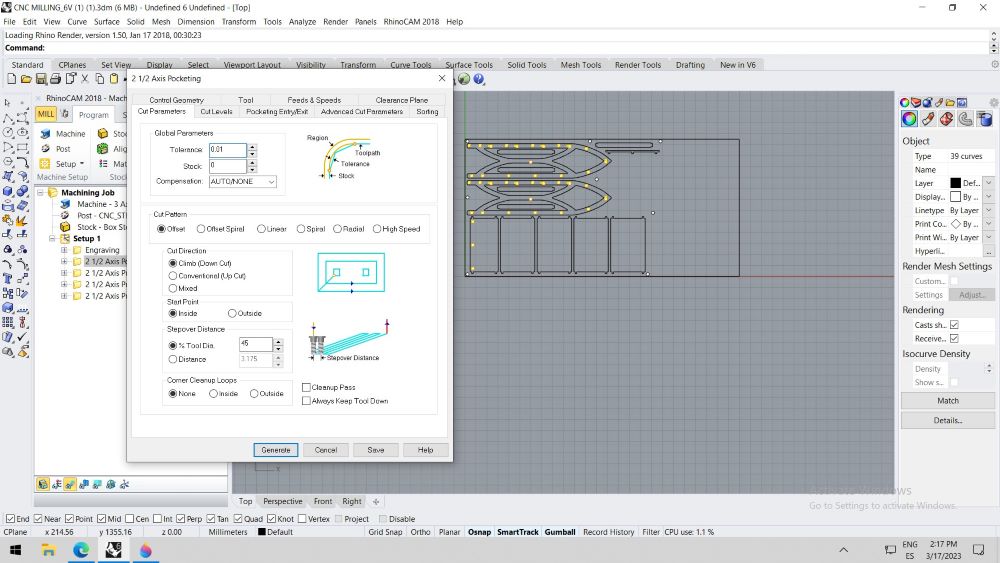

- Pocketing of joint holes, setting speeds.

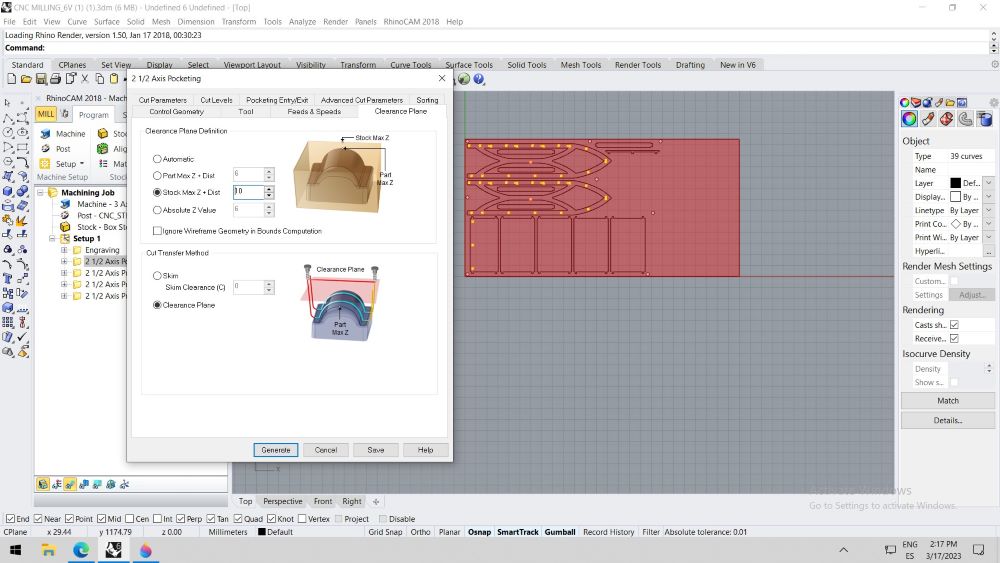

- Pocketing safe plane setting tab.

