PRINCIPLES AND PRACTICES¶

This week was based on defining the topic for the final project.

I was having two ideas that for the final project

The first Idea was based on making an extruder that will make flooring tiles from waste plastics

The second idea was to make an air mouse

TITLE:AMCAP(Alternative Method for Construction by abjecting Plastics¶

Overview¶

The project mainly focuses on the technique to eradicate the pollution caused by waste plastics upto possible level by converting it into a resoursabel product for the construction of building through digital fabrication

Goals¶

To reduce the pollution caused by waste plastic ,thereby maintain a sustained and eco friendly nature Reduce the cost and time for the construction of floorings and buildings

Research Specifications¶

1.AMCAP basically consist of 2 parts.

(i) Mixing chamber. (ii) Extruding part.

(i) The mixing part provides a chamber which mixes the sand and plastics using a stirrer and maintaining a temperature between 400-500 degrees to melt the mixture.

(ii) Extruding part consist of metal pipe which is made up of HS303 which Can Withstand Upto 700 Degrees (https://www.azom.com/article.aspx?ArticleID=964) with an extruder.

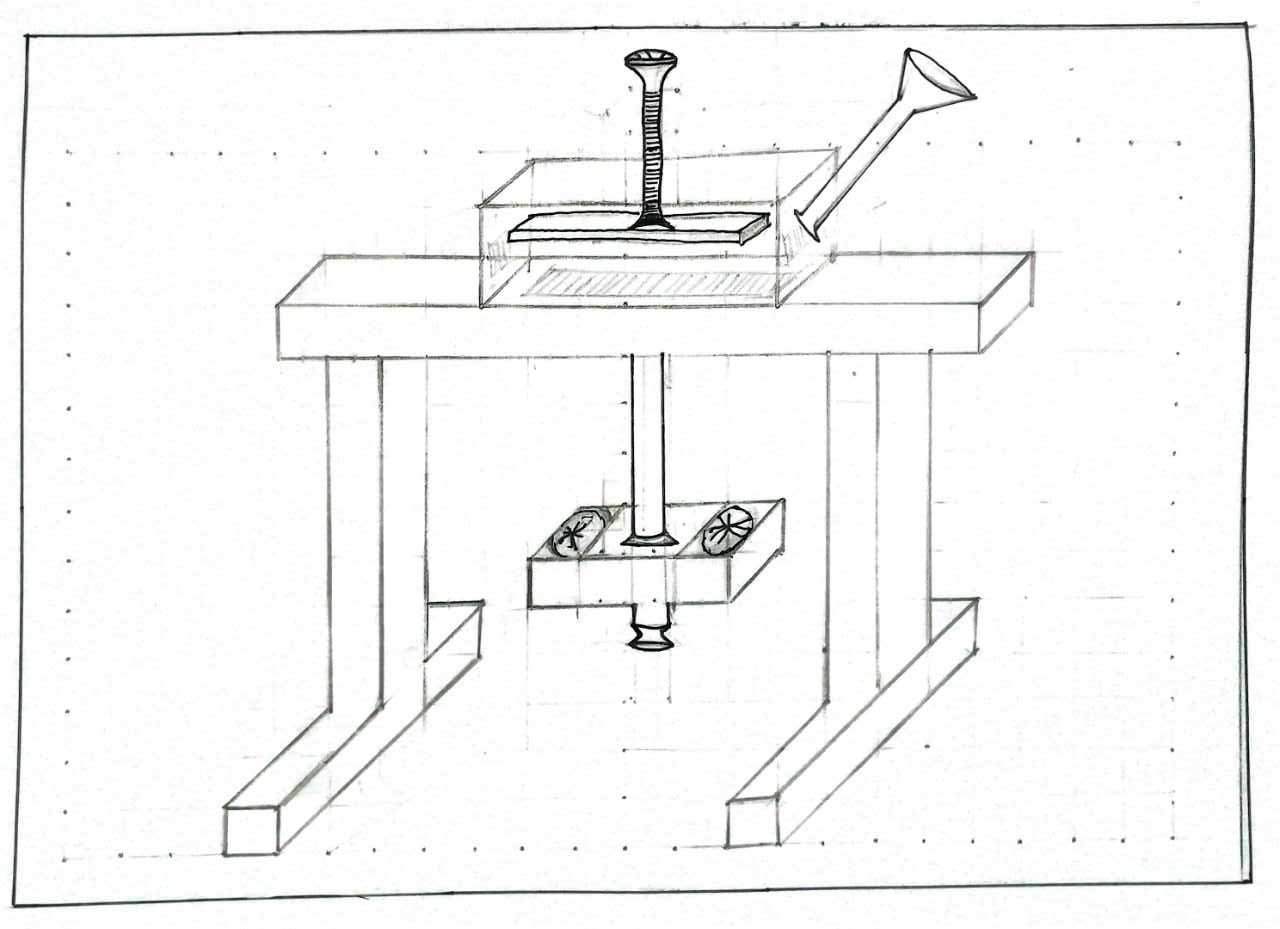

2. AMCAP is based on XYZ Coordinate positioning with a lead joint that can perform 360 degrees.

3. The ink used for production is a mixture of sand and plastic which is melted within 450 degrees.

Useful links¶

Click here to veiw the reference.

