4. Computer controlled cutting¶

In this week I got Familiar with both Laser cutting and vinyl cutting. and I achieved that by doing my individual assignment and group assignment. Learning the features of both laser machines and vinyl cutter. Where we calculated Kref for laser machine through a practical method and tested different features in both machine and produced products that we are proud of.

Individual assignment¶

VinylCutter Ronald gs-24.¶

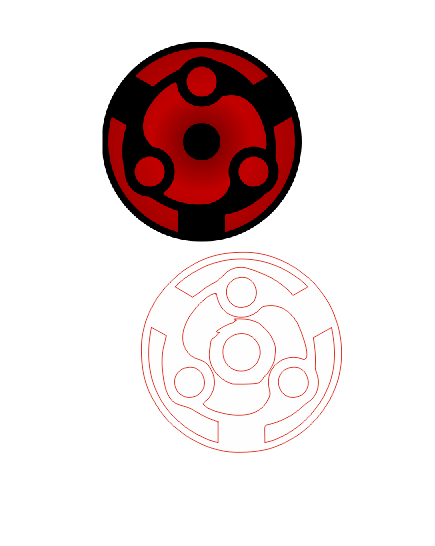

I decided to design a sticker for one of my favorite anime, so I started by designing it on corel draw,I downloaded Image from this link. Then I traced the outlines like this.

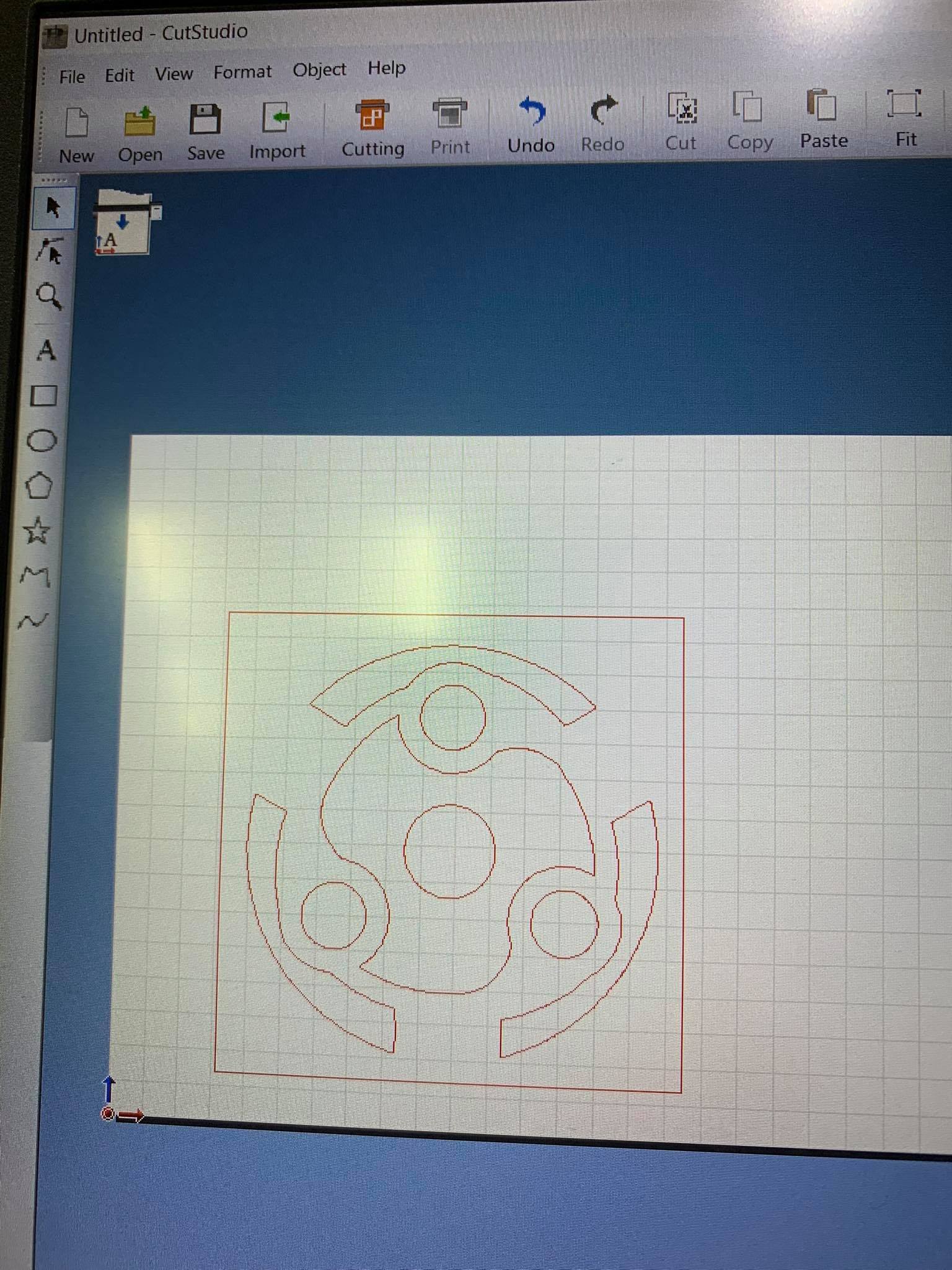

then I prepared it for cutting by making the outer line red and hair thin.

