11. Applications and Implications¶

This week was entirely about planning and detailing my final project - the Chanting Box. By breaking down the various components and aspects of my Chanting Box project & then integrating them to a holistic vision, I am able to reflect deeply on the current status of my project.

This is an incredibly important stage as I plan to create something of value as a stand-alone unit but also as a generative design that evolves into other interesting artefacts. Without this breakdown, the project seems to be getting complex and initial ideas start to bifurcate into new forms. So this is a necessary step backwards.

¶

Assignment Questions:¶

Why What How and Who’s

What will it do?

Who has done what beforehand?

What will you design?

What materials and components will be used?

Where will come from?

How much will they cost?

What parts and systems will be made?

What processes will be used?

What questions need to be answered?

How will it be evaluated?

& How does the project incorporate:

- 2D and 3D design,

- additive and subtractive fabrication processes,

- electronics design and production,

- embedded microcontroller interfacing and programming,

- system integration and packaging

- Making vs Buying parts of your project

- individual mastery of the skills, and independently

operability in case of joint project

1. Introduction to my final project¶

¶

My project is to design and create an Interactive Electronic Mantra chanting box.

The deeper goal is to use Audio electronics and Information Technology to mediate heritage and cultural archives that otherwise exist as perishable forms.

Awareness of Sustainable manufacturing and energy efficiency should be addressed in the design.

2. What will it do?¶

¶

The interactive Electronic Mantra box uses non-volatile memory - eg. through an SD card; in order to select, playback and optionally record MP3 chants in a loop.

3. Who’s done what beforehand?¶

Spiritual traditions in India uses electronics in creative ways, seeking a creative engagement with technology. It is almost a shadow counterpart to the west, where the trend is revinventing and remediating spirtuality through notions of Mindfulness and “isness” - such as the thinking egg or Gwyneth Paltrow’s wellness eggs

I see my electronic mantra box situated somewhere in the middle of these two extremes.

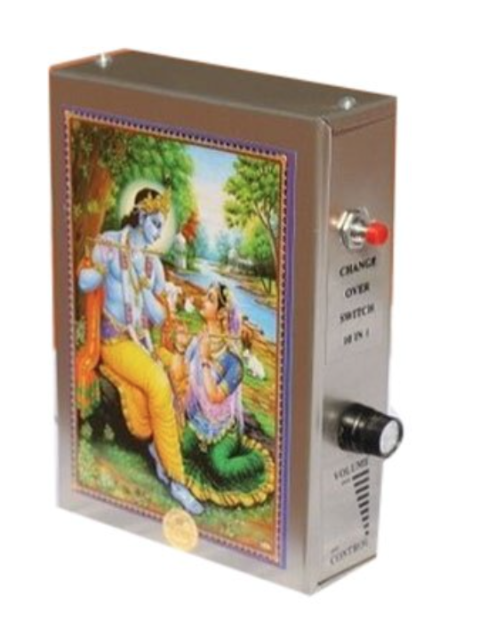

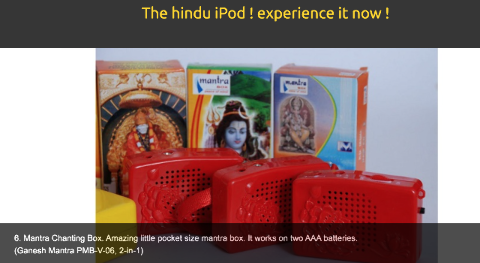

So what mantra boxes exist currently? If one looks close enough behind a small Indian restaurant cashier, in a small side corner of a temple or the “ritual rooms” of households - one might come across this little chant box.

These Chanting boxes contain an assortment of mantras to various deities - that are played back in a long loop. Each mantra can last from 5-20 seconds - and the chants are typically played during auspicious times of the day and also in spiritually events.

A typical chanting box has from three to twelve or more mantras (featured as 12 in one or 20 in one!) - that can be cycled through and played on repeat as many times as one likes. Basically each mantra is triggered as loop, and the cycling happens through a single switch.

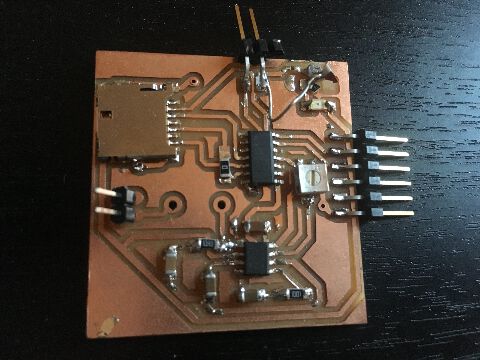

Below is a Chanting box to the lab which I opened up and explored the inside.

