7. Computer controlled machining¶

This week we visited Hamamatsu Fablab to work on CNC machine. As group assignment, - Test machine to know its characteristics such as runout, alignment, speeds, feeds, toolpaths and materials to cut.

CNC Machine with 6mm straight bit

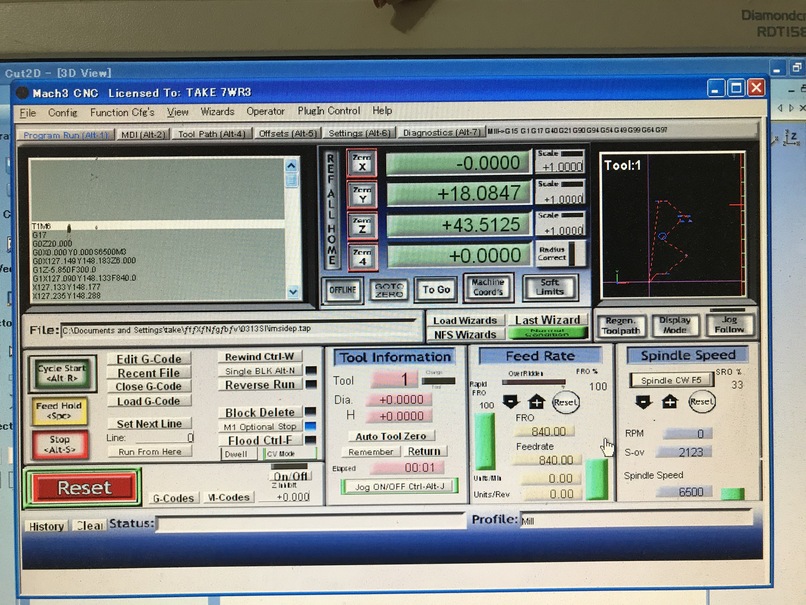

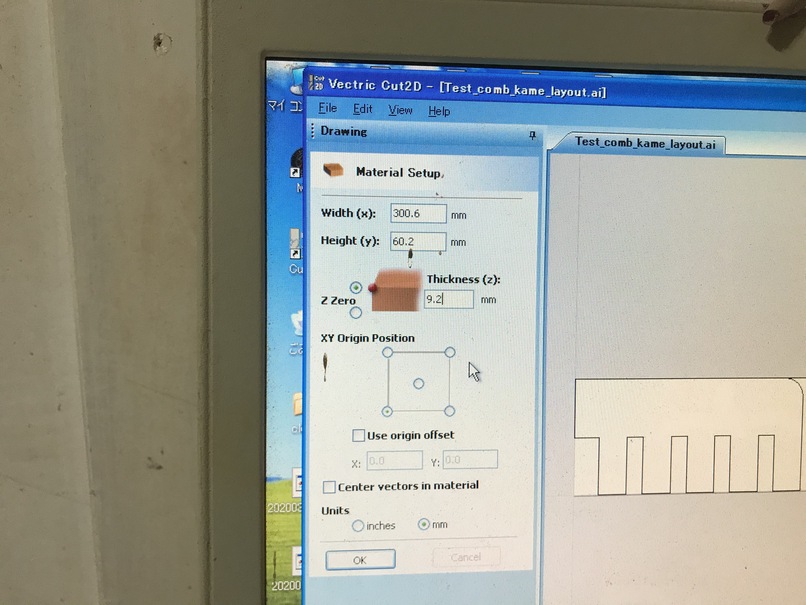

Using software - Cut2D : Path Creator - Mach3 : G-code generator to move machine

Machine setting - Mach3 G-code generation¶

We need think about frictional heat.¶

Higher speed => less operating time => Heat denature of bit & Higher risk of bit broken Per Takemura-san’s recommendation, we set 6500 as Spindle Speed. We have rather rough chips when we use the 6500 and the rough chip will remove heat than fine chips produced by high Spindle Speed.

Runout check by cutting 70mmx70mm square and measured actual size of cutout.¶

It seems that the machine is working as expected in design.

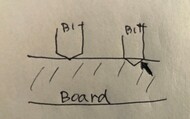

Alignment¶

There are two way of Setting Z axis. One is set Z on surface of board and add clearance to thickness (Left) The other way is to dig bit a bit in board.(Right)

We can utilize both way depending on condition of a board.

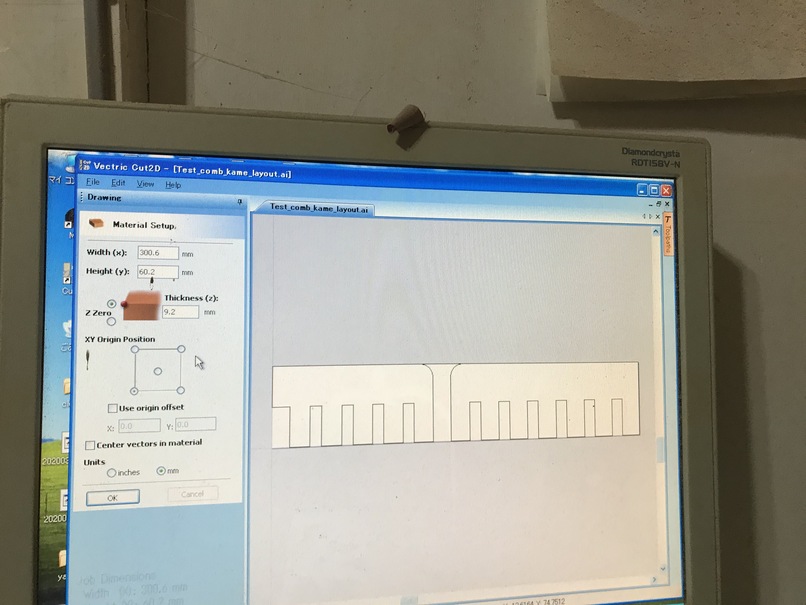

Material tested - OSB - Using comb shape for checking necessary clearances¶

Average thickness of a OSB board was 9.2mm. Center slot 9.2mm, increase 0.1mm to right. decrease 0.1

mm to left for each slot.

Cut2D Set 9.2mm of average thickness as thickness

Cutout The board thickness 9.2mm + clearance 0.1mm may good to go.

However the OSB board has various thickness from place to place.

So we need to adjust Z axis when we cut our Something Big.