11. Molding and casting¶

General Info¶

Nueval¶

- Global evaluation

- App screenshot -> English

Output devices¶

-

Parts

-

AVR-1

- megaTinyCore

- Arduino Board manager

- I2C (TWI) support

- You must be sure to use external pullup resistors on the SDA and SCL lines if the devices you are connecting do not have those on board

- 10k Ohm x2

- sample

- megaTinyCore

Assignment¶

Group assignment:¶

Note

review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Individual assignment:¶

Note

design a mold around the stock and tooling that you’ll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts

preparation of 3D modeling¶

- MDX-15

- work area: 152.4mm × 101.6mm × 60.5mm

- Machinable wax

- size: 152mm x 92mm x 39mm (real size is smaller)

- Endmill

- 0.1250” DIA 4FL SE LONG AlTiN 1/8

- Size: 1/8”=3.175mm

- OverAll Length: 2-1/4”(2.25”) =57.15mm

- 0.0625” DIA 2FL SE AlTiN 1/16

- Size: 1/16” =1.5875mm

- OverAll Length: 1-1/2”(1.5”) =38.1mm

- 0.1250” DIA 4FL SE LONG AlTiN 1/8

-

Design to think…

- XY size: real wax size

- Final Part size < (wax size - wax_wallx2 - mold_wallx2)

- distance between bumps凸 & dents凹: tool size > 1.58mm(1/16”) > 0.79mm(1/32”)

- Z depth

- tool: 1/16_endmill_lemgth=38.1mm -in_collet_lenght=10mm = 28mm

- machine: MDX-15_z=60.5mm - Wax_height_39mm = 21.5mm

- 2 sides mold: 21.5mm each = 43mm_max

- 1 side mold: 21.5mm_max -> 9 degrees tilt to prevent hitting collet

- tilt image

- tilt degree calculation

- Registration (for alignment)

- ref. How to Make Molds

- Registration Key

- nest (recommend)

- pour spout (lower position)

- air vent (higher position)

- part line -> deburring

- XY size: real wax size

-

Process

- 3D modeling

- Fusion360

- Tool Path

- Modela Player4 (Windows)

- Virtual Modela (Windows)

- Rough cut (1/8”)

- Finish cut(1/16”)

- cast silicone molds from wax

- cast final part from silicone molds

- 3D modeling

TODO: Group assignment¶

review the safety data sheets for each of your molding and casting materials,

materials¶

-

machinable wax, modeling wax

-

Silicone rubber

- Mold Star 31T 0.9KG Trial Kit

- Smooth-on SDS

- SDS_JP

- Mix ratio by Volume: 1A:1B

- Mix ratio by Weight: 1A:1B

- pot life: 5 min

- cure time: 23 min

- color: Translucent

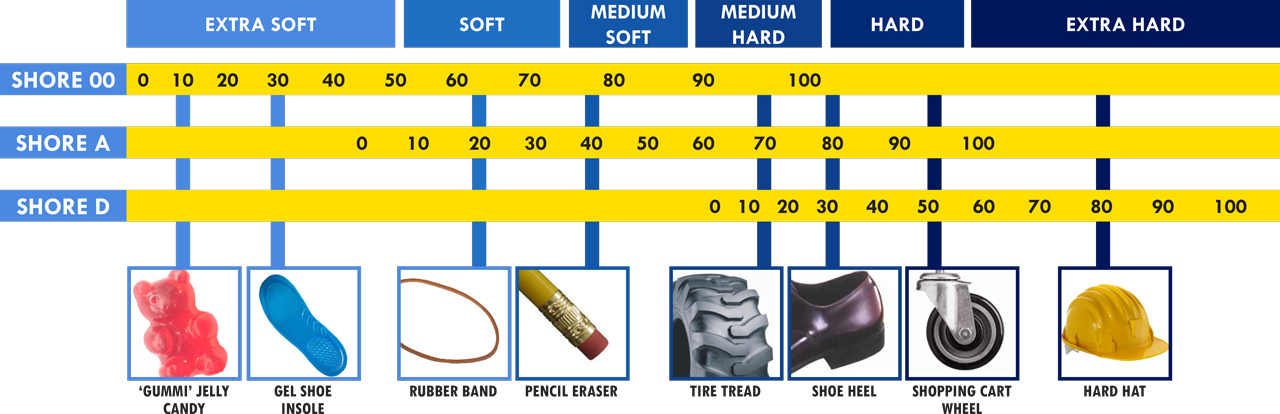

- Share Hardness: 30A

-

Urethanes resin

- Smooth-Cast 320 0.86KG Trial kit

- Smooth-on SDS

- SDS

- Mix ratio by Volume: 1A:1B

- Mix ratio by Weight: 100A:90B

- pot life: 3 min

- cure time: 10 min

- color: Off white

- Share Hardness: 70D

-

So-strong

- Color Tints for Urethane

- Smooth-on SDS

- 0.01% to 3% of total system weight

make and compare test casts with each of them

- test cast

- safety

- ventilation

- protection

- glass

- groves

- disposal

- finish chemicals reaction before dispose -> heat

- dispose cups and Stir bars directly into bin

- change groves

- do not touch any uncovered place, chair, desk…

TODO: Individual assignment¶

design a mold around the stock and tooling that you’ll be using,

-

negative/positive

- 3D modeling process

- sample

- design final part (positive)

- design molds to make final part (negative)

- design wax to make molds (positive)

- casting process

- pour liquid silicone rubber into wax to cast molds (negative)

- pour liquid resin into molds to cast final part (positive)

- 3D modeling process

-

Fusion360

- Final_part

- model as any way

- Silicon_mold

- model Silicon_block

- combine > cut

- Silicone_block - final part = Silicon_mold

- Wax

- model Wax_block

- combine > cut

- Wax_block - Silicone_mold

- add

- Pour Spout

- Air vent

- Registration key

- Final_part

mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts

Assessment¶

-

I want to only make a wax mould, and cast something in it. Is that acceptable?

- Answer: Only after you learn and go through the 3 step process. To break the rules, you have to master the rules.

-

Can I 3D print the mold? Can I do a lasercut?

- Answer: No, for this assignment you must mill the mould using a CNC milling machine. After fulfilling the requirements, please go ahead and experiment other techniques for fabricating moulds.