- Group Assignment:

- Characterize your lasercutter's focus, power, speed, rate, kerf, and joint clearance

- Individual Assignment:

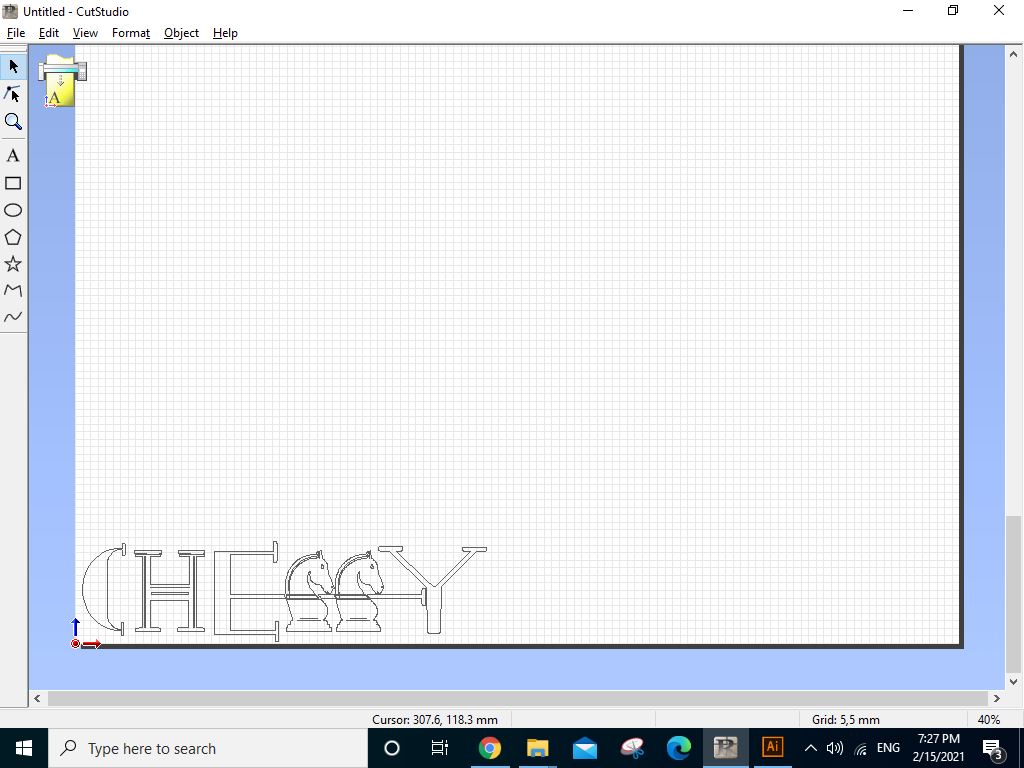

- Cut something on the vinylcutter

- Design, lasercut, and document a parametric construction kit,

accounting for the lasercutter kerf,

which can be assembled in multiple ways,

and for extra credit include elements that aren't flat

- Link to the group assignment page

- Explaine how I parametrically designed my files

- Document how I made my press-fit kit

- Document how I made my vinyl cutting

- Include my original design files

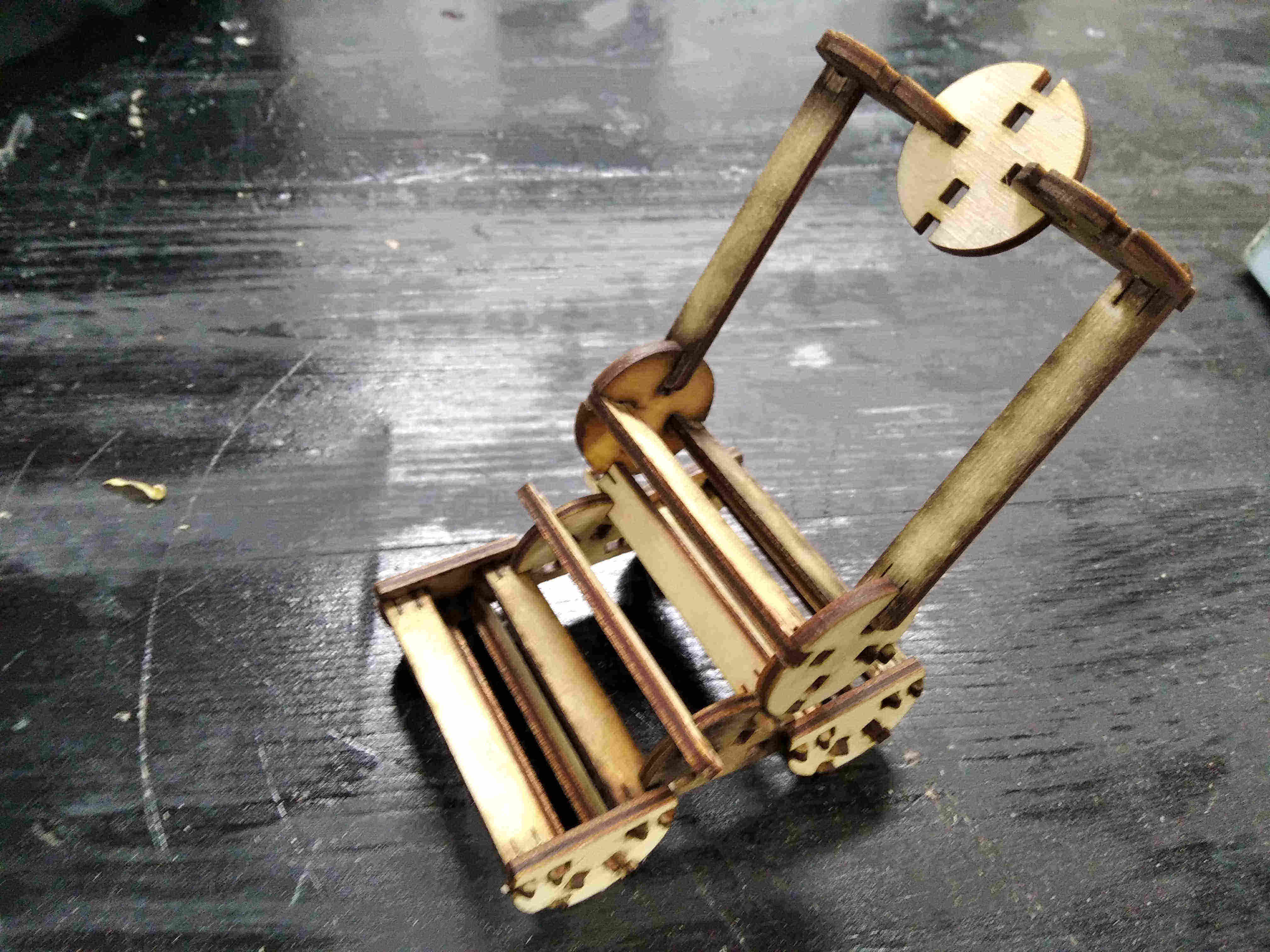

- Include my hero shots

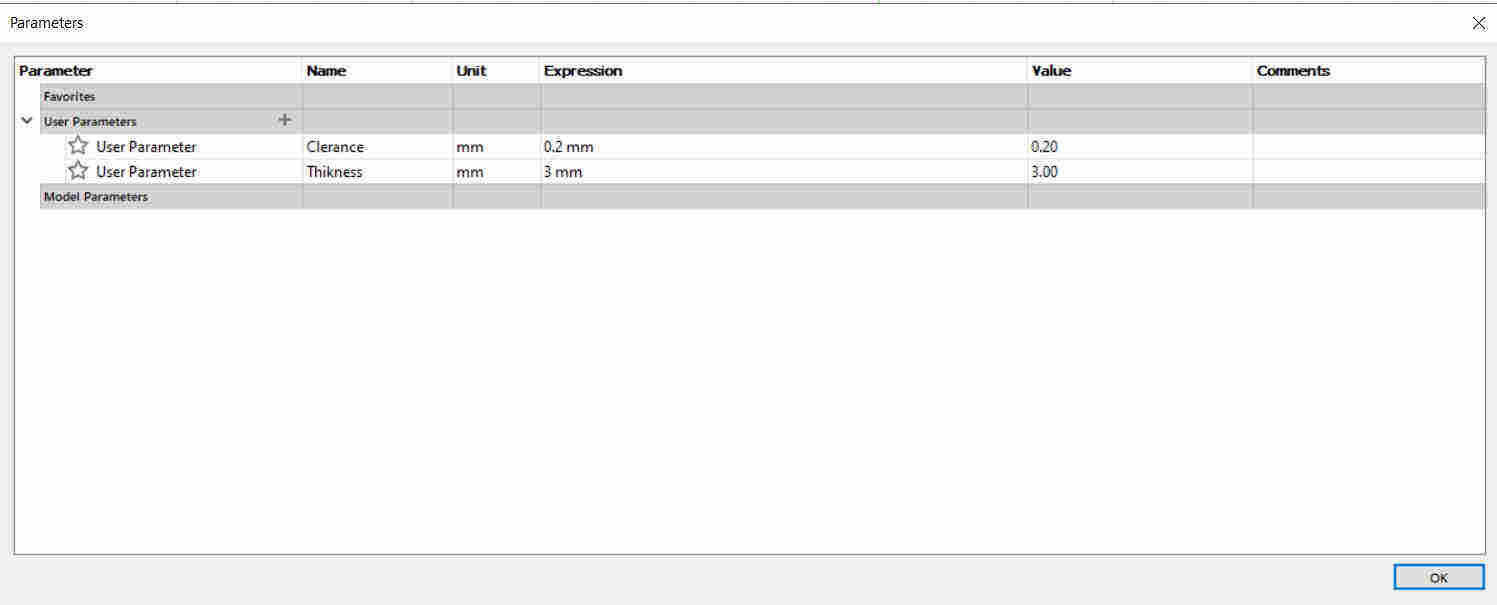

- Thikcness

- Cleaerance

Fusion360 CutStudio LaserWork CorelDRAW Morn:MT3050D Roland:GX-24

Group Assignment

Measuring the focus

We started by measuring the focus of the machine. The focus is the smallest dot the laser makes, so we leveled the bed up and down until we reached the smallest dot then we measured the distance between the nozzle and the material which is around 6 mm.