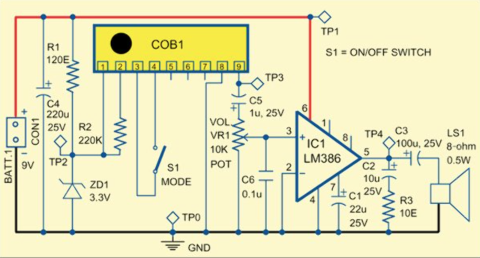

During some basic research online, I came across some of some “open electronics” schematics of these players.

So essentially, it is a simple amplifier circuit with a speaker - with a Read-Only memory (ROM) chip.

“The ROM chip is a complementary metal-oxide semiconductor (CMOS), large-scale integrated (LSI) chip.) Known as chip-on-board (COB), these boards are available in different sizes, under a blob of epoxy, with chips programmed with single or multiple mantras/artis such as gayatri mantra, ganapati mantra, krishna mantra, om namah shivaye, shri ram jai ram and satnaam wahe guru.” - https://www.electronicsforu.com/

There was a bit more detailed explanation on the choice of components and inner workings in this chanting circuit.

Most Indian mantra boxes come in a package of mantras (starts from 1 chant and go right upto 40 +, usually 7-12 in one is average ) in one package. After exploring some of the online pages in the chanting box category, it seems that most of them had a basic circuit as far as the amplifier, speaker, switching circuit goes. The mystery is in the IC chip using to store the mantra in the ROM (Read Only Memory)!

Here is electronics schematic of a typical Indian mantra chanting box.

The IC is typically hidden “under a blob of epoxy” as this is probably the most sensitive part of the circuit - and needs to be prevented to the vagaries of India - from humidity, heat, serpents, falls, short circuits and so many other serendipitous “anything-can-happenings.

The IC chip “under a blob of epoxy”

It is possible that these circuits are made-to-order from one of the Chinese OEM’s - however I am not too sure yet and need to trace the makers to get more information on sourcing. it is typical fo IC’s in China to get a small dab of epoxy material that electrically and physically protects the die and thin wire bonds from damage. The viscosity of the epoxy must be apparently tightly controlled to prevent the hairs from bending over and creating shorts. This is then cured for hours and then tested. So this is basically the “secret of the blob”.

The blob of epoxy can be seen in Chinese greeting cards and such toy-like products too, where a small loopy sound file needs to be stored and triggered.

COB or Chip-on-Board under an epoxy layer seems like a standard in these kinds of products. I did a bit of online research to know more about COB and came across this page on how COBs are made in China.

According to electronics stack exchange:

“IP protection example: until a few years ago FPGAs always needed an external serial memory to load their configuration from. This configuration could be an almost complete product design, and therefore expensive. Yet, simply by tapping the communication between FPGA and configuration memory everybody could copy the design. This can be avoided by COB-ing FPGA + memory together under a single epoxy blob.”

“The blob is an epoxy resin to protect the IC with the bonding mechanically; the bonding wires are very thin (as thin as 10𝜇m for gold wire) and therefore extremely fragile. Another form of protection it offers is reverse engineering protection. This is not fool-proof (the resin can be removed), but it’s a lot harder to reverse-engineer than simply desolder an IC.”

In the case of my mantra box, I have no intention to get paranoid about the IC chip, and would like to keep the electronic design as “open source” as the thousands of years old mantras I am using within them.

Labyrinths from Fab Academy /MIT Audio related projects/ other¶

I tried to look into blogs, research as well as official documentation to find out more about the Chanting Box. However, because the box belongs to lo-fi electronics category and the informal economy, there is no formal documentation of the scope and level of development of such pieces - they are made ad-hoc in small town multitasking electronic industries.

The only article closest I found online was from a transdisciplinary artist with similar curiosities as myself - Dr. Marc R. Dusseiller - who had blogged about hacking Mantra Chanting Boxes while in India.

