In our lab, we have a Roland SRM-20 milling machine rather than a MDX-20 machine which brought in a lot of problems, as Fabmodules seemed to only run with the MDX-20 machine.

After a couple of days playing around with the html5 version of fabmodules, me and Nat emailed the fabacademy group and was informed of a Beta version of the software that worked with the SRM-20 machine. Unfortunately we kept running into the error ‘Can’t connect to 127.0.0.1′- it seemed like Ubuntu and the milling machine weren’t talking.

We followed this tutorial but came into many problems in getting node.js running. Thankfully Fiore came to our rescue though and made an image of a system that had everything installed correctly and worked for us- we used virtualbox on our computers to run the image. After editing the send command to reflect which port the machine was plugged into, and giving ourselves permissions with the line

sudo chmod 777 /dev/lp0After that, we finally managed to get fabmodules and the mill talking. The first job was to set the origin point of the milling machine, which we did using fab modules. Aside from the send command, we tried a cut a board with all other settings on default.

Above you can see a picture of our milling machine milling the board, along with cut board, finished. As you can see, the bottom left hand corner wasn’t cut as deep as the rest so unfortunately this board won’t be suitable. This was likely because either the board wasn’t perfectly straight when in the machine- so the cuts weren’t uniformly deep- or because the milling head wasn’t secured tight enough and at somepoint in the cut was ‘pushed’ upwards, again meaning the final part of the process wasn’t cut as deep as the rest.

Another failed attempt

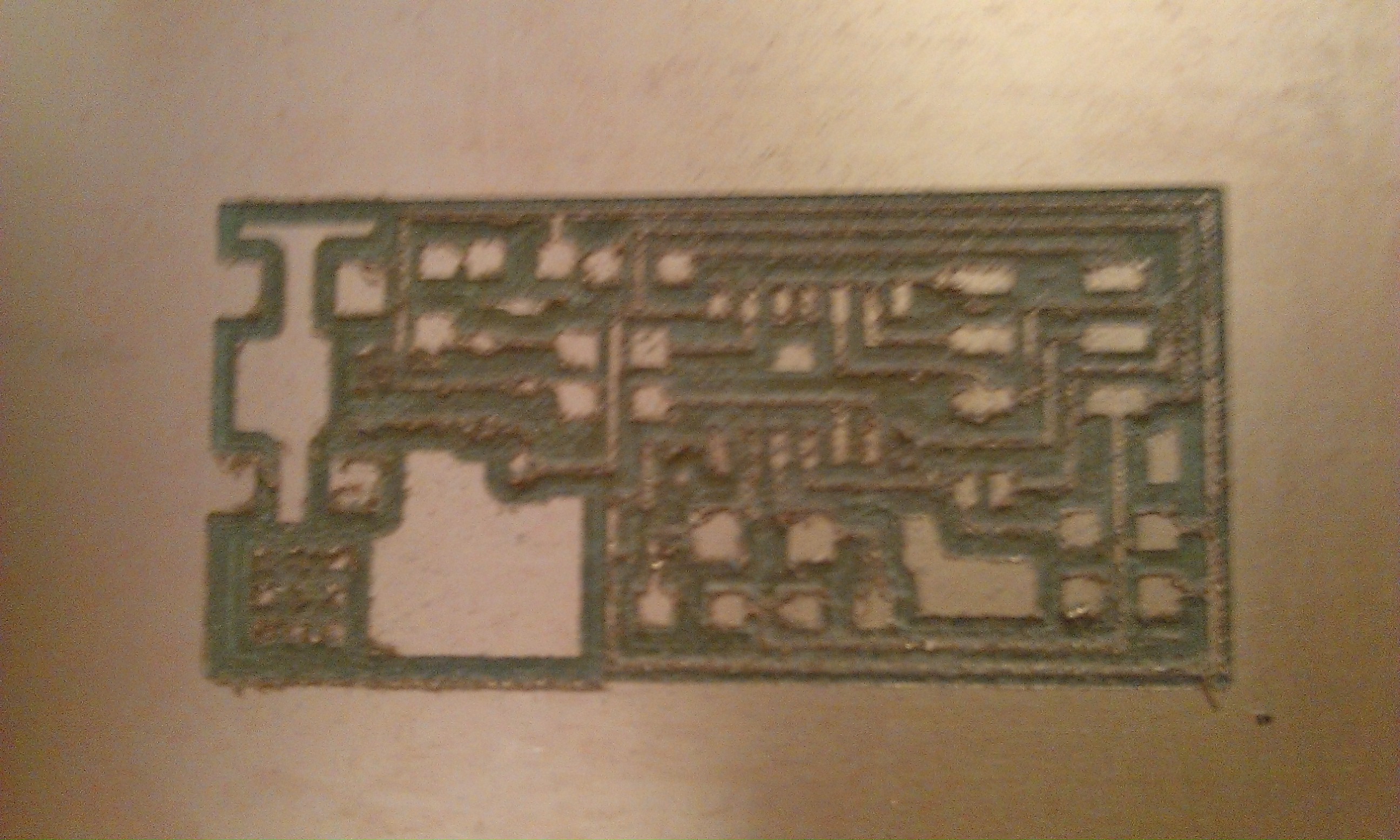

My next attempt was a few days later. The milling shank was broken, but I decided to have a go anyway- as we had nothing to lose except a small amount of copper, and it was good experience for setting the origin of the machine. This is the result:

It’s quite obviously not suitable to use as a board but ironically I think this cut is my most successful one so far, as the cut depth is uniform, if the shank wasn’t broken, I have a feeling it would have cut very nicely.