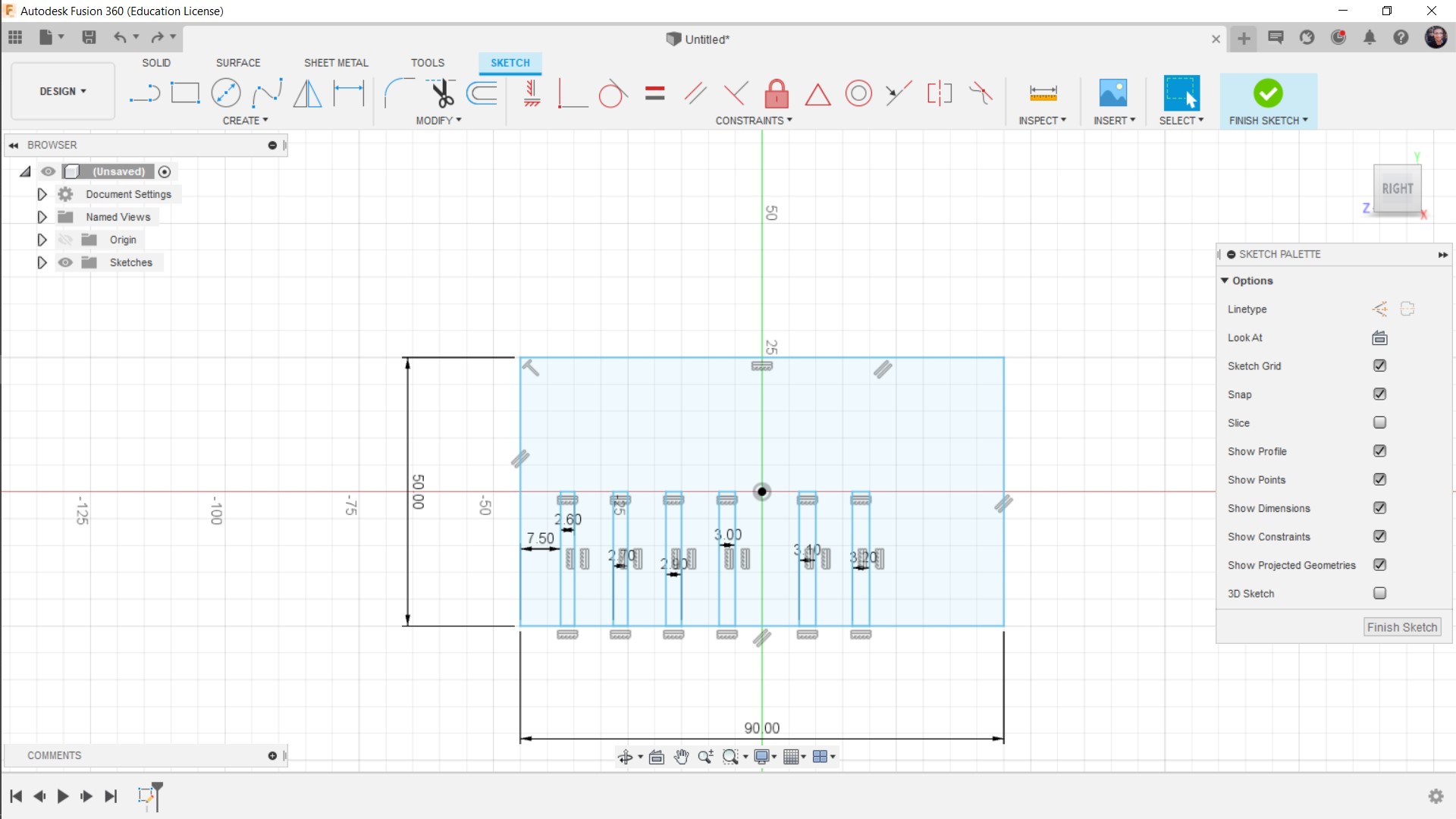

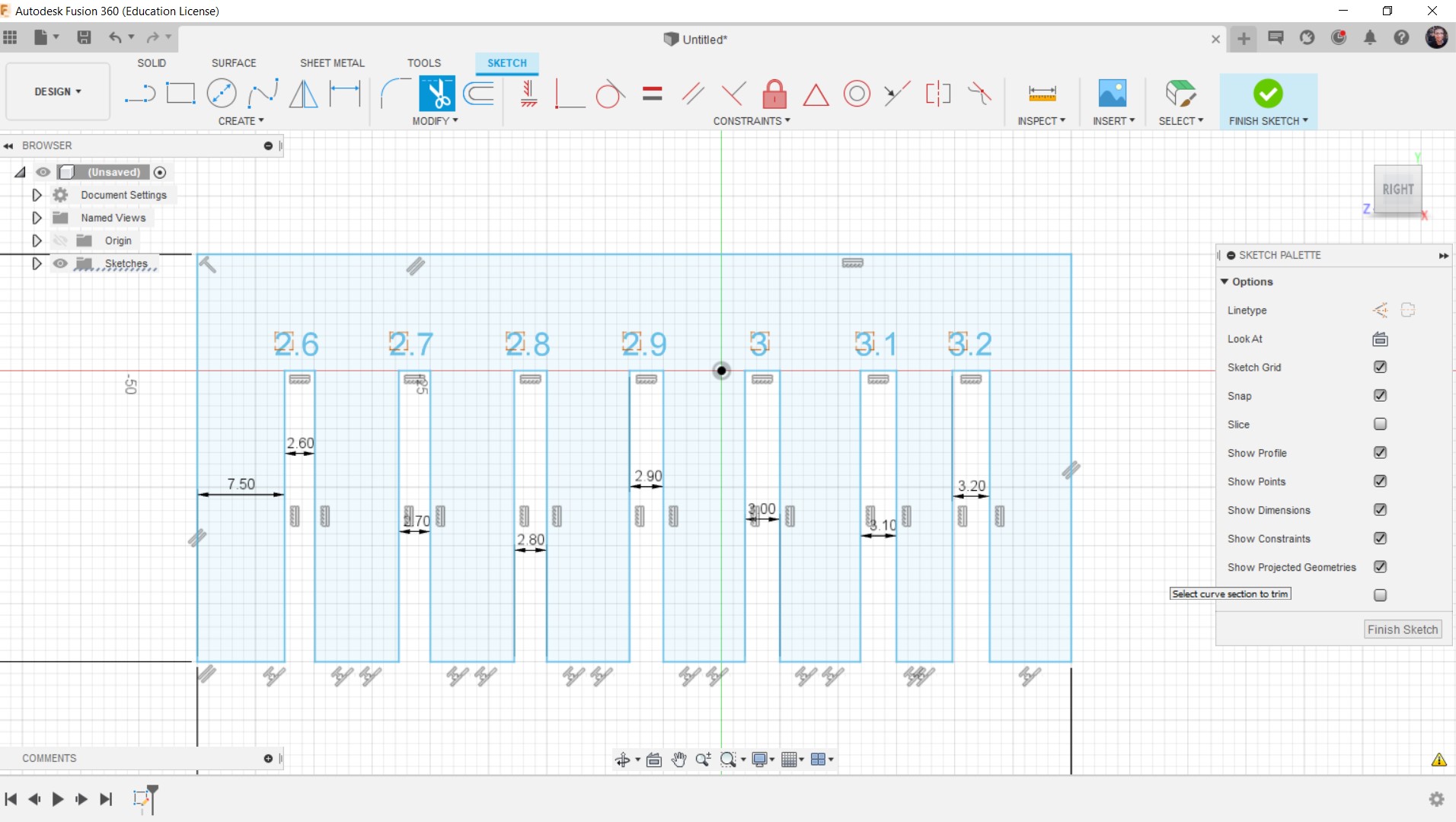

Kerf and clearance measurement

To measure the kerf and the clearance, we designed a comb part that has slots with width varying from 2.8 -> 3.2

We cut the part on the laser cutter using the proper cutting settings above and tried to fit the comb together. the comb fitted a hard fit in the 2.8 slot, however fit a proper fit in the 2.9 slot. we approximated the kerf to be between 0.1 mm and 0.2 mm. To measure the kerf we substract the slot width from the material thickness

Parametric Kit

Parameter(n): a numerical or other measurable factor forming one of a set that defines a system or sets the conditions of its operation.

I wondered a little about the meaning of Parametric Design, and I found this answer very helpful.

