8. Computer controlled machining¶

for this week I have to design, build and assemble something big.

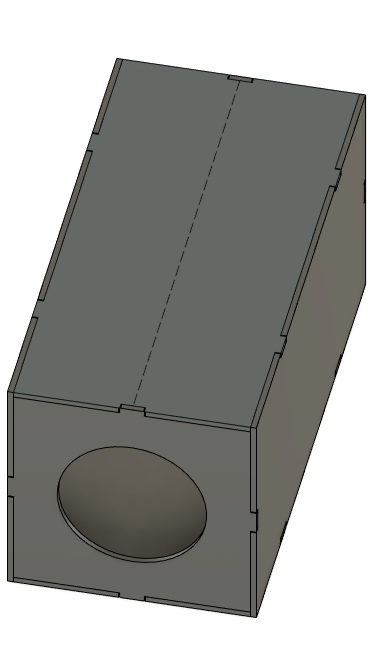

I’ve decided to build a cat shelter for stray cats in the neighborhood.

so first I designed it then scaled down the design and tested it with laser cutting then I built the original design and all can be seen in the following steps.

Designing¶

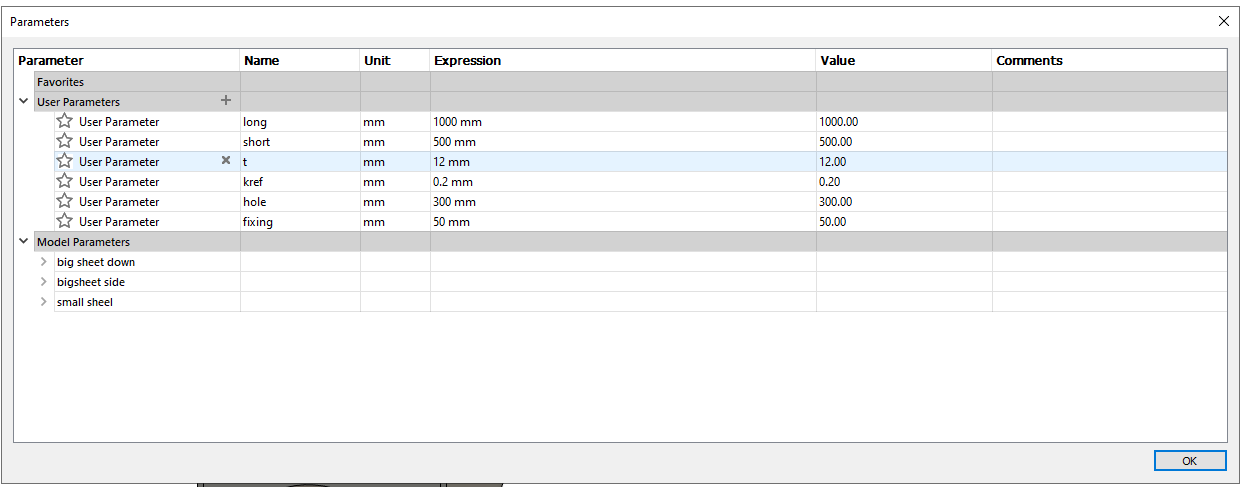

I used fusion 360 to design the cat shelter like following:

setting parameters.

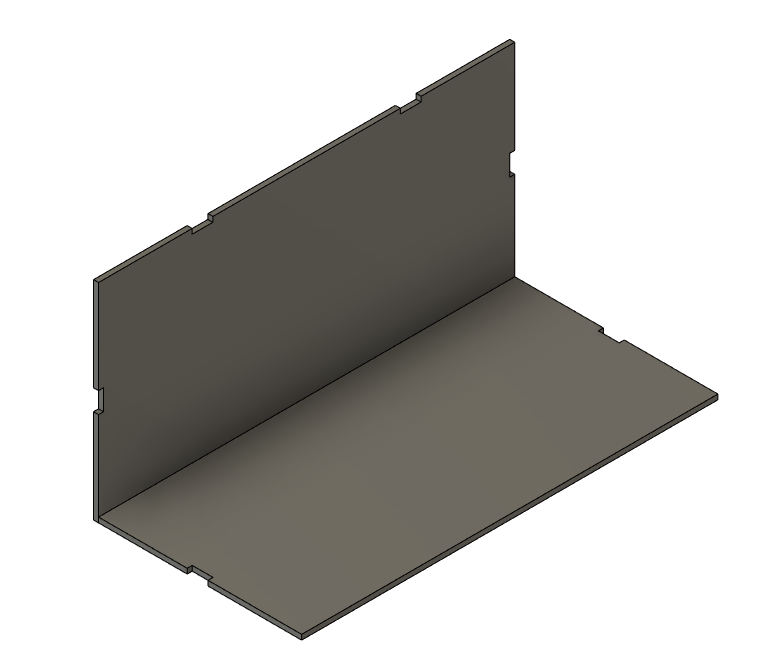

designing side sheet

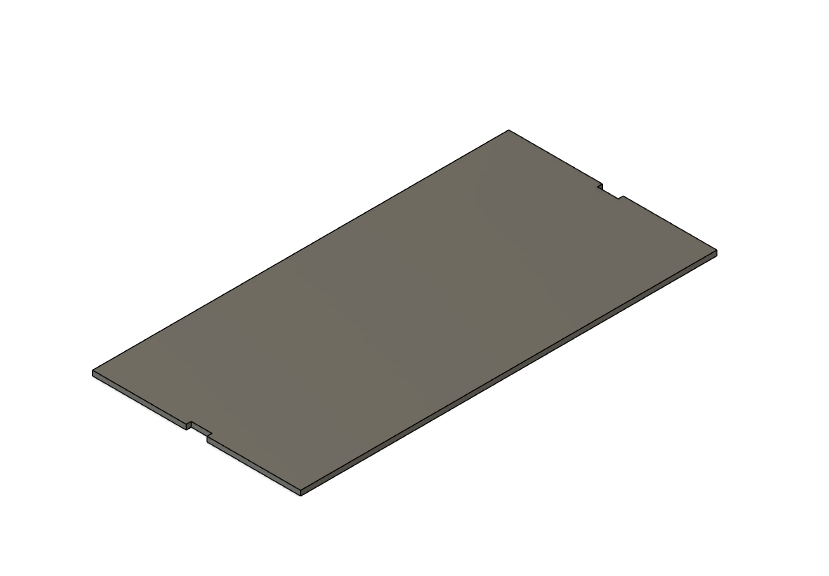

designing top sheet

designing front and back entrances and finishing the design.