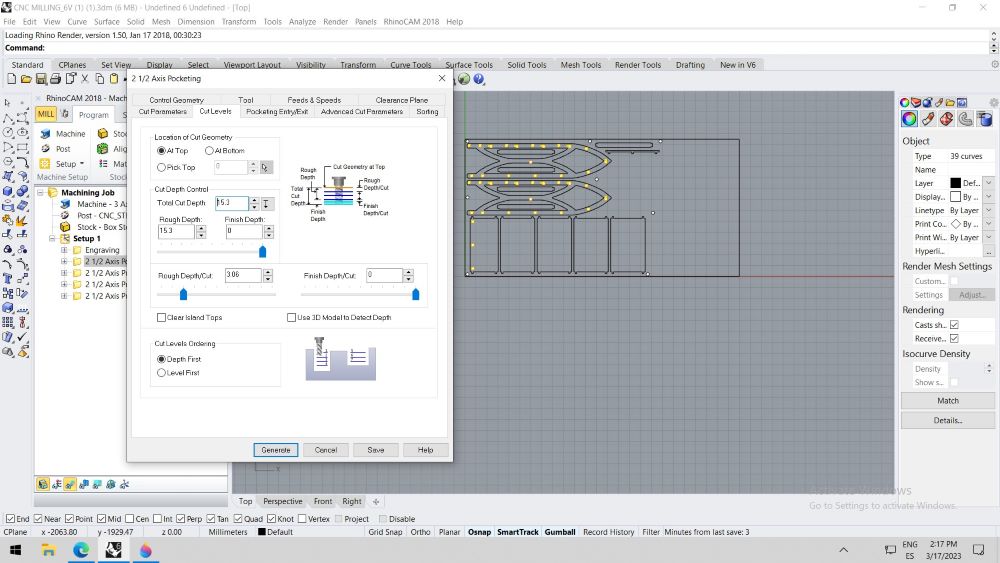

- Pocketing cuts preferences and depths.

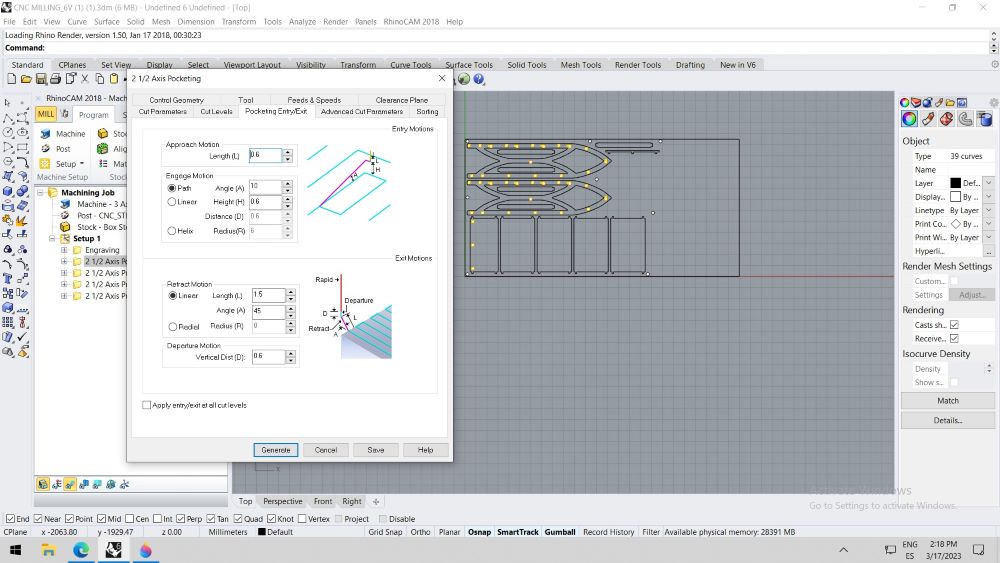

- Pocketing preferences of entering and exiting material.

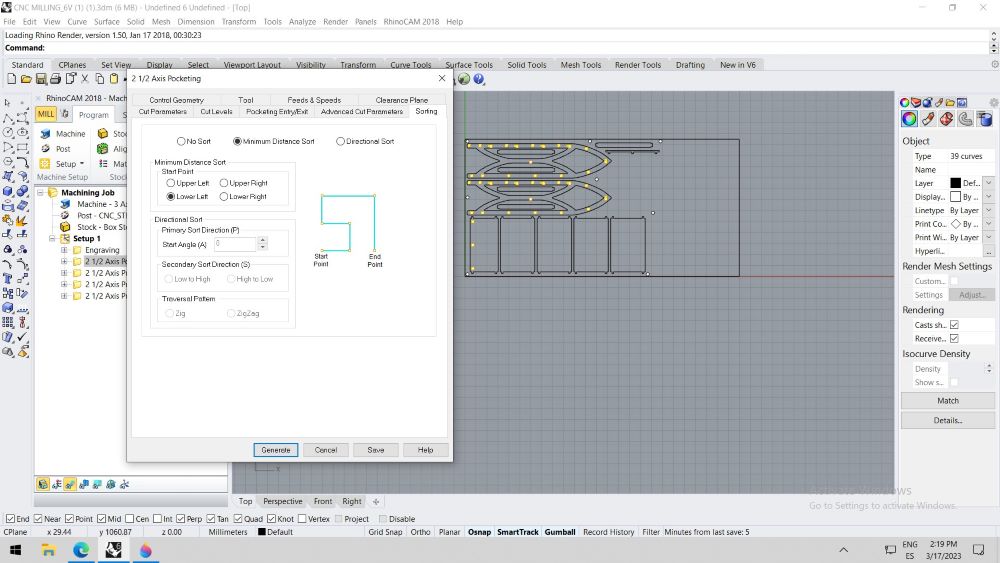

- Set minimum distance tool optimisation.