Generally speaking, the variables of my construction kit designs can be:

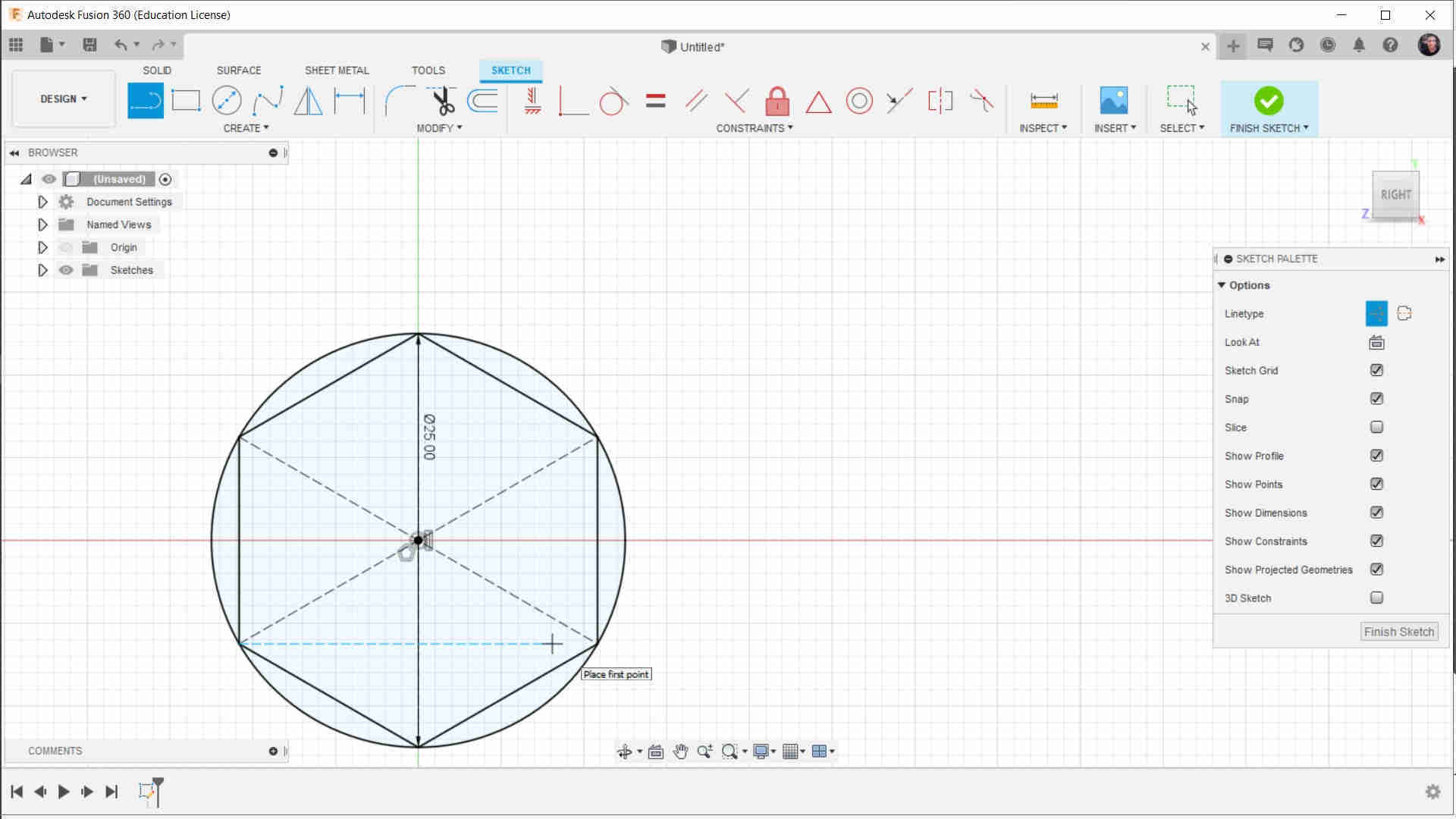

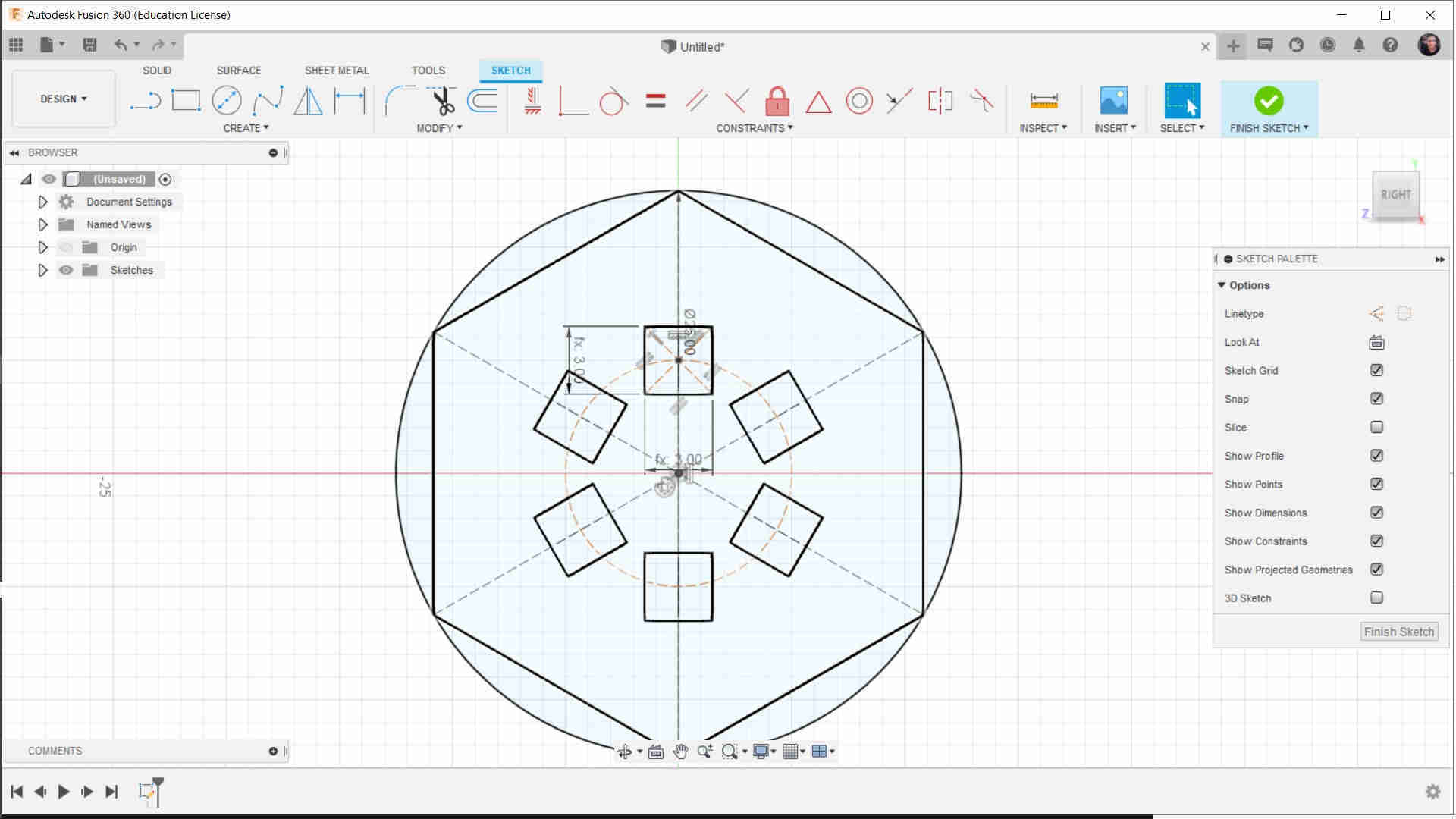

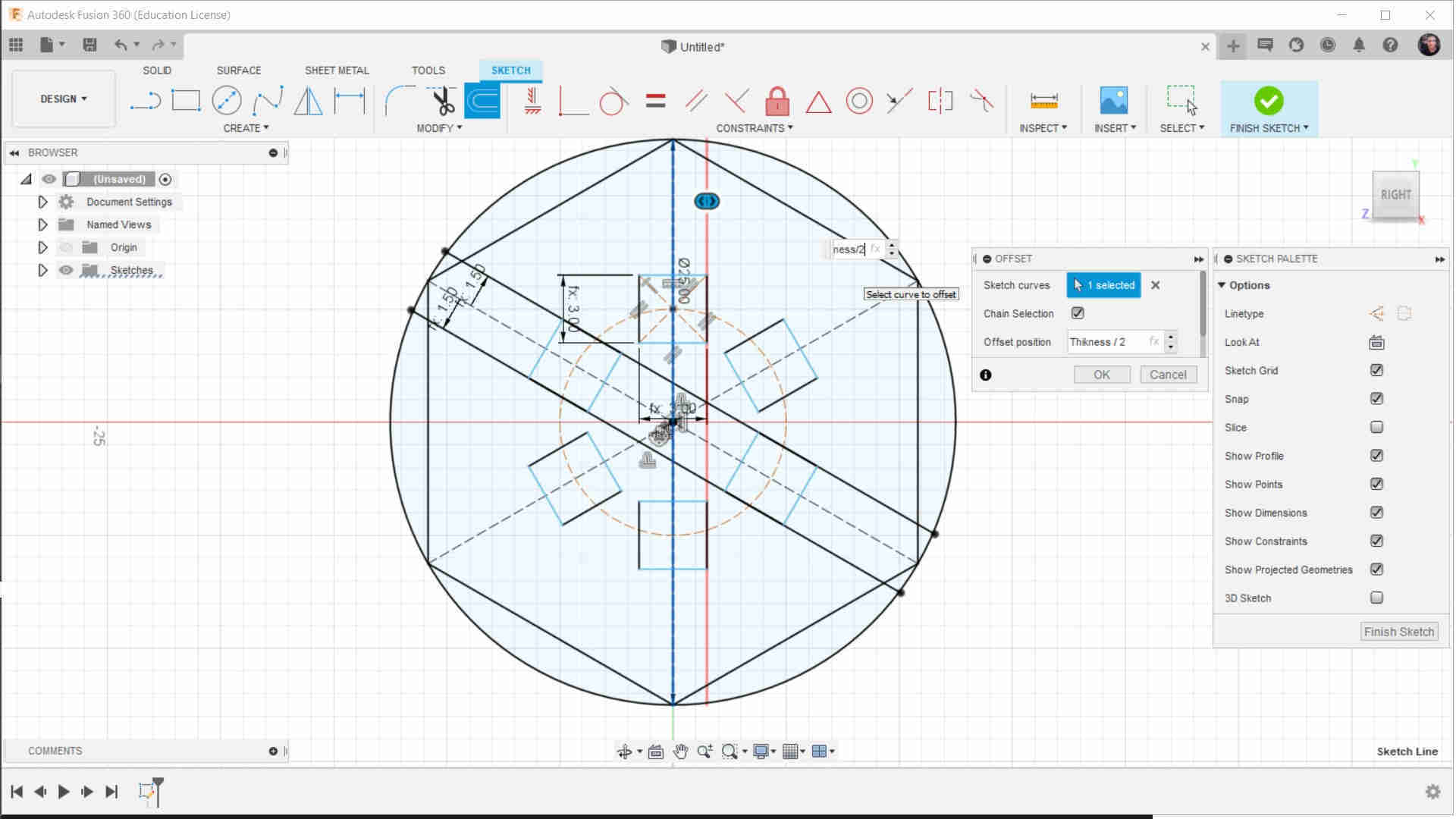

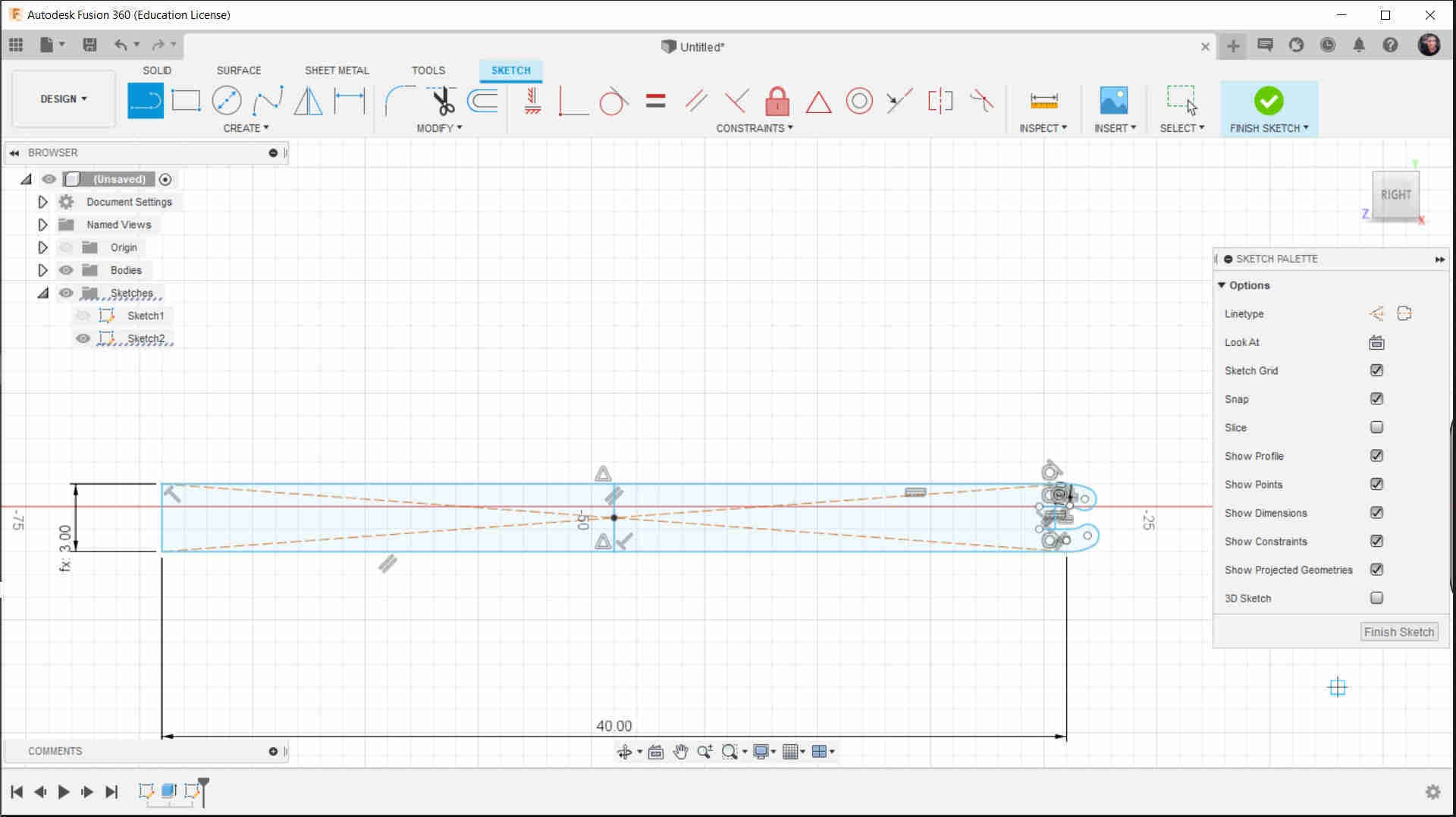