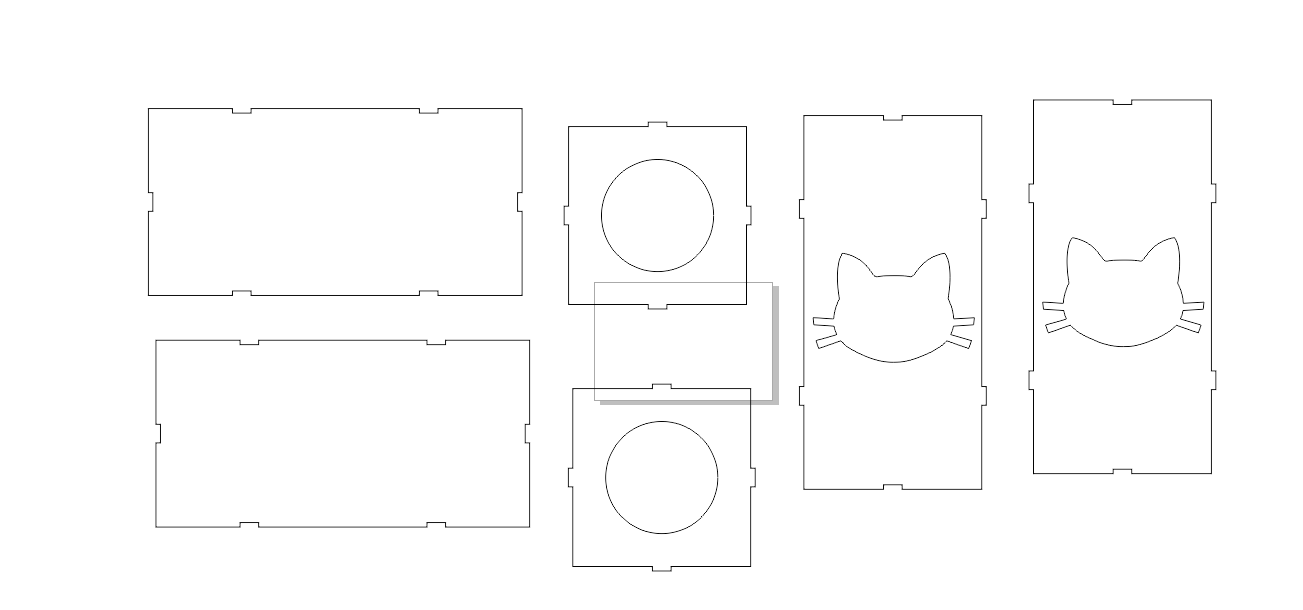

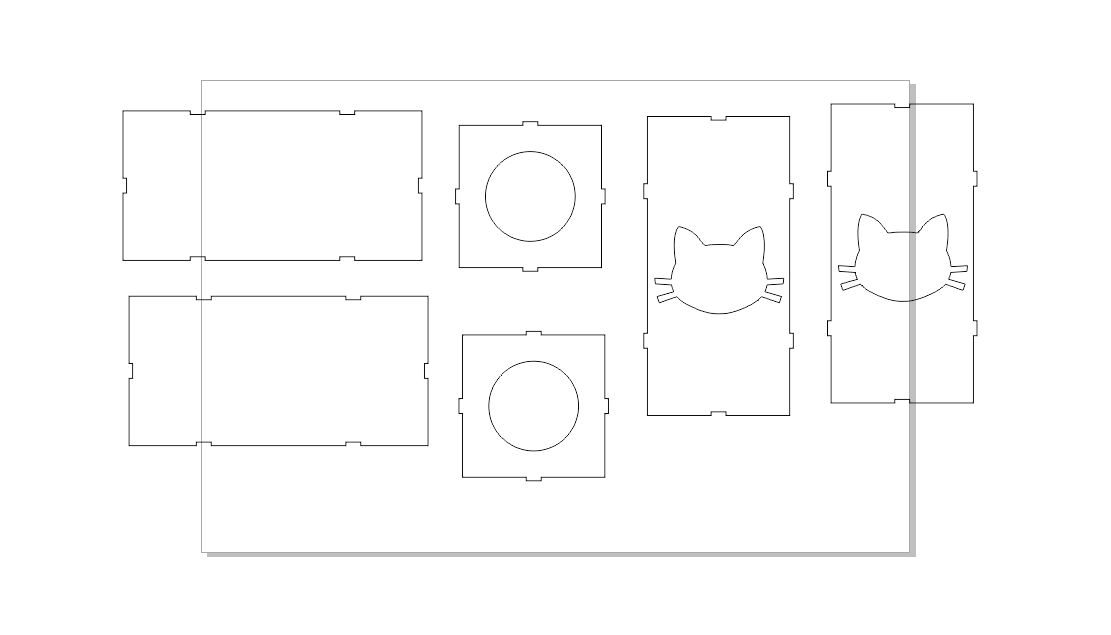

then after that I projected all the faces as 2d sketches and eported them as dxf.

then I scaled them down to test it with laser cutter.

