Molding and casting group work: Week 10

Group: Antero, Max

Group assignment:

-

Review the safety data sheets for each of your molding and casting materials

-

Make and compare test casts with each of them

Safety and equipment

In this section we discuss about the safety data and the safety equipment available in the casting room in order to show that we were prepared and safety-oriented.

Safety data

The safety sheets for the materials were observed. The links to the safety sheets of Oomoo-25 (the manufacturer likes to use bold letters), Smooth-Sil 940 and Smooth-Cast 300 are added in the end of this document.

Equipment

When using some casting materials, it is important to make sure that the air ventilation is in use. It is in "on" position now. Note the missing markings of the on/off position in the switch.

Vacuum pump is used for removing the bubbles in the material. The use of the pump results in smoother masks.

In case something goes to the eyes or a major problem with hazardous materials, there is a safety shower.

Preparing the molds

Example of the cast silicon mould. We are going to make one too.

A silicon mould we are going to use for the task.

A silicon mould we are going to use for the task.

A milled wax mould we are going to use in order to create a silicon mould.

A silicon mould we are going to use for testing the metal casting.

Example of the castings made.

The amount of material prepared for the mold is estimated by weight. First the empty mold is weighted.

The mould is filled with water and the weight is observed (23 g).

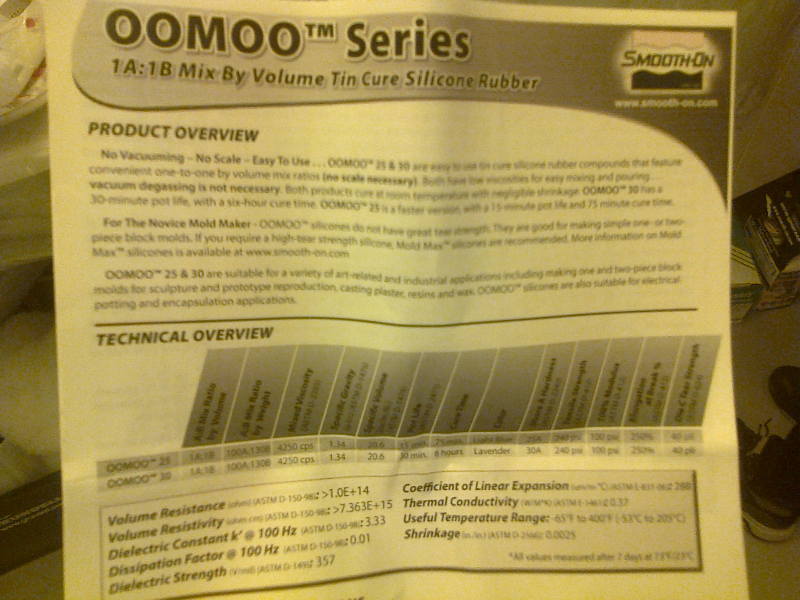

The safety sheet of OOMOO Series Silicone Rubber was observed. The weight mixing rate of the components for OOMOO 25 is 100A:130B. 23 grams of ready material (assuming equal density) should consist of (100/230)*23 grams = 10 grams of component A and the rest 13 grams is component B. It is hard to make accurate measurements, but this is how the amount of components is calculated.

The display is set to zero after the container is added.

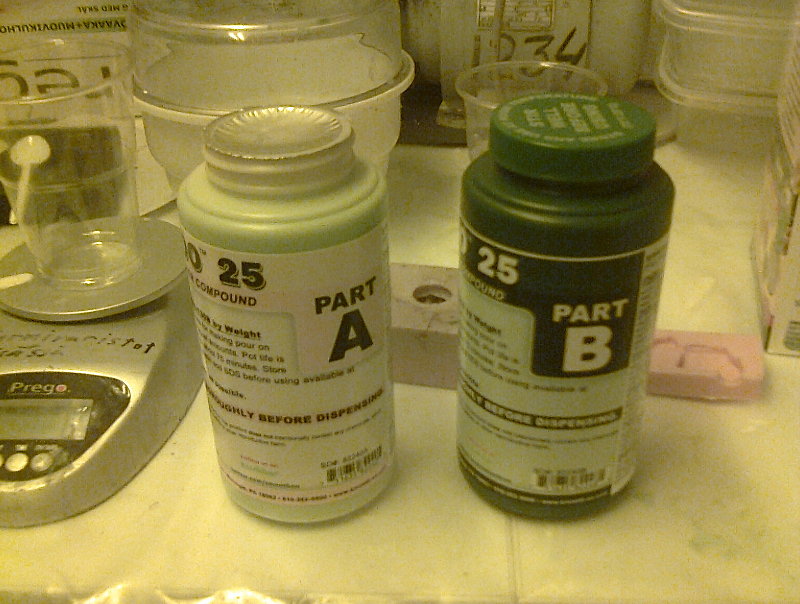

The new containers of OOMOO 25 were opened.

The components were added.

The mixture is then mixed properly. Note the spoon left in the component A container in background.

The mixture was then vacuumed.

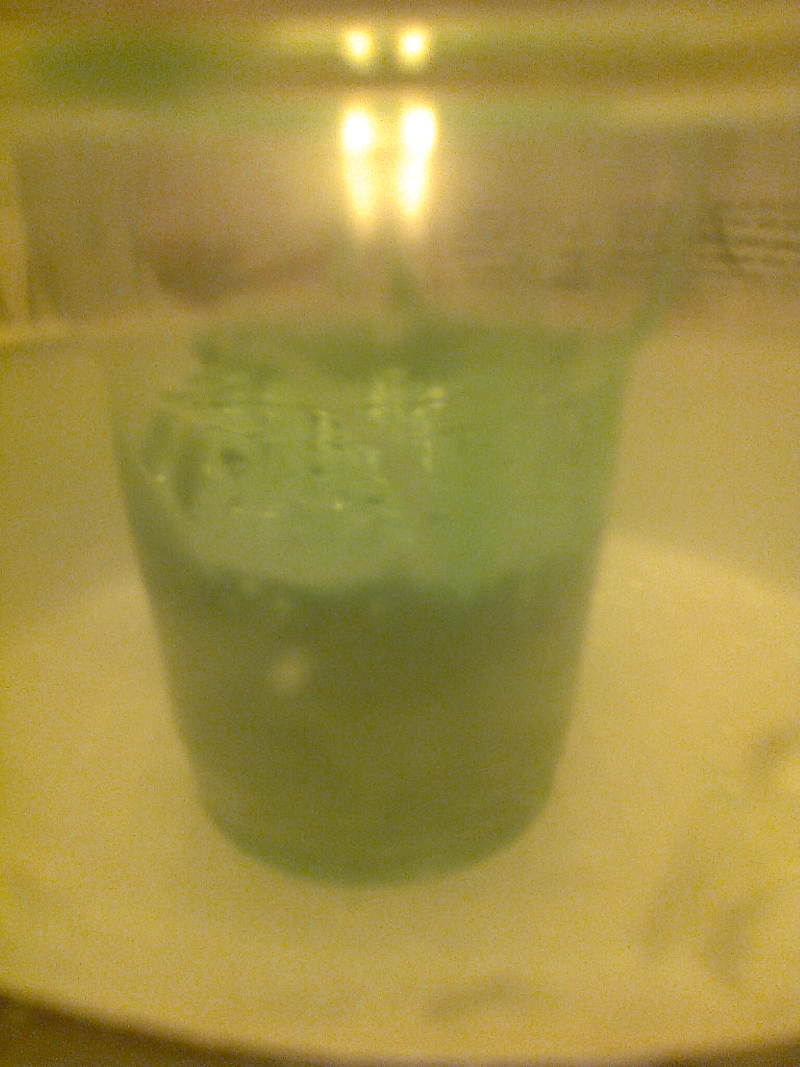

The escaping bubbles indicate that the correct pressure is achieved.

The silicon was then spooned to the mould.

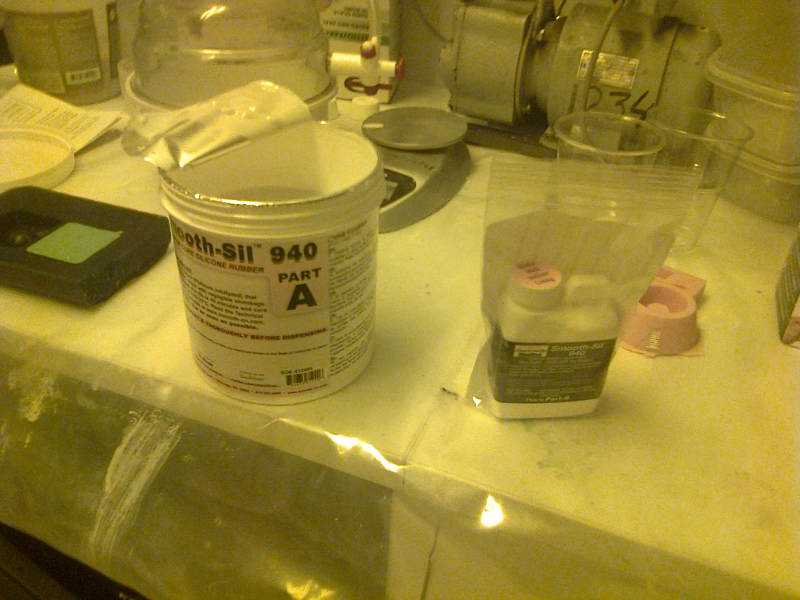

Smooth Sil 940 was selected for the second mould. Note the ratio of the components obvious from the size of the containers.

The components were measured as before and the mix was vacuumed. Observe the bubbles.

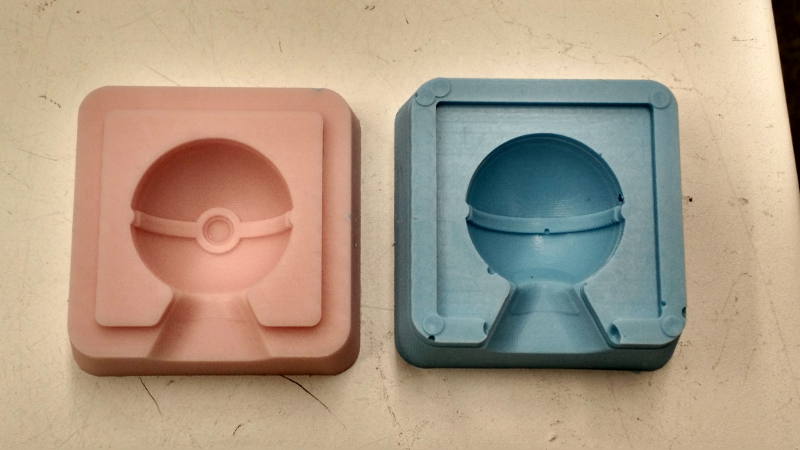

OOMOO 25 (blue) and Smooth Sil 940 (pink) in their moulds.

Metal casting

We were also shown metal casting. The metal used in metal casting was was Sn91Sb9 alloy with a melting temperature of around 235°C. This low melting temperature makes it possible to cast this metal into a silicone mold powdered with talc.

The results

Silicon moulds after curing.

Cast item after curing

Yet another item after curing

The first one after removing.

The second one after removing.

Silicon molds after removing.

A closer view to the silicon moulds. The results were great.

Bangor Contribution

Here we were looking for a Food safe product.

Safety Data

Smooth on have a document listing their food safe products: onlinefood safe silicones. We've decided on Sorta Clear 37. From it's own data sheet we find out that it's about as nice a product as you can get:

2.1 Classification of the substance or mixture

Not a hazardous substance or mixture according to United States Occupational Safety and Health

Administration (OSHA) Hazard Communication Standard (29 CFR 1910.1200), the Canadian

Workplace Hazardous Materials Information System (WHMIS) and Regulation (EC) No 1272/2008

and subsequent amendments.

3.1 Substances

No ingredients are hazardous according to Regulation 2012 OSHA Hazard Communication

Standard 29 CFR 1910.1200 criteria.

The safety sheets for OOMOO 25, Smooth-Sil 940 and Smooth-Cast 300 are available here: Oomoo-25 safety sheet Smooth-Sil 940 safety sheet Smooth-Cast 300 safety sheet