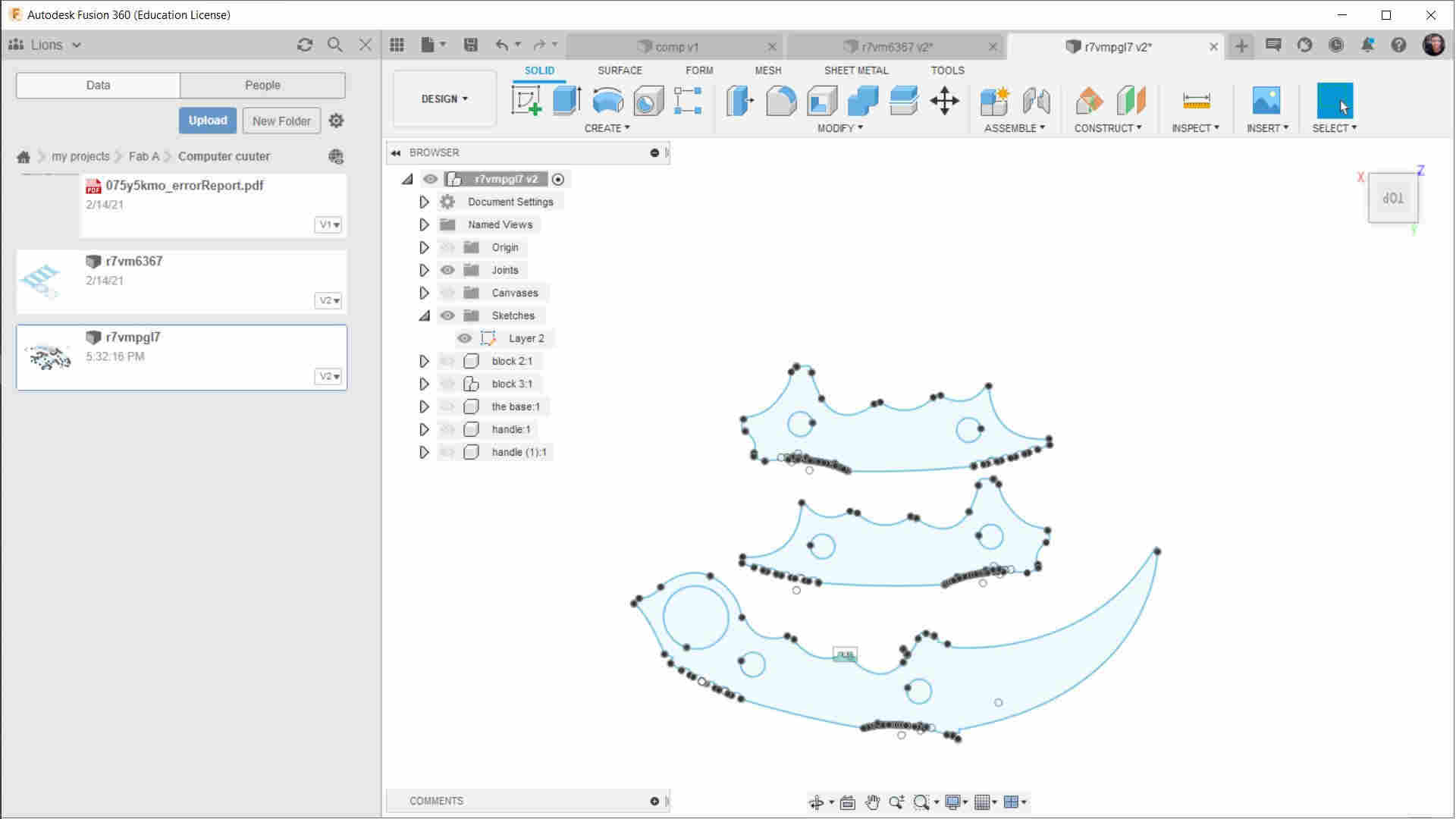

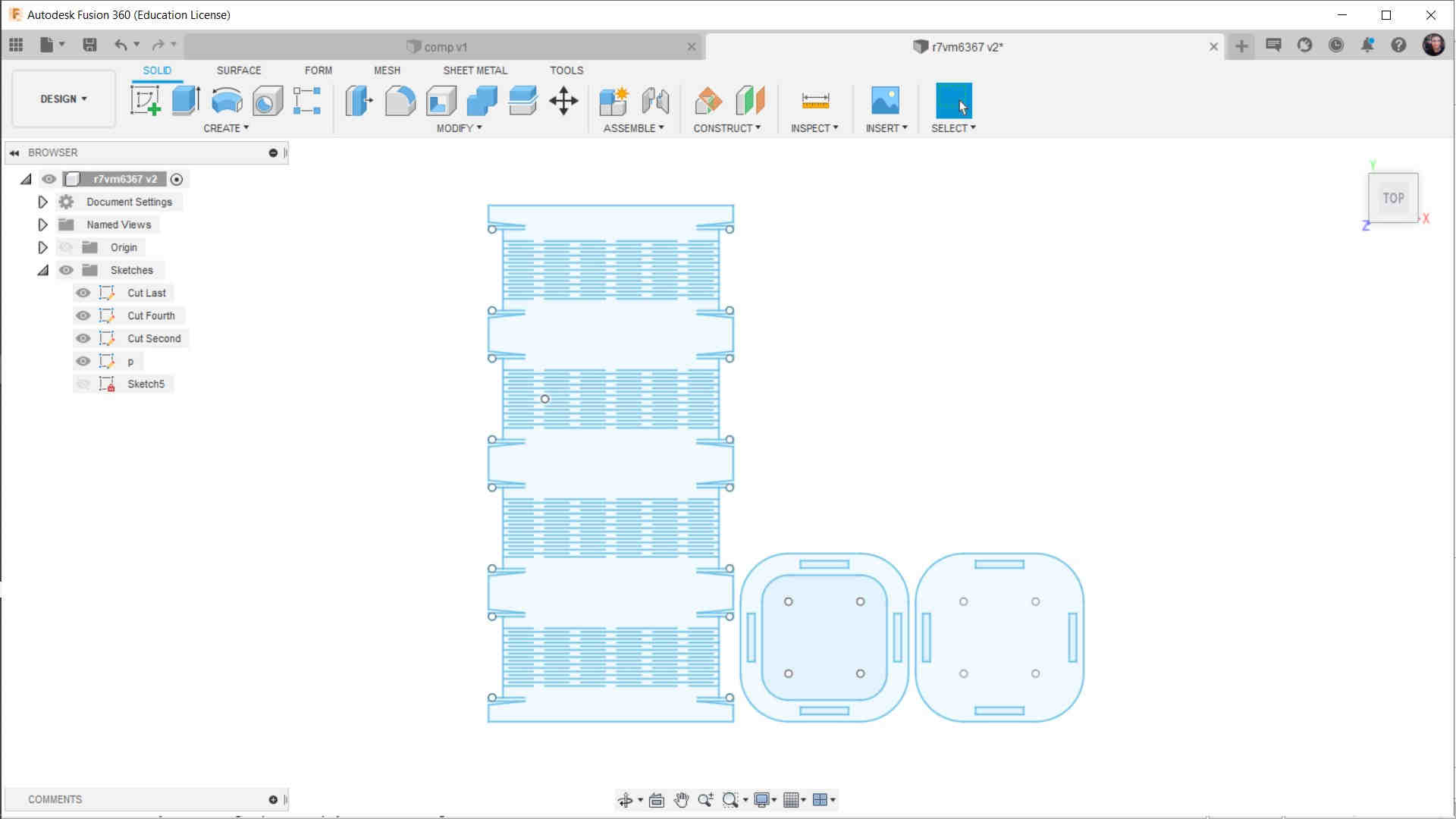

I built a Fusion360 sketch and defined my parameters as follows:

Then I start to Draw my Basic Shape (I Will call It SIP)