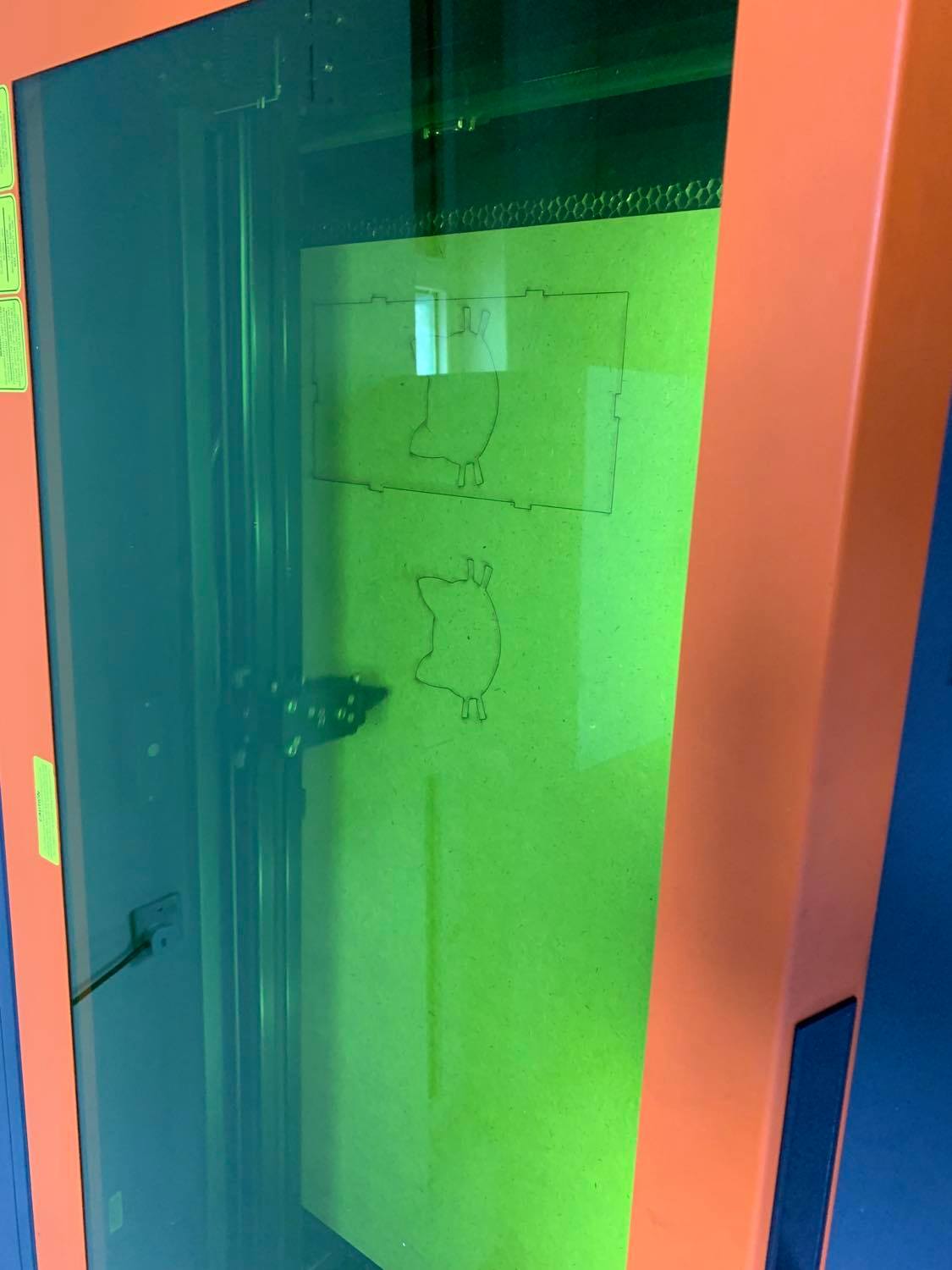

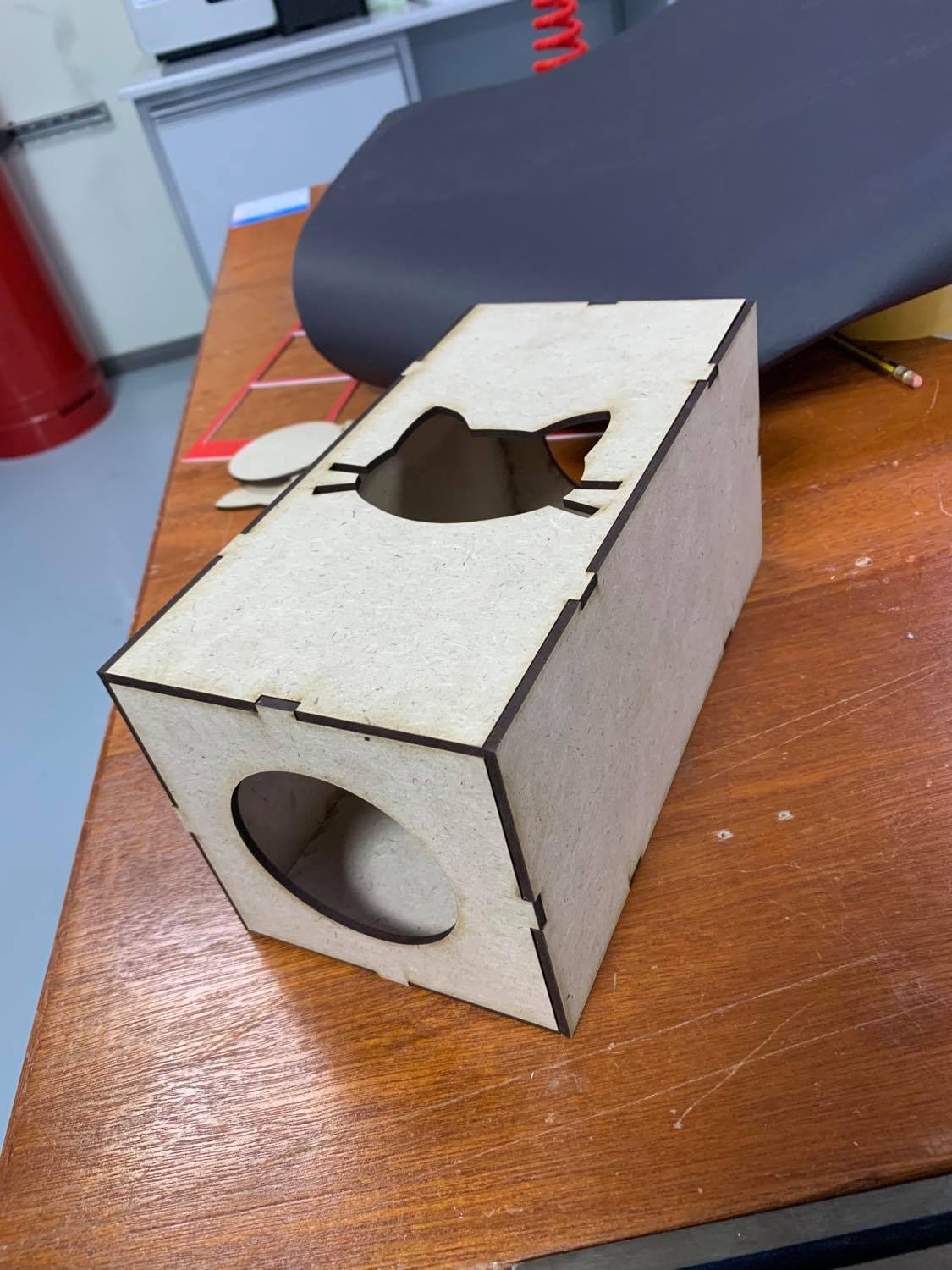

Laser cutting.¶

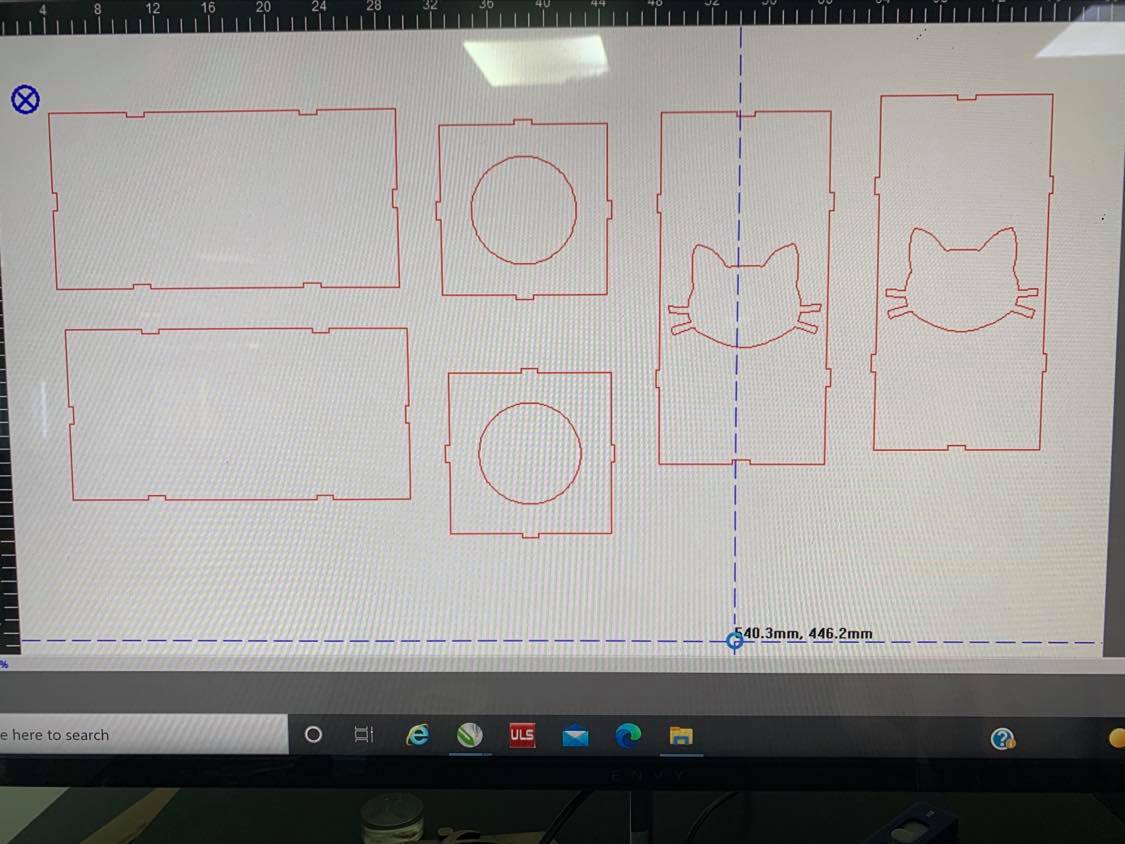

I imported the design to the laser cutting app and set it to MDF wood with 3mm thickness. then I started cutting.

then I assembled it and I was satisfied with the results.