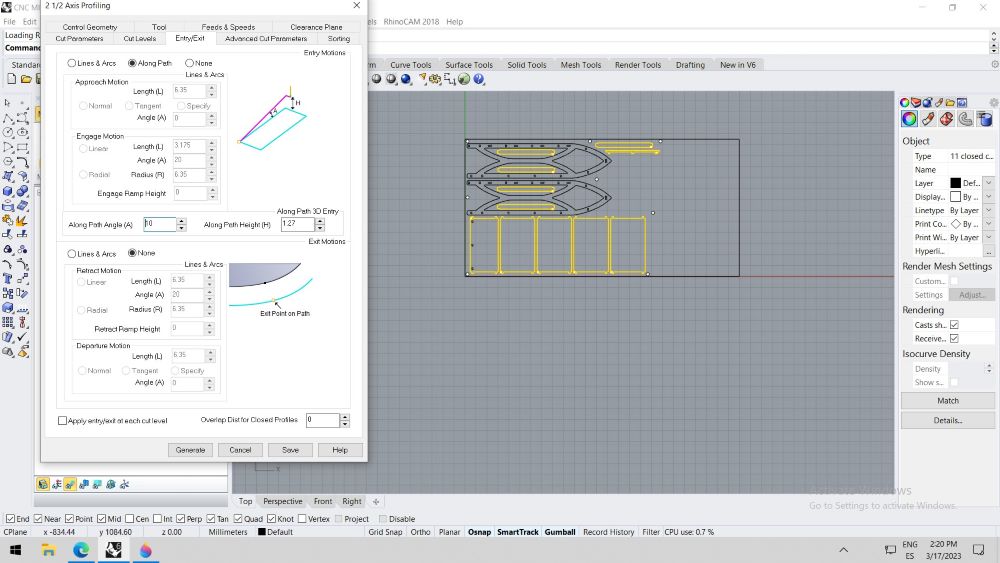

- Axis Profiling Exit / Entry settings have to be Along Path to not destract exterior material.

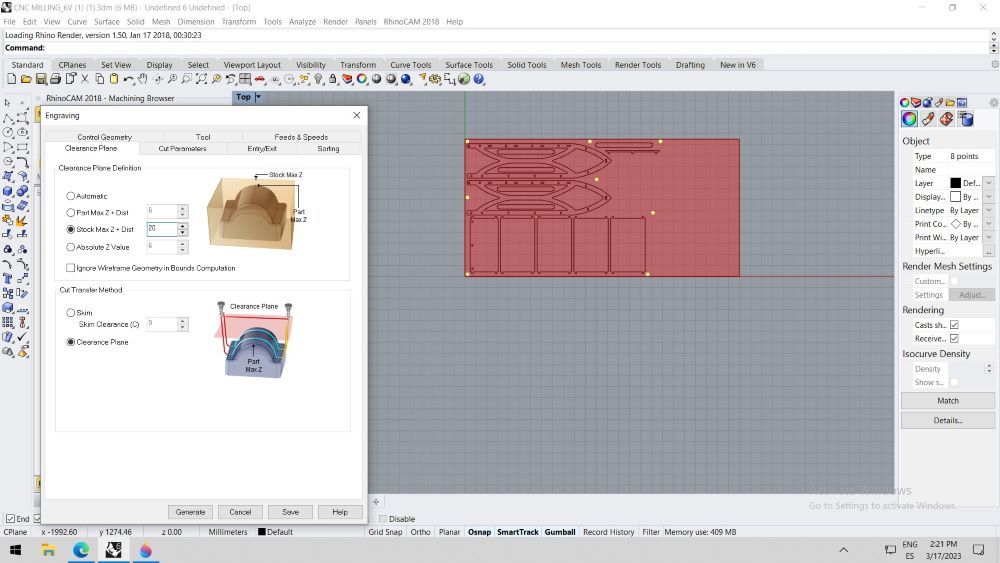

- For Engraving (screws pointing) safe plane should be twice higher, because when material not screwd, it is more curved.