Then I start to make the Stick

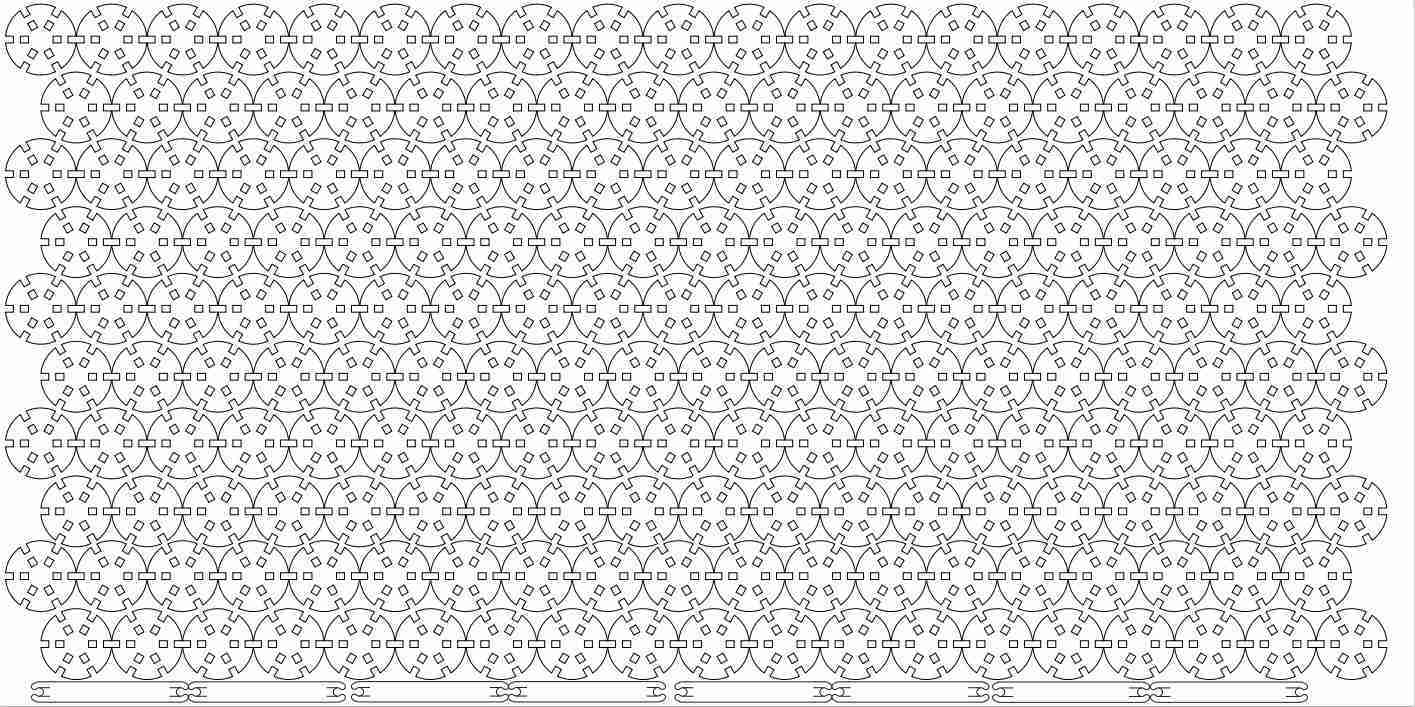

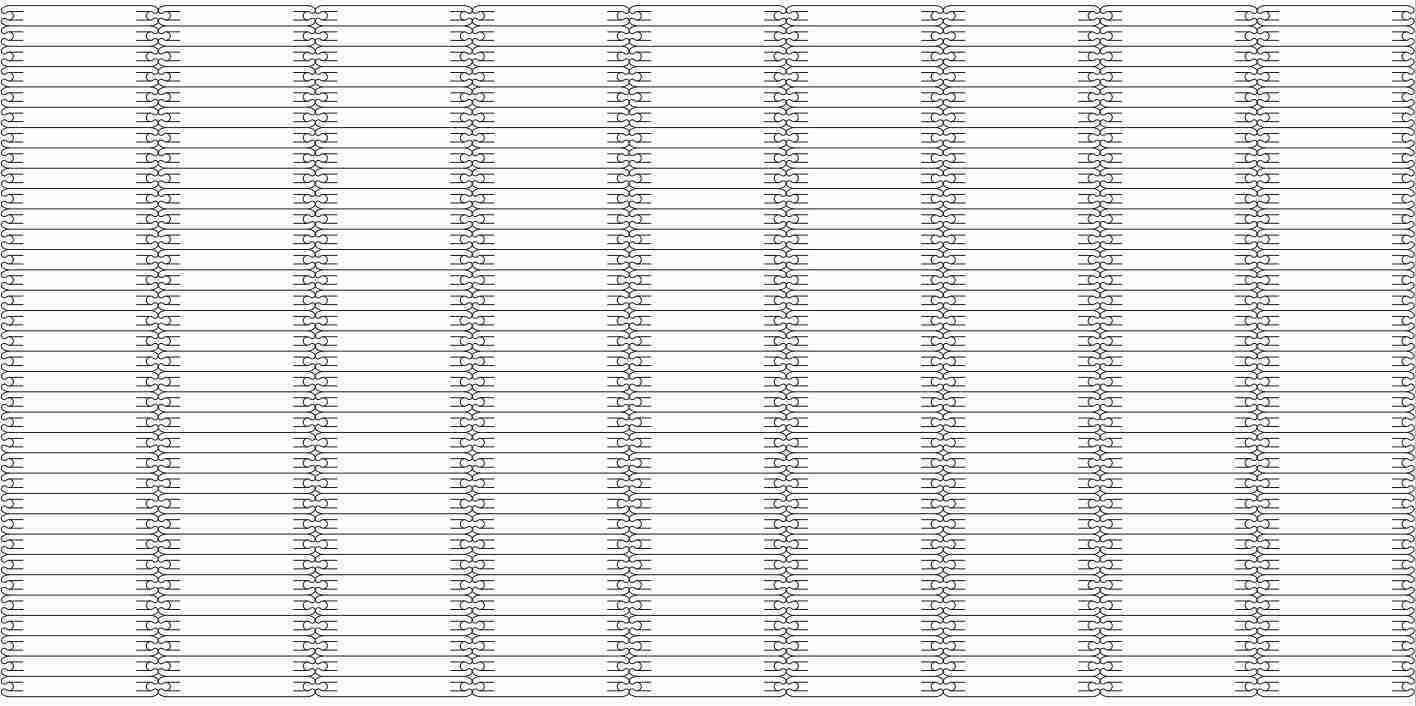

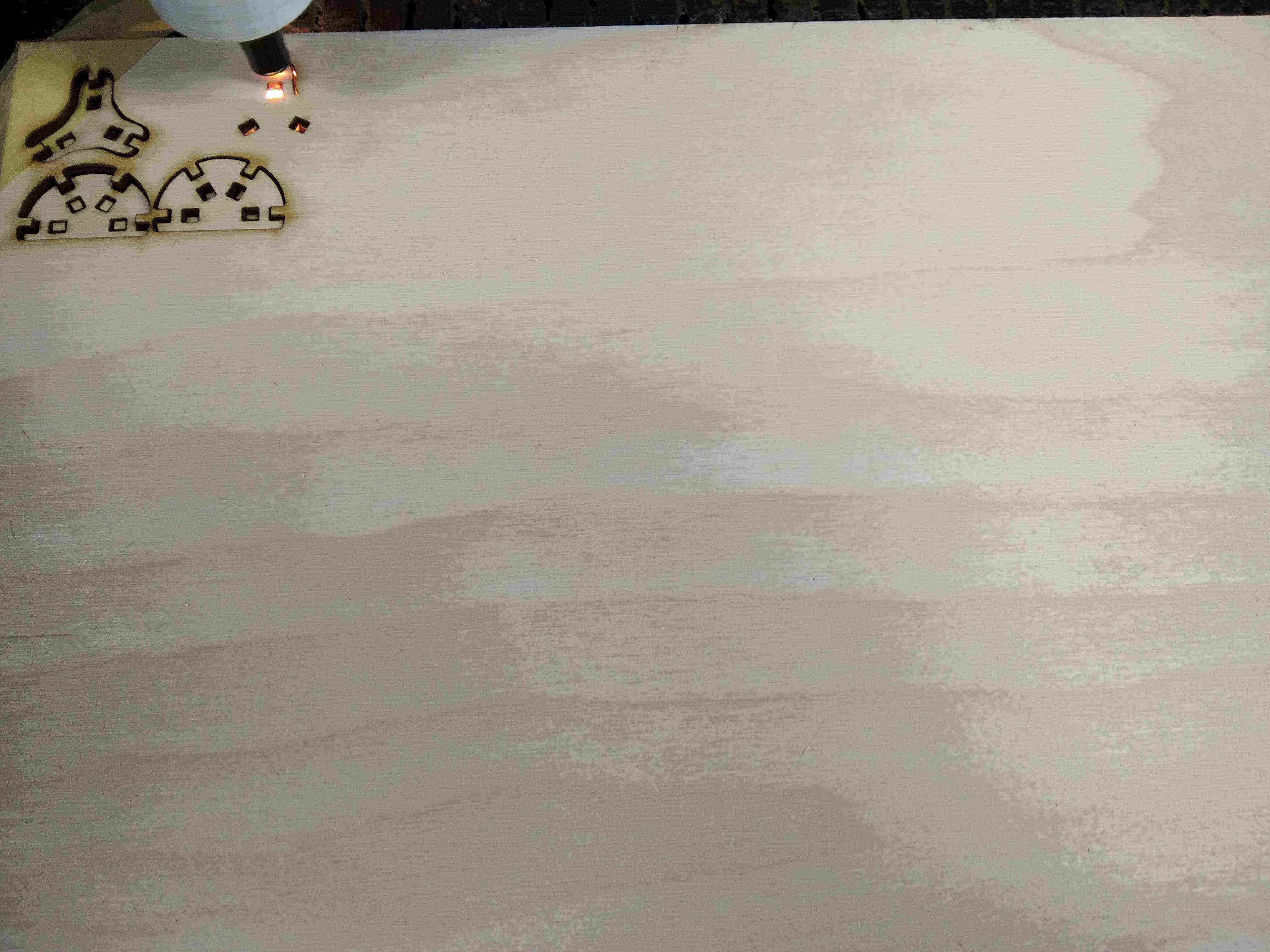

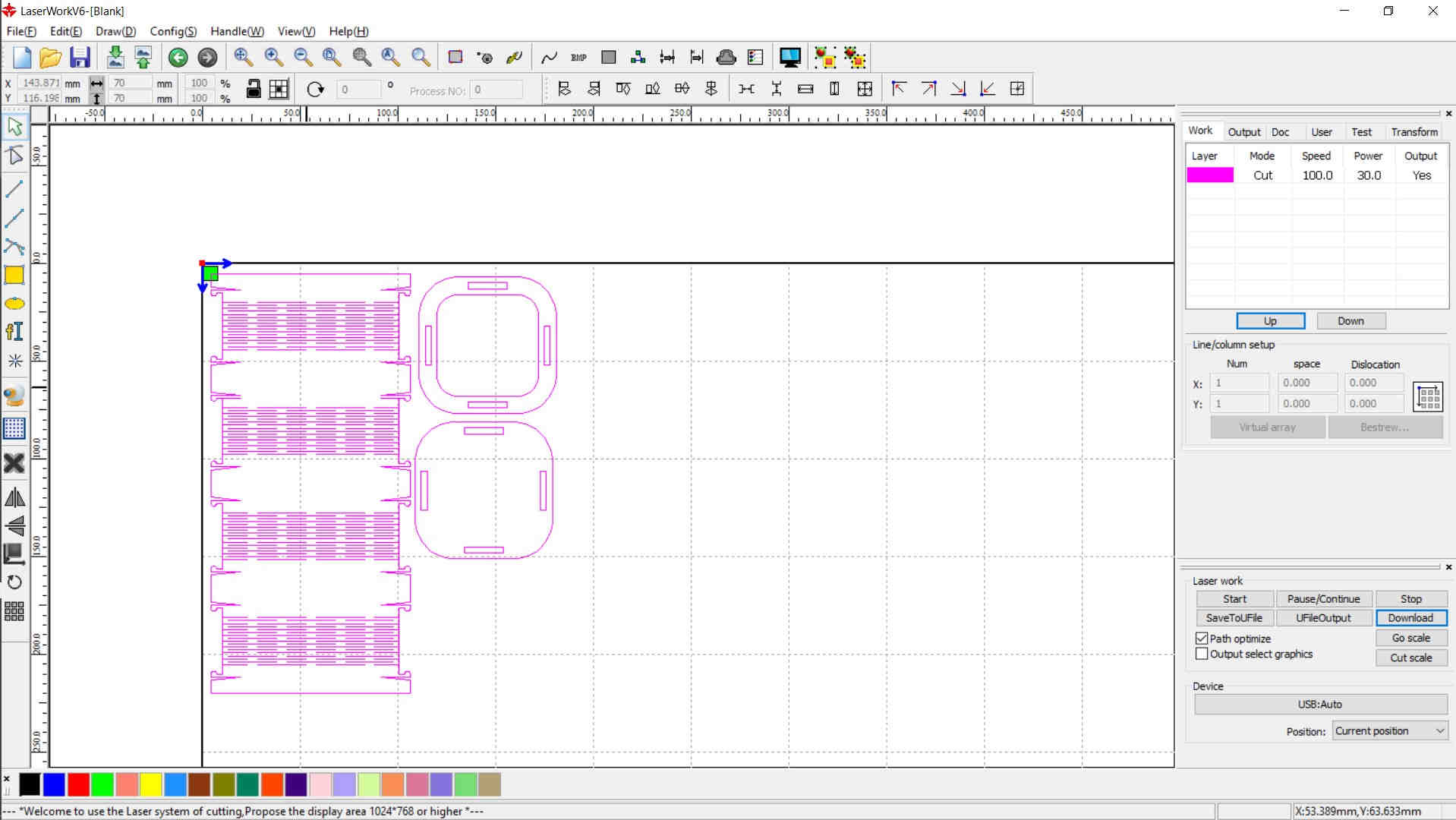