CNC Milling (Shopbot):¶

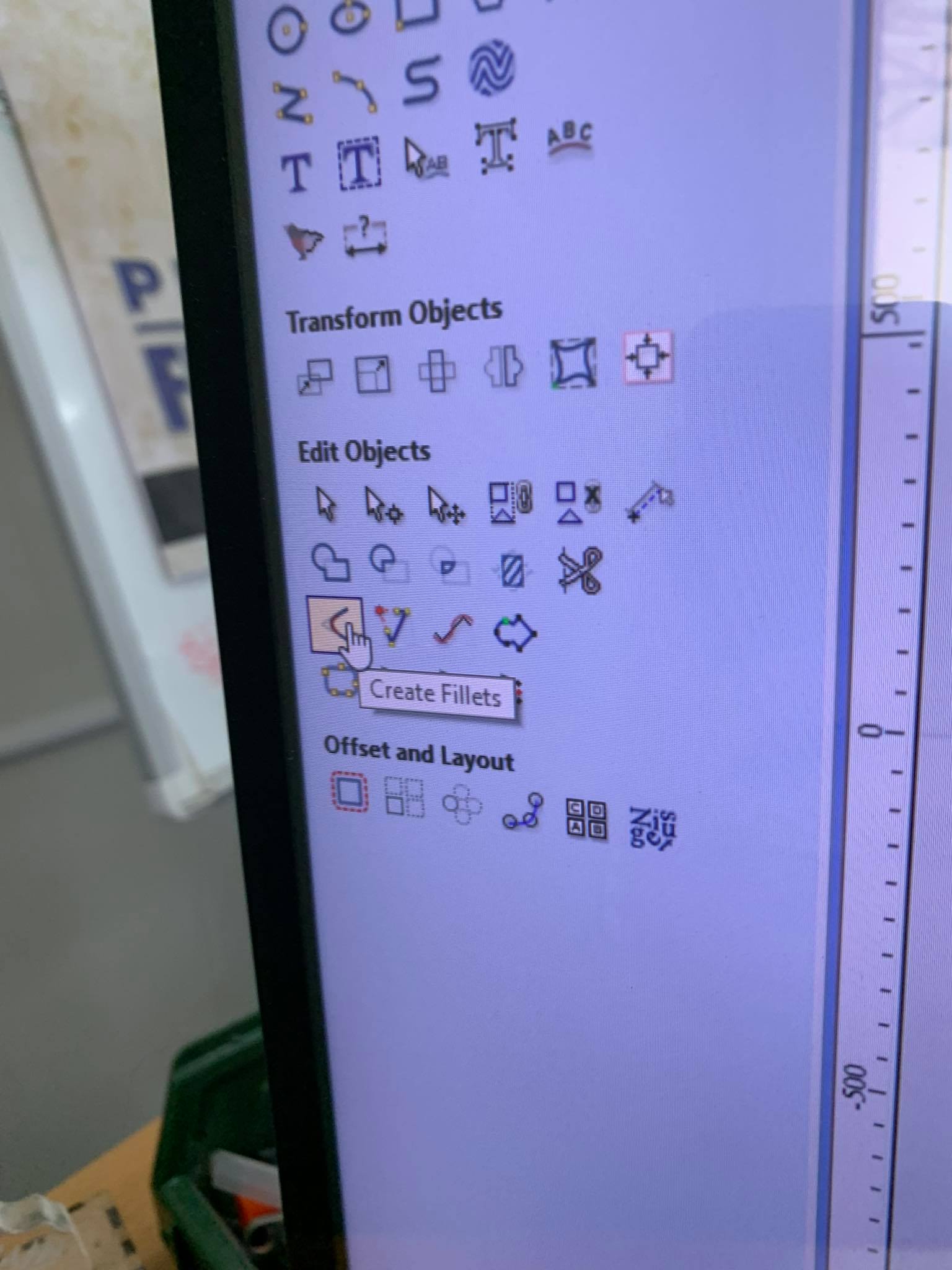

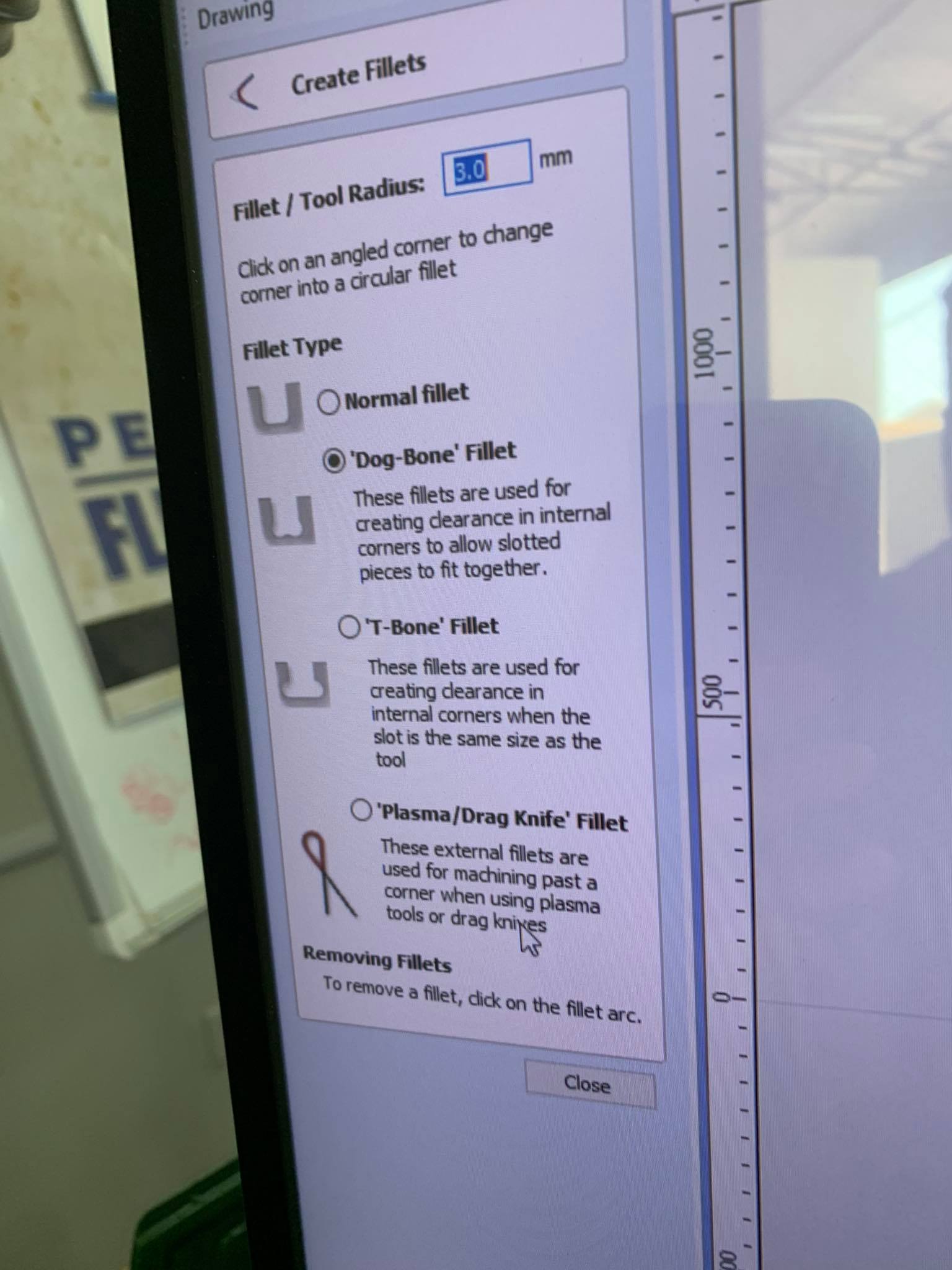

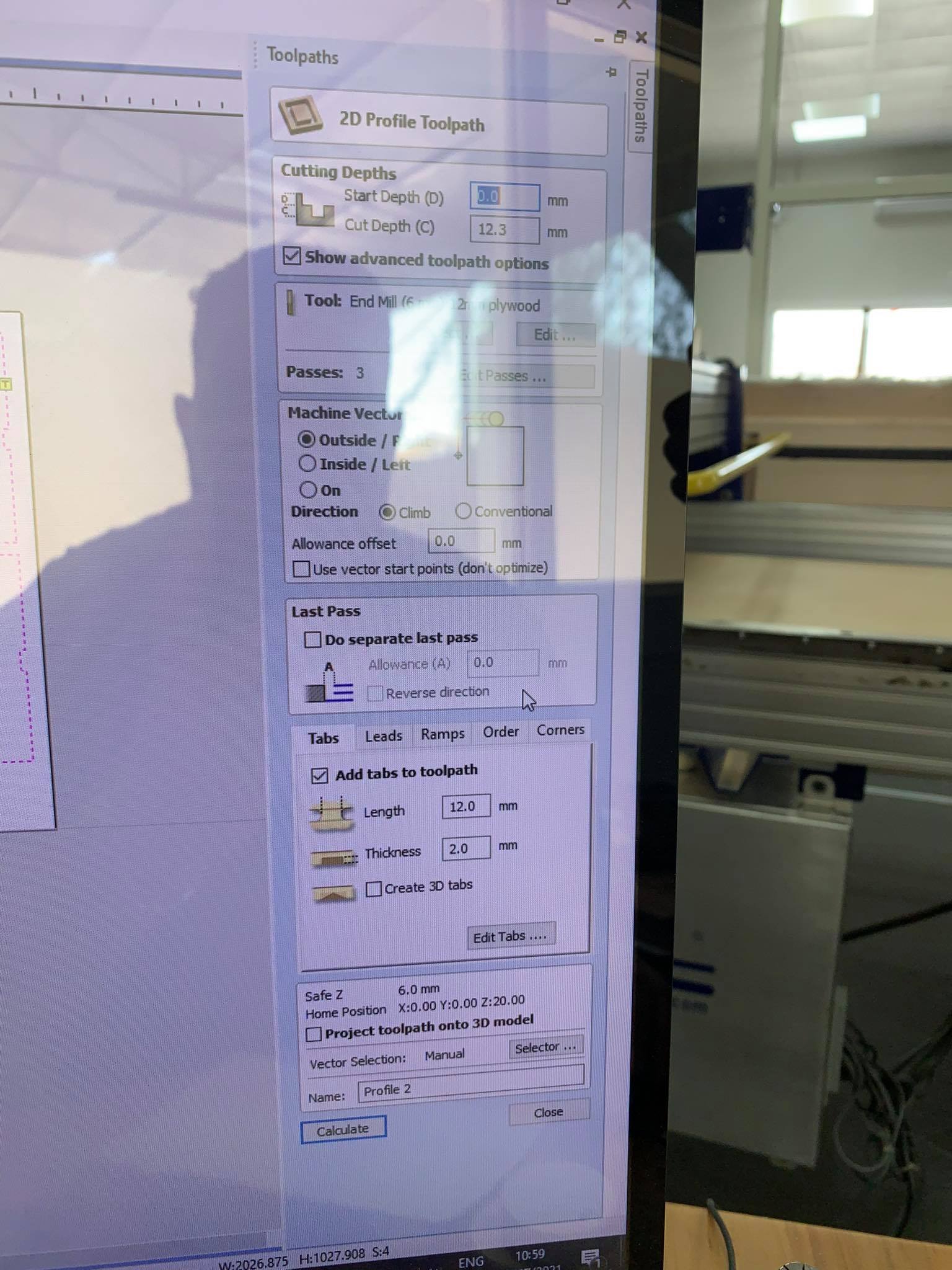

