About Week 12

Composites Exercise...

The assignment of this week is related to digital fabrication of composite material: design and make a 3D mold, and produce a fiber composite part in it.

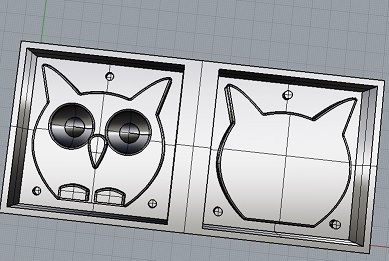

For this assignment I wanted to replicate the owl I realized during the mold and casting exercise with a bigger one version and starting from the negative of the 3D model.

The work is very hard cause the shape of the mold but I decided to try the experiment

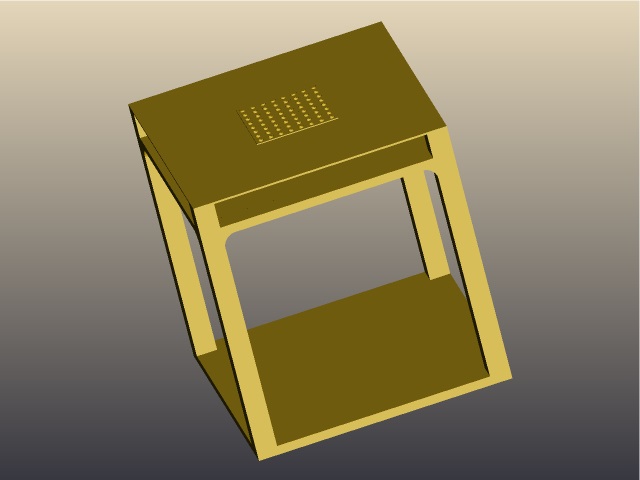

In order to produce the negative version of my previous owl with Rhino first of all I made the boolean difference between a box and the face of the owl. This produced the negative and finally I scaled to produce a bigger negative owl.

Download the Rhino file

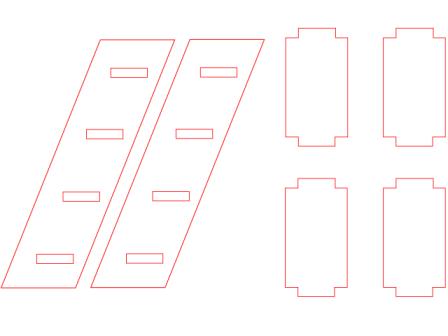

After this for the molding I used the CNC shotbot and I decided to use the same 2.5 cm MDF sheet.

In order to prepare the produced mdf mold, I used a water based impregnant in order to avoid any detachment of pieces of MDF and a carnauba wax. I've putted the wax in two different phases in order to produce a wax film useful during the composite release from the mold.

After this preparation phase It was time for the composite fiber composition, and for this phase I decided another risky approach: layering composition

For the textile material I used three different types:

1) thin felt , brown for the base and black one for the eyes

2) a plastic white grid for the eyes

3) A more dense cotton cloth for the final reinforcing fibre

Then I prepared the the epoxy resin by mixing component A (resin) and component B (hardness) for 3 minutes with a composition of 100A :25B by weight-scale.

Once the epoxy resin has been prepared I started the layer composition, starting from the eyes, place the resin, continued with the base with the brown felt, passing the roller on each layer, taking care of the edges , critical parts of the operation.

Once I finished I protected all with a plastic film and I waited 24 hours.

After 24 hours I tried to release the composite paying attention to broke the form. It was a hard phase and the the last part a piece of mdf mold came off: maybe less wax or mdf is not the suitable mold material.

It was easy to remove the piece of MDF , more difficult was to remove the composite from the edges , which dimostrates the strength of the realized composite

And finaly the two olws are together