8. Computer controlled machining¶

This week I worked on CNC on what it is and how it works and it amazed me and I use it to produce my first chair in Wood

Research¶

After seing ShopBot word on our local FabLab CNC machine, I googled what is CNC ShopBot on this link and I got more information. In short CNC (Computer Numerical Control) tool used in production for cutting, carving, machining, and milling in a variety of materials including wood,mdf,plastic,..

In the past, all types of computer-driven tools that create things by cutting material away such as CNC, Laser Cutter or other tools that build up material in layers to create an object(3D printing) was industrial tools only used in large factory settings now are called digital fabrication tools. ShopBot’s is innovations in CNC technology have made these powerful tools affordable for individual and small shops.

How CNC works

ShopBot tools, like all CNC tools move a cutter arround a big table(X,Y axes) and move it Up and Down as well(Z-axis) allowing it to make 3D movements and all sorts of shapes.

CNC use a router bit designed to cut from the sites as well as well as the tip. By precisely moving the cutter through material and create virtually any shape on wood or any other material.

Design software for CNC¶

Digital Fabrication software like CAD(Computer Aided Design) help you in designing , something that is represented on a computer as a 2D or 3D model. You may use InkScape for 2D drawing and SolidWorks for 3D modeling.

CAM(Computer Aided Machining) software helps you by using the design created using CAD(Computer Aided Design) to define the motions the machine will make during the cutting or machining of your parts. there are software that comes with both functionality where you can design and toolpathing using it.

Used links

Designing a chair in solidworks

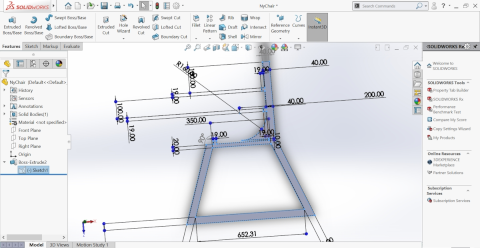

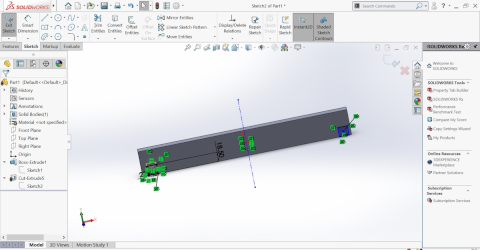

I have used Solidwork to design my Chair. Below is the secketch of cross part of my chair