Then I Put the Files Into the LASER Cutter

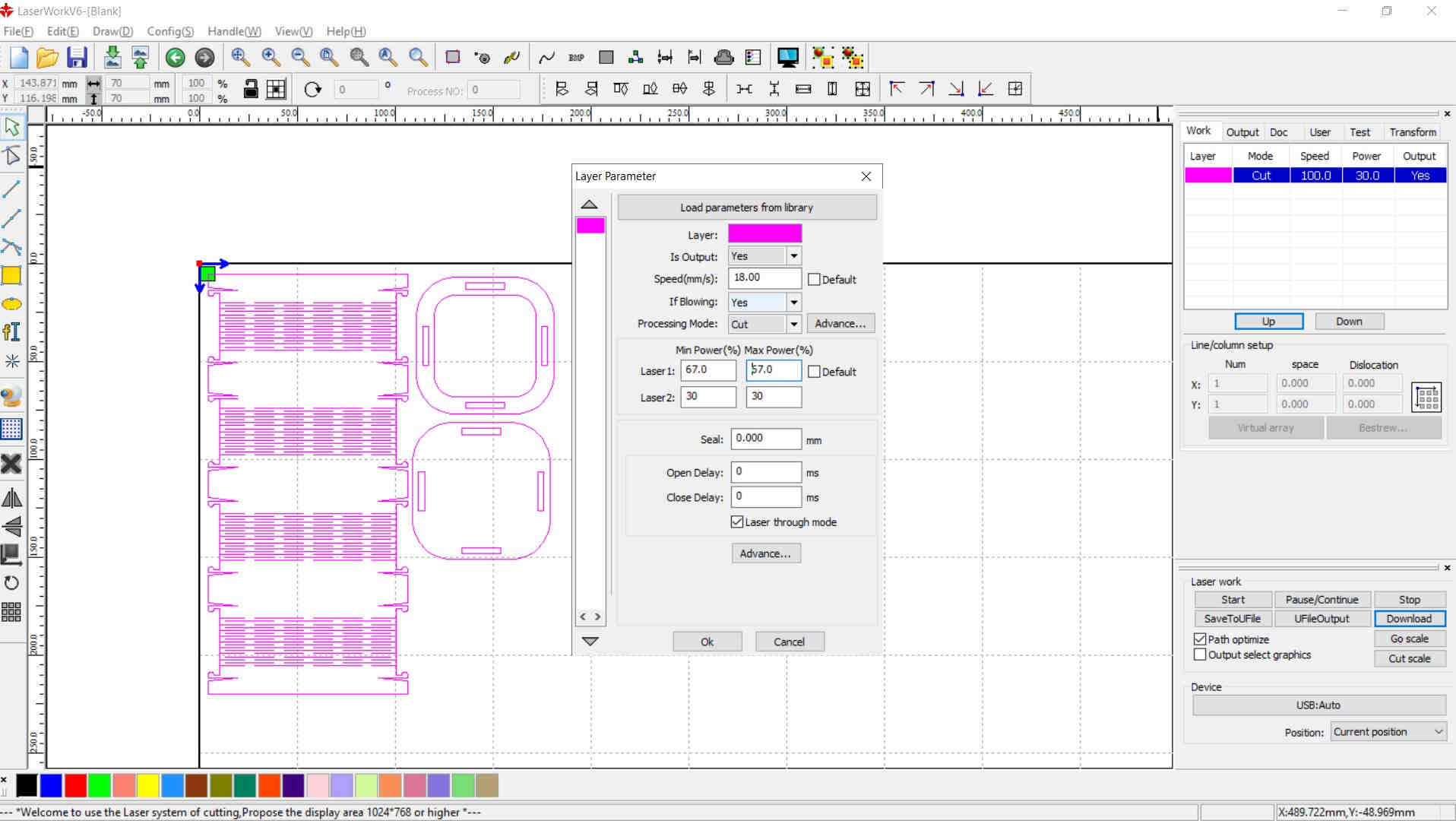

Note

For our Laser Cutter The Power of the Laser was 60 watt

So The Speed and Power I will choose Is depend on the Power of the tube of the laser