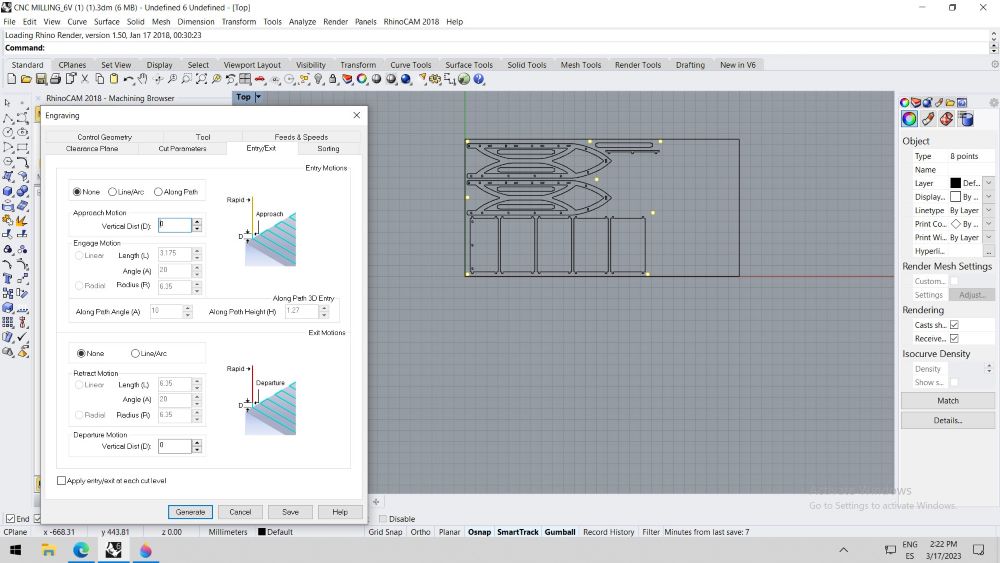

- For Engraving Exit \ Entry settings shouldnt be defined, to make only Z-axis movement.

