Vacuum form machine

Simple and effective

- Notes on mercurial

Notes on webdesign

Notes on digital drawing

Notes on 2D cutting

Notes on electronics production

Notes on 3D scanning and printing

Notes on electronics design

Notes on molding and casting

Notes on embedded programming

Notes on computer controlled cutting

Notes on input devices

Notes on composites

Notes on interface programming

Notes on output devices

Notes on networking and communications

Notes on machine design

Notes on the final project

Final Presentation Notes on Invention, Intellectual property and Business model

Notes on my final project

what will it do?

For my final project I still want to build a vacuum form machine. Albeit a smaller one than I had initially drawn up. I have drawn plans for a table vacuform machine. It will have a workspace of 300mm x 300mm and be able to vacform small molds and parts.

who's done what beforehand?

I have collected a lot of research in the last months. From resources like instructables and blogs around the subject. I think the machine basics are simple and the challenge for me lies in introducing sensors and lights to this machine.

what materials and components will be required?

I will require:

- Wood

- Heater element

- Temp sensor

- light sensor

- aluminium/ aluminium foil

- Vacuum cleaner

- vynil sticker

- motors

- Power supply

where will they come from?

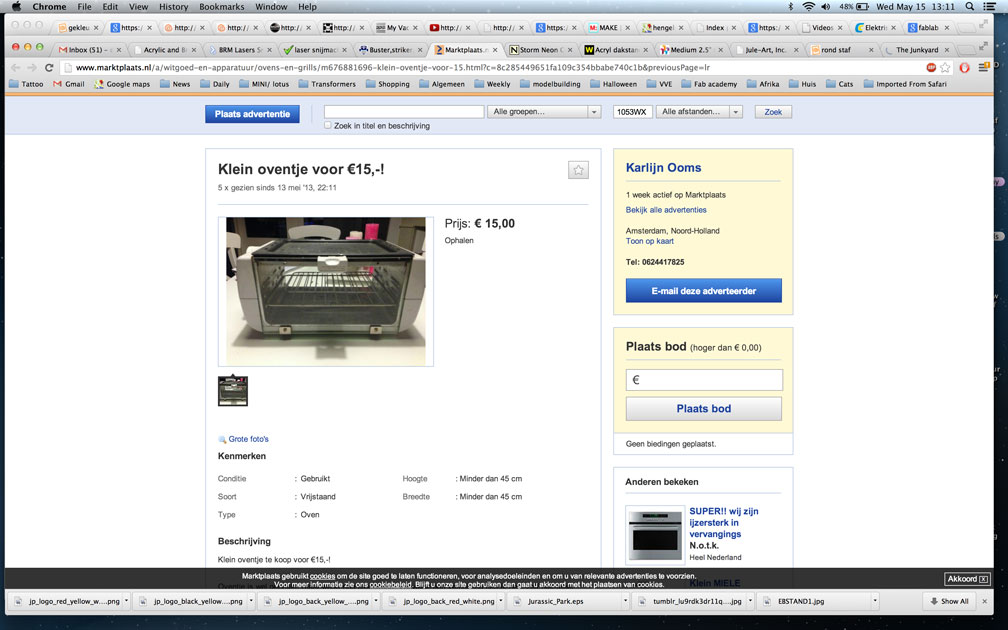

I have sourced a second hand heater element from a 1000w electric oven. I'm sure this will suffice. All other materials I'm sure to get from the lab storage.

how much will it cost?

I have sourced the oven for a mere €15. As all the other materials will be supplied by the lab I'm sure I can make this for under €50

what parts and systems will be made?

I will make a heating container to heat up the plastic. I want to make a working elevator to drop the plastic over the mold. I want to incorporate a temp sensor and a light sensor as well as to drive the elevator motors. Also if possible I would like to use molding and casting to make parts of the machine.

what processes will be used?

I will use eagle and the modela to make the PCB's. Soldering to finish them. Also the shopbot for all the woodworks as the laser is out of commision.

what tasks need to be completed?

First to dissasemble the heater oven and build that in a working isolated box with a way to fix the plastic under it. I need to figure out how to wire the light sensor and the temp sensor in the machine and have it work together.

what questions need to be answered?

Will it blend?!

what is the schedule?

I will start with taking apart the oven and working it's innards into a box. Then I will make the wood structure of the machine and then the sensors.

how will it be evaluated?

Probably by my tutor and peers.

I started out sketching the final form on good old paper:

You can see that I have incorporated a small oven I have bought secondhand. It was advertised at €15 but I got it for €10.

I took it apart and scrapped most of it. The heater elements are very simple.

I then drew up plans for the shopbot and cut them.

I glued most important parts together and hooked it up to a shopvac to see if it would work!

it works!

Still working on: Putting it together, Light sensor, temperature settings, refining shopbot/lasercut layout.

top