-

related from Fab Academy & MIT:

-

David A. Mellis David’s Fab Speakers and are made from laser-cut wood, fabric, veneer, and electronics. They are powered by three AAA batteries and compatible with any standard audio jack (e.g. on an iPhone, iPod, or laptop). The design is Open Source.

a. Uses an Atmega328, an SD card socket, an mp3 decoder + D/A chip, and a level shifter to convert from 5V to the 3.3V required for the SD card and mp3 decoder. b. Button functions via copper pads through 10 MegOhm resistors.

-

Dinan Yan’s Loop the Chop! + Arduino official project is a Looper with a easy to understand visual interface for recording loops via the mic.

-

Asaj - MIT “it’s important to keep current carrying traces thick, and signal traces as straight as possible to avoid any parasitic inductance. It also helps to keep sensitive traces as far away from current carrying traces when possible, to avoid inducing noise on that trace. “ His amplifiers were heating up as they were not class D amplifiers - and needs a heat sink. I would like to avoid a heat sink as far as possible.

-

Serenado’s Vinyl Player with Power Board and Amp circuit interestingly uses a power board to power LM386 amps and the motor via a barrel jack that distributes 12V to screw terminals.

-

Nadieh Bremer Almost any page from our fab academy classmate Nadieh simply rocks with incredible take-away’s IMO irrespective of your project genre and has the best documentation on the fab planet (prove me wrong). For my project, the possibility to use LED’s as an eye candy to the chants became a mesmerizing possibility, thanks to Nadieh’s inspiring-as-usual Output Week assignment.

¶

What will you design?¶

I will be designing a more interactive and aesthetically appealing version of the current Mantra chant boxes - that will allow the user to toggle through mantras stored in an SD card - and also allowing the user to record and playback his or her own looped mantras as well.

The first thing that comes to mind with existing box designs are potential short circuits, fire hazards and blown fuses. (For eg. I was introducing the FabLab assistant to this mantra box and the power was connected to the mains while the metal housing screws was loosened a bit. The power chord blew up due to a short right next to him and he was stunned for a good ten minutes.)

So the first feature of such devices will address issues such as : - Lack of Safety

I had brought back 2 other boxes which stopped working within a month. Hence the second issue: - Short product life cycle

Studies show that “The low cost of labor to offset the high capital outlay required for automation” The reason for the shabbiness of the current product is an overall symptom of low productivity, talent & skill shortage, inefficient supply chains and low levels of supplier competence.

- Design for Affordability and Energy Efficiency By making the prototype for an affordable, yet quality household product - I am hopefully able to understand the subtle aspects of localized design needs in terms of cost, energy, resources and community context that need to be understood and included in the Key Design Features.

Additional holistic features I would like to consider are: - Generative Design with room for evolution I begin to also think along these lines: “If the device already has electronics embedded in form of memory etc., why not use it to trigger other kinds of information as well? “

- Calm Tech From the feedback generated by colleagues, the mantra box created a sense of exotic awe among artists in the west, while being a strangely utilitarian object in India. The box and its overall look and feel, should amplify both these feelings in the universal user.

The key things I would design would be in the following layers:

- The electronics - An elegant single or double sided SMD based PCB that would allow the form factor to be adapted according to context (Eg. wallplug based mantra charger, a keychain version, a piece of jewelry or a prayer ritual electronic box). The electronic components would basically be covering the SMD components as needed, ie *resistors, capacitors, LEDs. timers, amplifiers, headers, transformers as per the design.

- Electricals - A transformer that would convert 230 V AC to 3-12 V DC with maximum safety features. The design choice extends to DC power connector choices, and I should conduct further research on.

- Energy components - Battery operated, USB Charging option as well as possiblity for Solar Powered charding vs AC/DC power supply.

- Ethical Transparency - The device should be repairable and possibly upcycled - with clear information on its hazards, disposability, and a small electronics booklet detailing the parts for replaceability : while discouraging the use of counterfeit models.

- Narrative - The artefact should prominently feature a graphic narrative on the outside and interesting patterns on the PCB level that would give a metaphysical & spiritual look and feel to the device - the inside of a box for instance could have the PCBs arranged as an Indian Diety with several hands or a subtle Avatar glow around the device. A fantastic example is the Berlin Wall Distortion pedal made by a Finnish artist friend, that embodies such an approach quite well.

- Audio Components - Audio Components such as the Speakers and Mics should be well calibrated to operate efficiently and reliably under reasonably extreme conditions of usage, including environmental aspects such as dust, heat and humidity.