For PlyWood 3mm :

Cutting : Speed (25mm/s)---Power (Min:65%---Max:65%)

For PlyWood 6mm :

Cutting : Speed (15mm/s)---Power (Min:75%---Max:75%)

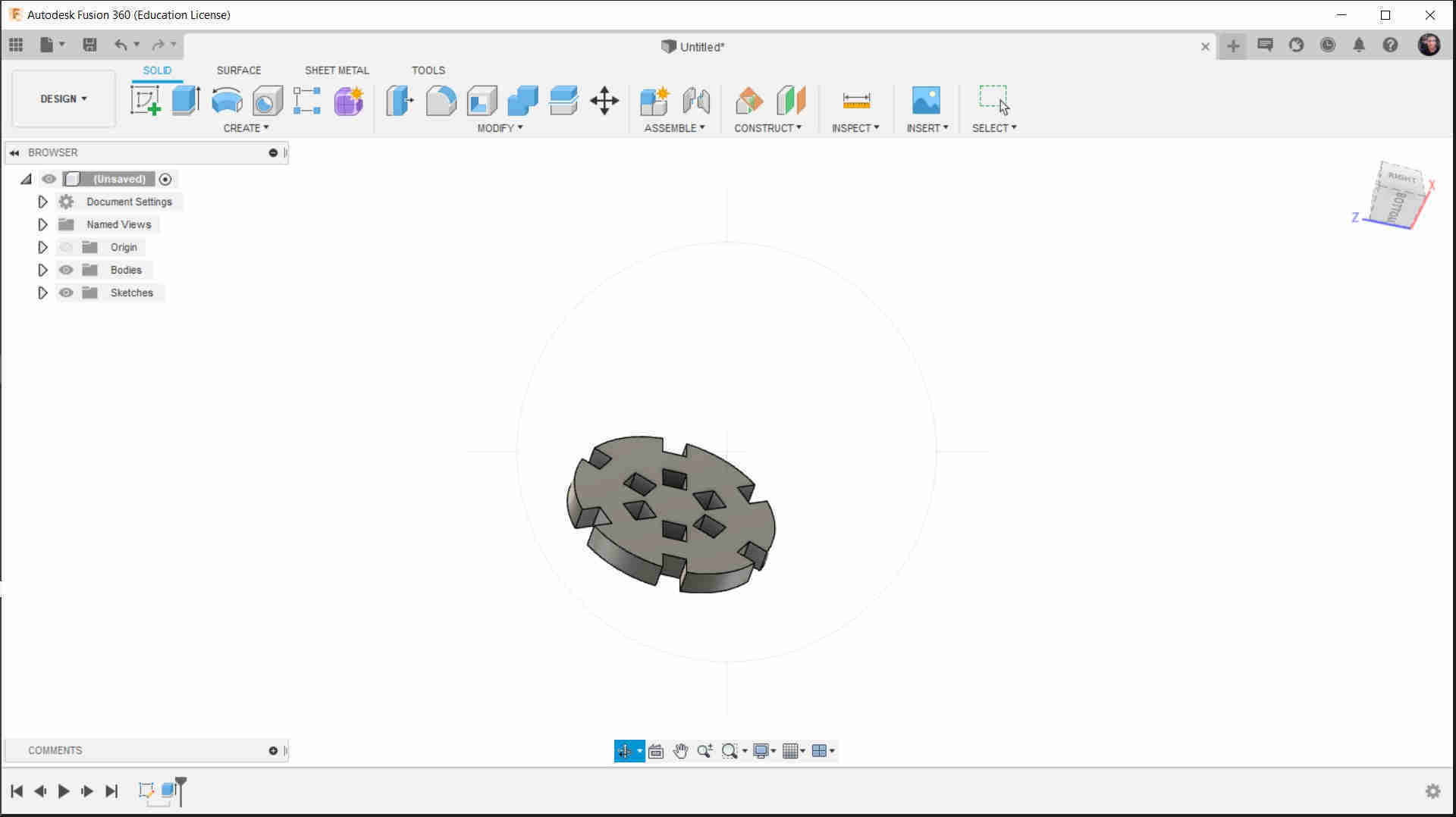

Then we Grap them From the Laser

and we Can Make Wonderful things With These Parts

Vainal Cutter

Blade

This part will be fun, It's Try to Produce something look Cool with the Laser cutter