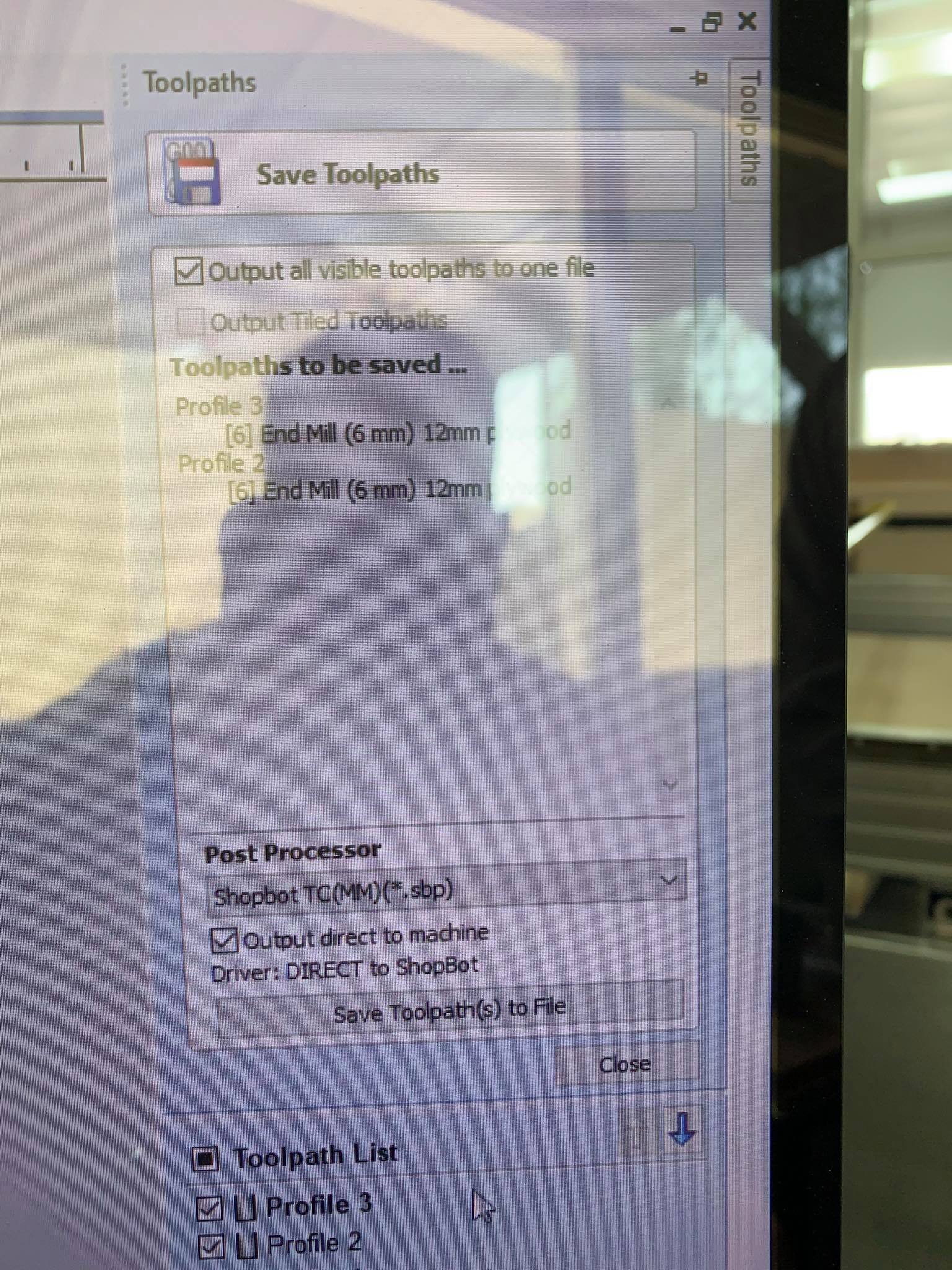

First I imported the design to Vcarve then added the milling bit for cutting

then I added tabs (3mm) to the design for safety reasons.