- Interface - If an app is needed to control the artefact, then prototype at least the basic features of being able to stop, record and playback a sound loop.

- Prototyping- breadboards, jumper wires, software for testing.

¶

¶

What materials and components will be used?¶

1. The electronics SMD components¶

| Component | Approx. unit cost |

|---|---|

| AVR128DB32-I/PT IC ATTINY3216-SFR IC | €0,88 - €1,70 |

| 6”x8” Single - 6”x8” Double sided board | €1,50 - €2,50 |

| LM3480IM3-3.3/NOPB voltage regulation (optional) | €0.90 |

| POT 10K OHM 1/20W PLASTIC LINEAR | 1.11 € |

| 0.1 uF capacitor * 2 | €0.16 |

| 2.2 uF capacitor | €0.16 |

| 0.47 uF capacitor | €0.16 |

| 100 uF capacitor | €0.16 |

| 0.1 uF capacitor * 2 | €0.16 |

| 1000 uF capacitor | €0.16 |

| 49.9K resistor | €0.05 |

| 10K resistor | €0.05 |

| LED RGB 4PLCC SMD | €0.35 |

| Batteries (AAA) | €0.34 |

| Coin cell battery 3V | €0.95 |

| # |

2. The electrical components¶

| Component | Approx. unit cost |

|---|---|

| AC/DC WALL MOUNT ADAPTER 5V 5W | €4 |

| USB to UART USB 2.0 UART Interface 16-SSOP | €1.75 |

| AC DC Connector Jack 0.70mm surface mount | €1.09 |

| SWITCH TOGGLE SPDT 0.4VA 20V | €0.90 |

¶

3. Audio Components¶

| Component | Approx. unit cost |

|---|---|

| 8 Ohms General Purpose Speaker 500mW 600Hz ~ 4kHz Top Round | €2,13 |

| MICROPHONE CONDENSER ANALOG OMNI | €2,61 |

| Amplifier IC 1-Channel (Mono) Class D 8-MSOP-PowerPad | €1.09 |

| FRS 5 - 8 OHM fullrange speaker (optional) | €7,69 |

¶

8. Prototyping components¶

| Component | Approx. unit cost |

|---|---|

| SPEAKER 8OHM 250MW TOP PORT 81DB | €4 |

| Breadboard + Jumpers + Wireloops | €15 - €20 |

| 10 kOhms 0.25W Trimmer | €0,96 |

| addtnl resources | links |

|---|---|

| Dropbox | [plugins/dropbox/README.md][PlDb] |

| GitHub | [plugins/github/README.md][PlGh] |

| Google Drive | [plugins/googledrive/README.md][PlGd] |

| EU India open science collaboration | [ https://euraxess.ec.europa.eu/worldwide/india/europes-global-approach-cooperation-research-innovation-india-valuable-partner] |

| Basic LM386 amp schem w bass boost | [https://www.circuitbasics.com/build-a-great-sounding-audio-amplifier-with-bass-boost-from-the-lm386/][breadboard compatible] |

| hi-quality John Broskie AMP boards | [http://tubecad.com/]+[https://glass-ware.stores.yahoo.net/newhardware.html] |

¶

What parts and systems will be made¶

- The casing

- The amplifier and microphone boards

- Electronic PCB housing the main ATTiny 3216 microcontroller and Memory unit

- Housing for Speakers

Here is a prototype single sided board that is already milled and houses the SD card holder, amplifier, AtTiny 1614, audio outputs (missing microphone input).

Since my SD card board has been giving issues and in case Audio signal noise continues to be a challenge - then as a backup, DFRobot’s DFPlayer Mini MP3 Player (a small and low price MP3 module with an simplified output directly to the speaker) will be considered. The module can be used as a stand alone module with attached battery, speaker and push buttons or used in combination with an Arduino UNO or any other with RX/TX capabilities.

What questions need to be answered?¶

Why am I Choosing a standalone sonic object in the age of on-the-fly Alexas, Speakers, Headphones, and other Wireless devices?*¶

in a nutshell - it is “anti-AI” & “pro cybernetic”. While anything launched into the internet of things becomes a storehouse and catalyst for surveillance capitalism - this is an example of the complete opposite, it is launched into the “innernet” and has a storehouse of memory - of content that tends toward such trends in the west as “calm technology” or “mindfulness tech” and at its essence, a series of sounds to explore both the inner self and consciousness.