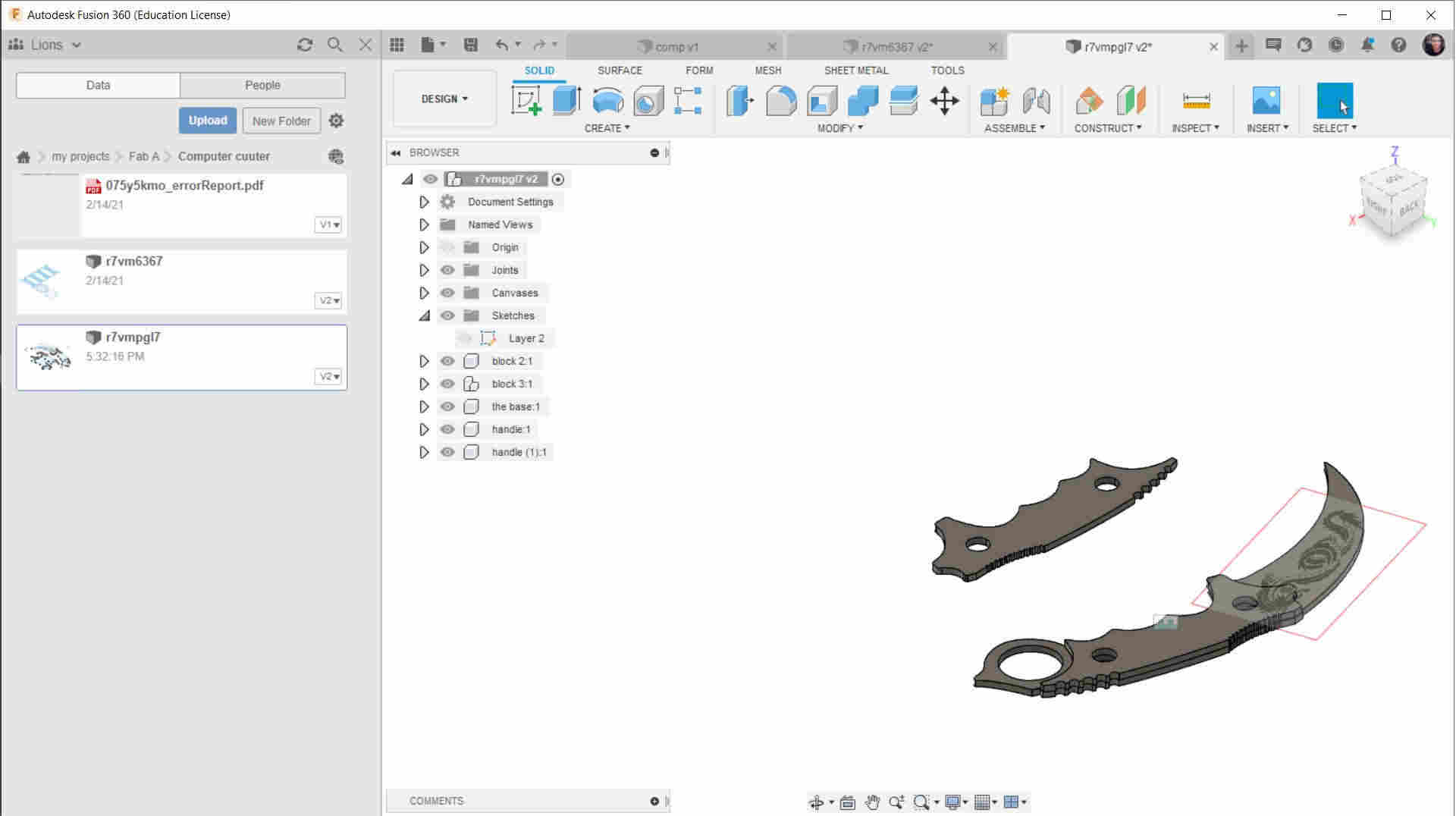

open Fusion 360 and draw sketch for the blade

make Extrude and see how look like in the real

Try to imagine the colors

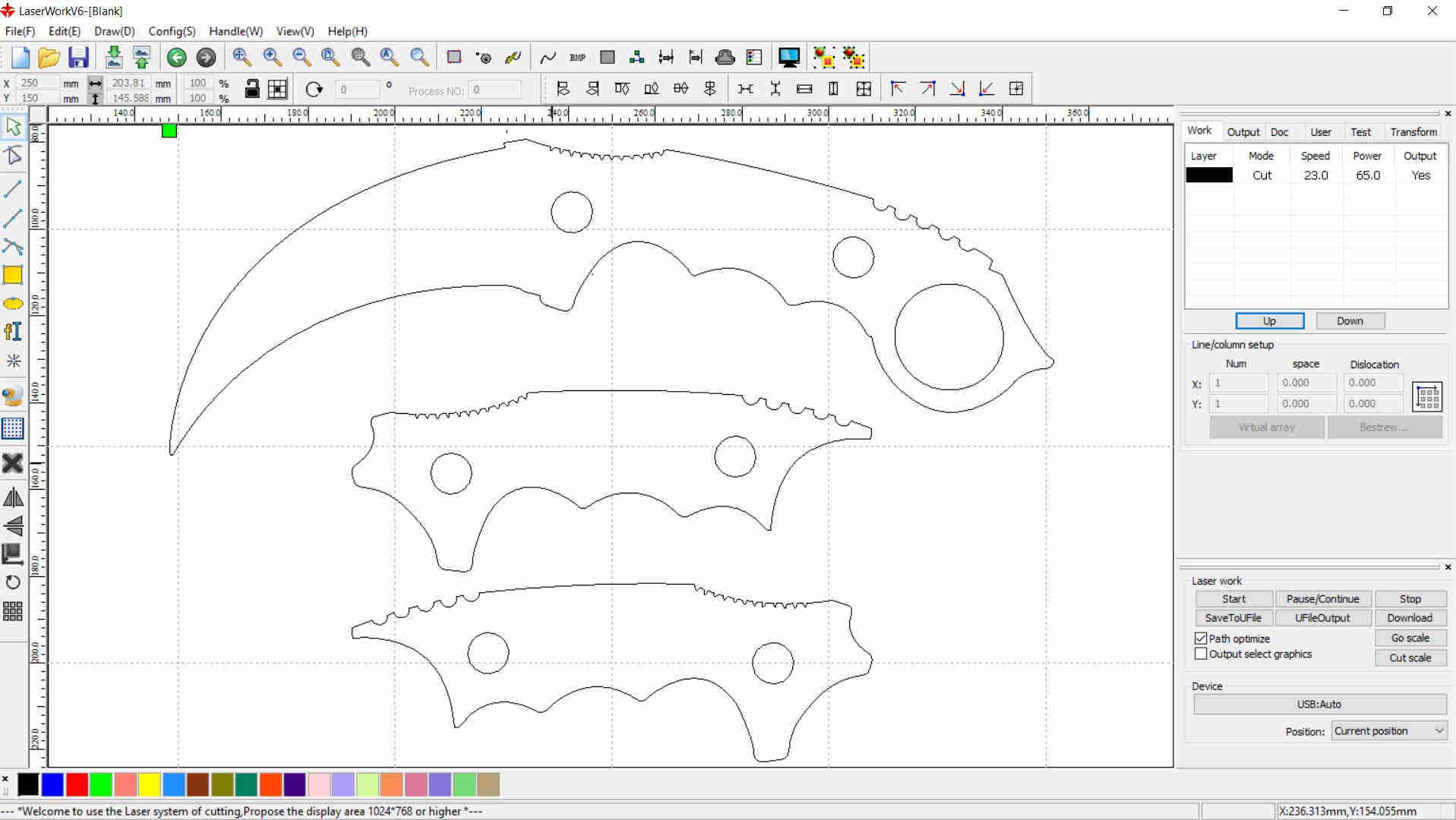

Put the DXF in Laser Works or Corel Draw

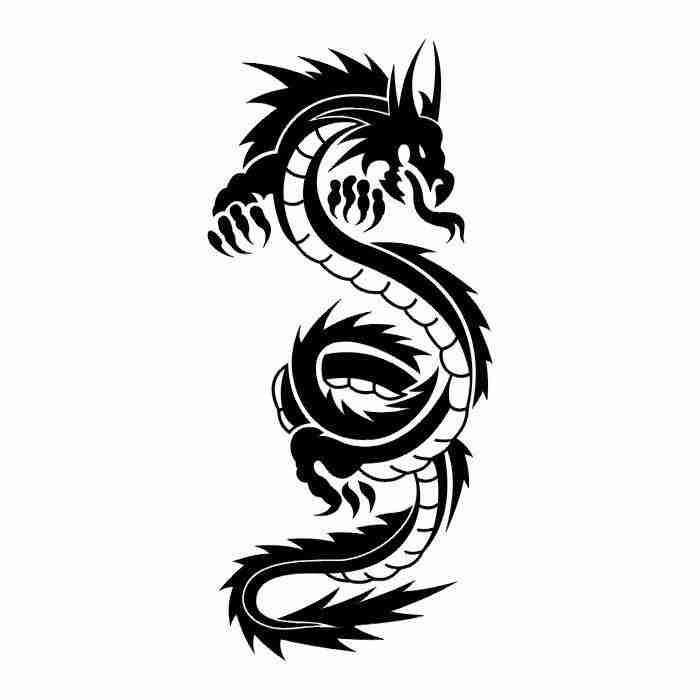

don't forget to put the dragon on the blade

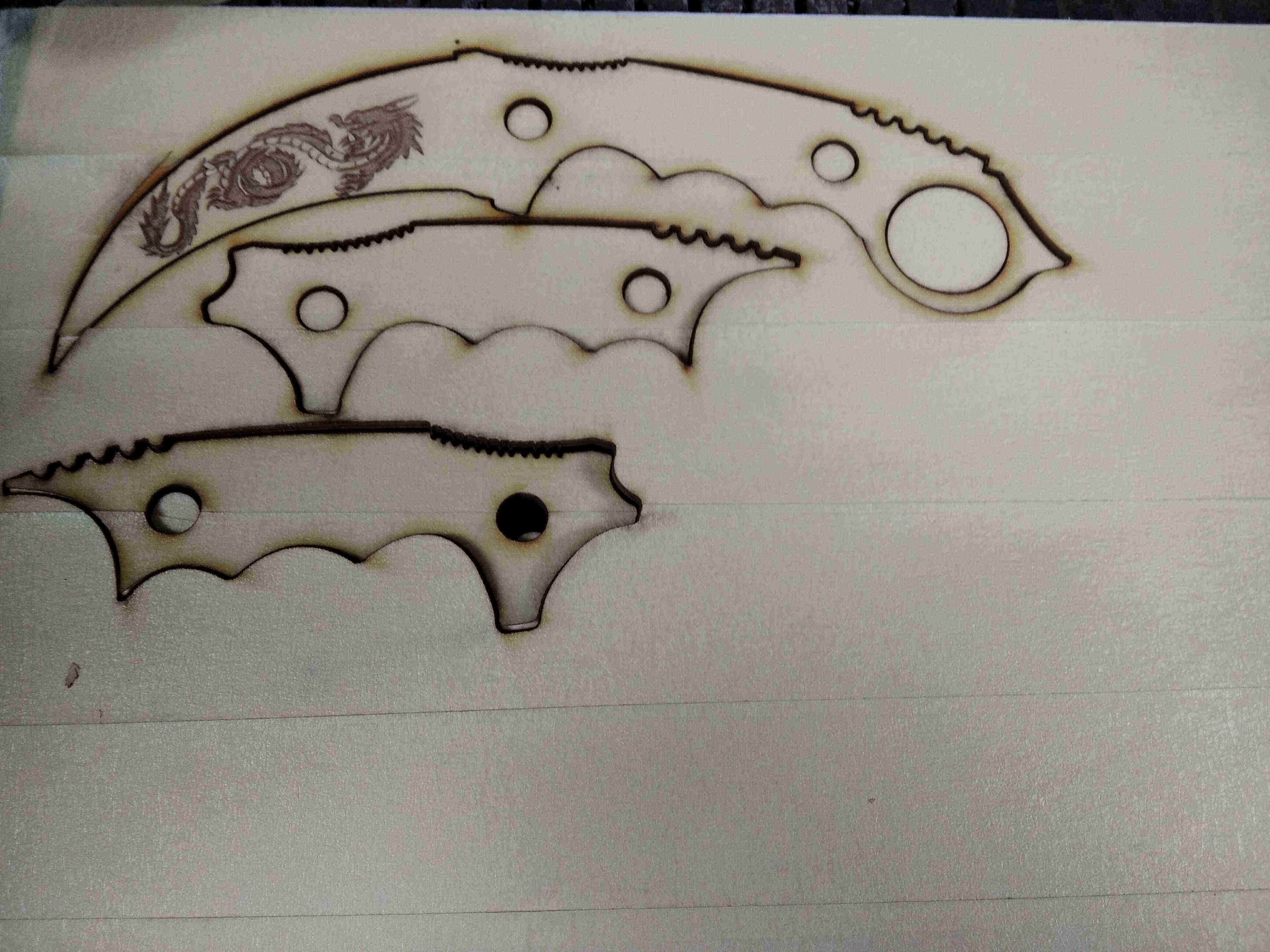

and get out the blade from the plywood

Prepare the blade by sand it to make the blade smoother

and after you paint it

Acrilic

here I will make Box from acrylic to put the Pincels in it

Draw the Acrylic Skectch on Fusion 360

Put the Sketch on the Laser Works

Modify the Speed and the Power of the Machine

Note

For Acrylic 3mm Cutting :

Speed (15mm/s)----Power (Min:65%---Max:65%)

For Acrylic 6mm Cutting :

Speed (8mm/s)----Power (Min:75%---Max:75%)

Cut the Acrylic sketch on the laser

Assemble the Acrylic Box