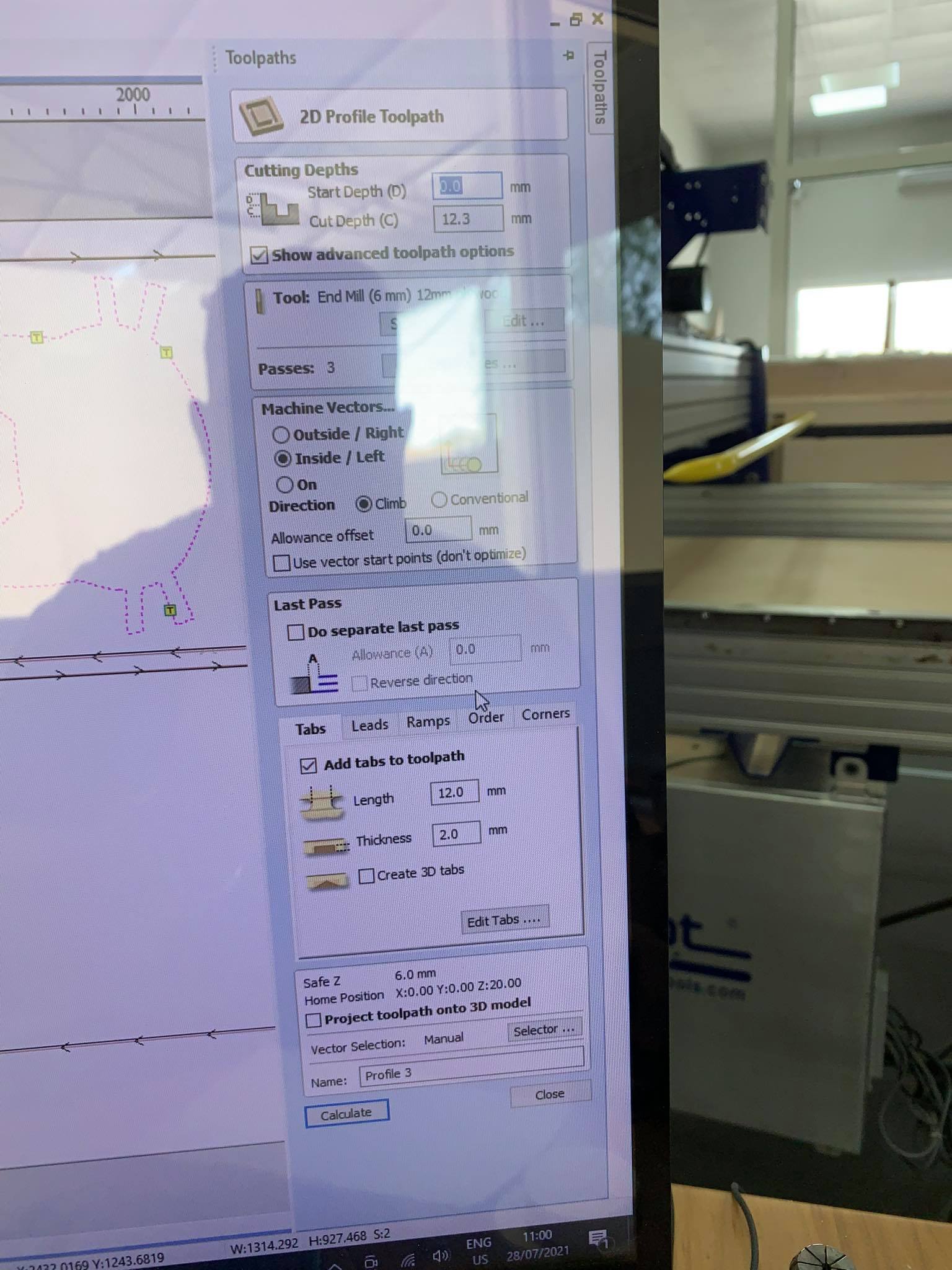

then I generated 2 toolpaths, one for cutting the outside and one to cut the inside designs.

and I put the depth to 12 mm and 3 passes each.