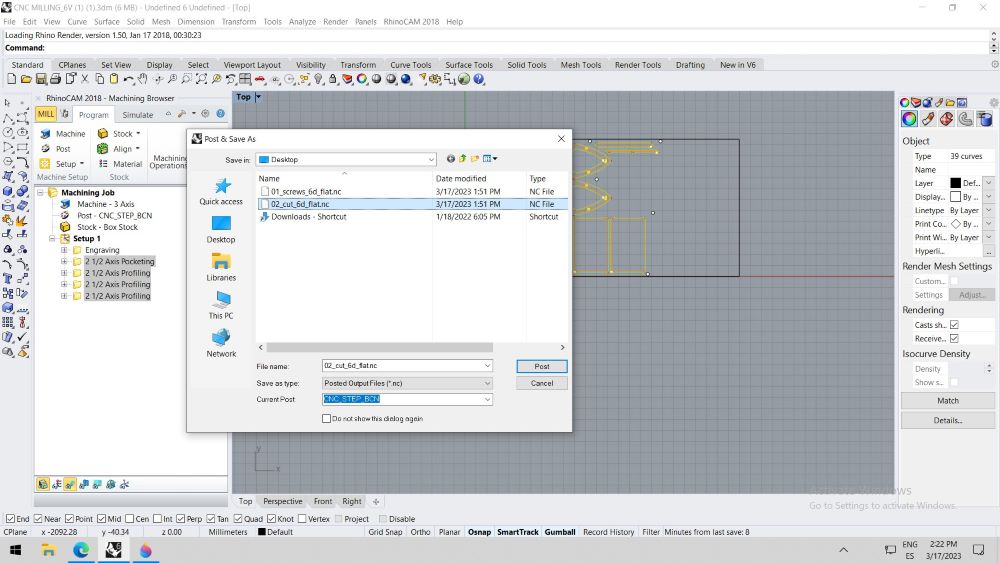

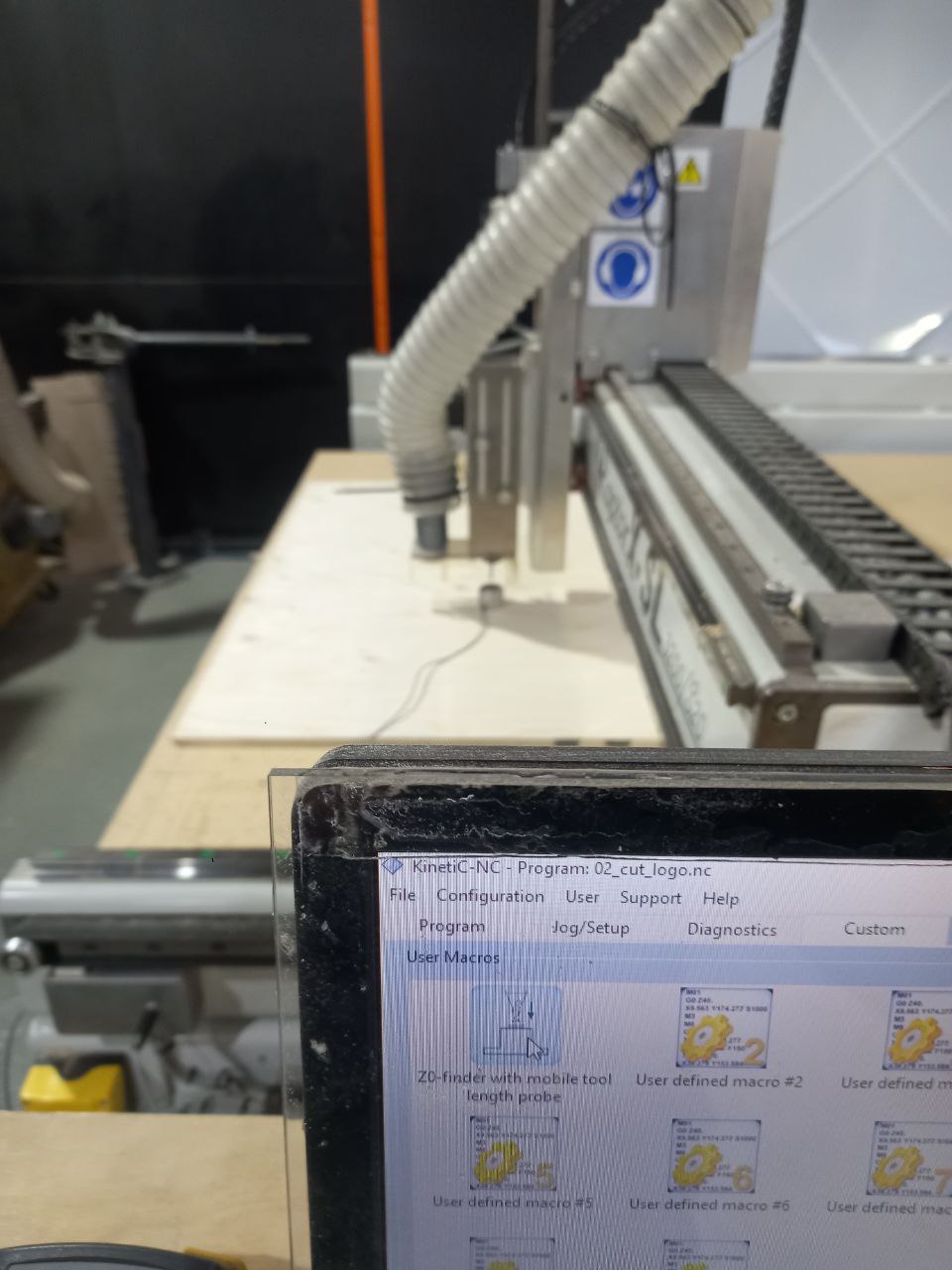

- To make algorithm for CNC need to Post slected cutting trajectories in correct order.

- Machine ON by turning switcher.