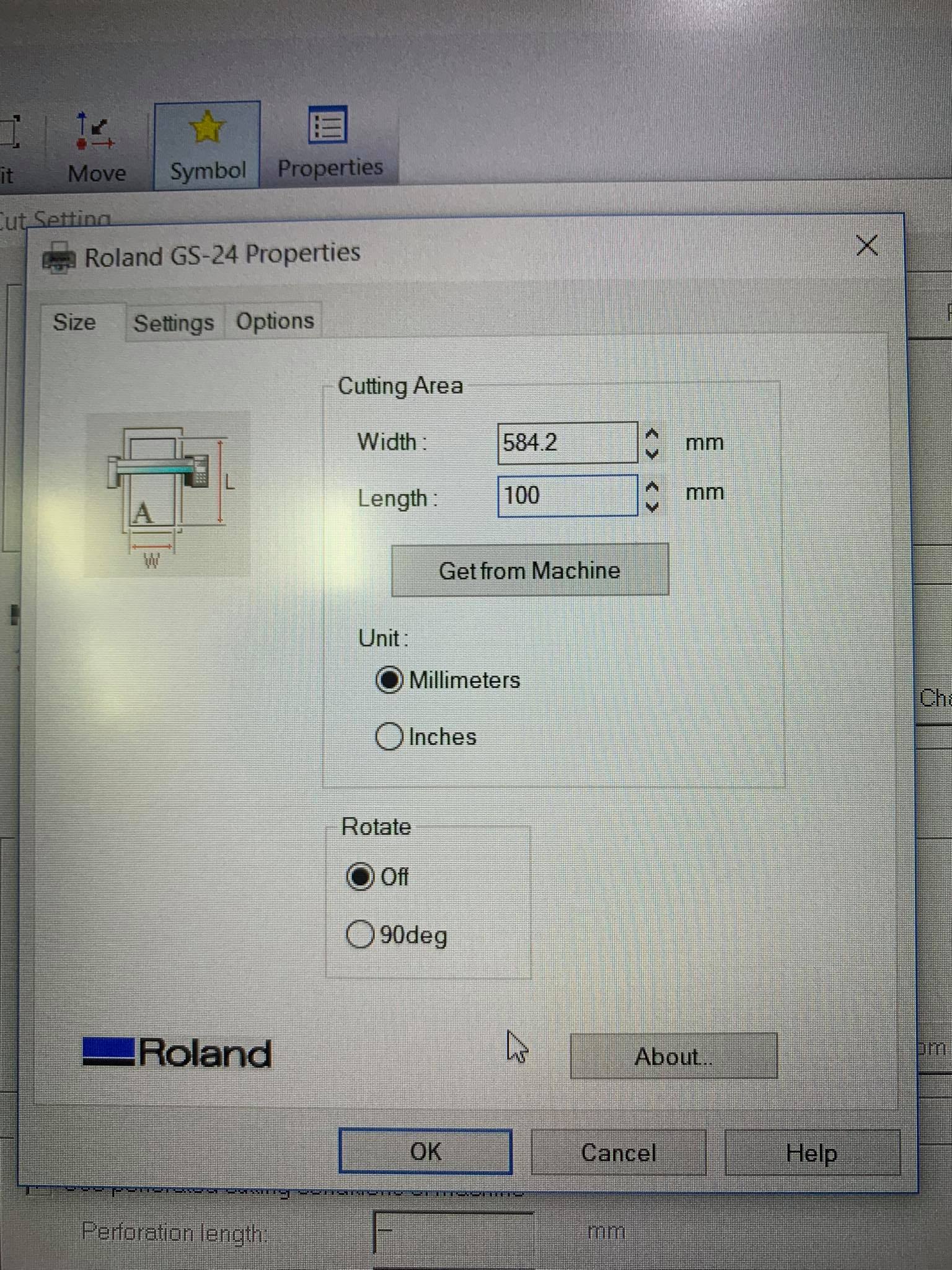

After that I exported the file by Print command and put the setting as following to suit the VinylCutter

From CorelDraw

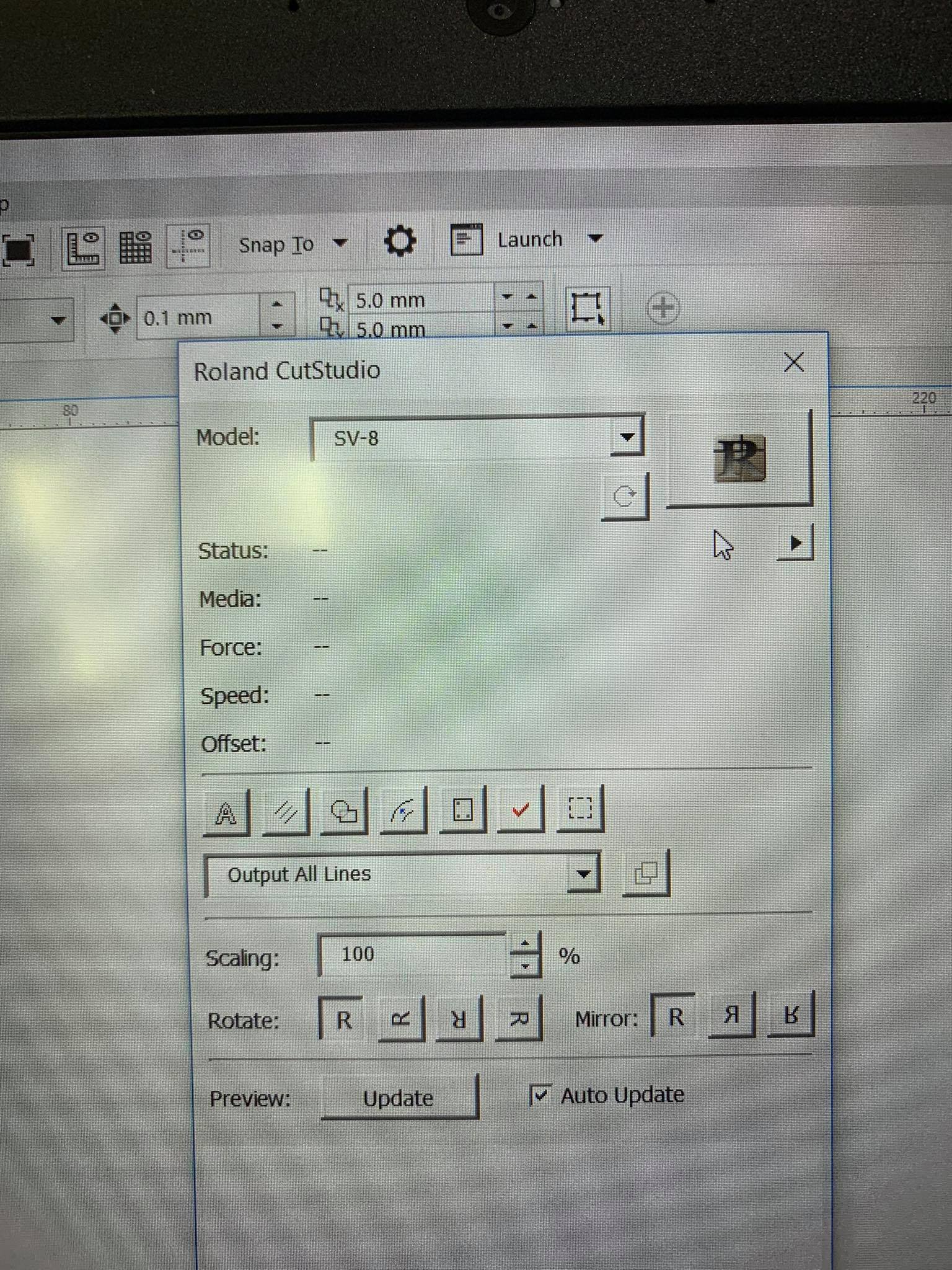

on the machine app (“Roland CutStudio)

then i took it to the VinylCutter and added the sticker roll and tested deffirent power for cutting till I found that the most suitable power is 120 gf.