Click here to veiw the reference.

Estimated Designs¶

I almost estimated three designs for prototyping.

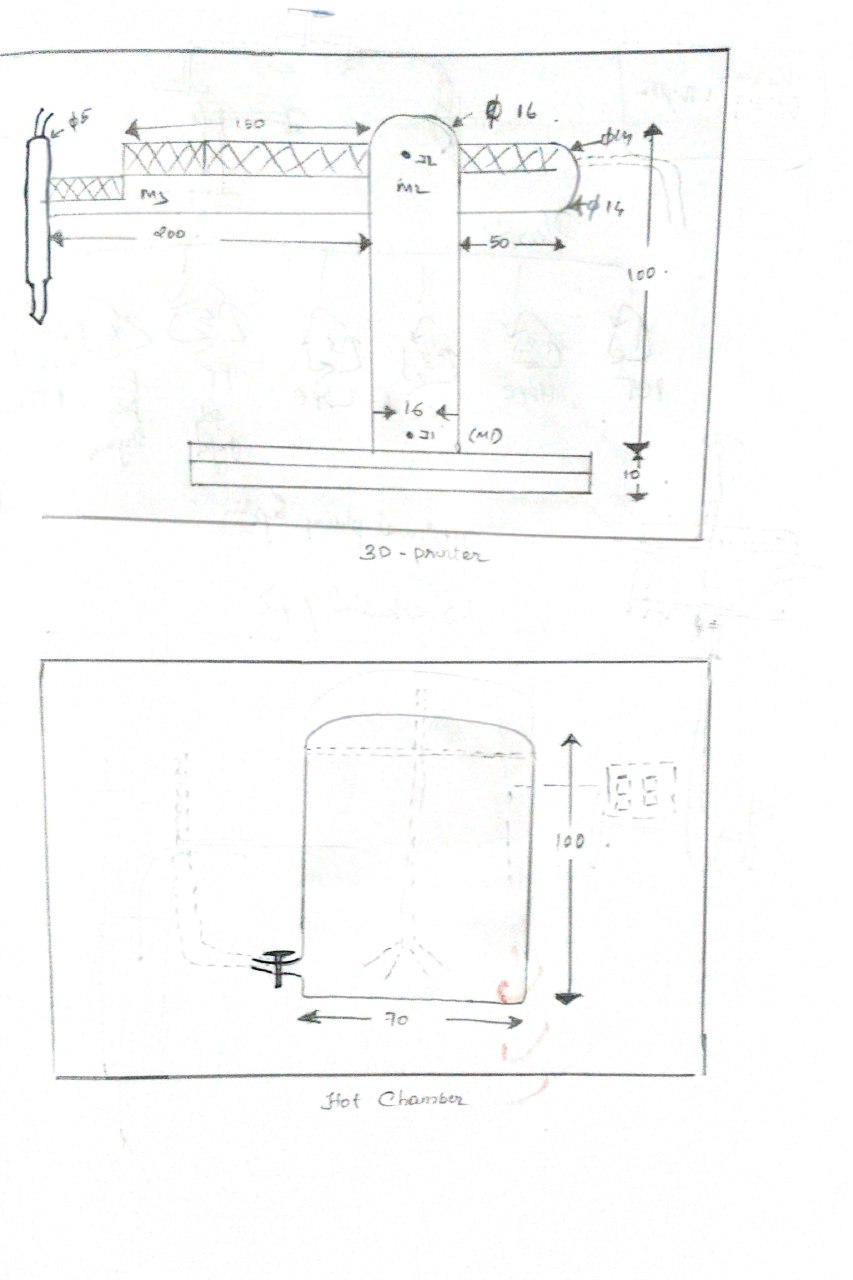

The first design i roughly drawn was about designing the shape of the extruder and its connection.Basically the extruder was connected to the chamber where the waste plastic has been treated and it is held with a nc controlled centre stand.

The second design was about the numerically controlled center stand

This was the initial complete design which was estimated.

Estimated Errors¶

1.The errors with the selection of materials used should be withstand higher temperatures.

2.The errors constrained with size.

3.The programming errors.

4.Safety issues etc.

Cost Estimated¶

It was estimated to make the extruder on Casting week and to try the casting with both ceramic and if it didn’t work out, then to carryout the casting with some metal or alloy and the rest of the parts from waste material itself like to make the chamber from the repaired oven box and the to make an arduino based numerically controlled machine and from veneer material and acrylic material the body can be cut by using a laser machine and the joints by 3d printing. Overall it is estimated to make a cheaper on which costs around 5000 INR to 7000 INR

MY SECOND THOUGHT¶

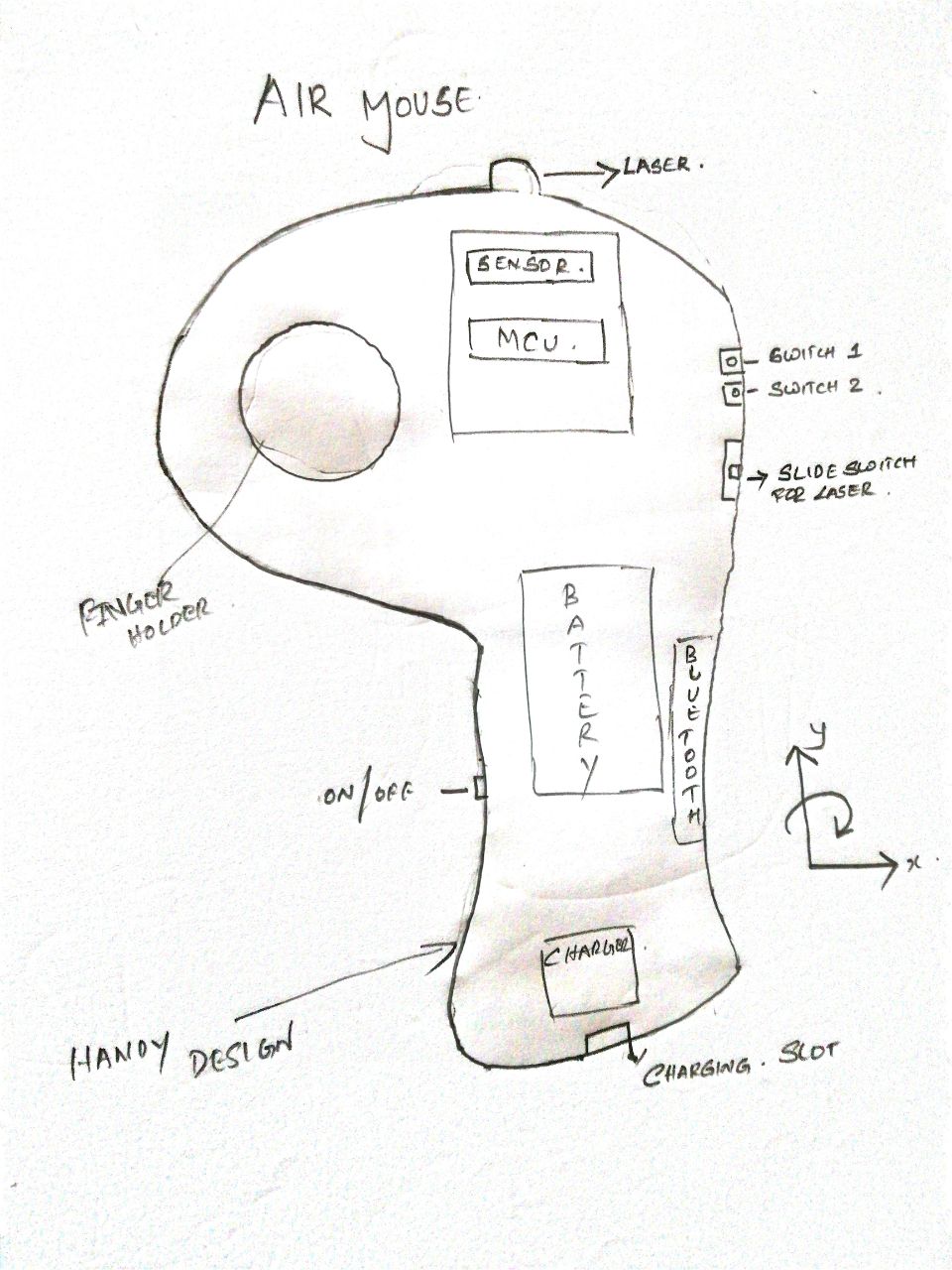

It was all about making An AIR MOUSEӦ

Afterall I Come from a teaching background, I will have to handle many presentations sessions and really I had faced problems in handling slide changers especially the time where i keep it in some place during presentation and when it is time to change the slide ,I look upon everywhere for slide changer,which was really irritating for the viewers and it will turn into a time wasting session.So I plan to make a wearable slide changer enabled with gesture control and added LASER and while thinking about it i extend the idea for adding some extra features to it and it reached the thought of making an air mouse because it will hold everything I need like slide changer,joystick for gamingmouse enabled operations etc.

ESTIMATED PROCEDURE

-

My plan is to make it with a 6axis MPU6050 GYRO sensor and to program the board with arduino and to interface it with wireless communication.

-

The wearable casing part is estimated to make with 3D printing technology.

-

The estimated procedure is planned to carry out the basics during electronic assignments weeks.

-

The basic idea is to function it as a mouse with a pointer so it is provided with laser.

This comprises about my fab academy first week.