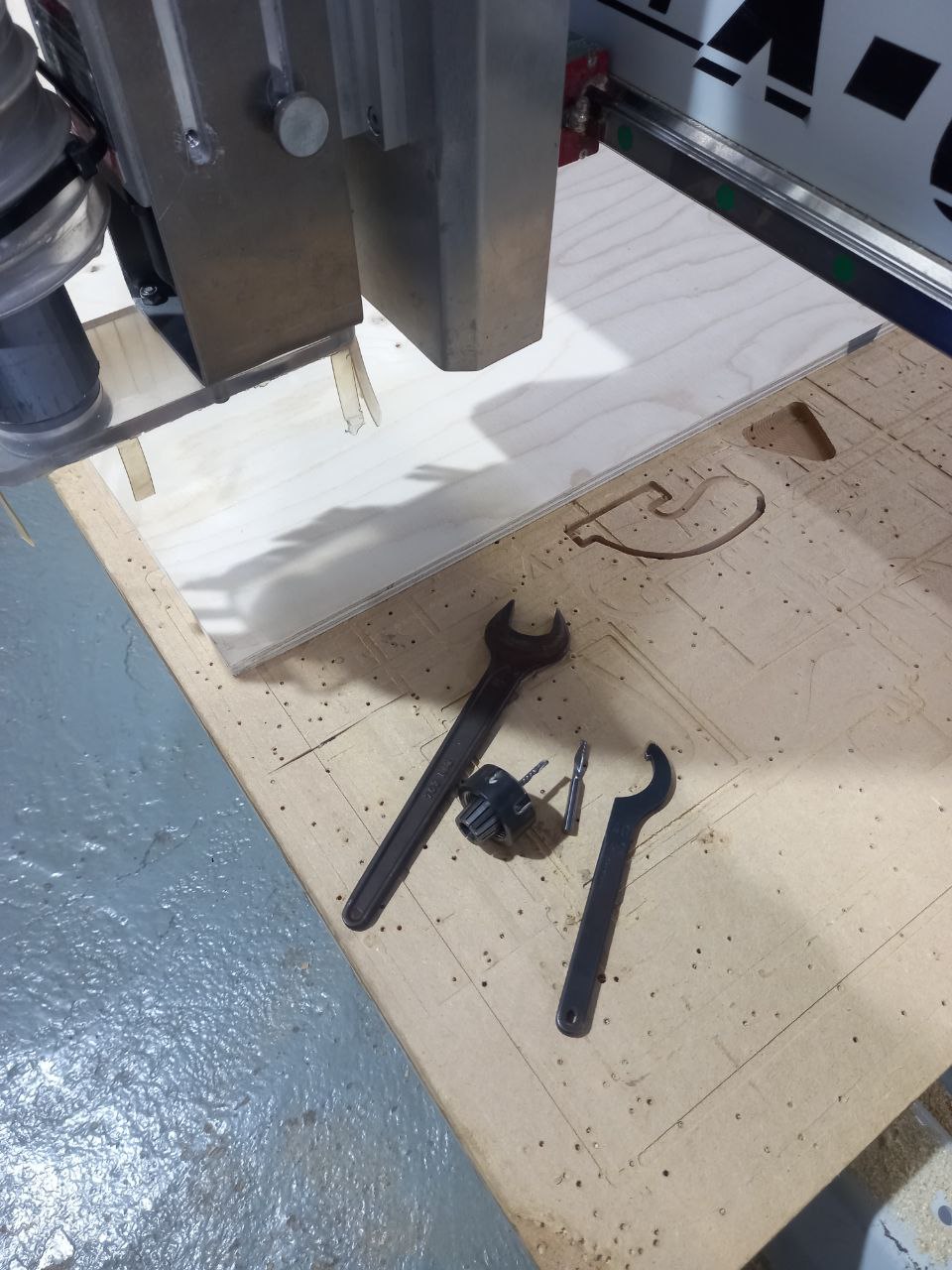

- Changed tool and clened collet.

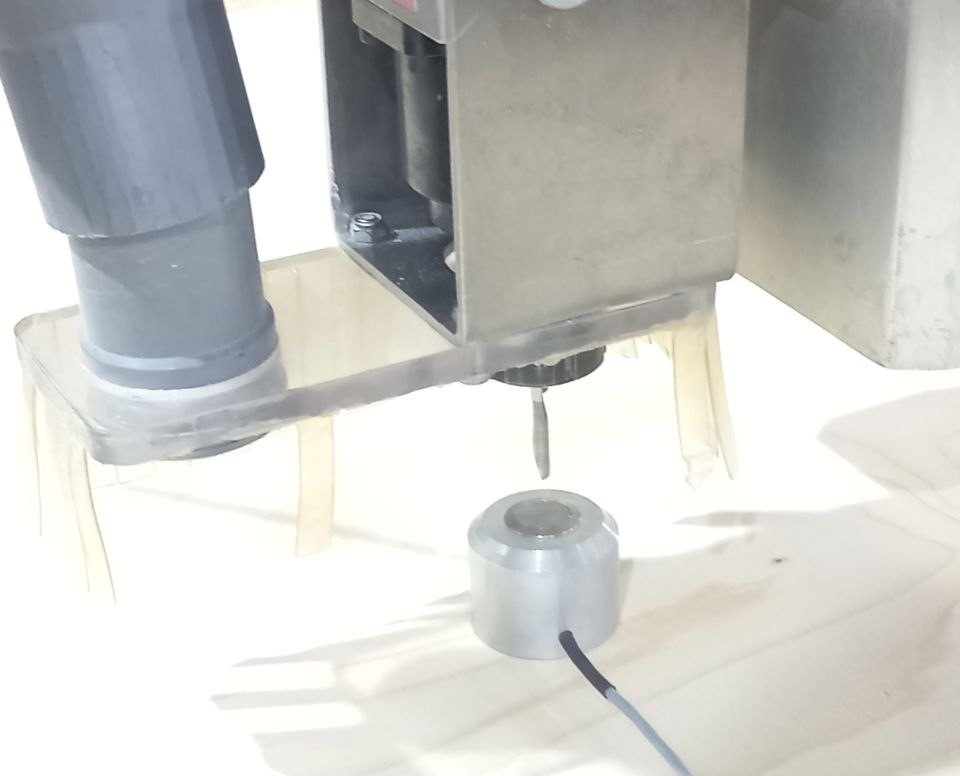

- Placed material, put collibration button on material.