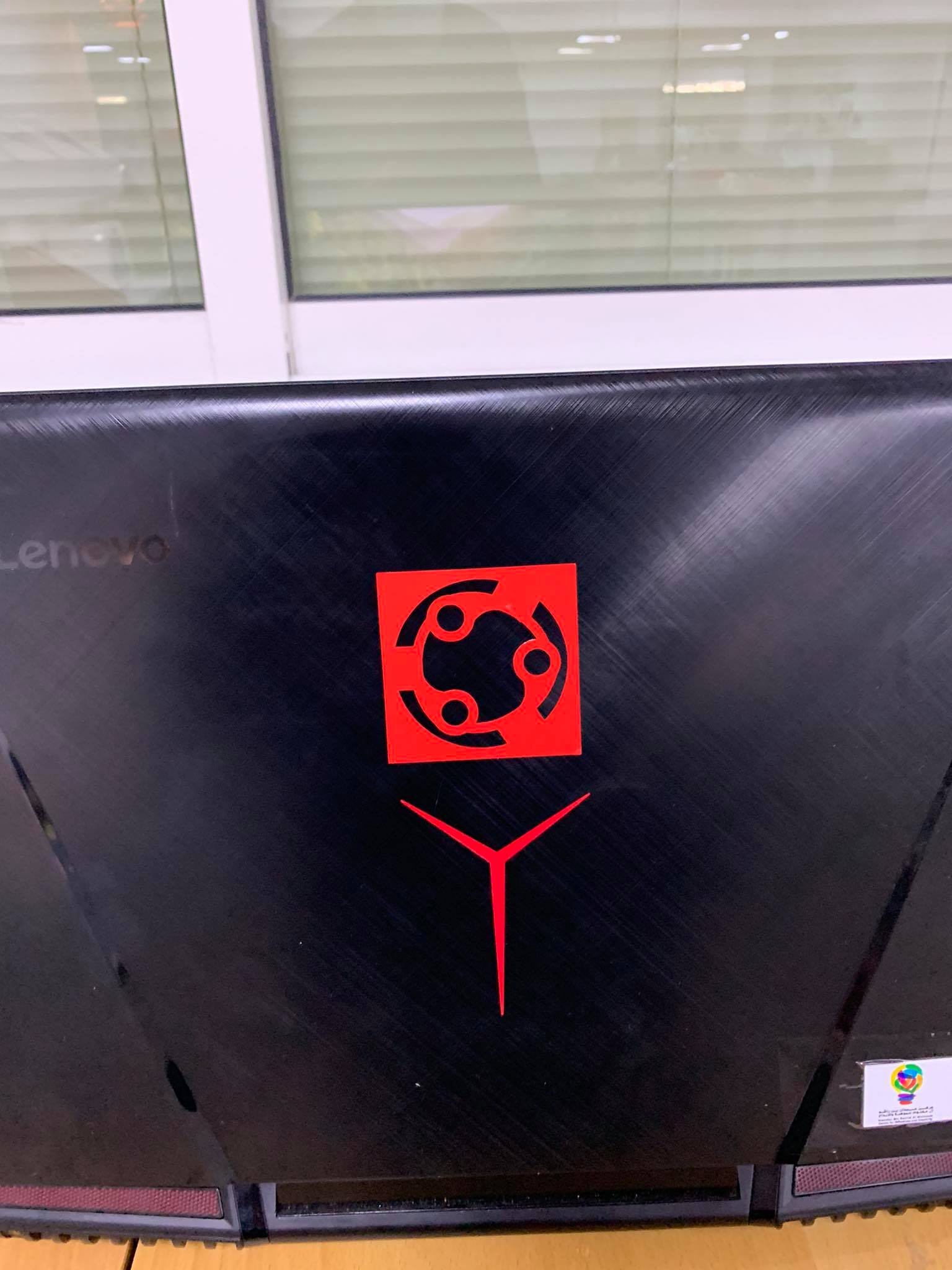

then I cut the sticker and moved it with a masking tape to the back of my laptop screen. and it looked like this.