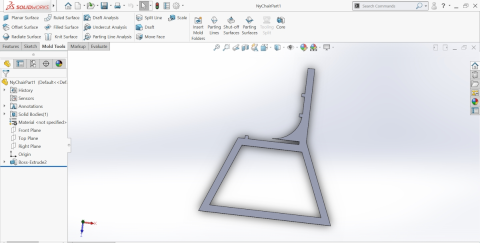

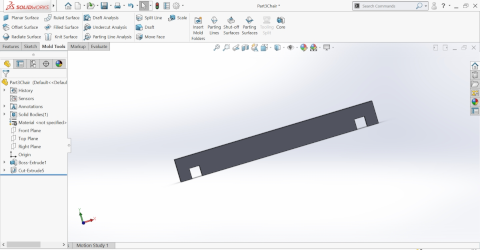

Below, is the finished cross part of my chair and it was how I want it to be

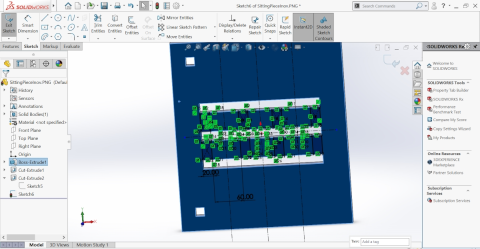

Below, Is the sitting part of my chair Scketching

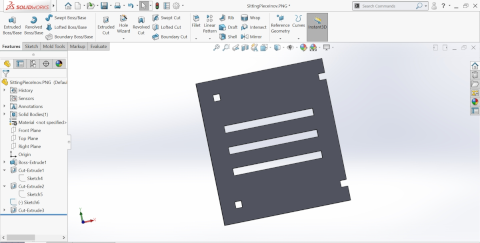

Below, is the finished sitting part of my chair

Below, is the last part of my chair

Below, is the finished last part of my chair

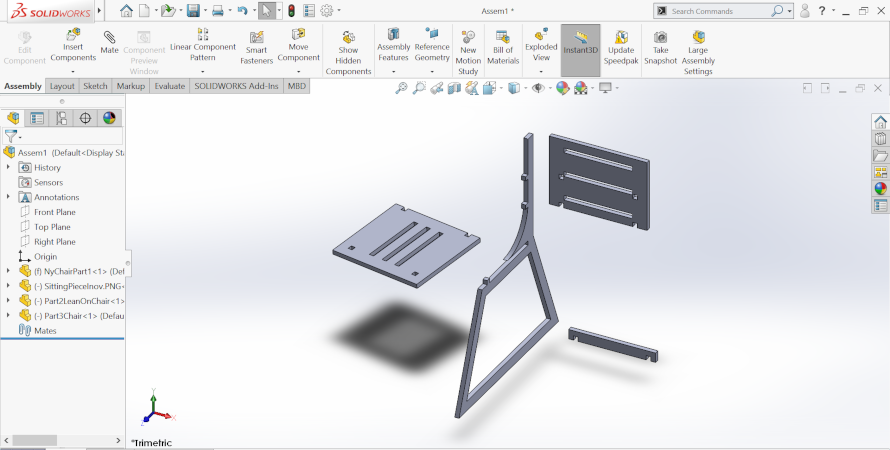

Now, it’s time to assemble all may chair parts to generate my firt chair in solidworks. I again Open up solidworks software then choose I choose Assembly then I brouse the first part of my chair, where I have saved;Other parts are inserted using Insert Components tool according to what part you need to assemble on.

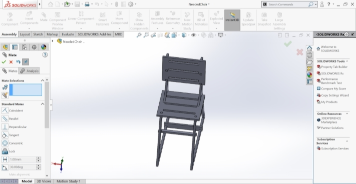

Then by using Mate tool I assembled my chair parts and generate the chair below.

Producing my designed chair¶

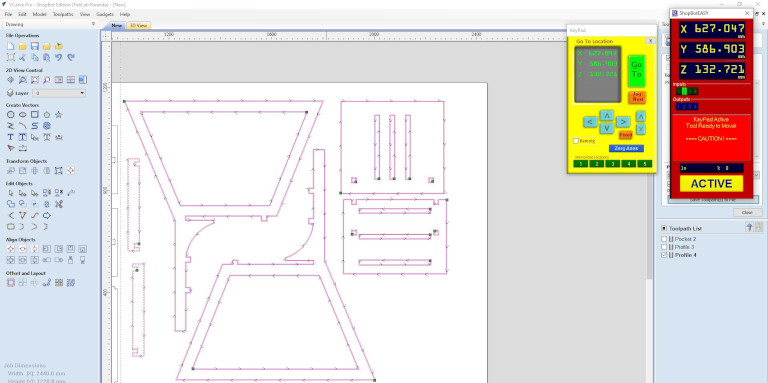

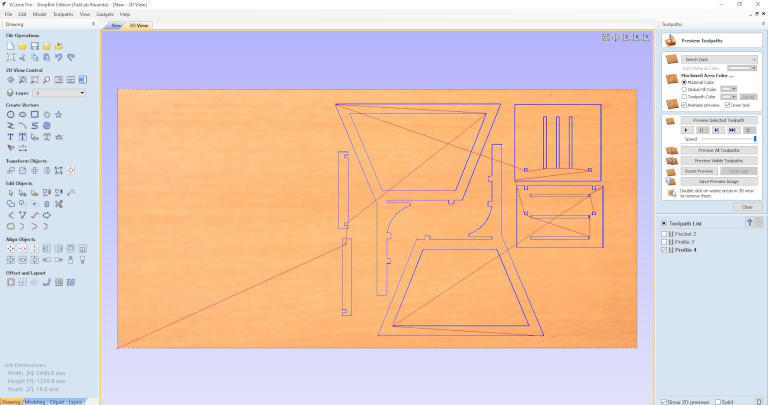

After getting a 3D table model, I save it as a DXF file to be accepted by our local Fab Lab CNC machine. With the help of softwares came with machine, I adjust some settings like grouping the object , Move, Rotate,.. all to enhance CNC production economicaly (related to the wood material used ) and efficiently,then the toolpaths were generated by Computer Aided Machining and Up and Down movements are added to move the cutter In and Out of the material for each cut.

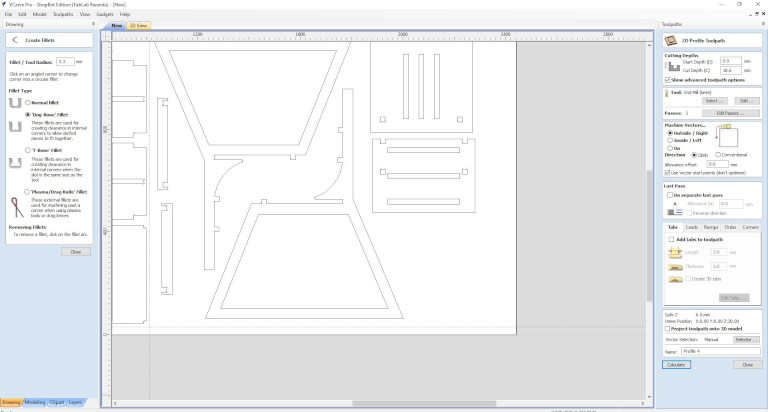

After viewing Preview Tool Paths, I decide to add on Dogos are types of fillets in holes for efficiency assembling help after CNC production

Below, is After adding dogos in every hole

Now, ComputerAidedMachining help me to set axises settings for CNC tool to start the production , Then by confirming allt required activities It starts

Amazing, Below is my first product using CNC and I appreciate my chair

Below is me, enjoying my CNC work

Dawnlaod Files used Here