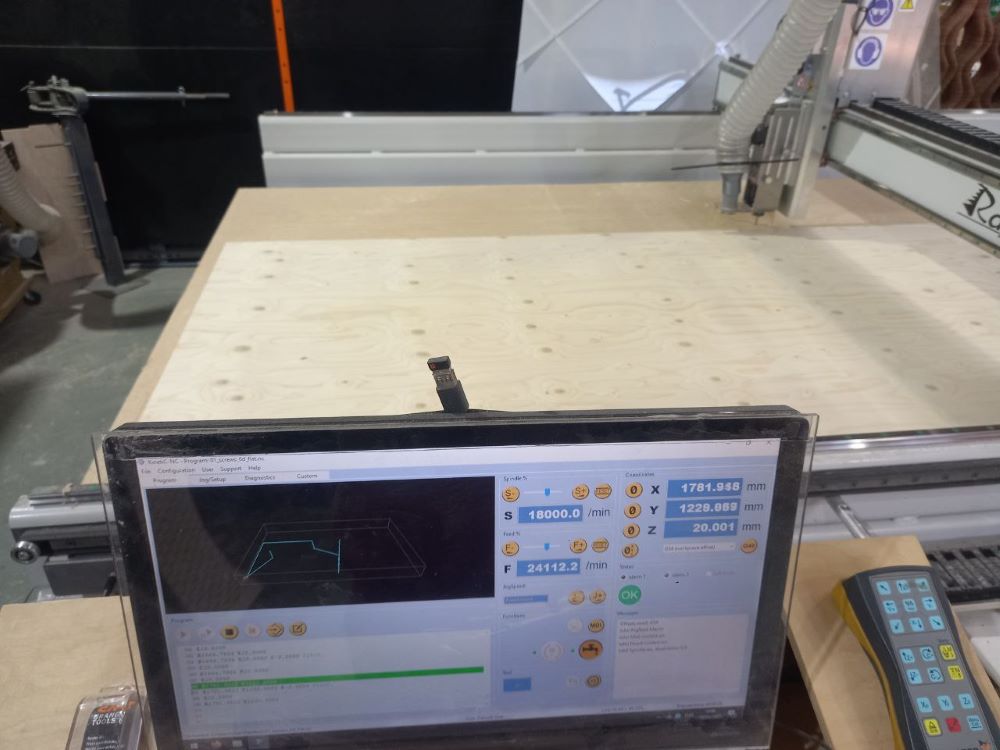

- Started programme for screws, screwed.

- After collibrated Z-axis again (screwed material more plane).

- Started to cut

- Bridges done well.