Press-fit Construction kit( Universal Laser Cutter).¶

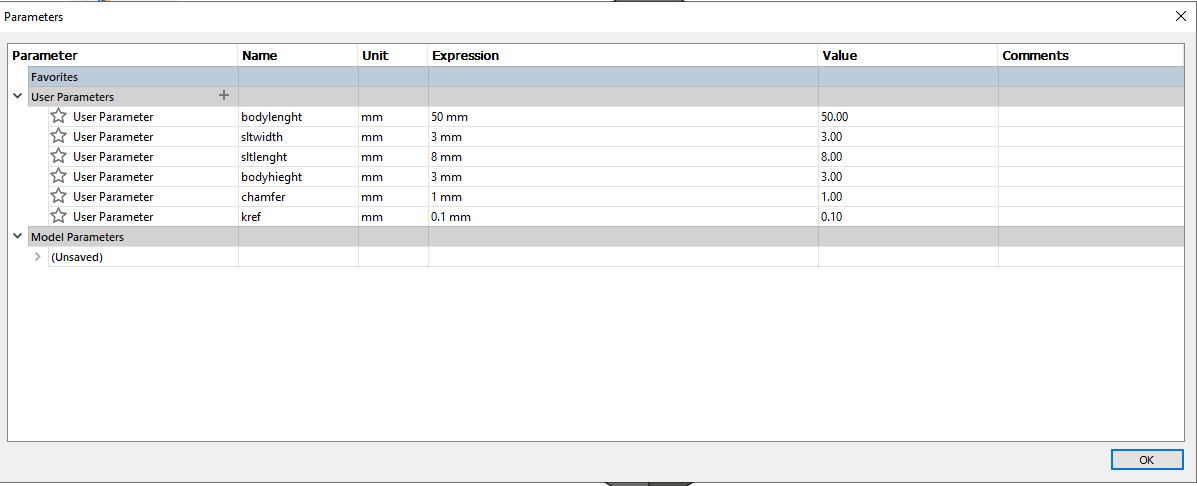

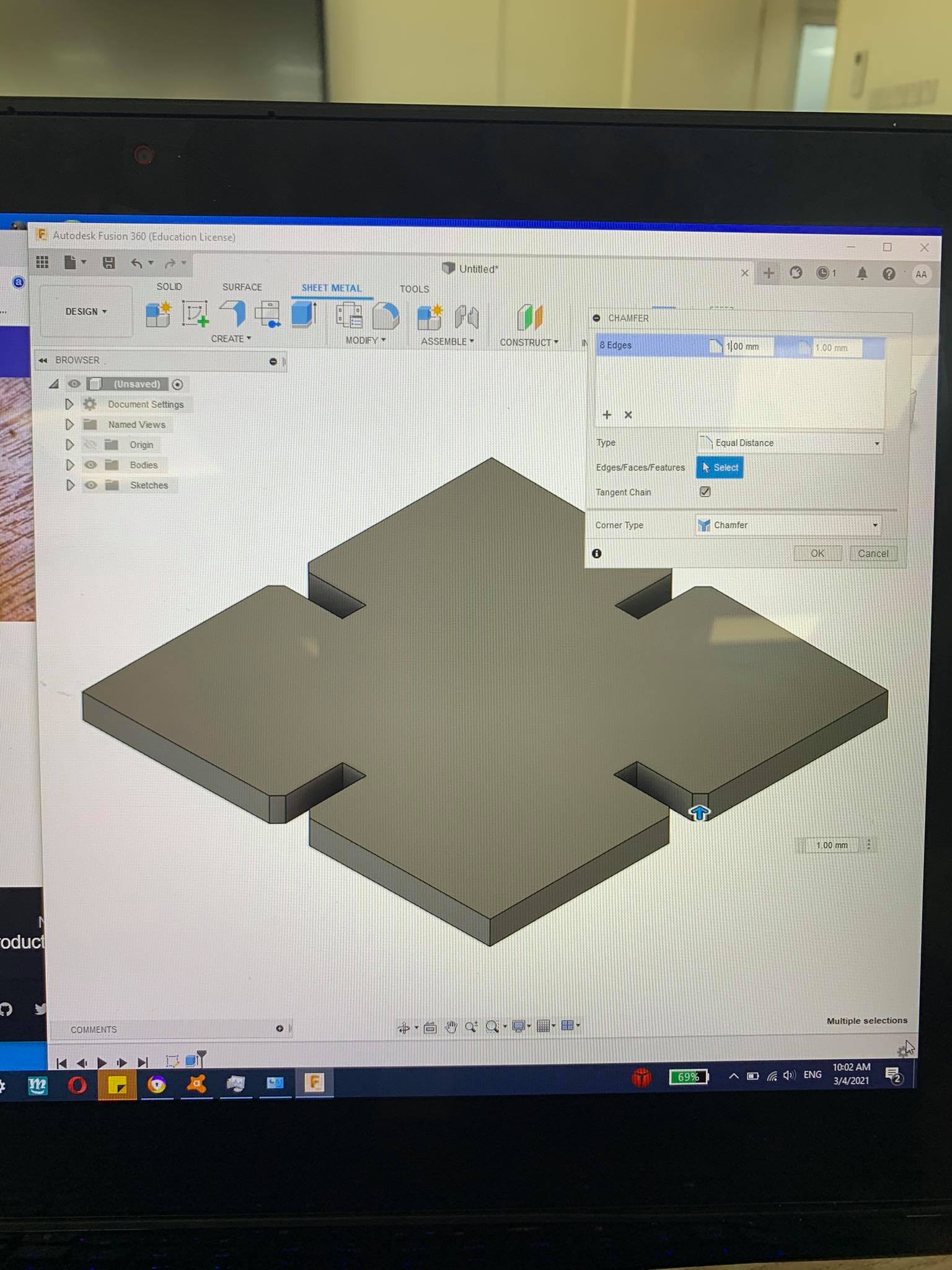

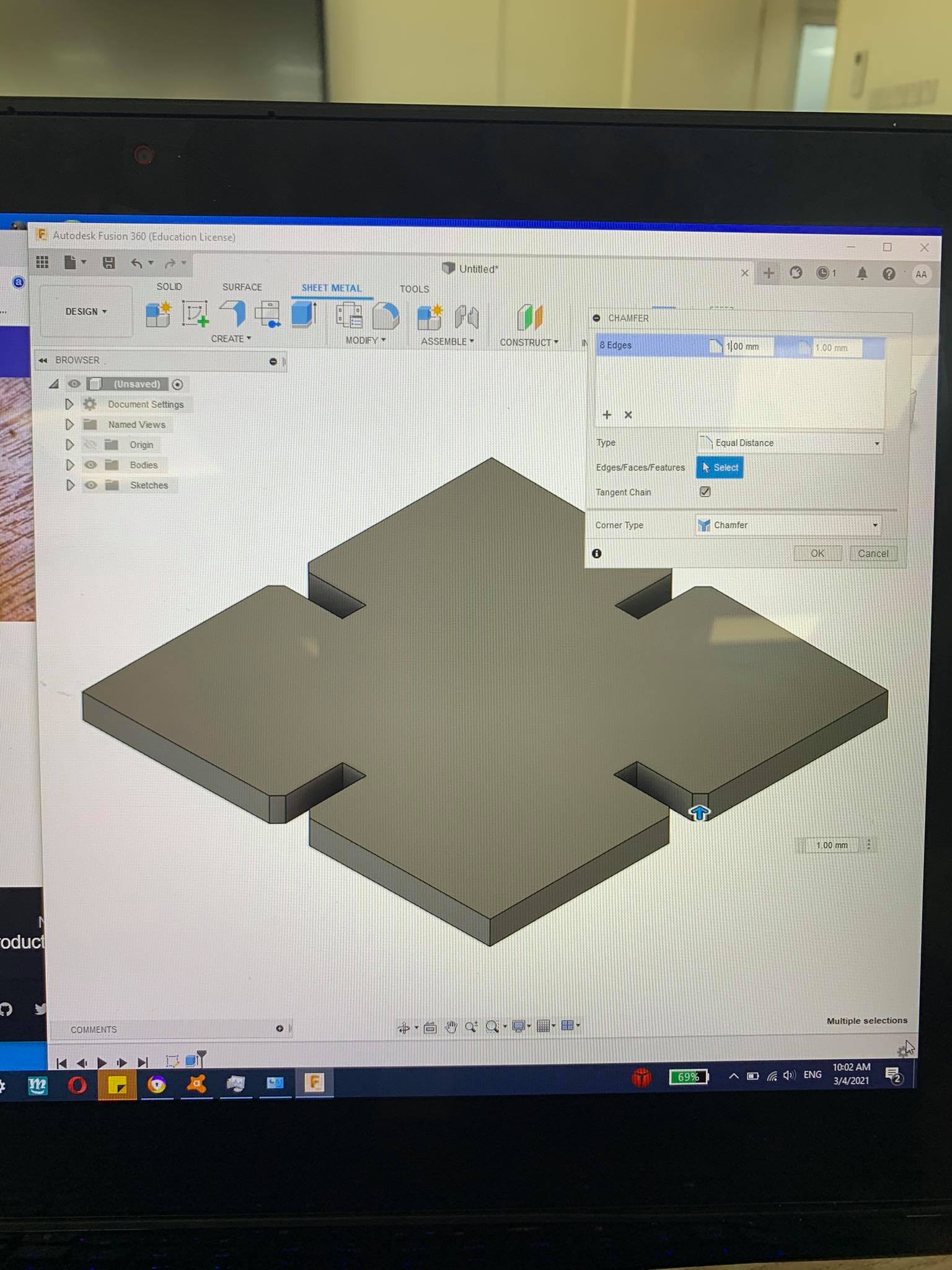

First I designed the 3D kit pieces on Fusion360 after calculating the Kref for the laser cutter and it looked like this.

and the parameters where like this.

I linked these parameters to each other so incase I change one of the parameters the other linked parameters will change too. also I drew all rectangles with center rectangles so its fixed locations on the drawing. and adding the KREF, parameter kept the design pieces fit to each others.

lastly, I projected one of the face on the plane to be able to covert the 2d design

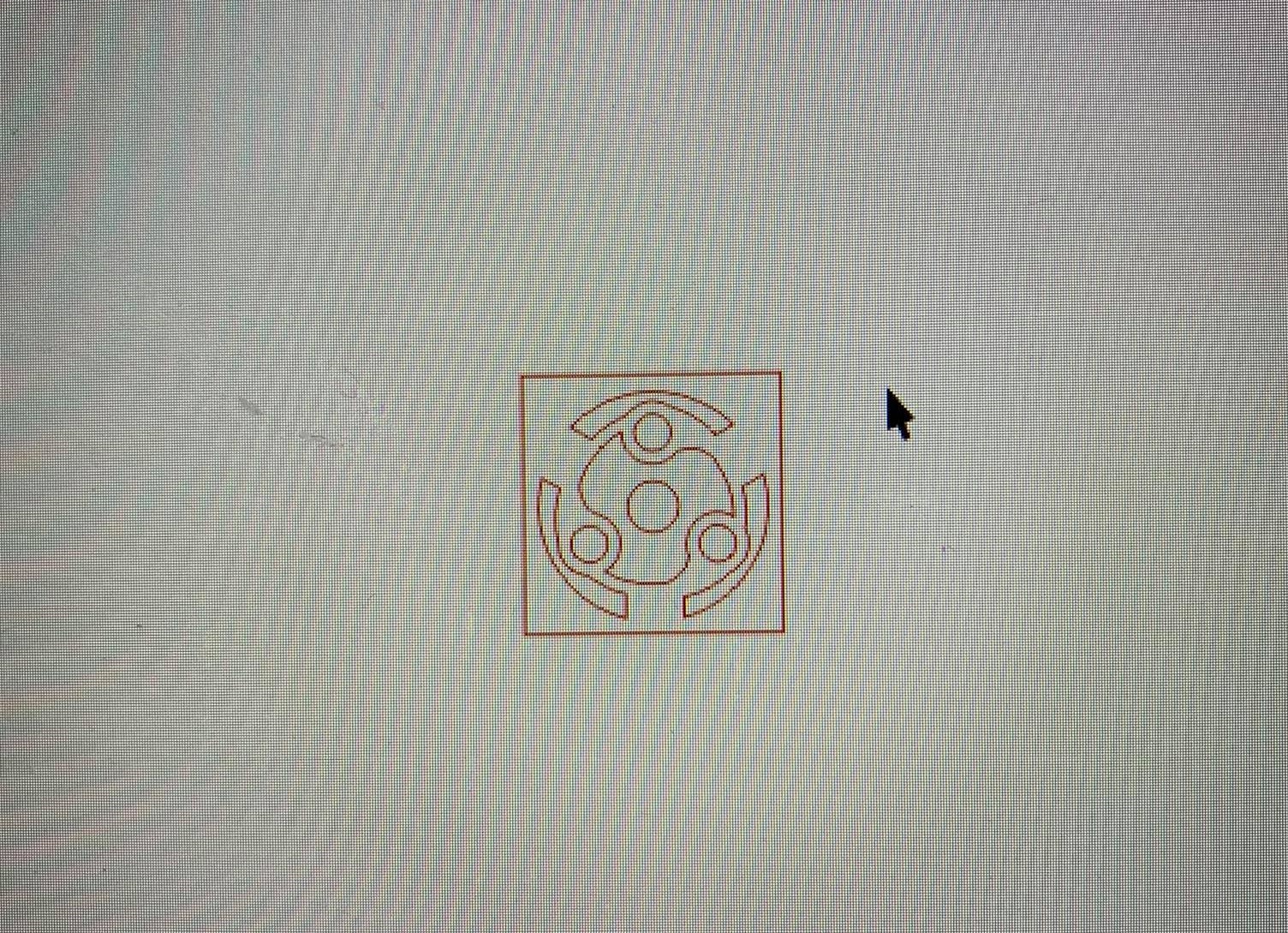

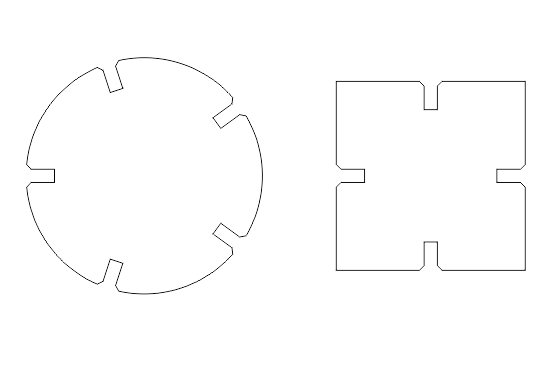

then I exported it to Coreldraw and it looked like this.

Then I prepared it for cutting by making it hairline and red. and I also made some copies to be able to complete the kit and it looked like this.

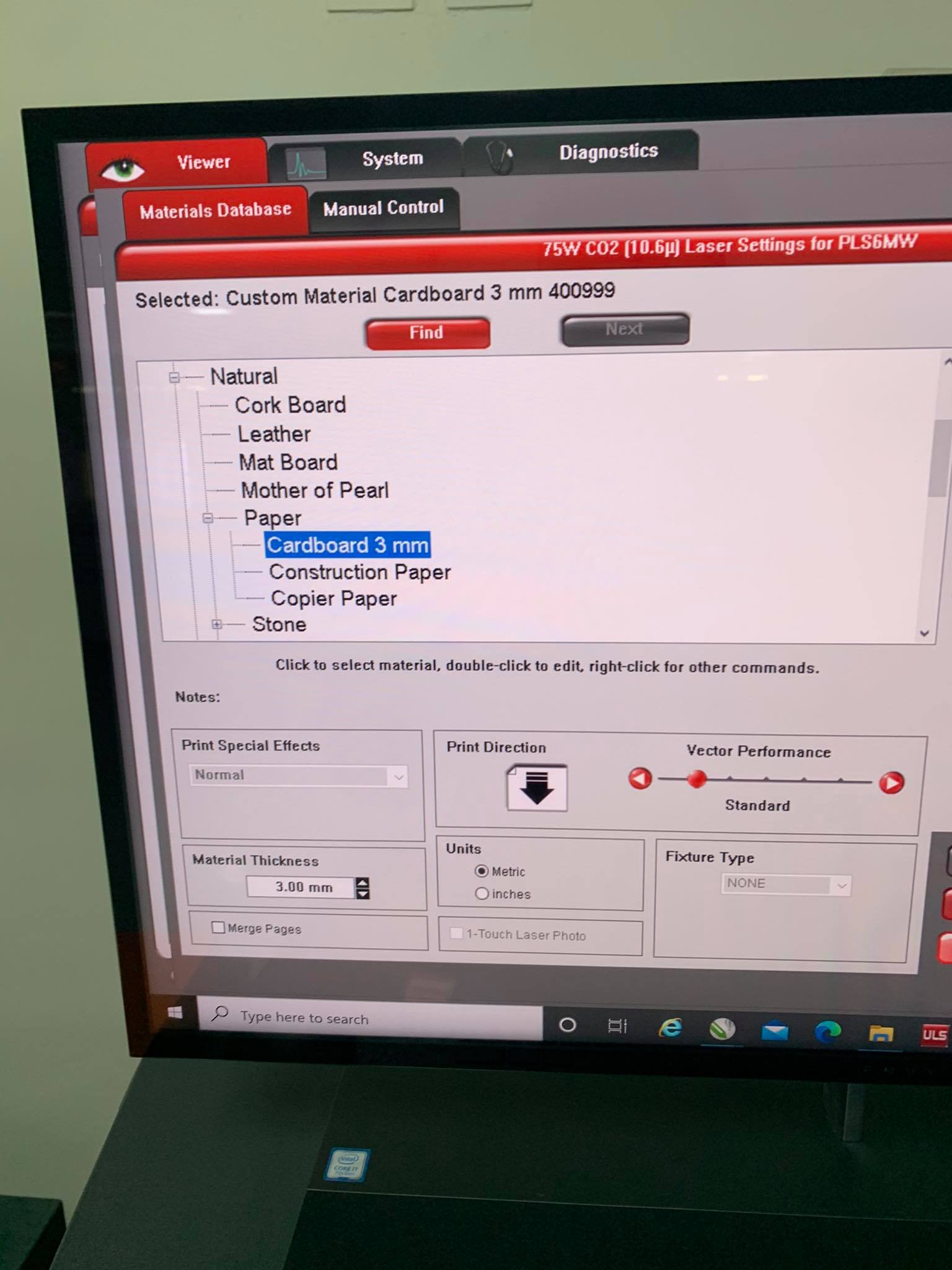

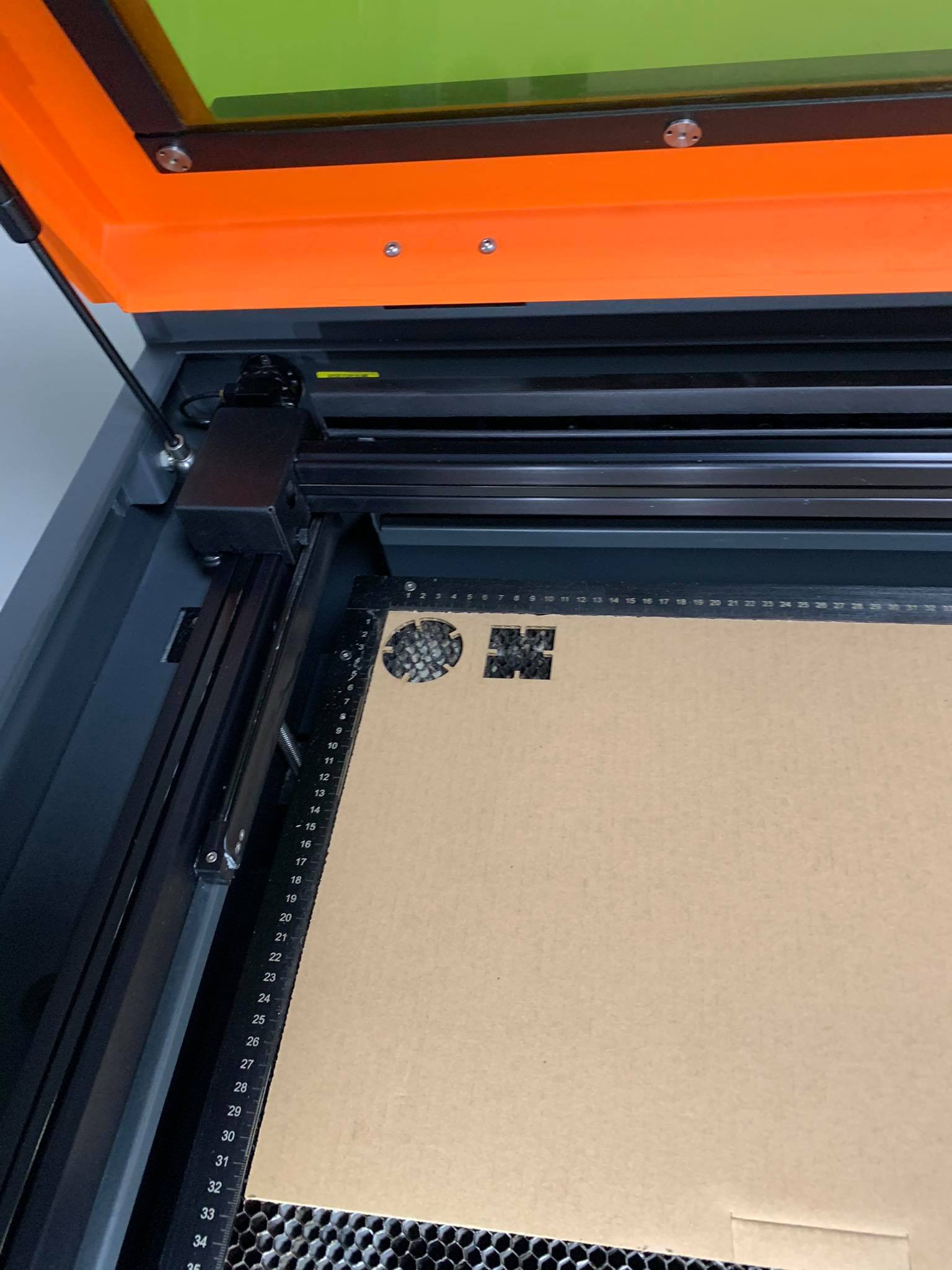

I put the setting on laser cutter for cardboard 3mm and it worked.

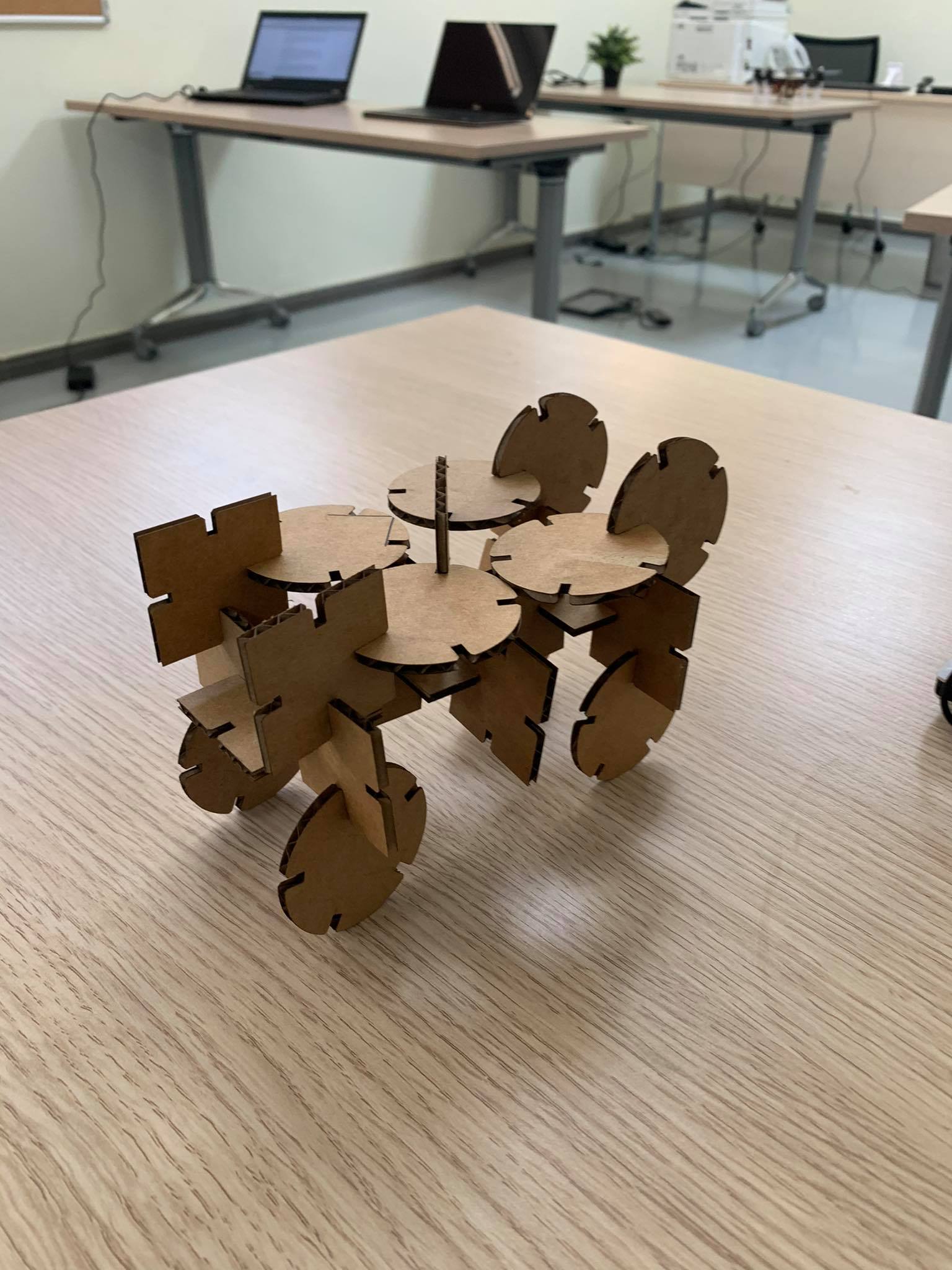

and the final product after fitting looked like.

Files.¶

Group assignment.¶

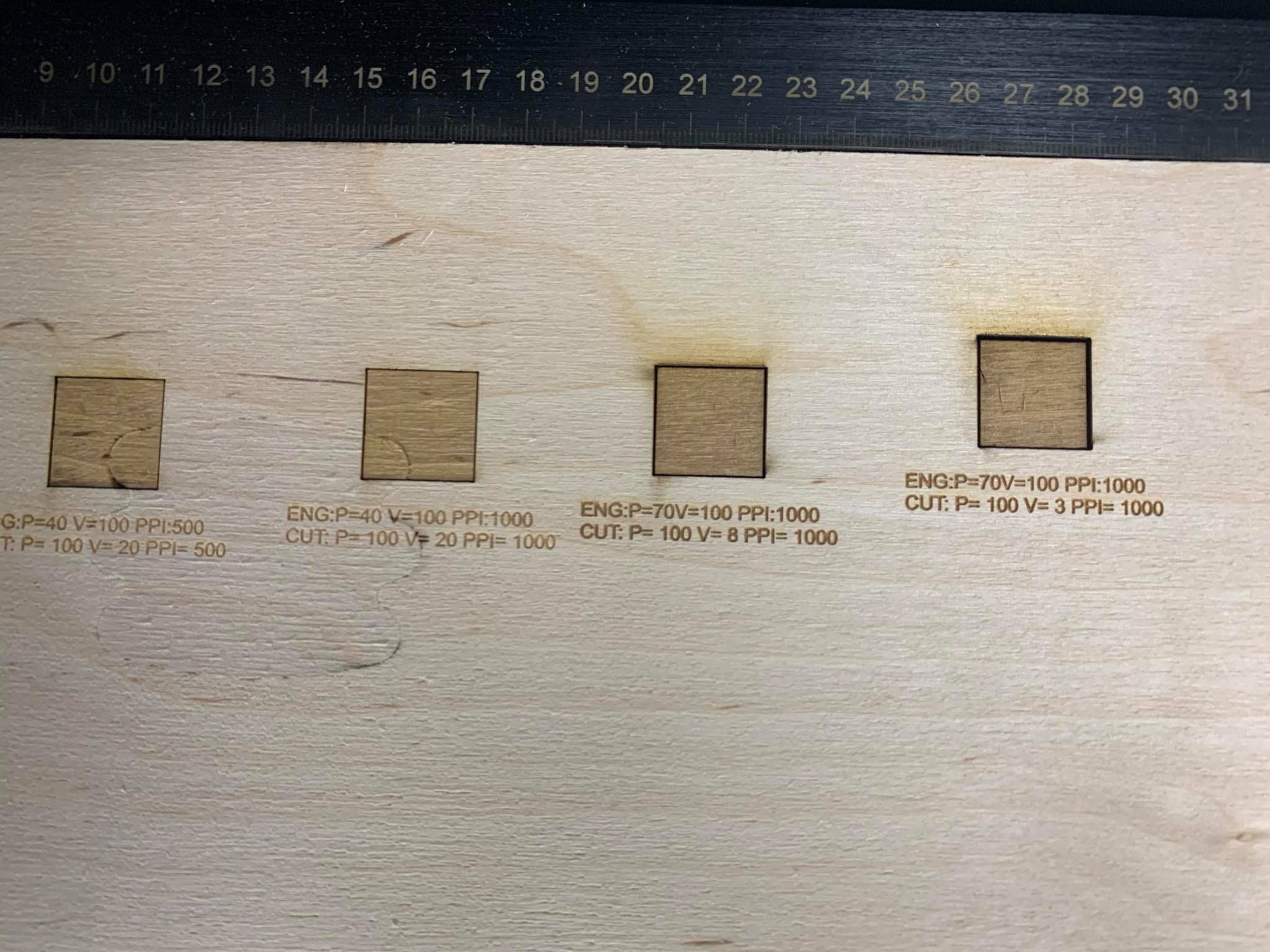

I wanted to test the diffferent parameters for the laser cutter and its effect on the on the 3mm MDF wood. So I did 4 different settings combinations where I changed the power and PPI for cutting and engraving.

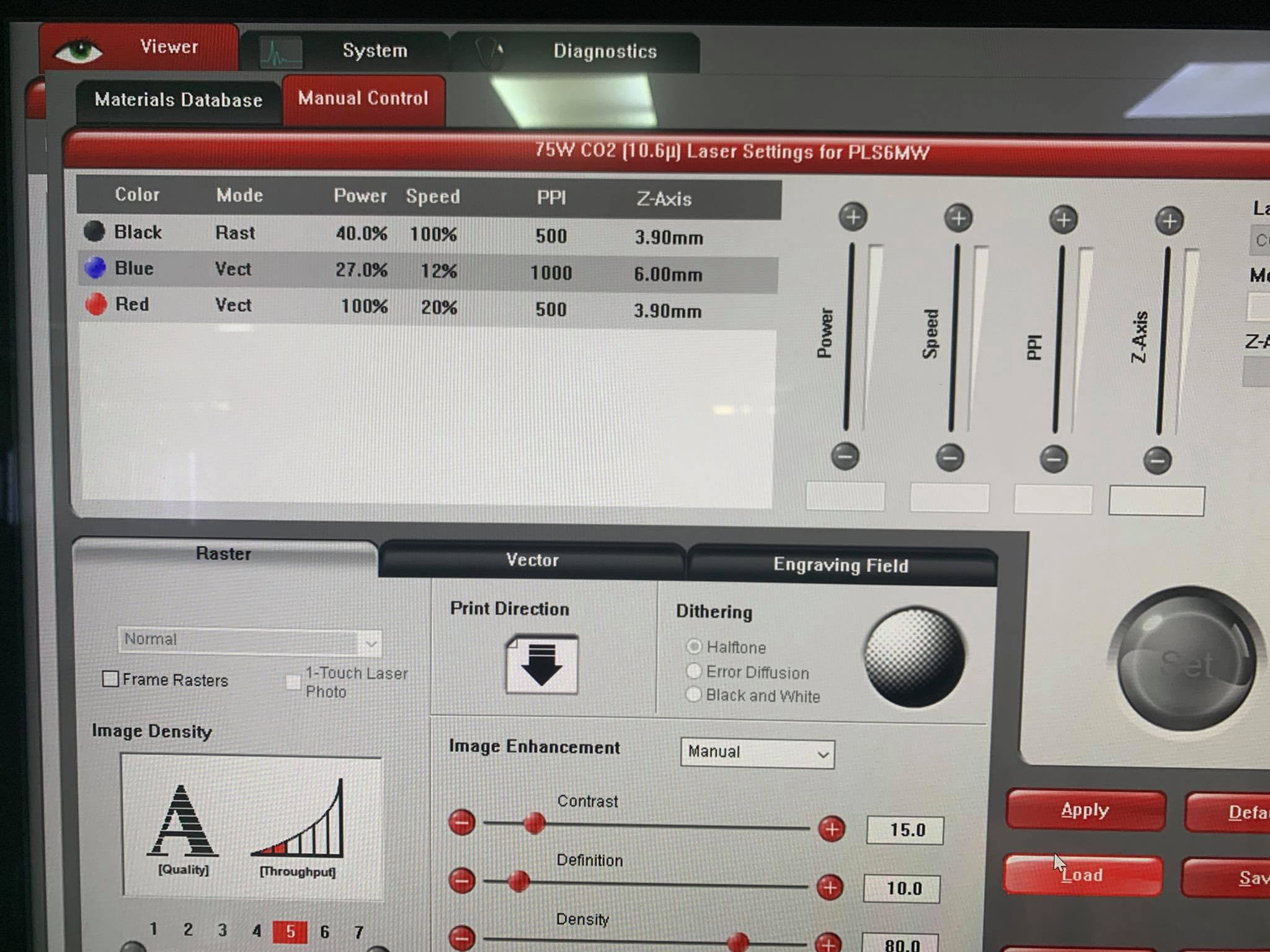

The setting for the machine look like this.

and the exact values for Power and PPI for both Cutting and Engraving are shown on the result trails here.

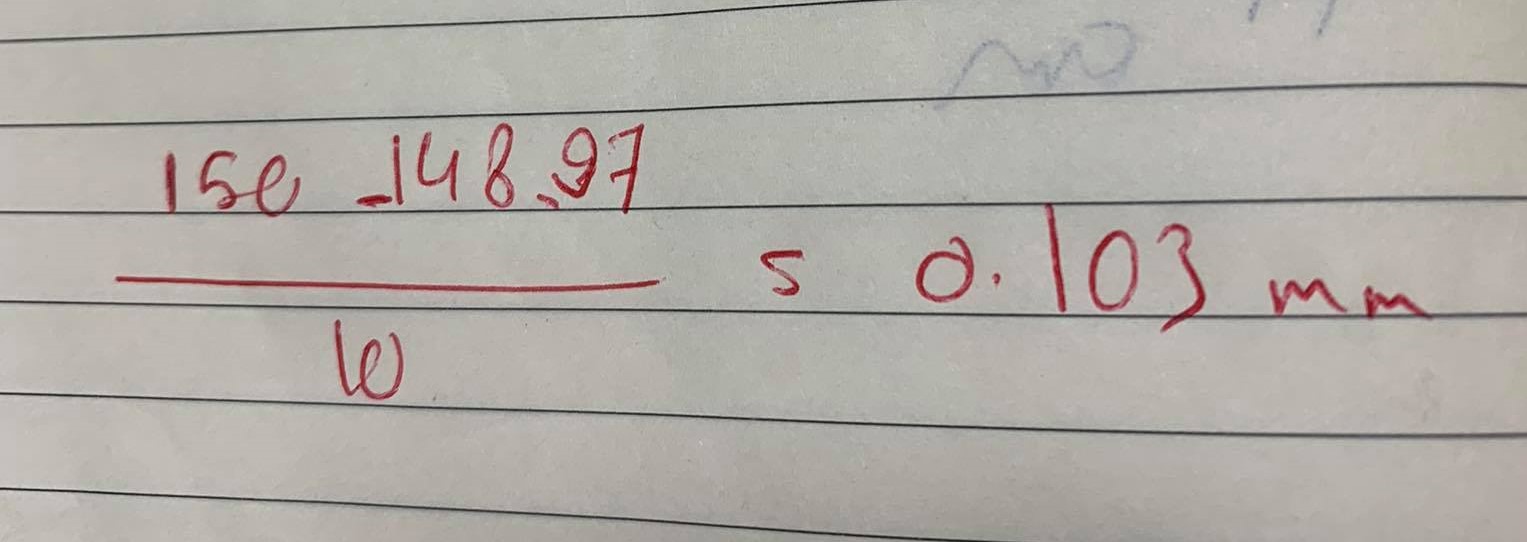

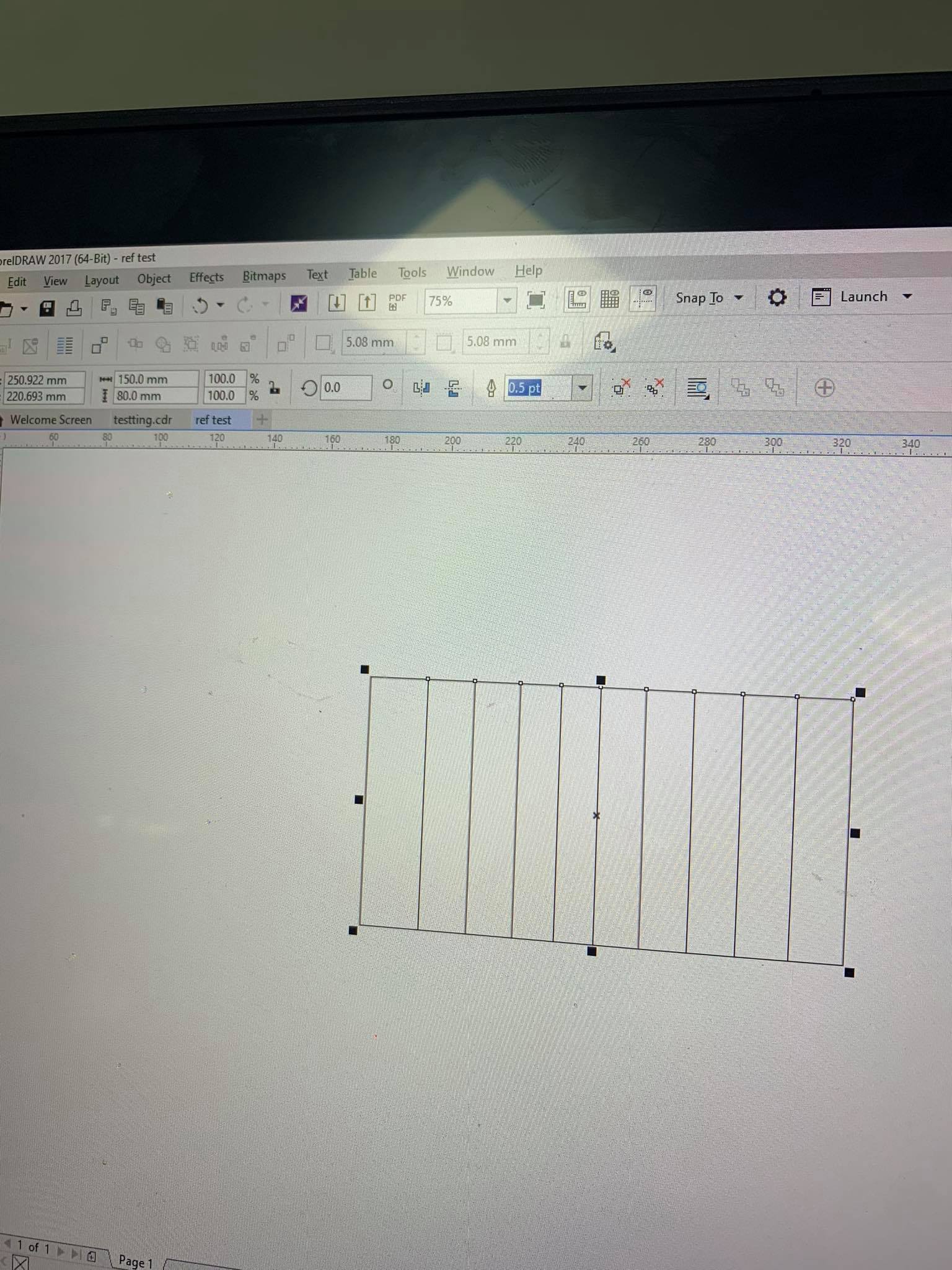

and for calculating the KREF of the laser machine I drew in CorelDraw a box with width of 15 cm and divided it to 10 pieces.

then the result after cutting.

and measuring the total lenght after cutting.

So the KREF for MDF wood was calculated to be = 0.103 mm.