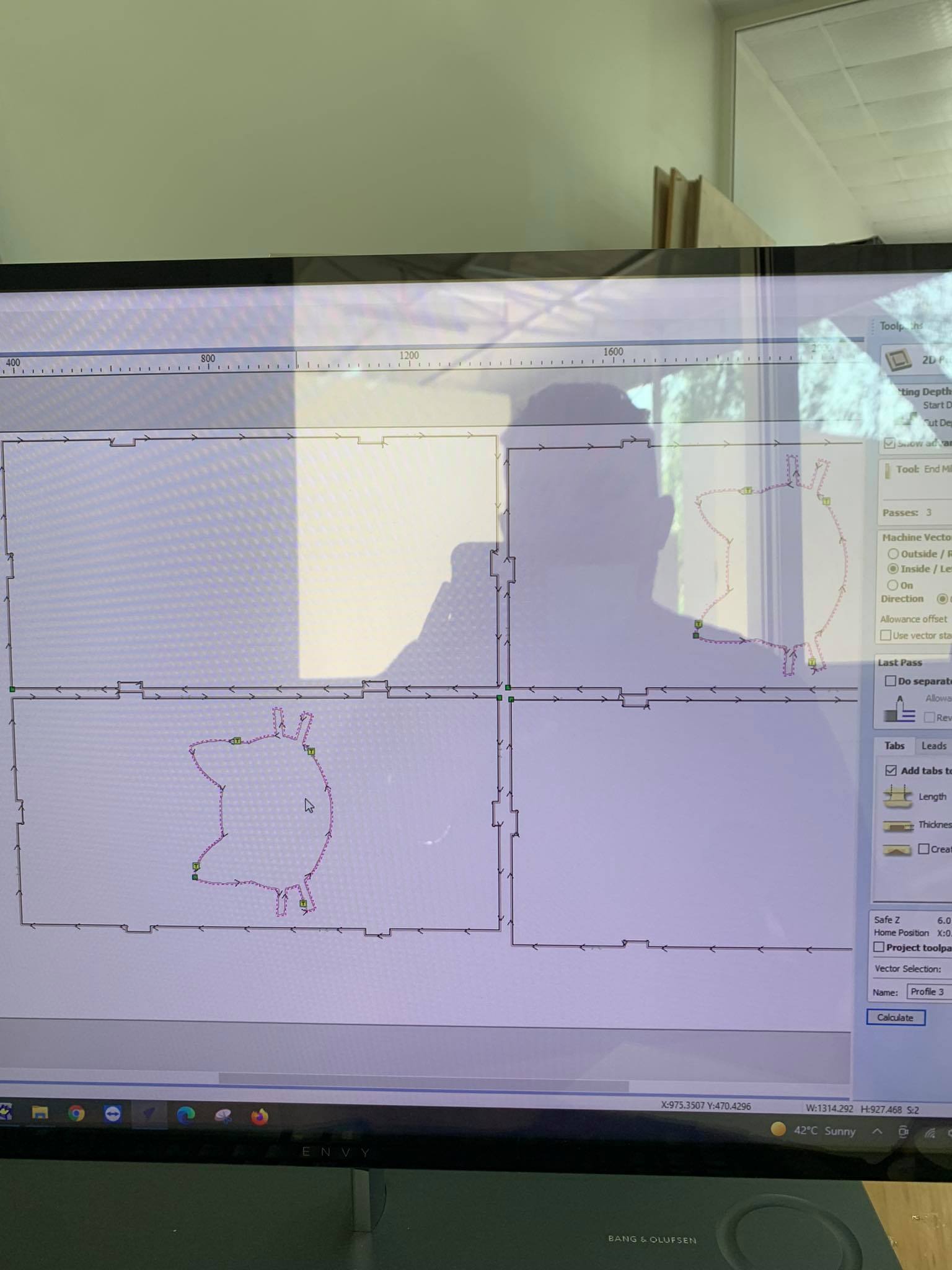

then the resulted toothpaths looked like

then i saved the tooth toolpaths

then I set up the shopbot by adding the milling bit then by placing and moving the shopbot head to the origin X,y axis by using the keypad to control shopbot movement manually, then I used the calibration metal sheet for zeroing the z axis.

then I started cutting

then after that, using sand paper I smoothed all the sides of the cutted parts then started to assemble

then I stained the wood and then varnished it with gloss varnish and the result was like this

