I then opened up Sketchup to make my model. The idea is our moulds will be made from food-safe silicon so we can make chocolates with them. Because our blocks of wax are not too big, the design had to be quite simple

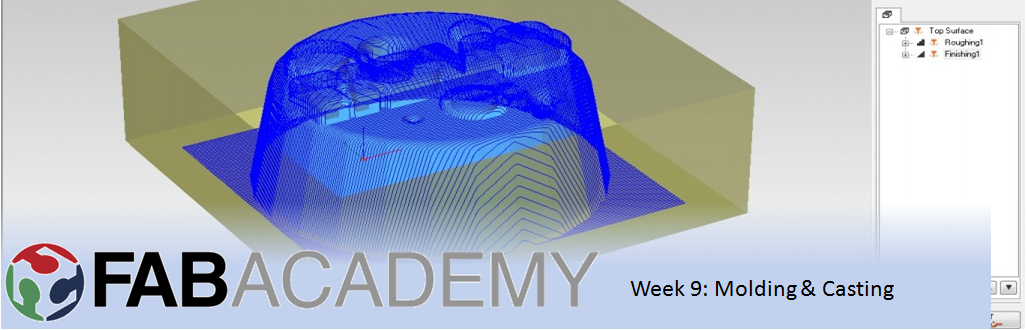

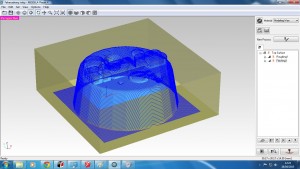

I used R3 mill shanks for the roughing process and R1 mill shanks for the finishing process. I decided to use Modela player to generate the tool paths.

I used R3 mill shanks for the roughing process and R1 mill shanks for the finishing process. I decided to use Modela player to generate the tool paths.

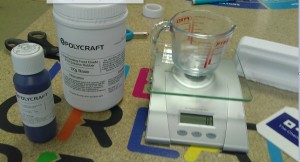

While the finishing process was underway, I made the silicon- RTV silicon rubber, which was very simple. All that was needed was to mix 10 parts of base to 1 part of curing agent- I did this by weight using a scale.

As you can see I mixed the two together in a glass measuring jug. This proved to be a mistake as it was impossible to clean afterwords and had to be binned. Using a disposable cup would have been a better idea. Don’t worry, air bubbles where removed before it was used!

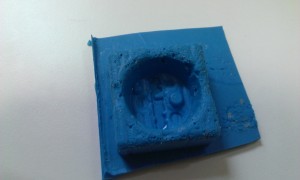

Here are a few pictures of the wax after it had been milled. The picture on the left shows the wax straight out of the machine- I used a Stanley knife to clean up a lot of the gunk and smooth out the edges. The second picture shows the wax after it had been cleaned up a bit and sprayed with release agent. Finally, the third picture shows the silicon in the wax mould.

A few days later…

After giving the silicone enough time to properly dry, I began the task of removing it from the wax. This was harder than expected. I used pliers to pry apart the wooden box (As some silicon had dried between the edges and acted as almost a glue, sticking everything together) before using a stanley knife to remove excess silicon. Then, using a saw, I cut an X into the top of the wax- which depth was about half the depth of the wax- which allowed me to break apart the remainder and remove the silicon mould.

I used warm water and soap to clean the mould. While I could remove most of the wax, some bits where just too stubborn to move. So I don’t think I’ll be eating the chocolates I make with them! As there is a Tesco’s just opposite the lab in a couple of minutes I was in and out with some cooking chocolate. Following their instructions I microwaves the chocolate for a couple of minutes so it was just about melted before poring it into the silicon moulds- (As there was so much I decided to also fill up Tony’s so not to waste any chocolate)