Vacuum form machine

Simple and effective

- Notes on mercurial

Notes on webdesign

Notes on digital drawing

Notes on 2D cutting

Notes on electronics production

Notes on 3D scanning and printing

Notes on electronics design

Notes on molding and casting

Notes on embedded programming

Notes on computer controlled cutting

Notes on input devices

Notes on composites

Notes on interface programming

Notes on output devices

Notes on networking and communications

Notes on machine design

Notes on the final project

Final Presentation Notes on Invention, Intellectual property and Business model

Vacuform Idea

For my design I looked at what I wanted to make and what I would like to learn making it. I've been toying around with the idea for a vacuum form press. It enables the user to easily copy a production mold in lightweight and durable plastics. (Styrene, ABS, etc). The machine incorporates a wooden skeleton, isolation, heating elements, sensors, compressor/ vacuumpump, dials, buttons etc.

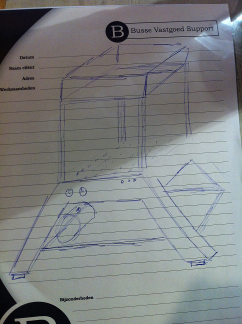

Sketching the project.

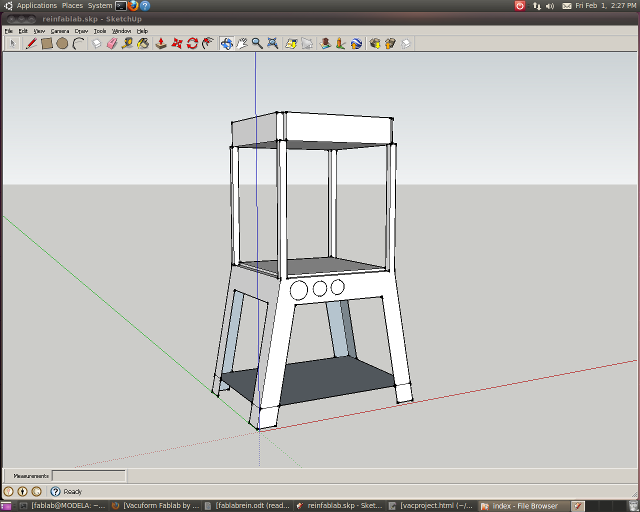

The next step is to start translating the sketch from 2D to a 3D model. I'm used to working in Sketchup (download the latest version here)

Breaking up the project into components makes this an easier build. Easier to manage anyway.

Component #1. The Heating element

I'm sure this is the most complicated element in the entire build. Not only in components and parts but also in programming. I want the machine to recognise that there is a sheet of plastic in place. Maybe have some presets for the different kinds of plastics but at least have a digital thermostat to setup the desired heat. Using an infrared thermometer the temperature of the plastic could be measeured and the heater turned on or off accordingly. This to prevent the plastic from melting all together. A warning needs to light up when heating/on too and a green light when it has reached the set temperature. Maybe even a beep or a buzzer to alert the user that the plastic is ready to be formed.Component #2. Down/ up mechanism (to lower the plastic and heating element)

Bringing the plastic down from the heater element to the mold and vacuum table will be simple. This could be done with levers or straight with gliding rails. This all depends and how big the machine will get. I would like to incorporate the function that as soon as the plastic holder reaches the table a sensor will pick up a signal and the vacuum start flowing. Instead of manually having to turn it on. I'm sure this is an easy fix.Component #3.Vacuum pump/ escape valve (to create suction on the worktable)

I have researched some ways of creating a vacuum on the table and I have set my mind on having a compressor with a tank underneeth the table and using a vacuum generator (like an Air-Vac.) I'll have to work out just how much vacuum is needed when I get there. I plan to try this out with a regular vacuum cleaner first. It would be very nice to have an indicator for the tank. One that says the tank is ready to be evacuated and to create the vacuum. And a gauge to view exactly how mush pressure it has built.- Adjustable legs (so the table can be level in all work spaces)/ or wheels to roll the thing around the workshop.

- Central on/ off switch with LED indicators

- The vacuform should be able to work with industrial standard sized sheets

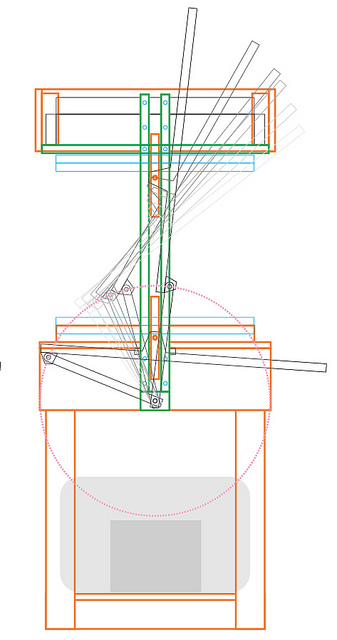

I found this handy parts sketch. It's an easy reference model to see if all functions are there.

The drop down mechanism.

1.Levers. To drop the top pull or press a bar connected to the top bringing it down over the project.

2.Pulley system. With one wheel (either operated manually or by a electromotor)

3.4 motors pulling on 4 seperate chains to pull the top down.

I've found a very nice example of how levers could be used.

It would be really cool to have the choice to have a fully automatically operated machine or operate it by hand anytime you choose.