The answer is in the purpose of this object - it is not a passive object but created with a deep cultural aspect in mind. And there is both a front end aspect of the concept, and a deeper and subtler need for invisible information to be revealed.

Essentially, the mantra is a sonic representation of energy forms. At the same time, there are much contemporary experiments on how to design everyday “artefacts” to address the “invisible concept” of energy. Essentially a mantra box is already a cultural and archetypal product that could expand into these other forms of representation as an independent object.

When it comes to Sonification of energy use, there have been numerous attempts to create an non intrusive interface for the purpose - such as continuous soundscapes and internet of things that start “giving sound codes” such as washing machines and so on.

In somehow my intuitive opinion, everyday activities are largely actions that occur in “flow” - and on breaking down these activities, the outcome of energy saving which is a high level purpose is often at odds with “getting the stuff done” which is a goal or task oriented purpose. This is why the justification of creating and installing a sonic object, connected to the internet of things, yet functioning without - could be an interesting example. Th fact that this sonic object would exist as a cultural object independent of the current ecosystem of sound objects, would also help to create a unique aura around this particular piece - and likewise introduce and also evolve people’s understanding of invisible forces such as energy.

Artefacts allow the materiality of energy to be manifested, discussed and explored practically (Pierce and Paulos, 2010) and is the utilitarian intention behind the decision to start with the successful prototype if a relatively simple mantra looping box as a design object.

However, the DNA of this mantra box is that there is the possibility of a unique sanctity in blending the spiritual and utilitarian in one box.

How will it be evaluated?¶

Design for Mass Manufacture¶

The PCB design and the casing would be the major design challenges that are to be addressed for the FAB Academy prototype. However, the bigger realities around mass manufacturing is also a case in point to be considered.

According to The Hitchhiker’s guide to PCB design, Design for Excellence (DFx) is one attribute of measurement for ensuring a PCB is designed for scaling up in mass production.

They include Design for Test (DFT), Design for Cost (DFC), Design for Manufacture (DFM), Design for Assembly (DFA), Design for Repair, Reuse, and Recyclability (DFR3) and many other “DF’s” that can be organized into a Design for Excellence (DFx) concept - in my case, with a special focus on DFM, DFA, and DFT.

¶

In this way, the design can somewhat try to shadow industrial best practices to understand (not necessarily mimic) mass manufacturing processes.

The mantra box project hopefully will extend to other fields - ultimately Mantras themselves are considered as sonic forms given to various energy fields i.e. Sonification of our ecological and “invisible” environment - especially energy data. Some of the more complex Product features I would like to think about and list within this Mantra Box:*

- Modular Structure - that can be easily taken apart.

- Ecologically conscious material (possible to upcycle or meet end of lifecycle)

- Working prototype for decentralized mantra boxes possibly connecting communities

- Operates in two modes : laidback “ritual mode” and hands-on “active mode” - and hence might have an interface.

- A compass or some directional indication to help it face the east in the direction of the rising sun.

- It should operate on bare minimum power (eg. 3v) - and be standalone preferably.

- Its modularity offers room to build future design features.

What processes will be used?¶

- Initial Design ideas and goals

- Basic circuit design, tests and characteristics

- Finalize initial design and tests

- Layout board and prototype

- Test prototype and tweak

- Finalize board and BOM.

After this or in parallel, comes the casing design as below:

Casing Design - subtractive and additive processes¶

The casing will try to use experiment additive processes via SLA PRINTING and subtractive processes with CNC milling and wood. The SLA printing some interesting Form Factors can be explored. On the other hand with CNC milling, design principles for mass manufacture can be explored where multiple casings are milled from a slab of wood.

- Explore enclosure features such as Snapfit and a bracket for securing all the components.

- Secure the PCB to a 3d printed casing, securing it with placeholders for screws.

- Possible back cover snapfits, and features a spot/exposure for a bigger speaker.

- If there is an add-on memory such as micro sd card slot, then plan a nice cutout section for the element.

- Possible toggle switch to power the device on and off

- can use a lipo battery that charges via usb - unless it is solar powered or AA batteries

- The faceplate can be designed to accommodate a custom keypad/buttons

The above interesting approaches to casing design comes from Adafruit - who have been sharing concepts and prepper videos for casings around which their off-the-shelf components could be fixed.

eg: BLE Buzzy Box pyportal adafruit

other “guerilla style” ideas include: