3. Computer controlled cutting¶

Schedule¶

| Day | JST | Name | Where | PW |

|---|---|---|---|---|

| Wed | 23:00-2:00 | Class | Zoom class | 1234 |

| Thu | 21:00-22:00 | Local session prep | Jitsi | |

| Sat | 10:00-18:00 | Local session | @kannai or Jitsi | |

| Sat | 24:00 | Global Open Time | Zoom mcu | 1234 |

| Mon | 23:00-24:00 | Recitation | Zoom class | 1234 |

| Tue | 21:00 | Regional Review(Asia) | Jitsi |

General Info¶

Group assignment¶

- Student site

- week03.html

<h2 id="group">Group Assignment</h2>- link from Kannai site/index.md

Website tips¶

- Bootstrap samples

- Bootstrap (included in Kross template) is more powerful and simpler than custom css in Kross.

- Let’s try typography(header and text), table(machine parameter), grid(images), alert(error and findings) etc. from this week.

Assignment¶

Group assignment¶

Note

characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types

Individual assignment¶

Note

cut something on the vinylcutter

design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways,

and for extra credit include elements that aren’t flat

TODO: Group assignment¶

characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types¶

Laser cutter : Universal VLS 2.3

- 30W CO2

- manual

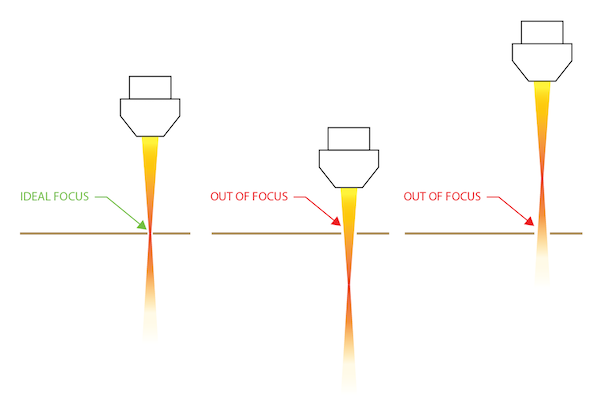

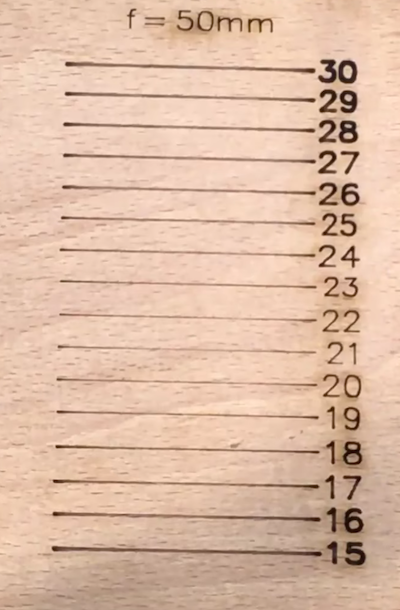

focus¶

Lense: 2.0” (25.4 x2 = 50.8mm)

- Jig on table (no material) -> Z= 0.0mm

- Jig on material (3.0mm) -> Z= 3.0mm

- Use up/down key from +0.5 to -0.5 by 0.1mm

- Make vector line and the thinnest is on ideal focus

ref. Laser Cutter Focus - Measuring Focal Point and Depth of Cut

power, speed, rate¶

Parameter for cutting a cardboard in 3mm thickness from last year

| Color | Mode | Power | Speed | PPI |

|---|---|---|---|---|

| Black | Raster | 80% | 100% | 500 |

| Red | Vector | 50% | 4% | 250 |

Power, Speed¶

| Colors | Power | Speed | ppi |

|---|---|---|---|

| ~~Black~~ | 40 > 80 | - - | fix:250 |

| Red | by 10% | 4 | |

| ~~Green~~ | - - | ||

| ~~Yellow~~ | - - | ||

| Blue | 10 | ||

| Magenta | 20 | ||

| Cyan | 30 | ||

| Orange | 40 |

Rate¶

| Colors | Power | Speed | ppi |

|---|---|---|---|

| ~~Black~~ | fix:best result | fix:best result | - - |

| Red | 250 | ||

| ~~Green~~ | - - | ||

| ~~Yellow~~ | - - | ||

| Blue | 300 | ||

| Magenta | 400 | ||

| Cyan | 500 | ||

| Orange | 600 |

download .cdr|

focus.svg|

power-speed-ppi.svg

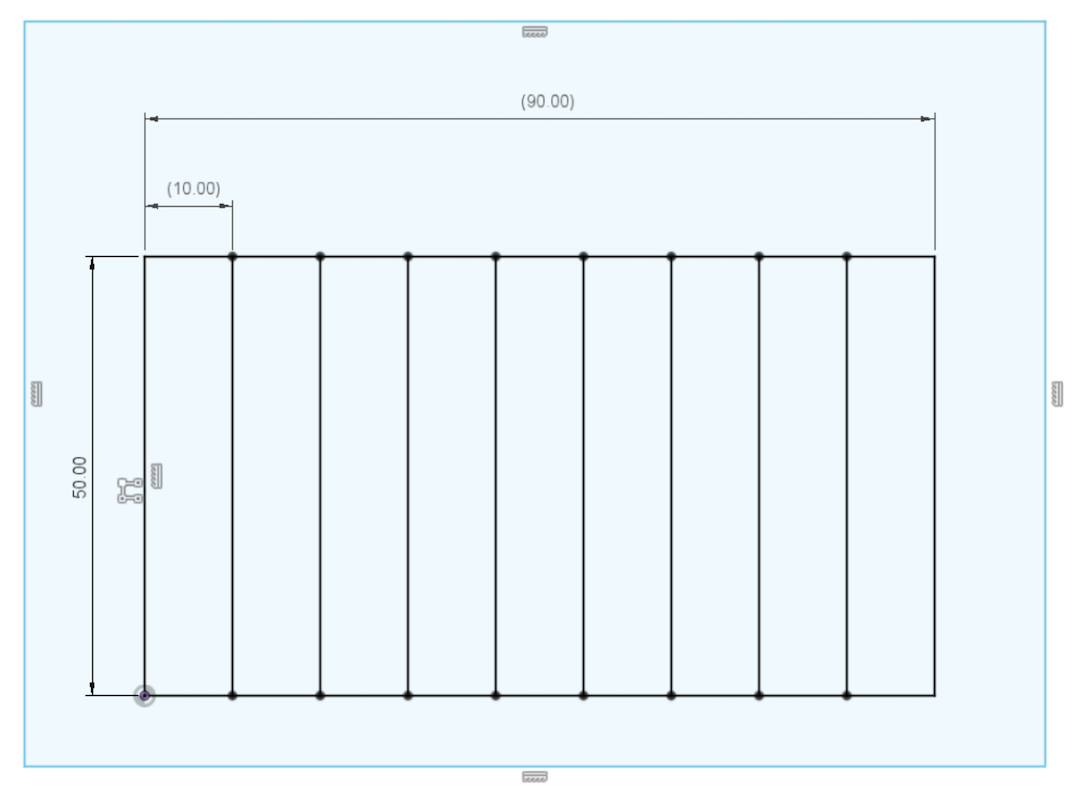

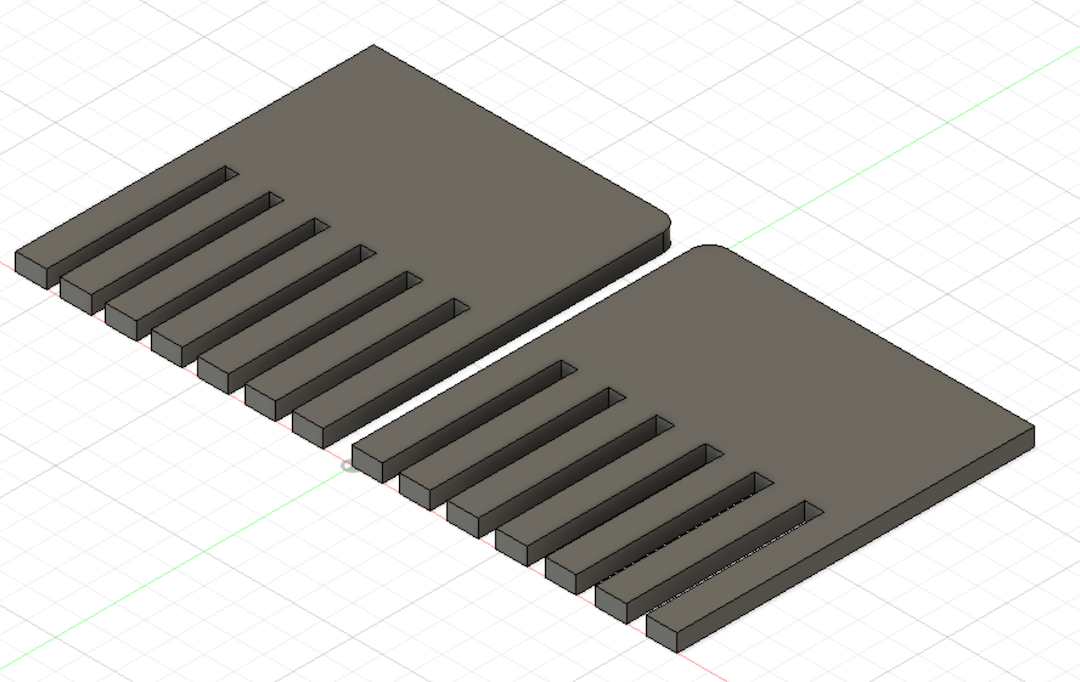

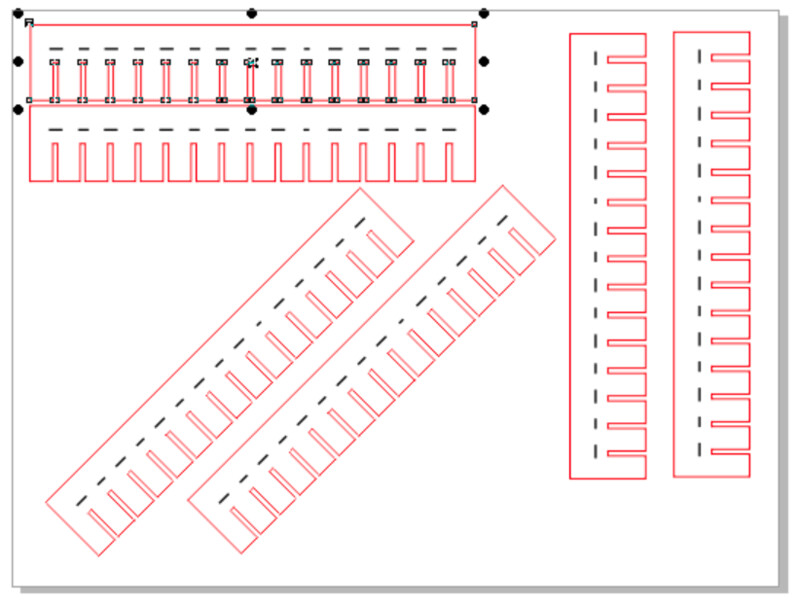

kerf, joint clearance¶

Kerf¶

- Measure 9 sticks together -> (1/2+8+1/2)= kerf x9

- Measure the open -> (1/2+1/2)= kerf x1

ref. pre-session

joint clearance¶

Mr. Doyo at Fablab Hiratsuka, Kerf Check Parts Generator

TODO: Individual assignment¶

Note

cut something on the vinylcutter

design, lasercut, and document a parametric construction kit,

accounting for the lasercutter kerf,

which can be assembled in multiple ways,

and for extra credit include elements that aren’t flat

design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways,¶

parametric construction kit¶

- Thickness is not 3.00mm

- kerf

kerf¶

from group assignment

can be assembled in multiple ways¶

not for one shape

extra credit include elements that aren’t flat¶

- kerf bending

- living hinge

- Inkscape Extension Living Hinge Creator

- ref.last year

cut something on the vinylcutter¶

vinyl cutter

-

silhouette CAMEO and Silhouette Studio

-

sand blast > Glass

- Ref. last year

- heat press > T-shirt

- Ref. Heat Press

Assessment¶

- Included your hero shots