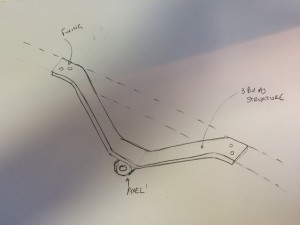

This week we decided to make a leaf spring for the fab bike

Tony made the design:

The sacrificial layer was a piece of wood. To bend it into shape I soaked the wood and then heated the joint with an clothes iron.

The next job was to prepare the epoxy resin. The label on the bottle indicated to mix 5 parts of resin to 1 part of hardener. We worked out what levels we’d have to fill to by first pouring in 500ml of water, marking the jar, then repeating with 100ml. Very precise.

Having already cut strips of Hessian to size we then layered one by one the resin and Hessian over the ply core, repeating 3 times on each side.

Having already cut strips of Hessian to size we then layered one by one the resin and Hessian over the ply core, repeating 3 times on each side.

Next, we wrapped the structure in cling film and wadding, before placing it in a vacuum bag and sealing it.

Next, we wrapped the structure in cling film and wadding, before placing it in a vacuum bag and sealing it.

At this point we noticed our leftover resin had begun to harden, and soon after that it begun to smoke so we decided to leave the room until it had aired out. Looking through the glass, it seemed to be solidying rapidly – we probably added too much hardner –

RIP paint brush