Files.¶

Group assignment.¶

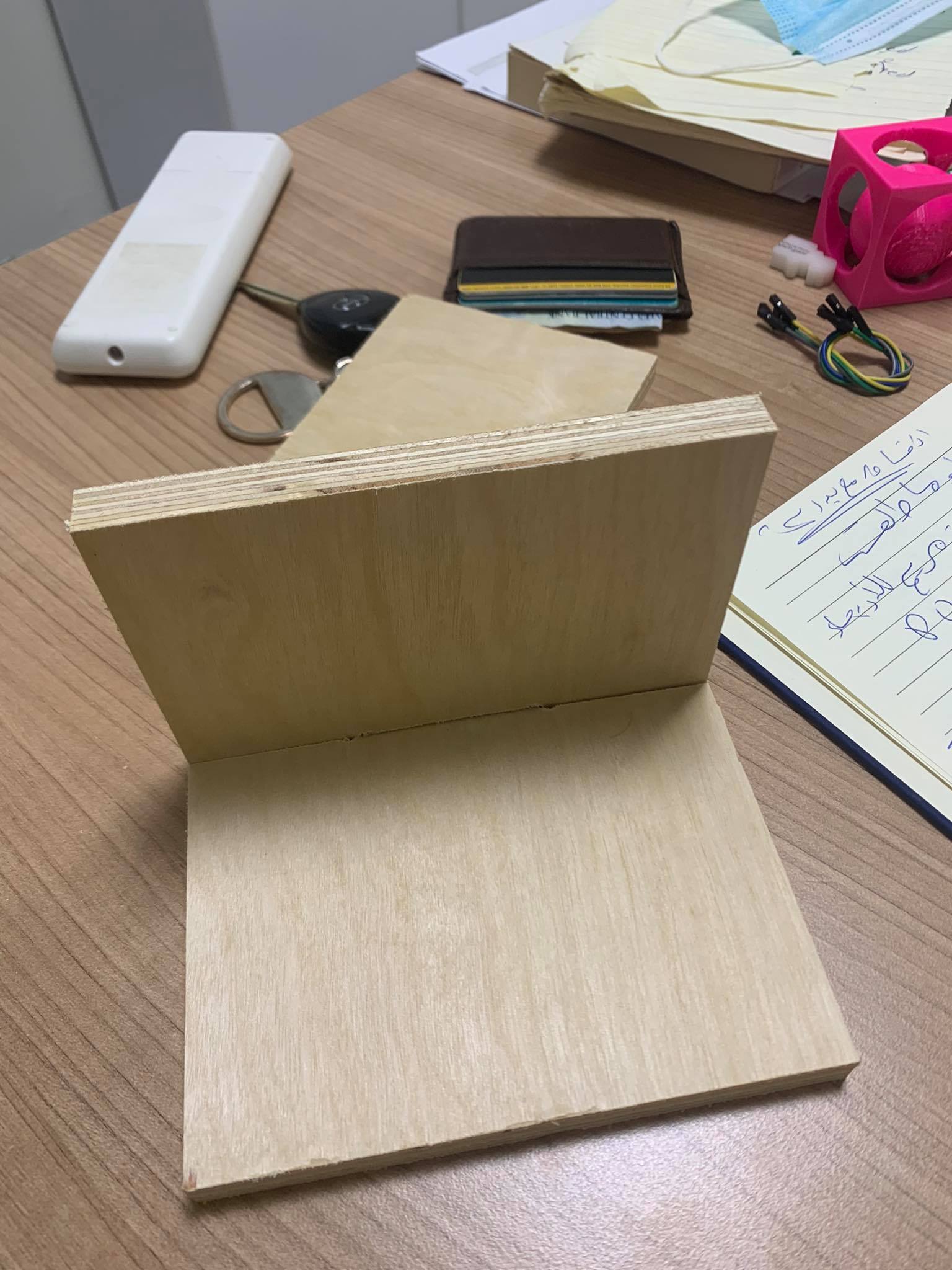

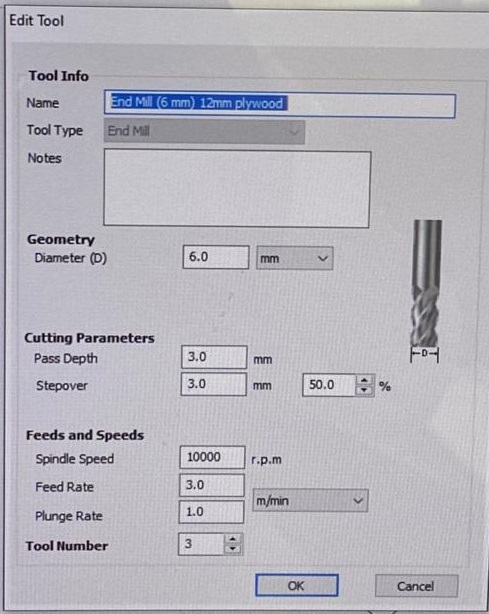

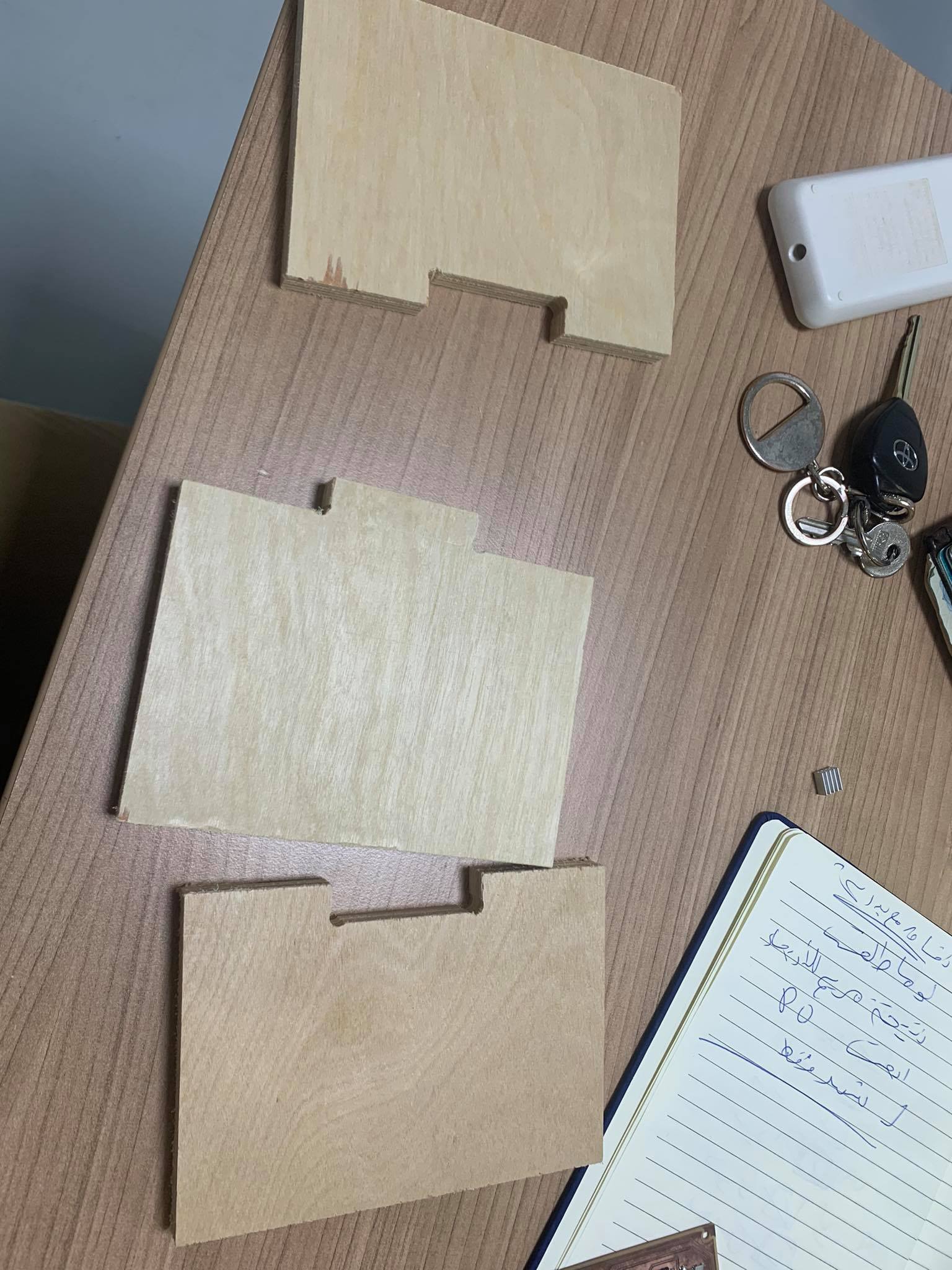

I wanted to test the fitting for the shopbot.

So Designed three pieces. and I cut them with Shopbot and I used 12 mm plywood.

the setting I used:

- end mill (6mm)

- pass depth:3mm.

- stepover: 3mm.

- spindle speed: 10000 rpm.

- feed rate: 3.

- start depth:0.

- cut depth: 12.3.

- outside cutting.

1 male piece with 50 mm pocket.

1 female piece with 50 mm head.

1 female piece with 49.8 mm head.

the 50 mm was fitting nicely but a bit lose.

the 49.8 mm was hard to fit but is firm and tight fit.