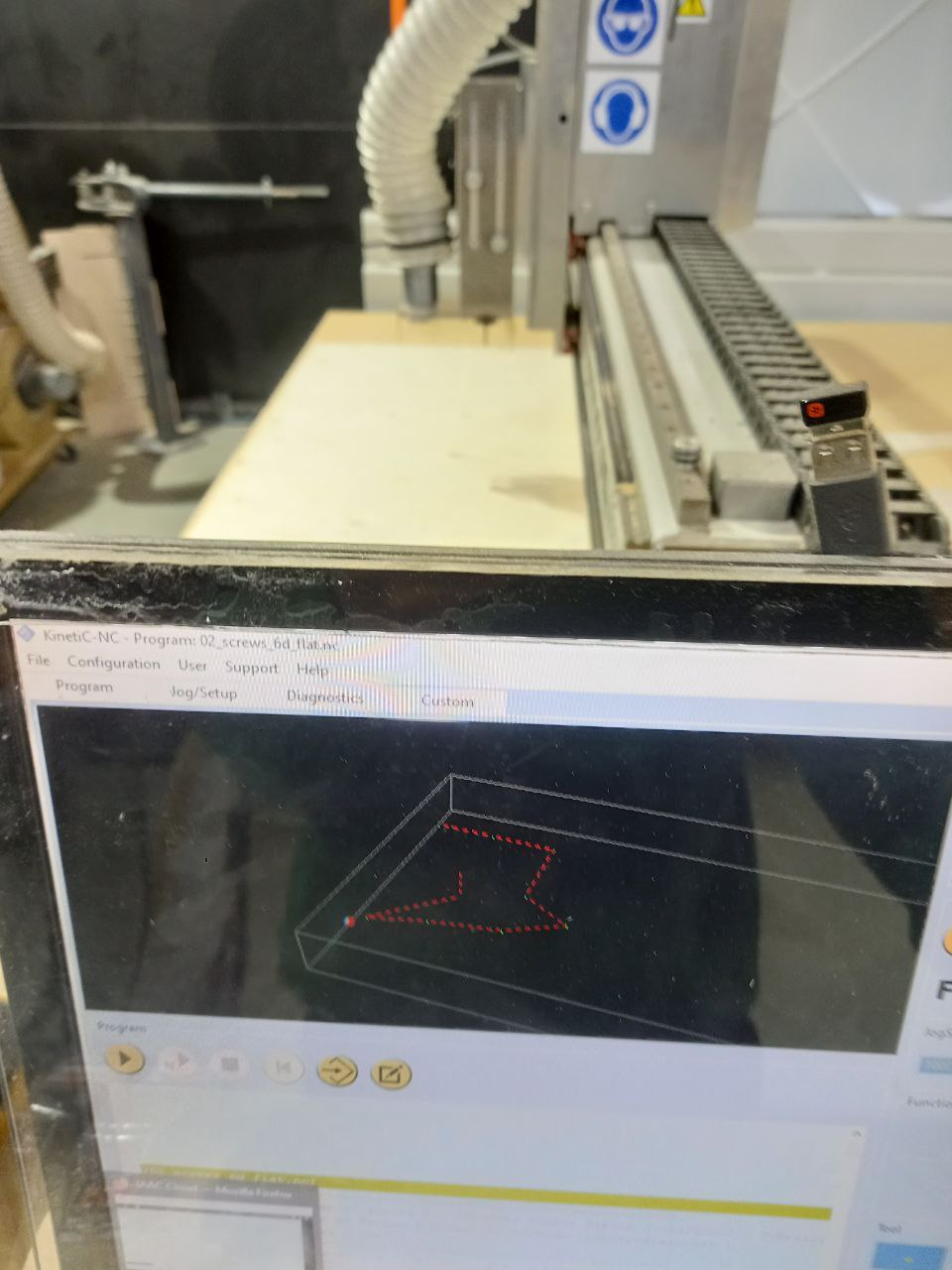

- Simulation corresponds to cutting process and looks good)

- This plywood quite soft,easily cleaves.

- Air pump ON.

- Mostly done.

- Tried to pump by vacuum cleaner, after used air pump.

- Used chisel and hummer to break bridges.

- Material was 15 mm, not 10 as I thought, so joints holes were not correct.

- Next day I changed sizes of holes and height of shelf ot arrange it on least material piece.

- Changed tool.

- Collibrated X, Y and after Z-axis Origin position.

- Checked that coose correct file on screen.

- Screwed.

- Recollibrated Z-axis.

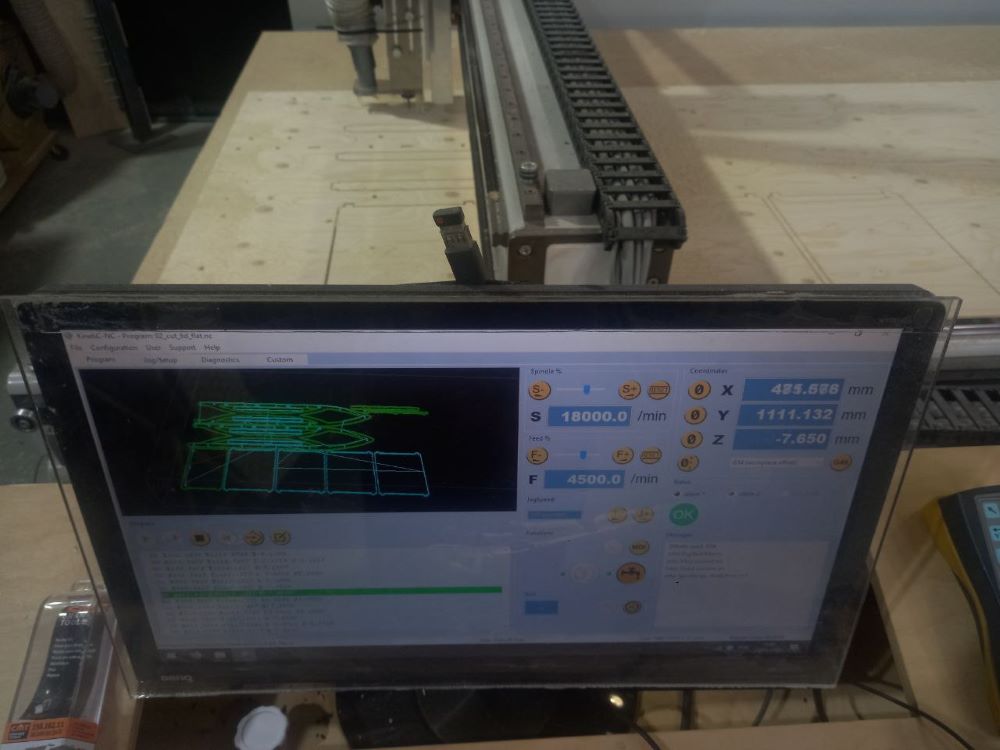

- Started to mill now holes have correct size, depth defined well.

- Remembered that need to switch on pump.

- Prosessing...

- Mostly done.

- Unscrewed.

- Vacuumed major part of chips.

- Cutted bridges by hummer and chisle.

- Now cutted well.

- Done. Actually milled not perfect, plywood too soft, chip off because of that.